- What is a foundation grillage

- Features and basic concepts

- Appointment

- Classification

- We mount the grillage foundation with our own hands

- Installation of a grillage for a pile foundation

- Making a base using pillars

- What is a grillage, device and varieties

- Types of grillages

- Monolithic grillage. Pile foundation with grillage Pile foundation with grillage

- Varieties

- Monolithic grillages

- Types of grillages by tape position

- Methods for mating tape with piles

- Fill pillars

- Calculation of the grillage

- Grillage device: preparatory work

- Pouring tape

- Frame standards

- Pick-up device

- Advantages and disadvantages of a grillage foundation

- Accommodation types

- Varieties by type of material

- Types by type of construction

- Conclusions on the grillage

- Video

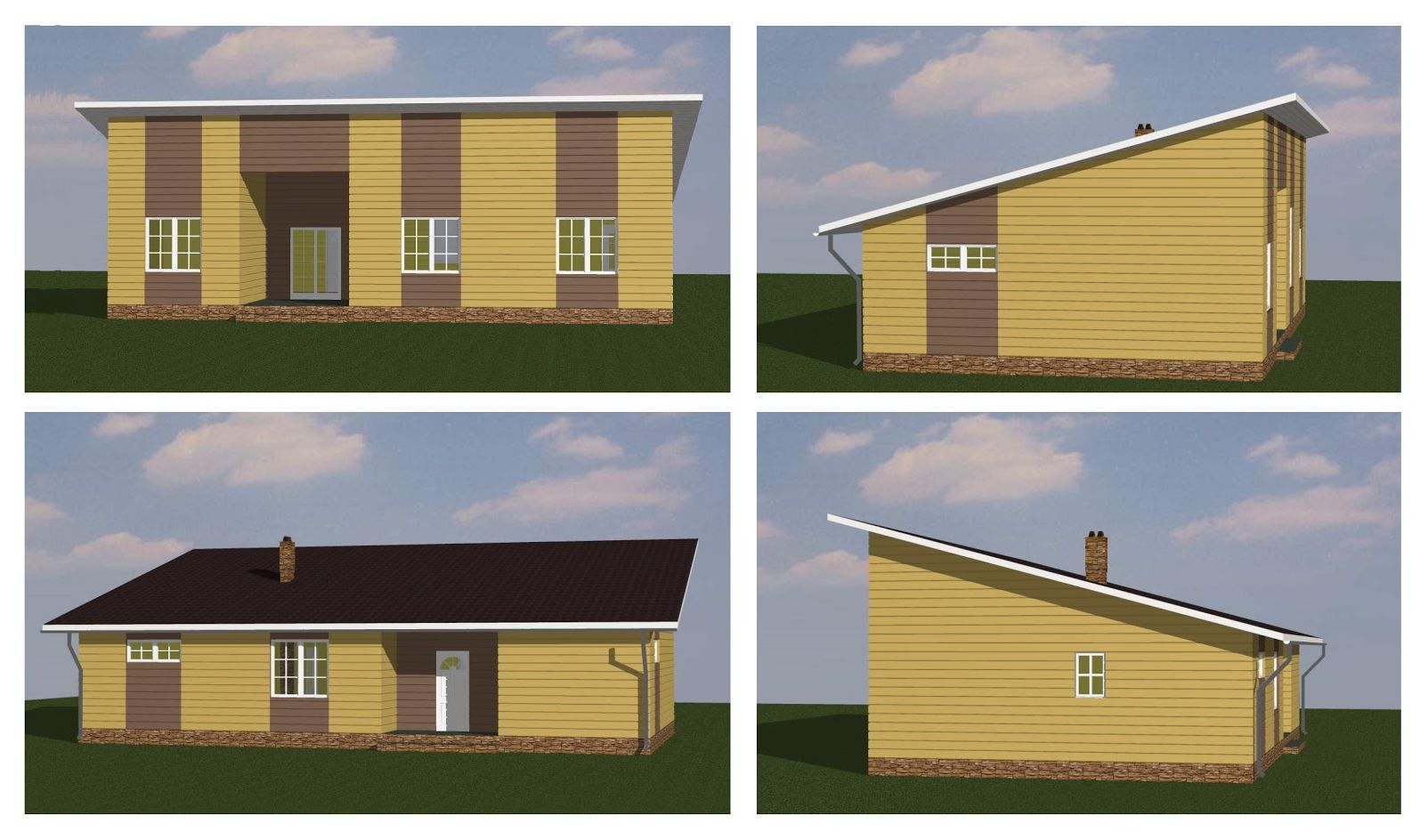

The construction of any private, commercial or industrial building begins with pouring the foundation. In this article we will talk about the pile-grillage foundation.

When choosing the type of base, the type of soil and the height of the building are taken into account. Calculations are carried out in advance. It is important to remember about the weight of not only supporting structures, but also equipment, furniture, people who will be inside. Therefore, the design procedure should only be trusted by professionals. Independent attempts to estimate “by eye” lead to premature collapses, cracks in the walls, constant repairs.

What is a foundation grillage

This is the name of the horizontal platform or strap, which connects the individual supports into a single system. This helps to redistribute the load from the building, eliminate its uneven subsidence and the appearance of cracks on the walls and supporting structures. Such reinforcement is especially important if the floor of the first floor is made of wooden logs. They will not develop colonies of fungus and mold, and you will not have to constantly carry out treatments from rodents. In general, thanks to the foundation grillage, the whole house turns out to be more durable and stable, and its service life is calculated for centuries..

Features and basic concepts

When laying the grillage tape, concrete or sand-cement mortar, channel bars, beams, reinforced concrete slabs are used. The platform can be raised above the ground or buried in it.

