The modern design of yard areas and landscaping plots are unthinkable without the use of paving stones. The industry produces several of its species with many colors and shapes. The cost of this material depends on many factors and varies widely. Today, even there is a mass of special forms for the independent manufacture of paving stones. And the video taken by handing paving slabs with your own hands: step by step instructions and even more. After all, those who have learned to do this on their own often often wish to help others with their skills.

Types of paving slabs with their pros and cons

Today, no one can be surprised by the beautiful design of the entrance to the house or garden plot with the use of paving slabs of the most inconceivable forms and colors. But few people know that behind this variety there are only a few basic types of paving slabs, which is classified according to the method of its production:

- Vibrated

- Vibropressed.

- Hyper pressed.

- Polymer sandy.

All types have their advantages and disadvantages, different cost, as well as laying technology. The paving slabs of any kind can be laid with your own hands, having thoroughly understood its specific features.

This is the easiest and cheapest way. It is based on the ability of concrete to compact during vibration. Plastic molds are filled with prepared solution and placed on a special table that produces vibrating movements. Then the blanks are placed in a thermal chamber to dry. After some time, the tile is ready for use. The whole process takes very little time and resources.

To create different colors are used dyes that are added to the solution. It is not difficult to even open your mini-factory in the garage for the production of this type of paving slabs. Video styling with their own hands and the production of this material will help to correctly implement this project.

The advantages of vibrocast tiles are:

- the presence of a glossy surface;

- susceptibility to a wide variety of dyes;

- low production cost.

However, it is not without significant drawbacks:

- weak strength;

- poor frost resistance;

- short term operation.

In addition, it is impossible to automate the production of this material. Based on the characteristics, vibro-molded tiles can only be used for arranging garden paths and, preferably, in the southern regions of the country, since significant temperature drops destroy it very quickly.

Quickly and conveniently, you can make a path using the form for paving slabs.

Helpful advice! High-quality tile when hitting each other produces a characteristic ringing sound.

The production technology of the vibropressed tile is noticeably different from the previous one. Forms filled with a solution of concrete are connected to a piston, which makes vibrating movements, creating alternating pressure in the working chamber. Due to this, there is a strong compaction of the mixture. Heat treatment is no longer required. Such tile turns out much stronger.

Hyper pressing allows you to completely eliminate the vibration of the pistons. In this case, an even greater pressure is created, due to which concrete is compacted. With this method, production can be fully automated.

Advantages of pressed types of pavers:

- low susceptibility to mechanical stress;

- a high degree of production automation;

- long operation;

- weak susceptibility to low temperatures and their differences.

Their disadvantages are:

- few colors;

- scarcity in a variety of forms.

Helpful advice! Too saturated colors of tiles can speak about the addition of cheap bright dyes, which are easily washed out by the rain.

Due to a sufficiently high strength and durability, pressed paving slabs can even be used for building entrances to houses, as it is able to withstand not heavy traffic of light vehicles, if you follow the installation technology. With their own hands, paving slabs of this type are able to lay each in the presence of elementary skills and tools.

This is a special innovative type of pavement. It differs from others not only in the method of manufacture, but also in the composition of the main components. The composition is completely absent cement. But the basis is the usual sand. Polymers and plasticizers act as binders. In addition, to give different colors used dyes.

Paving slabs for tracks in the country. Prices and types. Styles tracks in the country, paved with paving slabs. The right choice and laying of paving slabs. Inspirational photo. Video instructions.

Sand is sieved, calcined and mixed with polyethylene. Then heated to 250 degrees and add the remaining components. The resulting mass is poured into molds and pressed. The tile obtained by this method does not allow moisture in itself, which completely excludes the possibility of its cracking under the influence of freezing water.

This type of tile has many advantages:

- Wear resistance and strength is higher than in other species.

- Does not wear out over time.

- Water resistant.

- Not afraid of frost.

- Chemically inactive.

- Easy installation.

- A small mass of the product.

- Large color range and variety of forms.

- Long service life.

