The pellet burner is installed on a solid fuel boiler and is used for the organization of space heating. It can be purchased in finished form, but it has a fairly high cost. If necessary, such a device can be made independently. The pellet burner can be made from different materials and have both a simplified and more complex design option.

Why do we need a pellet burner: features of the device

Pellets are fuel that is of high quality and is able to compete with conventional wood. For the manufacture of such raw materials used wood and agricultural waste, as well as peat. Pellets are small granules.

What is the advantage of such pellets over standard fuels? First of all, it is necessary to note the high efficiency of raw materials. Ordinary firewood after burning out give from 40 to 80% of energy. The remaining material goes into recycling, so the economic feasibility of such heating is in question.

The boiler with a pellet burner allows you to increase the processing of material up to 90%. This is one of the highest rates of combustion among all types of fuel. It should be noted that the granulated raw materials are not recommended for some types of boilers. For example, such fuel can harm equipment, the principle of which is based on pyrolysis.

Useful information! When choosing a burner, it is necessary to pay attention to its power. Today it is possible to purchase models that automatically regulate this indicator. An example of this is the Zota pellet burner.

During fuel processing, the temperature inside the burner can reach 1000 ° C. It follows from this that when using such a device it is necessary to take maximum care. This is especially true for designs made by hand. Errors in assembly or improper operation may cause a fire.

This raw material has a high energy intensity. It is because of this that it has become widespread. One kilogram of granulated pellets during processing produces approximately 5 kW / h of heat. It follows from this that for the organization of heating of a standard private house, which has average dimensions, it will take about 2 kg of material per hour.

Pellets for the burner are loaded into the device approximately 1-2 times a day. When loading a new portion of raw materials, it is recommended to clean the ash pan from the products of combustion. Purchased burners require weekly cleaning, and home-made appliances are contaminated even faster. A self-made device is recommended to be cleaned approximately once every 3 days. Otherwise, it will quickly fail.

Some models of burners do not require loading for 5 days. An example is the APG-42 pellet burner. This model is compatible with boilers Teplodar-Cooper.

The disadvantage of pellet burners is reverse combustion, which is accompanied by the penetration of the pyrolysis zone into the bunker, which is intended for storage and supply of fuel. This entails the smoke of the room in which the heating equipment is located, and there is also the possibility of fire.

Pellets from sawdust or any other recycled waste with an excess of air in the structure can be blown off, leading to a large amount of waste (ash). The air supply must be clearly regulated, otherwise not only its excess, but also a deficiency can lead to inefficient operation and rapid clogging of the apparatus.

The need for granulated fuel in the air is determined primarily by the mode of combustion. Selection of the correct mode is paramount and very important task. The output to the operating mode of the burner is made in 5 stages. Before using the device, it is necessary to familiarize yourself with each phase in more detail.

The first step is to perform the ignition. The pellet boiler burner is ignited with a special ceramic rod lighter that, when turned on, is heated to a very high temperature (900-1100 ° C). Devices made with his own hand, you can ignite the usual torch.

Note! In no case should flammable liquids be used to ignite the burner. In this case, the combustion process immediately goes into the bunker, as a result of which a fire will occur.

The second stage of equipment preparation for work is the launch. It is very important to adjust the correct air supply in order to adjust the burner flame. Next is the acceleration of the device. At this stage, the burner enters the normal operating mode.

After acceleration, it is necessary to adjust the air so that the correct coolant temperature in the return pipe is set inside the device. Then you need to stop the supply of granulated fuel and set the required air intensity.

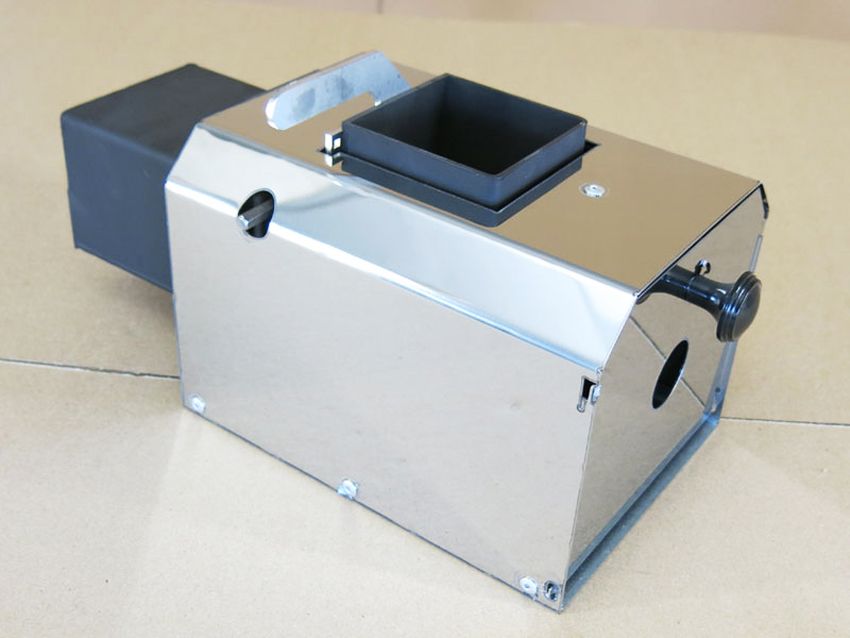

The main task of any burner is to ensure uniform heating of the boiler. This goal is achieved through the processing of granulated fuels. From a constructive point of view, the burner is a combustion chamber, which most often resembles a pipe. Combustion inside such a device occurs due to the continuous supply of air.

