In order for a house to be durable and warm, prefabricated and inexpensive, it is necessary to choose the right material for its construction. The construction services market offers innovative construction methods that allow you to build houses quickly, efficiently and cheaply. One of these technologies is the construction of houses from vulture panels. SIP panels: what is it? Houses from turnkey CIP panels, prices for construction services confirm the expediency of such a method.

SIP panel: what is it? Houses from turnkey CIP-panels, prices, advantages

SIP-panels are a durable building material that has been used for over half a century for the construction of residential and industrial buildings. The technology of building houses from CIP panels can be distinguished from other methods due to a number of advantages:

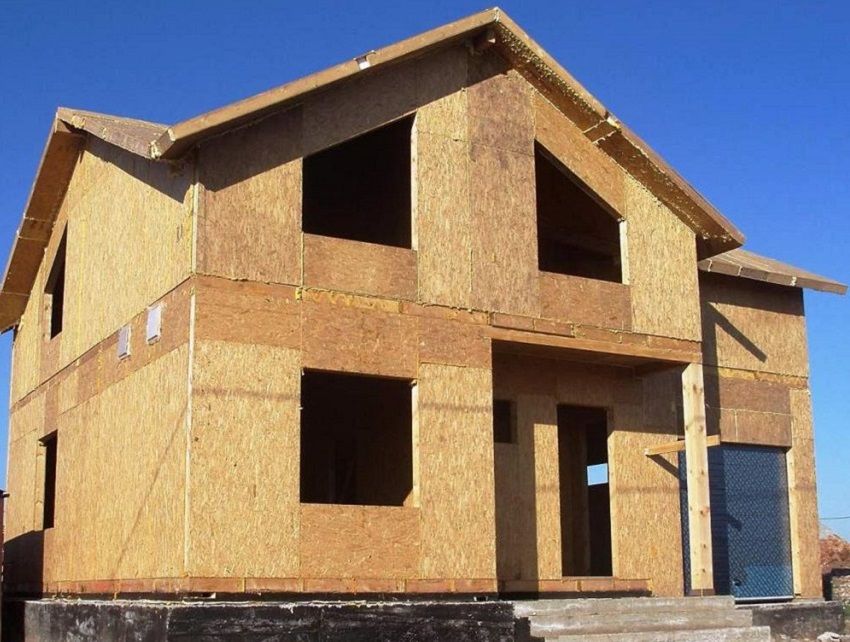

- rapid construction – a construction team of 3-4 people can build a structure according to a standard project within 3 months;

- stability, strength – monolithic construction of SIP-panels contributes to the fact that the walls of buildings made of this material can withstand loads of up to 10 tons vertically. Such structures can be operated even in seismically troubled areas;

- environmental friendliness – the production technology of CIP-panels is based on the use of safe and high-quality natural and polymeric materials, moreover, the construction of houses from these panels is not associated with the formation of a large amount of construction waste and garbage;

- duration of operation – expanded polystyrene, which is filled with CIP-panels, is not subject to rotting and deformation;

- low thermal conductivity – houses of such material are several times warmer than brick buildings, they are warm in winter and cool in the hot season;

- excellent sound insulation – sandwich panels filled with polyurethane foam able to absorb sound vibrations above 70 decibels;

Another major advantage is cost effectiveness: the price of a cottage made of brick will be 1.5-2 times more expensive than the cost of a house made of CIP panels of the same area. Cheaper prices are also due to the fact that a costly foundation for the construction of a vulture house is not required. The video of the stages of construction clearly confirms that such an object is sufficient to install on a lightweight foundation, the cost of which is four times cheaper than the foundation for a brick house.

The cost is also influenced by the speed of the construction of the object, as less labor is required. It will take about 3-4 months to build a house out of turnkey vulture panels, while the construction of a brick cottage can last up to 1.5 years. And all this time, the brigade of workers need to pay wages. Thus, having built a house from vulture panels, you get not only an object with excellent performance characteristics, but also at a relatively reasonable price.