At the same time, there is only one drawback – expansion in hot weather. In this regard, the technology of self-laying paving slabs of this type involves the remaining 3 mm of gaps.

Helpful advice! On the back of the tile should not be yellow spots. Their presence indicates a violation of technology, in particular, the use of clay sand.

If the decision is made to lay the paving slabs with your own hands, step-by-step instructions for the implementation of this process will be completely superfluous. If we talk about the methods of laying tiles, there are many. It all depends on the fantasy of the landlord. Drawing can be: in the form of a fir-tree, in a chessboard order, weaving or circles. Looks beautiful and just a chaotic pattern. Technology laying does not depend on imagination and it happens:

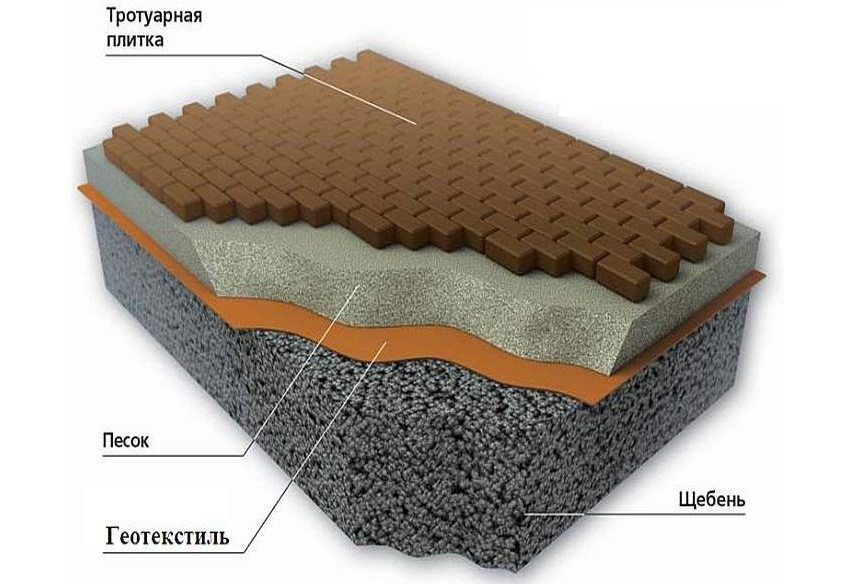

- on a substrate of wet sand;

- using sand-cement mixture;

- laying on grout from cement and sand.

The first method involves the preliminary installation of a sand pillow. In the second variant, cement is added to the sand and slightly watered. When using the third method, a solution is prepared in the proportion of 1 part of cement to 5 parts of sand.

Helpful advice! When counting the number of tiles, it is necessary to add from 5 to 7% of their planned number, since in case of shortage, you can not find exactly the same shade.

Having defined the pattern and technology, you can start laying paving slabs with your own hands. Step-by-step instruction includes the following steps:

- The top layer of soil is removed by 15 cm.

- Grades are formed, both along and across the path for drainage.

- Marking the area on which the work will be done, with pegs and twine.

- Curbing device if necessary.

- The formation of the selected type of pillow thickness of 7 cm.

- Leveling the surface.

- Laying pavers and tamping.

- Finishing grouting joints.

If the path will be curved, they must be firmly installed on the concrete solution before the coating. The tile keeps within at first about a border. Then you need to move to the middle. In order not to crush the already prepared surface, the movement must be from itself. Tamper is made using a rubber or wooden mallet.

If any tile falls unevenly, then the sand can be poured, or vice versa removed, subsequently producing additional tamping. It is advisable to select the width of the track immediately so that it includes a whole number of tiles. If it is impossible to do this, then along one of the borders the tile can be trimmed with a grinder with a special attachment over the stone.

The final step will be grouting. It is produced by sand-cement mix. The seams are filled up to the required level.

Helpful advice! It is always necessary to leave a few spare tiles for possible future repair of the track.

The paved stone path created with own hands will long please its owner with impeccable service in any weather only with the right choice of tile type and strict adherence to the laying technology.