The article describes in detail the technical characteristics of such a finishing material as PVC panels: the dimensions and features of products intended for installation on walls and ceilings of rooms, the differences between them, the general properties of materials. From the article you can find out the nuances of choosing plastic lamels for the kitchen and bathroom, the features of their use, the formulas for preliminary calculations.

PVC panels: dimensions and general material properties

Polyvinyl chloride panels (PVC) despite the relatively recent appearance on the market have already been able to win the attention of consumers, especially those who are going to independently carry out repairs in the house.

Such popularity of the material is due to many factors:

- favorable technical and operational characteristics;

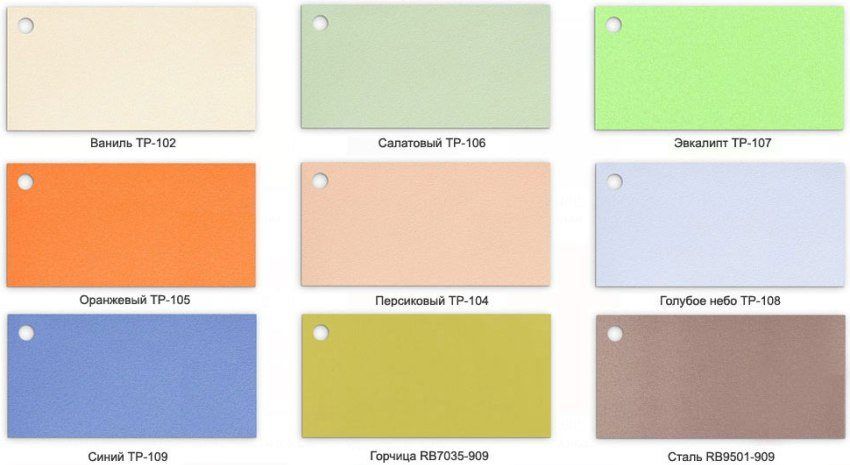

- extensive assortment (different types of products, differing from each other in color, quality, texture, cost);

- simple installation system.

Due to the extensive choice of sizes of PVC plastic panels, this type of finish is considered universal. In the assortment, you can pick up products for walls and ceilings, as well as panels that are suitable for finishing a particular type of room.

Helpful advice! In order to avoid mistakes with the choice of finishing, decide in advance on the design of the room, as well as on the dimensional parameters of the slats.

A modern range of products offered by the market can be divided into several groups. Allocate:

- tile-type PVC panels;

- clapboard;

- sheet products.

In each group, there are differences between PVC plastic panels: dimensions, prices, level of rigidity, weight. Dimensional and other parameters of lamellae depend on the group in which they are included. This may have an impact on the design of the bathroom, kitchen or bathroom, as well as finishing work, involving the processing of the ceiling or walls in other rooms.

The standard parameter of lamella thickness is within 0.5-1 cm. This indicator is very important to consider if you are planning to buy a molding. The molding is a decorative strip of laid-back type, used as a finishing element and decoration in the interior.

If we talk about PVC wall panels, the dimensions of these materials allow us to distribute products between two groups. One of them includes panels whose thickness is 0.5 cm. The second group includes slats with a thickness in the range of 0.8-1 cm. Despite such an extensive scope, moldings in the second group are made of moldings in a single universal size.

Buy a PVC ceiling panel with a length of 3 meters today is not difficult, since this size is included in the standard line of parameters.

Overall dimensions of polyvinyl chloride panels (standard):

| Product type | Standard width, m | Standard length, m |

| Rack panel | 0.13-0.3 | 0.9-3 |

| Wall panel | 0.15-0.5 | 2.6 / 2.7 / 3 |

| Tiled panel | 0.3 / 0.98 | 0.3 / 0.98 |

| Sheet pane | 0.5-1.22 | 0.98-2.44 |

PVC lamellas on the market for finishing walls and ceilings may have a different connection character. Based on this, the range of panels can be divided into several groups:

- products with a relief surface;

- seamless;

- products with a chamfer (rust).