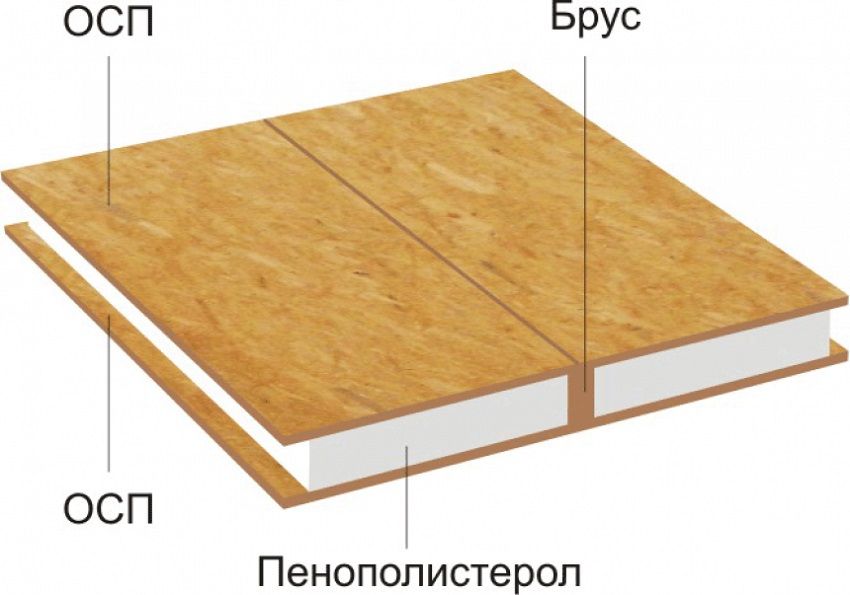

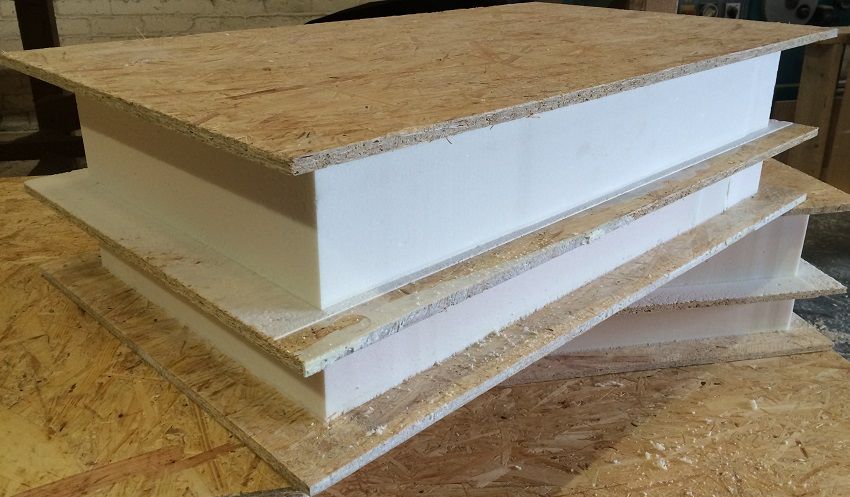

The classic CIP panel in its structure is a three-layer sandwich plate, where the function of the filler is performed by a polymer enclosed between two sheets of OSB. It is worth noting that there are two ways to fill CIP panels. In one case, it is a solid polystyrene foam, which is glued to the OSB-plates under high pressure. In the other – liquid polyurethane foam, which is pumped under pressure into the space between the plates.

Due to the porous structure, polystyrene perfectly retains heat, does not absorb moisture, but it is vapor-permeable material. The values of water and vapor permeability of polystyrene foam are dependent on the density of the material. In addition, it is not susceptible to the formation of mold and fungus, insects do not start there. It is not flammable and has sufficient sound insulation performance.

As for the outer layer of CIP panels, it should be durable and moisture-resistant, since it is he who perceives the main load. In order not to weigh down the sandwich construction, this layer should be made of lightweight material. These are the characteristics and have sheets of PCA. Thanks to special presses and gluing, wood chips are turned into a multi-layer slab with high strength characteristics.

In order to protect the contents of the CIP-panel from unwanted exposure to the environment, access to it is closed. For this, the ends of the sandwich are fastened tightly with a wooden bar. In high-quality constructions, glued laminated timber with a certificate of conformity is used. The structure of the finished sandwich can be seen in the photo of CIP panels.

PGood advice! The ability of CIP-panel to perceive high loads depends on the strength of adhesive bonding of the inner and outer layers of the structure.