Bases of this type are considered versatile and reliable. They can be used to erect small frame buildings for summer cottages, and complex structures of industrial workshops. A professional should select the basis, taking into account many parameters.

Appointment

Pile grillage foundations are recommended for:

-

Areas with difficult terrain, large elevation differences, high GWL;

-

Regions with soil freezing by 2 meters or more;

-

Houses built using frame technology, from gas silicate blocks, foam concrete;

-

Objects weighing over 350 tons. It is enough to lay the strength factor not 1.2, but 1.4. Neither tape nor slab substrates can withstand such a mass.

Rough logs of the lower floor can be laid directly above the ground. No site leveling required. For insulation, the underground is covered with expanded clay or fine gravel.

Classification

Pile grillage bases are divided into several types, depending on the selected support modification. Columns are most often used:

-

Screw. A pipe with blades welded onto one of its ends. It can be screwed in either manually or using a special machine;

-

Bored. Wells are preliminarily prepared at the marked points. They are reinforced and poured with concrete;

-

Concrete goods. Products of the required length and diameter are inserted into special pits;

-

Driving. Outer part – asbestos-cement pipes. Internal – solution. This option is recommended for objects with significant mass. The bottom is covered with layers of sand and cement.

We mount the grillage foundation with our own hands

Regardless of which type of foundation is chosen, some general work is required:

-

Load calculation. The number of supports and the general characteristics of the base depend on how correctly it is performed;

-

Clearing the territory. Careful leveling is not required, but all vegetation must be removed from the construction site. This is especially true for the roots of trees and shrubs. If this is not done, then in a couple of years it will be possible to observe how a couple of dandelions or other beautiful flowers make their way through the monolith;

-

Marking the points for placing pillars using pegs;

-

Purchase of materials in accordance with the selected technology.

Further actions are determined by the nature of the supports.