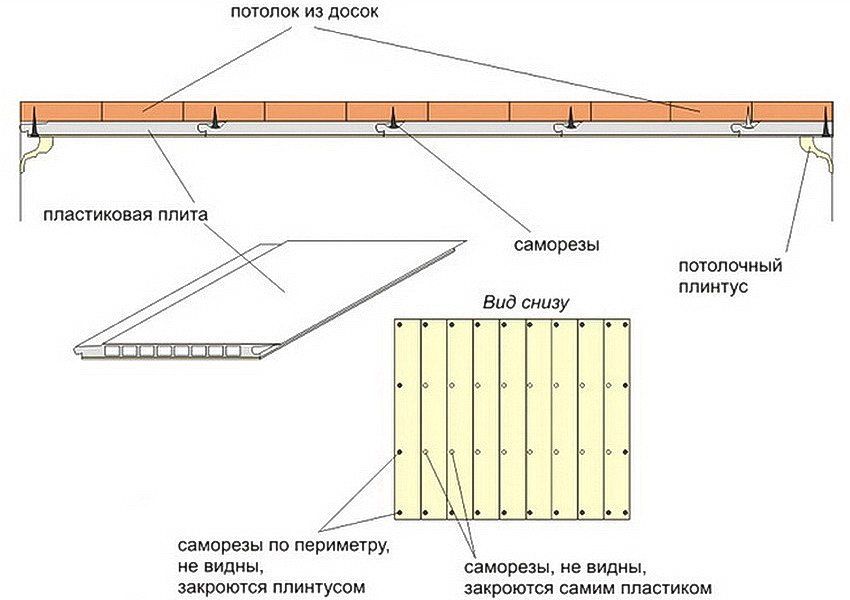

Seamless plastic panels in most cases are used to finish the ceiling surface. As a result of mounting the products are arranged very tightly to each other, due to which the size of the seams is minimal. Subject to compliance with the technology, it is possible to achieve an effect in which the connecting line between adjacent elements will be practically invisible.

Note! PVC slats react negatively to the effects of temperature fluctuations. As a result of this effect, the finish is subject to deformation changes. At the same time, changes affect not only the shape, but also the size of the PVC ceiling panels. For this reason, you should carefully select the material on the market and pay attention to its cost, quality and external condition.

Panels with a chamfer joint have much in common with seamless lamellae. The only difference is the presence of this chamfer in the end part of the product. Rust is a decorative recess used to connect PVC panels into a single canvas. Lamels with a facet, or as they are also called rustic panels, can be used both for wall decoration and for ceilings.

Rectangular products with a relief surface are more suitable for mounting on walls. According to external characteristics, they have similar features with clapboard. Relief finish stands out from the rest of the PVC panels with high strength and wear resistance. However, this also affects the price, which increases significantly.

To purchase material with the appropriate technical and operational parameters, it is necessary to understand the difference between ceiling-type products and wall products. The fact is that the size and price of PVC panels are not the main indicator, as well as appearance.

As a rule, the plastic finish for the ceiling base is much thinner than the wall, its thickness ranges from 4-5 mm. This moment is caused by the fact that products intended for installation on walls will be subjected to higher mechanical loads during operation. Therefore, they should have a large margin of safety, durability and, of course, should be thicker.

To provide the increased strength of wall panels, manufacturers increase the amount of material in a single product. The consequence of this is an increase in the weight of the panel. Therefore, wall decoration is different from the ceiling slats also by weight.

The standard width of the panels is 25-30 cm. In length, they can reach 6 m and have a thickness of from 6 mm to 1 cm.

Sandwich panels are often used for finishing works on the walls. Moreover, the high price of these products does not stop buyers. They look elegant and combine advantages such as mechanical strength and high quality.

Helpful advice! Sandwich panels can be used to design such complex areas as slopes. This type of material is simply indispensable for the construction of partitions.

The size range of sandwich panels is very extensive, but among the range there are also standard sizes, where the length is 3 m, and the width of PVC panels for walls varies in the following values: 0.9; 1.15 and 1.5 m. At the same time, the products can have different thickness – 1; 2.4; 3.2 and 4 cm.

Price of PVC sandwich panels 10 mm, 24 mm, 32 mm and 40 mm (standard size 3×1.5 m):

| Products manufacturer TBP PLAST | ||

| Panel thickness, mm | Product class | Price, rub. / Piece |

| ten | Economy | 900 |

| Station wagon | 950 | |

| Premium | 1000 | |

| 24 | Economy | 1520 |

| Station wagon | 1600 | |

| Premium | 1650 | |

| 32 | Economy | 1720 |

| Station wagon | 1770 | |

| Premium | 1820 | |

| 40 | Economy | 1930 |

| Station wagon | 1980 | |

| Premium | 2050 | |

High durability of PVC sandwich panels is the most significant advantage of this finish. The service life is at least 20 years. Of course, the intensity of operation and the external conditions affect the effective service life.