The main step in the production of SIP-panels is the application of glue, since the strength of the finished structure depends on the quality of the connection used in sandwich materials. There are standards for the use of glue in the CIP-panels, according to which for 1 m? should be 115-140 g of glue. Such clarity can be achieved with the use of special equipment for the production of CIP panels, which means that a high-quality sandwich can be obtained only under production conditions.

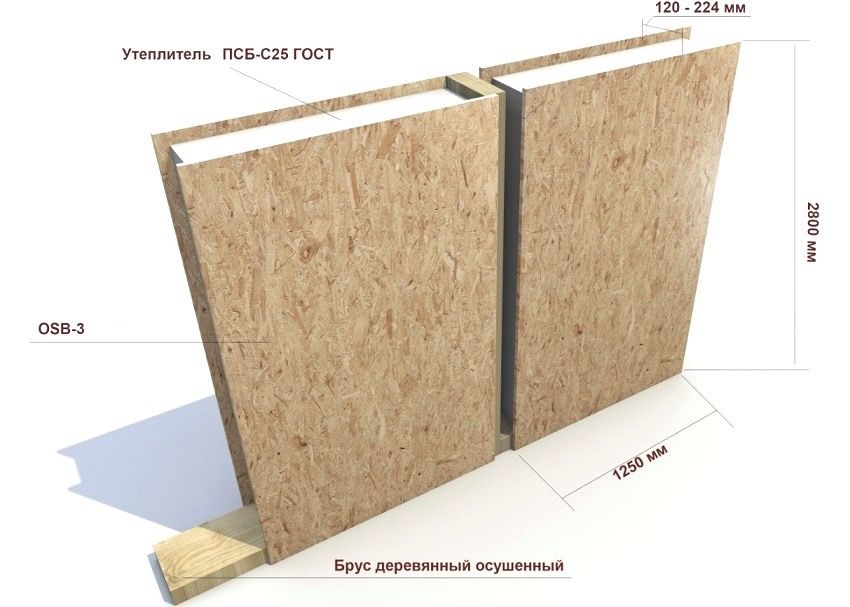

The thickness of the panels and their sizes can be different, as they are made not only for external walls, but also for internal partitions, floors and floor coverings. In addition, it can be observed that among different manufacturers, the dimensions of the panels are slightly different in size. As a rule, in the production of SIP panels use two sizes of 2500×1250 mm and 2800×1250 mm.

The thickness of the panels is also selected depending on their application. In order to use the material for external walls, the thickness must correspond to 160 mm, the internal walls can be made of 120 mm thick panels. In the ceilings between the floors, SIP panels with a thickness of 200 mm are used, for the construction of roofs it is recommended to use structures with a thickness of over 240 mm. It should be noted that when using SIP panels for floors, it is necessary to cut it lengthwise in order to comply with the prescription along the deflection.

The cost of CIP-panel depends on the quality and price of materials and glue used for its production. Therefore, if you are offered a product at a clearly undervalued price, there is a possibility of acquiring a CIP panel produced in an artisanal way. A building made of such material has a huge risk of destruction under load. And it will happen not at the stage of construction works, but in the process of operation, when there will be no one to file a claim.

Helpful advice! The acquisition of cheap CIP panels does not justify reducing the strength of the structure made of them.

When the price of SIP-panels is formed, it also matters how high-quality equipment was used for their production. This fact explains some fragmentation in prices on the panel of a manufacturer. Comparative table of the cost of CIP panels in prices of 2016 from different companies.

| Name SIP-panel | Manufacturer | Sizes of the panel, mm | Price, rub / piece |

| Egger (OSP-3 plate of the German company Egger is used as the outer layer) | PSK “House Stroy” | 2500x1250x124 | 3000 |

| Company “TekoDom” | 3100 | ||

| DK “Fansip” | 3080 | ||

| EcoEuroDom Company | 2700 | ||

| Egger (OSP-3 plate of the German company Egger is used as the outer layer) | PSK “House Stroy” | 2500x1250x174 | 3315 |

| Company “TekoDom” | 3500 | ||

| DK “Fansip” | 3395 | ||

| EcoEuroDom Company | 3000 | ||

| Kalevala (OSP-3 DOK Kalevala stove, Russia is used as the outer layer) | PSK “House Stroy” | 2800x1250x224 | 3850 |

| Company “TekoDom” | 3700 | ||

| DK “Fansip” | 3780 | ||

| EcoEuroDom Company | 3710 |

If, having weighed all the pros and cons, you chose the frame technology, then you will need to buy CIP panels for building a house. Prices for material can be different, and the question of its quality is very serious. The market is replete with inexpensive CIP panels produced by the artisanal method. The danger of cheap panels from questionable manufacturers is the use of low-quality components and manual application of glue, which leads to a decrease in the strength of the material.

