A monolithic foundation slab is a common way of organizing the foundation of various types of buildings. This is due to its performance and economical cost. Let’s talk about the available varieties and construction technology. We will also analyze for which types of soils it is better to choose them, how to build it with your own hands, what materials are needed for this. Below you will find detailed instructions, as well as photos and videos that will help you study this issue in maximum detail..

Content:

- Features of slab foundations

- The type of soil where it is best to use a slab foundation

- Monolithic foundation device: constituent elements

- Varieties of slab foundations

- Pros and cons of the foundation

- Slab base design

- Calculation of a monolithic foundation slab: procedure

- How to calculate a concrete slab using a calculator

- How to choose the right fittings

- DIY foundation slab construction technology

- Summing up

Features of slab foundations

This structure is defined as floating. Its main feature is its location in the ground at a shallow depth. The presence of a “monolith” in the name indicates a solid shape, which provides additional stability to structures under construction of any size and weight. Laying is carried out under the entire area of the object being erected, which also contributes to an increase in the bearing capacity, taking into account the non-standard conditions of use of this basis.

The type of soil where it is best to use a slab foundation

Let us analyze the main types of the soil layer on which it is necessary to use the described structures. Other types of foundations will not work for them and will not be able to ensure the reliability of buildings..

Fine sandy, silty, sandy loam

These are loose rocks, which consist mainly of dusty and sandy particles..

Clay, loam

More than 50% here is accounted for by small particles with a size of no more than 0.01 mm.

Water-saturated

These are band clays, silts, loess species, which are characterized by a high degree of water saturation, porosity, deformability and low strength..

Bulk

Formed as a result of dumping solid household waste, mineral production residues, natural soils.

Weak bearing

As the name implies, such soils have a weak load-bearing surface. For this reason, they are practically unsuitable for construction without prior reinforcement.

Monolithic foundation device: constituent elements

A mandatory element is a monolith slab. Its thickness must ensure a high degree of strength for the entire building. In addition to it, the structure includes the following layers:

-

Litter. This is a cushion for cushioning from a mixture of sand and crushed stone 40-60 cm thick. It is a thin layer of concrete to level the base and protect the waterproofing carpet. Waterproofing. These are special moisture resistant rolls.

-

Thermal insulation. This is a tile or roll material made of polystyrene foam.

-

Reinforced grid concrete.

Varieties of slab foundations

The modern market offers several options. Check out each of them to choose the best option for you.

Monolithic flat

This is a reinforced concrete slab, as simple as possible in terms of design.

Usb

Has 3 layers: expanded polystyrene, filling, backfill. This system is most common in Alaska and Canada..

Stiffening rib

Here there are 2 subspecies, based on the direction of the elements:

-

Down. The foundation monolithic slab is placed on the belt and is responsible for stiffening.

-

Up. The tape follows the shape of the load-bearing walls. At the same time, the ribs form the zero floor, they must be insulated. Insulation materials can be used for laying communications.

Pros and cons of the foundation

Like all designs, the monolith has its advantages and disadvantages..

Benefits

-

It becomes possible to erect structures with significant weight on soft soils.

-

Minimum shrinkage deformations.

-

There is no need for deep foundation laying, which reduces the amount of used special equipment.

-

A monolithic concrete slab can be used as a ground floor floor, as it has a flat top surface.

In addition, the use of ribbed structures:

-

Increases the strength of the base, which allows the thickness of the flat part to be reduced.

-

Improves resistance to mechanical damage and deformation.

-

Allows you to evenly distribute the load of the building.

disadvantages

-

Special equipment required.

-

Substantial consumption of material.

-

Labor intensity of construction.

Slab base design

The calculation is based on the parameters of the soil, how saturated it is with water and what are its load-bearing characteristics. In order to determine these indicators, geological surveys are necessarily carried out in compliance with applicable rules and regulations..

It’s important to know! A monolithic slab for the foundation of a house is characterized by a thickness of 15-35 cm. This is the value recommended by specialists. It is important to entrust the selection and calculations to qualified professionals with many years of experience.

The load of the structure’s weight must be measured, it should not exceed the bearing capacity of the monolith. In order to calculate the pressure, the weight of building materials used for the construction of floors, walls, and roofs is calculated. In addition, the following types of loads must be taken into account: wind, snow, useful. The obtained values are summed up and divided by the support area. The final parameter must meet the requirements of SNiP 2.02.01-83. If it is abnormal, one of the following options should be considered:

-

Extend support area.

-

Change base.

-

Replace bedrock.

-

Reduce the weight of the aboveground part of the structure.