Installation of a grillage for a pile foundation

If everything that is needed has been purchased, the vegetation has been removed, you can proceed to the following stages:

-

Excavation of soil to a depth of 5-10 cm at critical points;

-

Screwing in columns. This can be done by hand using a crowbar or shovel. If the soil on the site is difficult, it is advisable to hire a special car. There should be no deviations from the vertical;

-

The tops are trimmed with a grinder so that they are in the same plane;

-

Reinforcement of cavities is in progress;

-

free space is filled with concrete. As soon as the solution in the piles gains strength, you can go directly to the grillage;

-

Formwork is under construction. Plywood sheets and supports or special pre-fabricated panels with supporting elements can be used;

-

The bottom is sequentially covered with layers of sand and gravel with obligatory leveling and compaction;

-

The reinforcement cage is installed. The rods should not protrude outward;

-

Cement mortar is being poured. This should be done in one day around the entire perimeter so that there are no distortions.

Further, the grillage must be sustained by periodically piercing the surface with a stick or steel bar. It must be left until concrete cures. In the warm season, he picks up it earlier than 28 days. Drying should not be allowed. If this happens, the concrete is poured over with water. From above, from direct sunlight, the entire structure is covered with a black film. Once the strength is gained, the horizontal and vertical surfaces are covered with bitumen mastic. Can be additionally sheathed with mineral wool for thermal insulation.

Making a base using pillars

Foundation preparation begins with standard clearing and marking. Further:

-

A pit of the required depth is prepared for each support;

-

The bottom is covered with sand and crushed stone to a height of 15 cm with mandatory pouring and tamping;

-

In the pits, the walls are covered with polyethylene;

-

A reinforcing frame is installed;

-

The free space is filled with concrete. You can proceed to the continuation of work only after gaining strength;

-

Surfaces are coated with bitumen for waterproofing.

Then the formwork is prepared, a layer of sand is poured, a frame made of reinforcement and wire is mounted, a mixture of cement, sand, water and crushed stone is poured.

What is a grillage, device and varieties

One of the most demanded types of foundation is pile. It is distinguished by the relative simplicity of the arrangement, the ability to work on almost any soil. But for greater stability, the supports are additionally tied together with a monolithic, steel or wooden tape. It contributes to the redistribution of the load from the building, does not allow the house to sink.

Additional functionality:

-

protection of the lag from dampness, mold and mildew formation;

-

providing the ability to build in regions with unstable soils, frequent floods or floods;

-

reduction in labor costs. A voluminous pit is not required, there is no need to decide where to export tons of earth.

Types of grillages

Pile foundations are classified according to two criteria:

-

by the material used;

-

by type of supports.

Monolithic grillage. Pile foundation with grillage

This name is given to the part of the base that unites all the retaining columns together. To obtain, formwork is prepared, which is then filled with a semi-dry mixture of cement, sand and crushed stone. A reinforcing frame is required.

Varieties

The bases can be classified according to several criteria at once:

By the type of supports. For swampy soils, screw ones are suitable, for clay and sandy soils – bored and driven ones;

By placement (buried, surface and raised);

By material (wood, steel, reinforced concrete and concrete).

You need to choose a specific option after careful calculations, not forgetting about the factors that can change the bearing load.

Monolithic grillages

They are used more often than analogues made of wood and I-beams. Are not affected by temperature extremes, moisture. They are not gnawed by insects and mice. There is no nutrient medium for the growth of bacteria, the appearance of colonies of mold and fungus.

The most time-consuming process is the preparation of the formwork and reinforcement frame. It also requires exposure for 30 days before the start of construction. During this time, the base gains strength, excess moisture evaporates from it.

It is better to bookmark in spring or autumn before the start of the rainy season. In summer, surfaces will have to be watered regularly to prevent drying out and cracking. In winter, work can be done, because the material can withstand up to 100 degrees of frost. But after fruitful work, it will be necessary to close the result until the next stages, which can be carried out only in the warm season..