All companies engaged in the development of projects of houses from SIP-panels and their construction, as a rule, have their own factories for the production of panels. The material is made on high-tech equipment using only high-quality plating, insulation and glue. All products of the companies are confirmed by acts of testing for compliance with GOST and TU. Buyers are provided with certificates for products.

In addition, by purchasing a VULTURE panel from the manufacturer, you exclude from their cost the payment of intermediary services. In addition to the panels, the companies are engaged in the sale of related products. If you are planning to build a house from SIP panels with your own hands, it is possible to order the cutting of panels according to the available drawings. The service will include the cutting of parts, the selection of the groove, the marking of all elements.

Before you buy a SIP-panel, you should visit the manufacturers’ websites. Perhaps this will help to find products at the most favorable price. The site contains all the necessary information about the manufacturer, panels, their components, size and cost. Here you can also see the catalogs of finished projects of houses from SIP panels with descriptions and prices.

Helpful advice! When purchasing a CIP panel, ask the seller for certificates and documents confirming the production of the product.

The use of SIP panels for the construction of houses, garages and other structures is associated with the excellent strength characteristics of this material and the rapid construction of the structure. And yet the flagship in the list of advantages is the low price of the finished house of CIP panels with high quality construction. In houses built according to the Canadian method, it is always warm and they can be used for many years.

The advantages of sandwich panels include low thermal conductivity, which is significantly less compared to other materials used in the classical construction of houses. This is achieved through the use of polystyrene foam in CIP panels, in which the fixed air inside the bubbles serves as a heat insulating layer. The cost of heating in the house of CIP panels can be up to 5 times lower than would be required for heating a brick house.

Among the undoubted advantages include light weight sandwich construction, the ability to perform construction work at any time of the year. Easy installation allows you to build a house of vulture panels with your own hands. It is possible to carry out a project of any complexity, whether it is building a house or a garage from CIP panels, with the minimum set of tools and small construction skills.

The disadvantages of CIP panels include some degree of flammability, given that the outer layers are made of wood chips. However, the treatment of OSB fire retardants reduces the risk of ignition to a minimum. Negative points include the fact that the top layer of the slab can be damaged by rodents, but the core of the panel is absolutely of no interest to them.

Helpful advice! Compliance with fire safety rules, high-quality electrical wiring, correct placement of electrical outlets is the key to safe operation of houses from CIP panels.

For those who are not faced with Canadian technology for building houses, it is worth reading the reviews. What it is, CIP panels, you can learn from the opinions of those who already live in such a house. Many people note that a positive thing is that when building a house from CIP panels there is no need to lay a strong foundation. In addition, the lightweight sandwich is much easier and more economical to transport and unload, and for the conduct of work does not require the involvement of expensive construction equipment.

Among the recommendations of residents, you can find advice on the need to pay special attention to the device ventilation in the house of CIP panels. Negative reviews indicate that this material is weakly permeable to moisture and air. Some conclude that it is more expedient to use such a building as a country house, since it does not freeze through, even if there is no heating in it.

A positive effect on the popularity of the use of SIP panels, the fact that the design can be erected on any soil, to carry out construction work in any season of the year, as well as the fact that the construction of the box is relatively cheap. Many of the negative factors include the fact that communication is only possible in an open way.

There are often cases when they arrange the decoration of the facade of the house of CIP panels. Many people point out that with such an application, drafts appear on the line connecting the panels, condensate forms in these places and they freeze. However, you can find tips on how to avoid this effect in the forums and in the reviews of tenants. SIP-panel at the joints is enough to handle mounting tape to eliminate this disadvantage.

The feedback from residents and their experience in operation will help you better understand the advantages and disadvantages of CIP panels when using them in building a house for permanent residence.

In an effort to save money, many practice hand-made production of CIP panels. Considering the average price of component materials (OSP-plates, filler, glue), the cost price of the finished CIP-panel will be about 1300-1400 rubles, which is much cheaper than the factory product. The process of making CIP panels with their own hands is not difficult, but it is important to observe some features.