In this article we will try to figure out how to choose polypropylene pipes for heating. To do this, you need to clearly understand what polypropylene is and what properties pipes from it possess. What types of pipe products exist and what are its consumer qualities. It is necessary to stop and on a method of installation of polypropylene with the help of a soldering iron for polypropylene pipes. How to choose this device correctly – you also need to know.

Features of polypropylene pipes and restrictions imposed on them

Polypropylene, like many other polymers, is a thermoplastic, that is, a material that changes its physical characteristics within fairly wide limits depending on temperature. In particular, when it reaches 140 degrees, polypropylene becomes much softer, and at 175 it simply melts. For this reason, it is important to remember that the maximum that any product made of this material can withstand in long-term operation conditions is 120 degrees, although manufacturers, for reinsurance purposes, indicate a temperature not exceeding 95 degrees.

Polypropylene with its too high rate of thermal expansion creates the problem that when heated to 80 – 90 degrees, the three-meter length of pipe becomes longer by as much as 3 cm.

Helpful advice! When installing heating pipes made of polypropylene, it is necessary to take into account the thermal expansion of the material. This is that the pipes should not rest against the walls. It is necessary to leave a gap of several centimeters.

Under the conditions of extremely low temperatures in the north, the coolant can heat up above 100 degrees, which in combination with a pressure of 6-7 kg / cm? can lead to mechanical rupture of pipes and a serious accident. For those regions where the climate is temperate or warm, the use of polypropylene pipes has no restrictions.

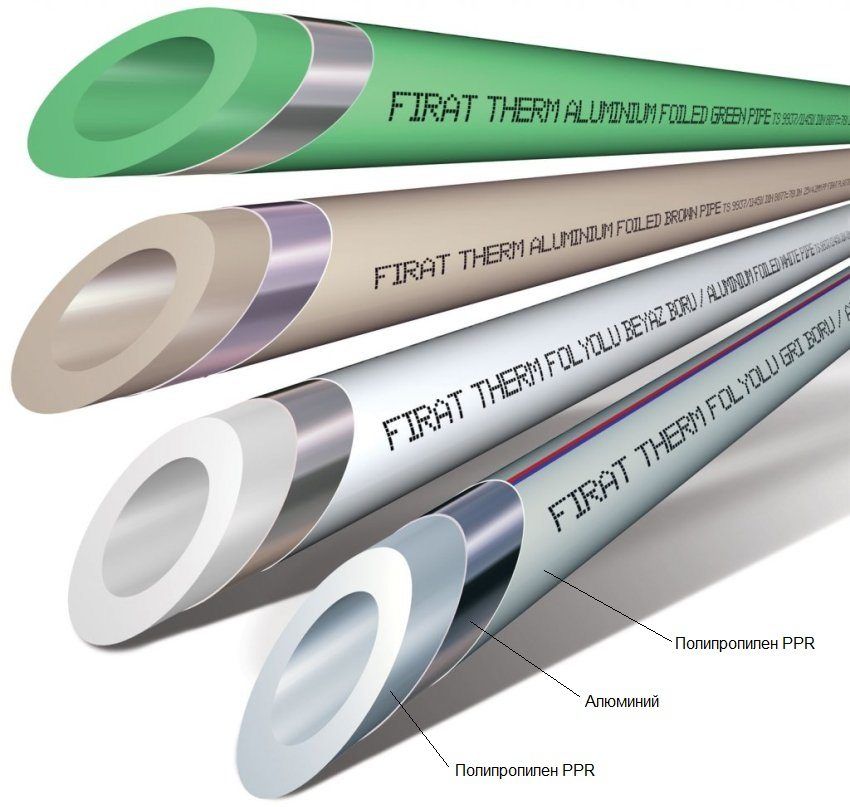

Today, for the installation of heating systems, mostly reinforced fiberglass or aluminum reinforced pipes are used. Thanks to these materials, the coefficient of thermal expansion is reduced. In addition, the installation of such pipes is more convenient, as it does not require cleaning with a shaver. Fiberglass fiber is melted into polypropylene, and there are no layers. This circumstance does not allow to stratify the pipe material.

Helpful advice! Reinforcement significantly reduces thermal expansion, but does not remove it completely. Therefore, it is recommended to provide long straight sections of the pipeline with U-shaped compensators or coils of the pipe.