Types of grillages by tape position

-

High (up to 50 cm). This option is often used in regions with constant or periodic waterlogging. It will not be possible to equip a basement or basement. In addition, if the foundation is not solid, you will have to solve the problem with insulation. During the winter months, the wind will blow out the heat and cool the lower floor. To minimize heating costs, all the space between the piles is sheathed with siding or profiled sheet;

-

By ground level. This modification is the easiest to use. No need to dig a ditch or build a formwork on an elevated position. Sometimes, in order to reduce the possibility of getting wet, the soil is taken out from below by 10-15 cm. But such a trench needs to be strengthened. Otherwise, sliding of layers of chernozem, sandstone or loam is inevitable;

-

Recessed. The base goes into the ground by 30-40 cm, and often up to a meter. The advantages of the modification include a decrease in heat loss. The disadvantage is the complication of work. We have to take out significant amounts of land.

Methods for mating tape with piles

The following methods are used to connect individual components to each other:

-

articulated. The rods reaching the surface of the column (at least 30 cm) are bent so that they cover the wire laid in the formwork;

-

hard. The metal frames of the two systems are welded together to eliminate movement.

To increase reliability, it is recommended to use corrugated steel rods without corrosion or staining. The individual parts should be connected very carefully so as not to destroy the top layer. Ideally, the reinforcement is connected to each other using wire. This reduces the likelihood of rust formation..

Fill pillars

The grillage of the pile foundation is a mandatory presence of supports. The process of their installation begins with marking. Columns should be located along the perimeter of the future building and at points with maximum load. If the screw option is chosen, they are simply screwed into the ground. For bored ones, pits have to be prepared initially. The bottom is covered with sand, followed by careful compaction. In some cases, asbestos-cement pipes are used as walls. The length of the columns is determined individually. They are supposed to go down to hard, incompressible rocks..

In any case, the core of the supports is filled with concrete so that the structure is not pushed to the surface during the winter heaving of soils. But first, a wire frame with a diameter of 10-14 mm is installed inside. The rods should protrude 20-30 cm above the ground to mate with a monolithic tape.

Calculation of the grillage

This stage precedes the construction of any house or structure. In order not to observe distortions and cracks in the walls in a year or ten, it is necessary to collect information on:

-

Geological structure of the site;

-

Physical and chemical properties of soils;

-

Building parameters (weight, number of storeys);

-

Freezing depth and groundwater level.

Based on the data received:

-

The characteristics of the grillage and the depth of piling are determined;

-

The load is calculated;

-

A decision is made on the number of posts, their diameter and length, as well as the dimensions and materials of the grillage.

It is better not to do this work on your own. It is better to entrust the calculations to professional designers in order to avoid distortions and other sad consequences..

Grillage device: preparatory work

The supports are installed, cut to size. Heads, if we are talking about screw modifications, are mounted. You can go directly to the strapping. At this stage, the most important thing is to correctly assemble the formwork. It must withstand the weight of concrete for many days..

Plywood with a thickness of at least 12-14 mm, boards processed on one side are used as a temporary fence. You can buy or rent ready-made shields. They are designed for a certain load and are already equipped with supports.

The raised grillage on piles is the most difficult to build. Here, in addition to the walls, a solid bottom is required. To avoid failures, temporary bricks or wooden beams are installed between the permanent columns. They are subsequently dismantled.

Inside the formwork, a frame is assembled from reinforcement. The rods are stacked in several rows. They should not touch the walls, come out to the surface. In the corners, the whips are bent. It is not recommended to weld individual elements. For connection, use a special knitting wire.

Pouring tape

Once the base is ready, you can fill it with M300 concrete. For its preparation, one part of M400 Portland cement is mixed with 0.6 h of water and 1.9 h of sand. Add crushed stone of the middle fraction in the amount of 2.9 h.

You can prepare the solution yourself or order a ready-made one. In the first case, you should be careful when adding liquid. If there is a lot of it, stratification of the composition is possible..

The filling is carried out immediately along the entire perimeter. You cannot work today on one side, tomorrow move on to the other. They will gain strength in different ways. Result – drawdowns and distortions.