Calculation of a monolithic foundation slab: procedure

Cushioning is the foundation of the foundation

First of all, we calculate the dimensions of the pillow. Do not forget that all sizes have a direct impact on the final cost. The gravel-sand substrate performs such important functions as shock-absorbing and waterproofing (compacted under the action of the structure and form a strong top layer). The thickness in this case can be up to 0.6 meters..

We need to accurately calculate the amount of reinforcement so that the base under the concrete slab is rigid. The mesh must be mounted in layers, the distance between them is no more than 5 cm. Then the actual depth itself is determined. The main parameter that is taken into account is, again, the degree of soil freezing.

Calculation of the thickness of the monolith

To get reliable information, you first need to calculate several important parameters. First of all, this is the distance between the two reinforcement meshes used. The location of these elements is of great importance. After that, it is necessary to determine the characteristics of the concrete layers: which will be under the reinforcement, which will be above it. It is important to take into account the features of the rods used to collect the mesh structure..

In the standard version, the base plate for the house has a thickness of 25-30 cm. But this indicator is not universal. Such dimensions adversely affect the soil composition, deforming it..

In the course of computational work, it is important to consider the following point: how high the base goes beyond the ground line. Use the following proportion: the further apart the walls are, the deeper the monolith is. Accordingly, the stronger it will act and the more material is required..

Determination of the safety factor

This parameter is necessary to calculate the bearing capacity of the slab under the foundation. It is he who determines the validity and feasibility of changing the original purpose of the structure. The indicator is in the range from 1 to 1.4 and directly depends on the building materials used and the level of loads. For a structure made of reinforced concrete, its value is fixed – 1.3.

Determination of the thickness of the monolith using the formula

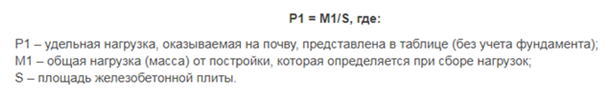

First, we multiply the load indicator by the total area, and then by the previously calculated reliability factor. We sum up the results and get the total weight. Now let’s determine the specific load using the following formula:

It is important to consider the types of styling..

After that, we calculate the mass of the foundation from the concrete slab. For this purpose, we multiply the tiled area and the difference in loads. Then we move on to the basic calculations using the formula:

Most likely, the result will be expressed as a non-integer number, we round it.

How to calculate a concrete slab using a calculator

The online service is a convenient specialized program for calculating the dimensions of the structure being erected. It allows you to calculate the thickness, the size of the formwork, the required amount of reinforcement and its section as accurately as possible. The use of modern software has a wide range of advantages. We list just a few of them: the accuracy of the results obtained, saving time and effort, the ability to visualize the picture.

Visualization is effective because it provides an assessment of the feasibility of the planned object as a whole. Having a model, before you start building a foundation from a monolithic slab, you can easily find errors and inaccuracies made when performing design and computational operations..

How to choose the right fittings

The choice of material is necessary based on the specific operating conditions. For example, you have a dense soil on the site. In this situation, AI rods with ribbing with a diameter of at least 1 cm should be used.If construction begins on an area where the soil is unstable, it is necessary to choose rods with a thickness of 1.4 cm or more with reinforcement. It is also the best fittings for constructions on slopes..

It is important to pay attention to the material for the walls, how heavy they will be. If the mesh is not correctly selected, the concrete base under the house will most likely not cope with the pressure..

DIY foundation slab construction technology

Required materials:

-

Concrete.

-

Expanded polystyrene.

-

Sand and gravel.

-

Knitting wire.

-

Reinforced film.

-

Geotextile.

-

Armature.

-

Formwork board.

Insulated foundation monolithic slab: phased construction technology

Let’s analyze the main stages.

Preparatory work

First, the construction site is cleared of debris and growing plants. Then they agree on the site plan and the developed building project, establish the markings. The entire perimeter of the future structure is marked with pegs, between which the cords are pulled. Excavation work is carried out inside the marked perimeter: the upper soil layer of soil 0.3-0.4 meters deep is removed.