Sheet finishing material of polyvinyl chloride is a plate whose width is 0.5-2.3 m. The length of most products is in the range from 1.5 to 4.05 m. The minimum thickness of sheet panels is 1 mm, and the maximum – 30 mm. .

Due to such large sizes of PVC sheets, this finishing material is most often used for wall decoration, since it requires minimal effort during installation and one element covers a large area. Therefore, sheet panels are in high demand among buyers who want to make repairs with their own hands.

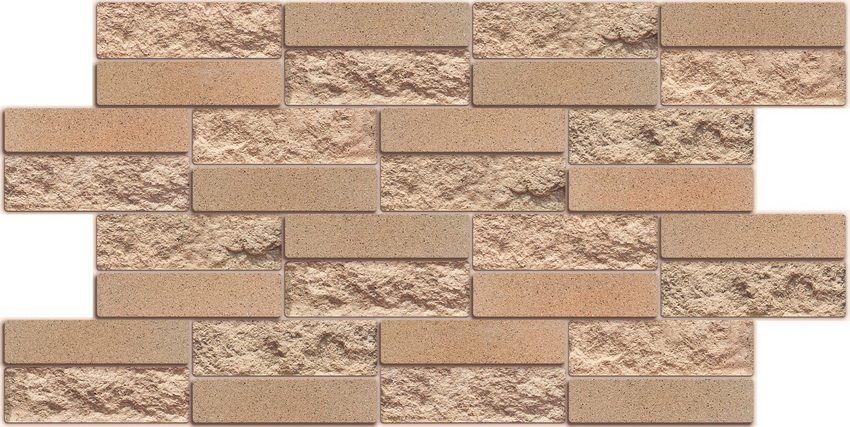

Sheet products can have a volumetric relief surface and offer an extensive choice of design, most often used imitations for:

- wood;

- brick;

- tile;

- mosaic;

- slate

Note! The most common sizes of sheet panels are: 980×480 mm, 955×480 mm, 980×498 mm. In the table below, you can see the average prices on panels of these sizes. As an example, StarLine products with 4 mm thickness are considered.

The price of sheet panels with imitation of natural surfaces:

| Name | Product size, mm | Price, rub. / Piece |

| Bleached oak | 980×480 | 119 |

| Brick | 980×480 | 119 |

| Sakura tile | 955×480 | 112 |

| Natural slate | 980×498 | 112 |

These panels are easy to store due to their small size, easy to install, durable. They have a high resistance to moisture and very quickly installed on the walls.

PVC decorative panels, imitating a mosaic, have a very simple installation system. Working with them does not require special knowledge and skills, so any person can perform wall cladding with this material. At the same time, decorative PVC panels look no worse than tiled or ceramic tiles.

In the process of assembling decorative PVC panels 485×960 mm and other sizes, construction debris or dust is not formed, as is usually the case with ceramic tiles, and the procedure does not require the use of additional tools, such as tile cutting. The service life of such a coating is at least 10 years, and its minimum thickness is 1 mm, which opens up wide possibilities in terms of design.

Standard sizes of decorative PVC mosaic panels: 485×960 mm, 480×950 mm, 480×955 mm. There are other variations, but they are less common and are usually custom made.

Pricing for PVC mosaic sheet panels:

| Name | Product size, mm | Price, rub. / Piece |

| White mosaic | 485×960 | 115 |

| White mosaic | 480×950 | 115 |

| Mosaic Turquoise | 480×950 | 128 |

| Mosaic with brown patterns | 480×955 | 128 |

| Mosaic vanilla | 485×960 | 132 |

| Relax | 480×950 | 135 |

| Terrazzo Naples | 485×960 | 151 |

| Fruits | 485×960 | 151 |

Unlike wall products, ceiling panels are lightweight. Taking into account the fact that the strength characteristics are not so important for the ceiling trimming, manufacturers have placed the main emphasis on maximum lamella relief and the creation of various design options.

Note! Finishing material for ceilings is more fragile. In the process of lining should be observed maximum accuracy.