Frame standards

In the standard version, two rows of corrugated hot-rolled rods, connected by jumpers, are laid in the base. Diameter – 12-16 mm. Steel class – A3. To connect them together, rectangular clamps of smooth wire with a cross section of 10 mm or more are used.

The whips coming out of the posts are folded at the upper row of planks and connected to the lower.

Pick-up device

If the grillage foundation is raised above the ground, you inevitably have to solve the problem with insulation, reducing heat loss. Zabirka will help with this. She may be:

-

wooden, siding, plywood, profiled sheet. Sheets are cut to the desired size and sheathed with them all the space along the outer surfaces of the supports;

-

brick or reinforced concrete. In this case, a depth of 30-50 cm is recommended. This option is considered the most laborious. In addition, it is associated with significant costs..

Advantages and disadvantages of a grillage foundation

Among the positive characteristics, it is necessary to highlight:

-

Resistance to adverse external influences (precipitation, rock movements, wind, etc.);

-

Minimum laying time in comparison with monolithic counterparts;

-

The ability to work even in winter. It should be at least -10C outside. At lower temperatures, additives are required to prevent water freezing and cracking in concrete.

Speaking about what a foundation grillage on piles is, it is necessary to highlight a number of positive features. It:

-

Reducing the amount of land work and labor costs. You do not have to remove and move tons of soil, prepare a pit;

-

Undemanding to soil types. You can build on sandstones, peat bogs, loams;

-

The ability to create bases with complex geometries: with rounds, cones, polygons, etc. The main thing is the assembly of the formwork of the desired shape. It is ideal for regions with complex geology, with significant differences in elevation. Do not forget about this type of basis, if there is a river in the immediate vicinity, spills occur.

In fairness, it is necessary to note a few shortcomings. Basis of this type:

-

Does not imply the presence of a basement, “zero” floor;

-

requires accurate preliminary calculations;

-

Not suitable for mountainous regions. Mineral rocks are difficult to break through. Pre-reaming will be required. In addition, the likelihood of pushing the piles to the surface increases during winter heaving. For the same reason, the foundation is not recommended for areas with significant horizontal soil movements..

Accommodation types

The foundation grillage can be:

-

Deepened by 30-50 cm. The process of arrangement is laborious, similar to pouring a standard tape base;

-

Lying on the surface of the earth. To avoid faults, the site is pre-cleared of any vegetation;

-

Raised. The lower surface is separated from the ground by up to 50 cm. The free space is closed by a pick-up. Otherwise, significant heat loss is possible. This option is chosen if the construction is carried out in a region with a high GWL or heavy precipitation, on the shore of a body of water with the possibility of flooding.

Varieties by type of material

The pile grillage is a combination of supports and top strapping. It is performed from:

-

Durable timber treated with fire retardants, special compounds that increase fire resistance;

-

I-beam. It is used in conjunction with screw posts. The main problem is a high-quality connection of individual components;

-

Concrete goods. The finished structure is highly durable;

-

Concrete. A reinforcing frame is required to level the bending forces. The manufacturing process takes a long time due to the strength gain.

Types by type of construction

The foundation pile grillage for the house can be:

-

Monolithic. It is a single slab or tape around the perimeter. Recommended for low-rise construction;

-

Team. The base consists of individual elements interconnected. The construction procedure is highly labor intensive. Building it yourself without proper experience is almost impossible..

Conclusions on the grillage

It is ideal for regions with complex geology, with significant elevation differences. Do not forget about this type of basis, if there is a river in the immediate vicinity, spills occur.

Labor intensity is higher than that of standard tape modifications. The main task is the correct placement of the supports. They should not deviate from the vertical. A defect made at the driving stage cannot be corrected later..

The strapping can be made of wood, reinforced concrete blocks or pour concrete. The specific option is selected taking into account the dimensions and weight of the building.

Video