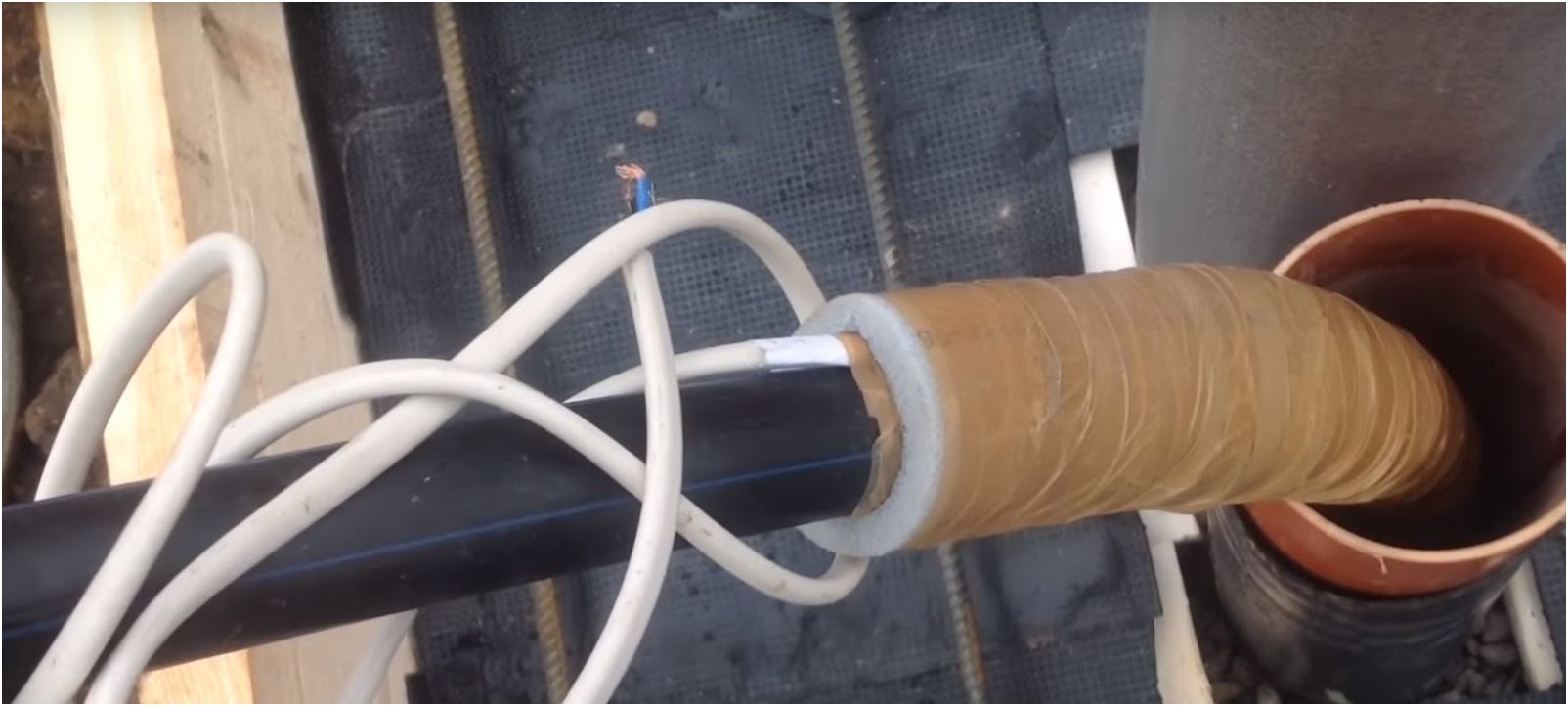

After that, a pillow is poured, which consists of three layers: compacted sand (20-25 cm), a mixture of gravel and crushed stone (20-25 cm) and geotextiles (mounted between these two building materials). Now the communications are being laid in a special corrugation for protection. The corrugations and pipes are then brought out to the above-ground part of the structure, directly at the connection points (approximately at a height of 50-60 cm).

Heat and waterproofing

First, a waterproofing material is mounted along the upper edge of the laid out pillow. At the same time, it is important to make an overlap between the canvases of 15 cm. The edges of the used canvases should extend beyond the slab as much as the tiled thickness, and it is also necessary to leave 10-15 additional cm. Why is this necessary? In order to subsequently protect the ends of the structure from moisture. The best option for waterproofing is polyethylene with reinforcement.

Note! Places where overlaps are observed must be carefully sealed. To do this, you can use specialized tape..

The next step is to install thermal insulation materials. These can be composite elements made of extruded polystyrene foam with an L-shaped section for the collection of permanent formwork. It is allowed to use fiberboard boards, however, auxiliary fasteners must be provided for them. An alternative is flat polystyrene sheets that have been pre-extruded. From the outside, the insulation must be strengthened with special stops and enclosing formwork.

Where the construction of walls is planned, the insulation is mounted in 1 layer. Where the operational loads are increased, it is necessary to install double thermal insulation material. The minimum thickness is 10 cm. If a two-layer installation is performed, the joints between the slabs of the upper tier should not coincide with the joints of the lower tier. Their fastening is carried out using butterfly dowels and polyurethane adhesive.

At the end, special holes are made for laying utilities. The resulting gaps are then treated with foam..