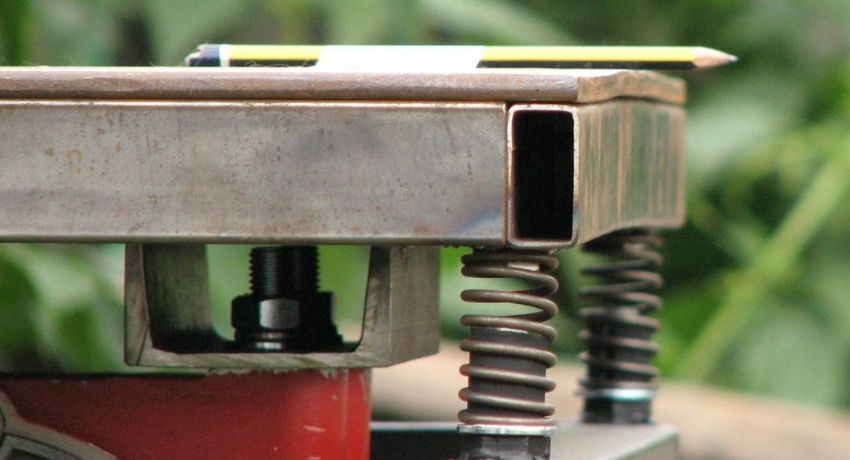

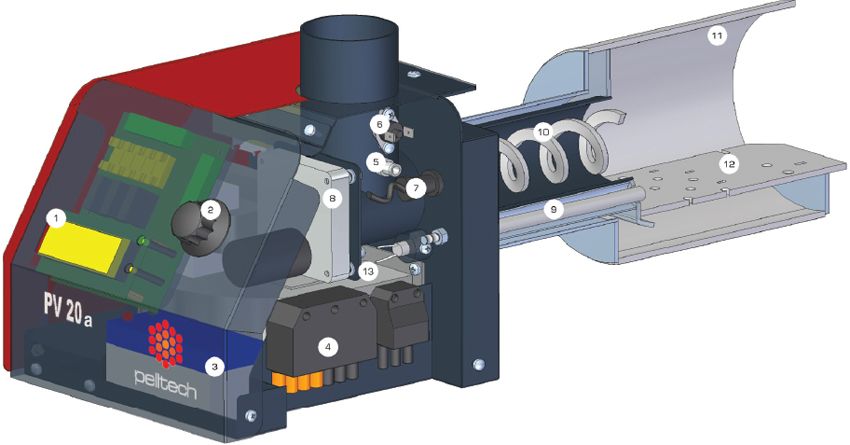

Fuel delivery is carried out by a special device – the screw. For air injection, a fan is provided in the structure, whose operation does not extinguish the flame. The burner can have a variety of shapes that do not significantly affect the efficiency of the device. Cameras that have a circular cross-section are the most common. This is due to the fact that they are the easiest to make. However, rectangular variants are quite common.

In the round burners used for processing pellets, a flat base is installed. It is used to place fuel and is mounted outside to the front surface. It is worth noting that some burners have the ability to connect a GSM-module. An example of this is the Terminator 15 pellet burner. Its cost is approximately 75 thousand rubles.

The principle of operation of these devices is quite simple. First, the sawdust is loaded into the bunker, after which they are delivered through the channel to the burner. The fan forcing air maintains the required level of flame inside the device. Combustion products accumulate in the ashpit. It is recommended to clean this compartment at least once a week.

Devices that are used for the processing of granulated raw materials are divided into two types depending on the principle of operation – with forced sampling and gravity. The choice of one or another type of equipment depends primarily on individual operating conditions.

Note! The most common version of the burner requires the mandatory availability of electricity. In this case, electricity is necessary for the operation of the mechanism ensuring the uninterrupted supply of granulated fuel. Automatic pellet burners (with a forced fence) are considered the best solution for the organization of heating buildings.

Devices of this type include several mechanisms by which pellets are delivered. The first of them operates with the help of a pneumatic system. The second mechanism is equipped with a special tool – a screw. Security in the system is ensured by the design of the channel installed from the bottom up, through which the pellets are fed.

Automatic devices have one major advantage – fire safety. Such devices are used in the technique of different manufacturers. For example, they are integrated into the boilers Teplodar. Pellet burners, reviews of which are mostly positive, have a rather high cost. The price of some models exceeds 150 thousand rubles. More budget options can be purchased for 60-80 thousand rubles.