To save money on the purchase of material, you should select the panel based on the dimensional parameters of the room. In this case, it is desirable to achieve an optimal indicator, in which after the installation procedure there will remain a minimum amount of construction waste (scrap).

If the width of the ceiling base in the room is 2 m, then as a finishing unit it is most advantageous to buy a PVC ceiling panel with a length of 4 meters. During installation, such panels are cut in half. Thus, the number of lamellae doubles, which, after cutting, acquire a length of 2 m. Similarly, you can do with 3-meter panels, provided that the ceiling width is 1.5 m.

Before purchasing the material should perform a preliminary calculation of the required quantity. As an example, you can take a bathroom with the parameters of 1.5×1.7 m. It is advisable in this case to take PVC panels for a bathroom of 0.25×3 m. In view of the above, the slats will be cut in half.

The formula for calculating cladding for the bathroom:

1.7 m (room length) / 0.25 m (lamella width) x 0.5 (lamella cutting factor in two) = 3.4 lamella.

The result must be rounded to an integer numeric value. In this case, it will be equal to 4. That is how many PVC panels will be required for facing the ceiling base in the bathroom.

The standard thickness of ceiling panels is 8-10 mm. It is these parameters that formed the basis for the creation of moldings, which are selected according to the size of the lamellae.

Note! On sale you can find a ceiling trim of PVC with a thickness of 4-5 mm and even 12 mm. However, the choice of suitable moldings in this case will be extremely difficult.

Types of moldings:

- F-shaped;

- ceiling plinth;

- connective;

- starting or edging;

- inner corner;

- outer corner.

By type of construction, the following types of PVC ceiling lamellae are distinguished:

- “European” or eurolining – long panels with a wide locking system. Standard width 10 cm, length – 3 m.

- “Polka” – slats with a length of 3 m and a width of 10 cm with a narrow locking system.

- Reinforced wall paneling – it is distinguished from standard panels by the presence of a double profile, as well as dimensional parameters. In this case, the width corresponds to 12.5 cm, and the length remains unchanged – 3 m.

- Plate – square-shaped panels that do not have a locking system.

- Extended panels – the width of these elements is in the range of 15-50 cm, and the length can correspond to the following parameters – 2.6 m / 2.7 m / 3 m.

- Sheet panels – sheet material that does not have a locking system. The width of the sheet elements can reach 0.8-2.03 m, their standard length is in the range of 1.5-4.05 m.

Lining can have several sections. On sale there are one-, two-and three-section products with different design.

Pricing for PVC ceiling panels:

| Name | Thickness mm | Product size, mm | Price, rub. / Piece |

| White lining Economy | eight | 100×3000 | 45 |

| White lining single-section | ten | 100×3000 | 60 |

| Color lining single-section | ten | 100×3000 | 80 |

| White lining three-section | ten | 240×3000 | 130 |

| Color lining three-section | ten | 240×3000 | 180 |

For an economy lining, the cost of any of the moldings is on average 75 rubles / piece, for sectional ones – 85 rubles / piece.

Most often polyvinyl chloride panels are used for finishing kitchens and other rooms, the operation of which is accompanied by an increased level of humidity. These finishing materials put forward special requirements that correspond to PVC panels:

- environmental Safety;

- reliability;

- resistance to wear and moisture;

- durability;

- practicality;

- hygiene;

- attractive appearance;

- chemical resistance;

- fire safety.

Note! For the production of sheet panels used moisture-proof and very durable food grade plastic. On the surface of products there are no pores, so that fungi and microorganisms, including mold, can not multiply on the floor.

If we talk about rack panels for the kitchen, then, as a rule, such elements have a uniform color. It is impossible to find lamellae with imitation under natural stone or brickwork. Rack variant of a covering is expedient for getting only in the event that it would be desirable to find for kitchen the budgetary alternative to a ceramic tile.

Decorative panels are recommended to be used for partial wall finishing or processing of the apron area. The most profitable and effective option will be mosaic products, offering an extensive selection of ornaments and colors.

There are modular variants of tiled panels. Their structure allows you to independently create a mosaic pattern, combine patterns, or compose whole images from them. Modular panels look particularly advantageous in the combined areas of the dining room and kitchen.

Sheet products belong to the category of versatile materials, because they are suitable for partial (working area), and for the full decoration of the room.