Every room, even a utility room, must be properly finished for functional and aesthetic reasons. An important part of finishing work is creating a durable floor. Today, more and more often, technical porcelain stoneware is used for its arrangement. This material is well suited for utility rooms and the garage. Heating is not always connected in these rooms, so the frost-resistant properties of the floor material come to the fore.

Porcelain stoneware – technical characteristics

This building material is obtained by pressing precious ceramic granite. After pressing, firing occurs at a temperature of about 1000 ℃, which makes it hard and resistant to damage. Unfinished tiles are called technical porcelain stoneware. It has a very low absorbency, which means it is resistant to moisture, frost and thawing. It can be used both inside and outside buildings. Due to its high strength parameters, it can be used for finishing floors, countertops and window sills. Technical porcelain stoneware for floors is used primarily in rooms where the appearance of the tiles is not so important. It can be used not only in residential construction, but also in technical and industrial premises, where, for example, heavy equipment can stand or ride on it. This type of porcelain stoneware is the most durable of all.

If we analyze the technical characteristics of porcelain stoneware tiles, then one of the important properties is the degree of strength and hardness of the product. On the Mohs scale, the hardness of this building material is estimated at 7-8 points (slightly less than that of a diamond). Surfaces lined with these materials retain their attractiveness for a long time, since they do not form scratches or chips. The material is not afraid of constant loads, therefore it is often used in rooms with high traffic. The strength of a material is assessed by its thickness and structure. The minimum acceptable thickness is considered to be 8mm; such tiles are often used for wall cladding. Products with a thickness of 12 to 20 mm are intended for the arrangement of floors in rooms with high traffic. Tiles up to 30 mm thick – thickened, used indoors and outdoors with high impact loads.

The tile does not emit dangerous vapors, due to which it is safe for use, harmless to humans, which cannot be said about natural granite, which has a certain radioactivity.

Types of technical porcelain stoneware

There are three types of technical porcelain stoneware on the market:

-

Natural. Also known as unglazed porcelain stoneware, this type of porcelain stoneware has a rough texture making it difficult to clean. Its feature is high hardness, abrasion resistance and durability. Thanks to the production technology used, its structure is homogeneous, which has a positive effect on the technical parameters of products made of natural porcelain stoneware. Due to the specifics of the production process, the colors of the tiles are very limited, therefore technical gray porcelain stoneware is mainly used in technical rooms, public buildings, on stairs. However, the building material can also be used in residential interiors..

-

Polished with a shiny smooth surface. To keep these tiles clean, they need to be properly protected. Its smooth surface can be quite slippery, so the tiles should not be placed in places where moisture can form on the surface of the material..

-

Anti-slip (structural). Material with increased anti-slip coating – suitable for garage and utility rooms. Its rough surface prevents slipping even in damp places.

Matte technical porcelain stoneware, not processed after firing, is highly abrasion resistant, practical to use. Satin-finished porcelain stoneware is a material on which a layer of mineral salts is applied before firing, which makes the surface of the products shiny, while completely non-slip.

Application of technical porcelain stoneware

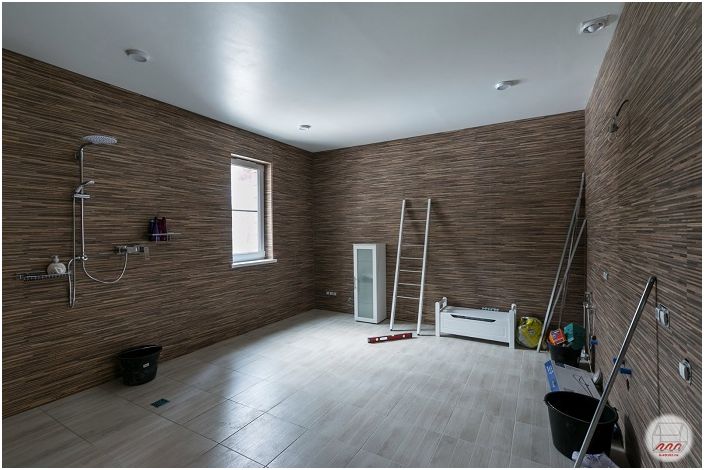

Due to its strength, this material can be used in all rooms where the floor must be extremely durable. First of all, it is recommended for the garage, as well as for warehouses where heavy equipment can drive it. Technical porcelain stoneware has frost-resistant properties, is not afraid of dampness in rooms and flooding of the floor (the exception is polished technical porcelain stoneware, which becomes slippery under the influence of water, which can be dangerous for floor users). Floor and walls made of this material is a long-term investment..

Technical tiles “porcelain stoneware” are used in the following areas:

-

Cladding of floors and stairs in rooms with high traffic (in shopping centers, railway stations, in apartment buildings).

-

For laying floors in industrial premises, as well as in workshops, technical centers, where traffic is foreseen.

-

For arranging floors in utility rooms.

-

On terraces, outdoor pedestrian areas.

-

When arranging hinged ventilated facades.

Due to all the advantages of the material, it is often used for cladding facades. Ceramic granite for the facade allows you to make it more aesthetic, and also protects the walls from external factors. Additional thermal insulation and ventilation – protection of premises from cold and dampness. For this reason, facade ceramic granite is used more and more often in Russia. For facades, you can use a material with raw edges, which creates a monolithic coating without visible seams.

Porcelain stoneware tiles for outdoor decoration are resistant to UV rays, atmospheric precipitation, chemicals and low temperatures. Due to its increased strength, moisture resistance and resistance to wear and tear, this material is often used in the decoration of bathrooms and swimming pools. The difficulty lies only in the selection of texture, color, style of products.

Advantages and disadvantages of technical porcelain stoneware

The advantage of ceramic granite is its durability, resistance to frost, therefore it is suitable for unheated rooms and technical rooms where the floor is exposed to heavy loads. The disadvantage of this material may be its porosity, due to which dirt accumulates on it. Another disadvantage is the limited choice of porcelain stoneware colors..

Technical tiles – sizes and prices

Technical porcelain stoneware – floor tiles, most often square in shape. The most common tiles are 30 × 30 cm, some manufacturers also offer 20 × 20 cm tiles.To visually increase a small space, it is worth using porcelain stoneware in the form of large tiles (60 × 60 cm). There is also an oblong rectangular tile on the market: 30 × 60 cm.

The cost of the material depends on the following factors:

-

Features of production technology. Double-fill technology helps to save colorant. With this technology, the tiles are not completely painted, but only the outer layer (2-3 mm). This does not in any way affect the properties of the material, but the price becomes lower. Material that undergoes additional processing (lapping, polishing) is more expensive.

-

From the size. Often, larger tiles are more expensive because they are positioned as an individual, higher quality product. Also, the price increases due to the fact that special equipment is used for the production of large format tiles..

-

Logistics. Delivery of building materials from the manufacturer to the facility can significantly increase the total cost.

-

Order volume. If you have planned a large order, then you can count on a discount. Its size depends on the manufacturing company (often, the higher the prices, the greater the discount).

Technical porcelain stoneware is cheaper than the glazed or polished counterpart of this material. The higher the price, the better the product quality. Sanded tiles are among the most expensive materials.