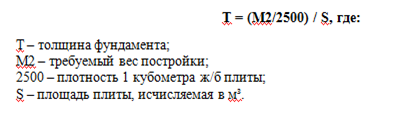

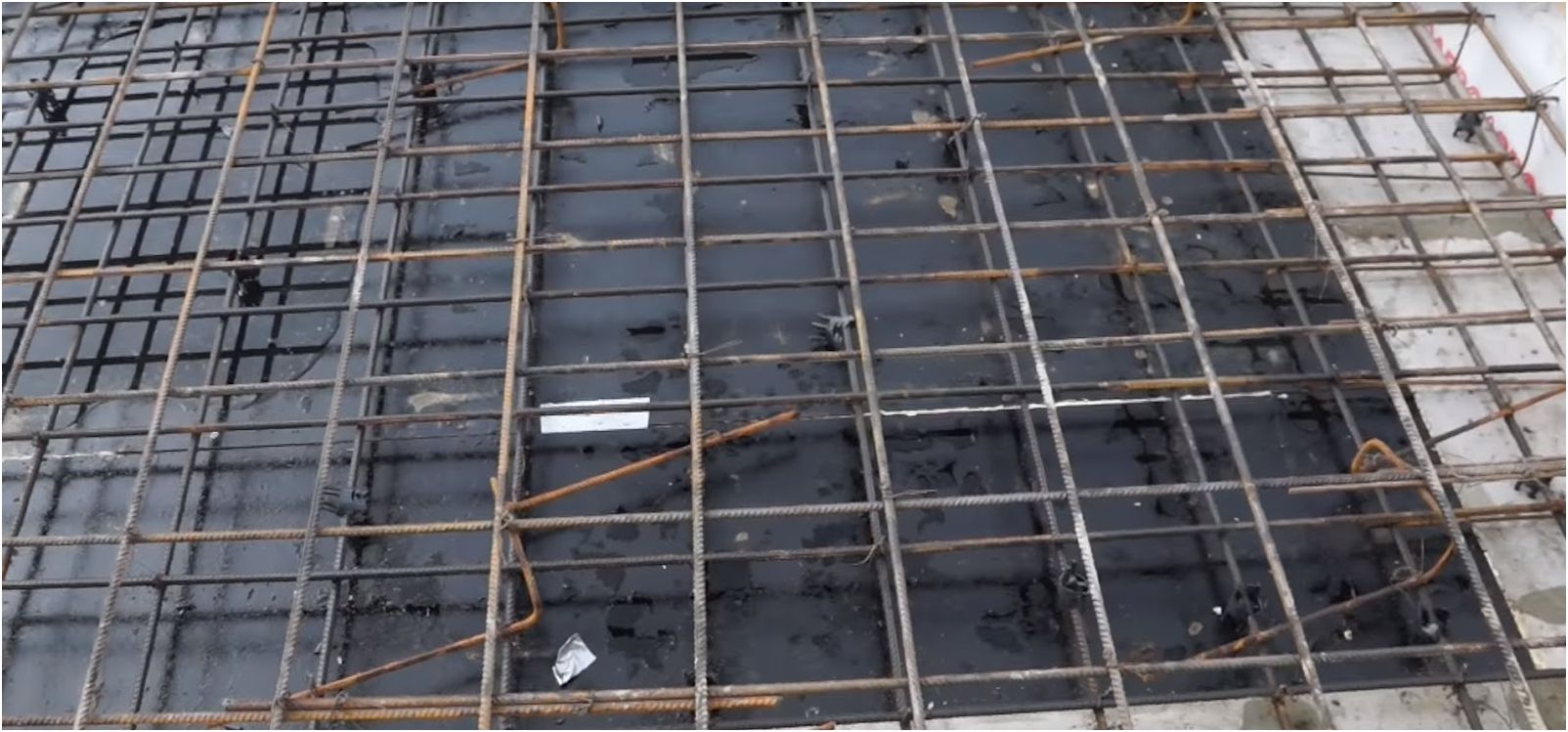

Reinforcement

This stage includes the following stages:

-

Bundle of the reinforcing frame for the formation of stiffeners.

-

Reinforcement of the slab itself in the areas of the highest operational loads.

-

Laying reinforcement mesh and framework on pre-installed supports.

Heating elements

First, pipes are laid to organize underfloor heating. If the system circuit has been planned for several buildings and the pipe is laid under the frame, it must be protected with a sleeve. Then the pipes are connected to the collectors.

Plate shaping and maintenance

The frame is prepared for pouring concrete. The poured surface is leveled. To prevent drying out, the monolith is covered with a special film. When the strength of the base is 80% or more, the formwork is removed. This may take from 8 days (if the temperature is +30 degrees Celsius and above) to 1.5 months (if it is 0-3 degrees outside).

Summing up

The construction of a monolithic foundation slab is a crucial stage that determines the reliability and durability of the entire structure. Therefore, it is important to take the calculations as seriously as possible and strictly observe the technology..