The design of the pneumatic type is characterized by maximum safety. This is because the pellet delivery system delivers fuel in small portions. Thus, it does not stay in the connected channel. For such a burner, there is the possibility of installing an overall bunker that does not need frequent loading. If desired, this type of device can be purchased. Currently, Pneumatic Pellet Burners are the most popular.

Feeding mechanisms related to the screw type include two main nodes. With the help of the first screw, granulated fuel is collected from the bunker. The operation of this device allows you to forward the pellets to another receiver. After this, the second screw directs the raw material directly to the burner.

The disadvantage of the devices, the supply of fuel in which is enforced, is their volatility. In the event of a power outage, the burner stops working.

Pellet fuel-powered devices of this type have a different principle of pellet feeding. Immediately it should be said that such units are more convenient to use. The main advantage of the gravitational mechanism is that it does not require a mandatory connection to the power grid.

Pellets in this case are located in the bunker and can enter the cohesive channel under the action of their own weight. There are several popular domestic companies involved in the production of such units (Pelletron, Behemoth). This type of pellet burner starts very simply – by changing the position of the flap. It is important to remember that a draft regulator is installed on the chimney, which can also be adjusted.

Note! The main disadvantage of all gravitational structures is that they do not provide such high safety at work as their counterparts. During operation, there is the likelihood of ignition of granulated fuel in the bunker. The increased risk of ignition exists due to the design features of the bunker, which has a direct connection with the hole through which fuel is supplied.

The efficiency of gravitational devices is somewhat lower than that of analogs, which function due to the forced supply of granulated fuel. Installation of this type of pellet burner is not a difficult task. It can be fully connected in just a few hours.

In order to increase the fire safety performance of this device, many manufacturers install special valves on it. They are equipped with thermal sensors that, in the event of a flame entering the channel connecting to the bunker, operate and block the passage.

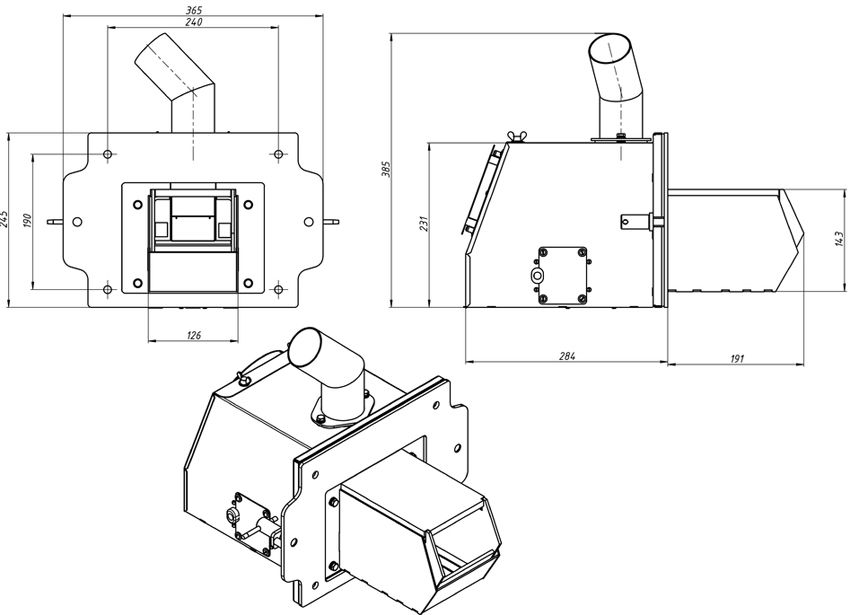

Before starting the independent design of the burner intended for the processing of pellet fuel, it is recommended to execute its individual drawing. The scheme must necessarily contain information about all nodes and details. The drawing requires you to specify the main elements:

- a camera;

- fuel bunker;

- screw;

- fan.

The scheme should contain all the necessary dimensions of these products. When making a drawing of a pellet burner with your own hands, you should remember that it depends on the detail of its performance how reliable the device for processing fuel pellets will be.

Before starting the drawing up of the scheme, it is recommended to calculate in advance the necessary sizes of the bunker. When performing the calculation, it is necessary to take into account what area the structure will heat. It is also worth noting that the parameters of the bunker have a direct impact on the frequency of its cleaning.

Fan operation is regulated by the electronic unit. When drawing up the scheme you need to remember that the performance of the main nodes of the device depends on the availability of electricity.

These devices are installed on the heating equipment brand Cooper. Pellet burners of this type are equipped with an improved screw, thereby increasing the overall reliability of the design and its operational life. The control panel has a convenient and clear display, which shows all the necessary operating parameters of the heating equipment.

Thus, in order to manufacture a pellet-processing burner, it is required to first calculate the power and prepare the drawing. During operation, you must be careful, as any mistakes made during the assembly of the structure, can lead to fire pellets in the bunker.