In order to make the right choice of pipes for the installation of the heating system, we need a good understanding of their labeling and relevant parameters. One of the main indicators is the working pressure. It is usually indicated in the marking of the pipe immediately after the letter combination of PN. For example, PN20 indicates that this pipe is intended for use at a working pressure of 20 atmospheres and a temperature of 20 degrees. In this case, it is not peaking pressure values that can exceed the indicated, but maximum long-term working pressure values.

If we talk about how to choose polypropylene pipes for heating, it would be preferable to use PN25 pipes for this purpose. Indeed, with an increase in the maximum coolant temperature, the tensile strength properties of polypropylene pipes are significantly reduced. This circumstance leads to the fact that at 900? С the limit of the transferred pressure for a product with the marking PN20 is already far from 20, but about 6.5 kg / cm ?. This is acceptable, but less desirable, since a sudden increase in pressure in the heating system can lead to an accident.

Temperature indicators should be in the marking of the pipe explicitly or in the form of an indication of the possibility of use in heating systems (hot&cold). As mentioned earlier, pipes for heating must be reinforced. Than this is done: fiberglass or foil – it does not matter.

It is also necessary to know what diameter polypropylene pipes should be chosen for heating. As a rule, inside the apartment, the cross section of the polypropylene pipe should not be less than the cross section of the risers. In both cases, this is an internal section. Therefore, we must bear in mind that the thickness of the walls of polypropylene pipes is somewhat larger than that of similar steel water pipes. Based on the foregoing, it is proposed to use 26 mm pipes in Khrushchev and newer houses, 32 mm in Stalin houses. When installing a heating system in a private house with any type of wiring, pipes 32 to 40 mm in diameter are used, and radiators (radiators) They are pierced through a pipe of 20 or 26 mm.

Important when choosing a polypropylene pipe is their manufacturer. Here, undisputed leadership remains for German companies: Akwatherm, Banninger, Rehau, Wefatherm. Some Czech brands are not far behind them in the rating: FV-Plast, Ecoplastics. Somewhat cheaper products from Turkish manufacturers with a fairly good quality. It’s probably worth looking at Pilsa, Kalde, TEBO, Firat, Vesbo and Jakko products. Among the manufacturers from China, you can stay at Dizayn and Blue Ocean. Russian options are inexpensive, but they also fully deserve attention: Polytec, PRO AQUA, Heisskraft, RVK, Santrade.

When choosing polypropylene pipes it is necessary not to miss the question of purchasing a tool for installing heating from them. Perhaps the main link here is a soldering iron.

The assembly of any pipeline using polypropylene is carried out by welding. All pipe lengths of the required length are connected to the system with the required configuration using special fittings. They are selected in accordance with the size of the selected pipes.

Helpful advice! Buy connectors and pipes need one company. In this case, there will be no problems with the joining of parts, and the melting point will be identical. After all, both overheating and underheating of various elements adversely affect the connection, which threatens to break the system in this place.

For tight and tight connection to the pipe fittings and these parts are heated to the melting point of polypropylene. This is done by special soldering irons. Sometimes they are also called irons or welding machines. How to choose a soldering iron for polypropylene pipes, it is worth saying separately.

Such welding machines can be supplied separately or in a set with the necessary nozzles, scissors for cutting pipes, gloves, building level and tape measure. All this is placed in comfortable suitcases made of plastic or metal. Such sets are completed in metal or plastic suitcases.

An important characteristic of irons for welding polypropylene is their power. Here you do not need to chase after heavy-duty expensive machines, since you simply will not need them if you are designing in-house heating where there are no pipes with a diameter of more than 50 mm. For domestic purposes, it will be enough to buy a soldering iron with a capacity from 600 to 800W. When buying, you can navigate using the attachments that come with the device. Their diameter corresponds to the pipes that can solder the device.

If you are a beginner and you are concerned about how to choose polypropylene pipes for heating, then you should buy branded time-tested products with accompanying documents. They have all the characteristics of the pipes, and most importantly, the melting point. This information will help you to set the thermostat on the soldering iron correctly, depending on the diameter of the pipes and fittings, which will make the weld quality and perfectly safe to use.