Warm water floors of residential buildings and apartments are the main element of heat exchange in the room or complement the traditional radiator circuit. Wiring diagrams of water heated floors in a private house are developed for individual design, repair or replacement of the heating system. The owner of the house chooses the type of heating devices.

Wiring diagrams of water heated floors in a private house

Wiring diagrams of water heated floors are developed in accordance with the calculated heat consumption and its losses through the building envelope. Features and rules for calculating a water heated floor were cited earlier in the article “Calculation of floor heating heat”. Getting to the self development of wiring diagrams, you need to remember:

- the total heat load of the room depends on the degree of insulation, thickness and material of the walls, floors (floors, ceilings), window and door openings. The calculation is made taking into account the climatic zone of the area of residence. If the calculated value of heat transfer exceeds 100 W / m ?, then it is not profitable to use warm water floors as the main heating option;

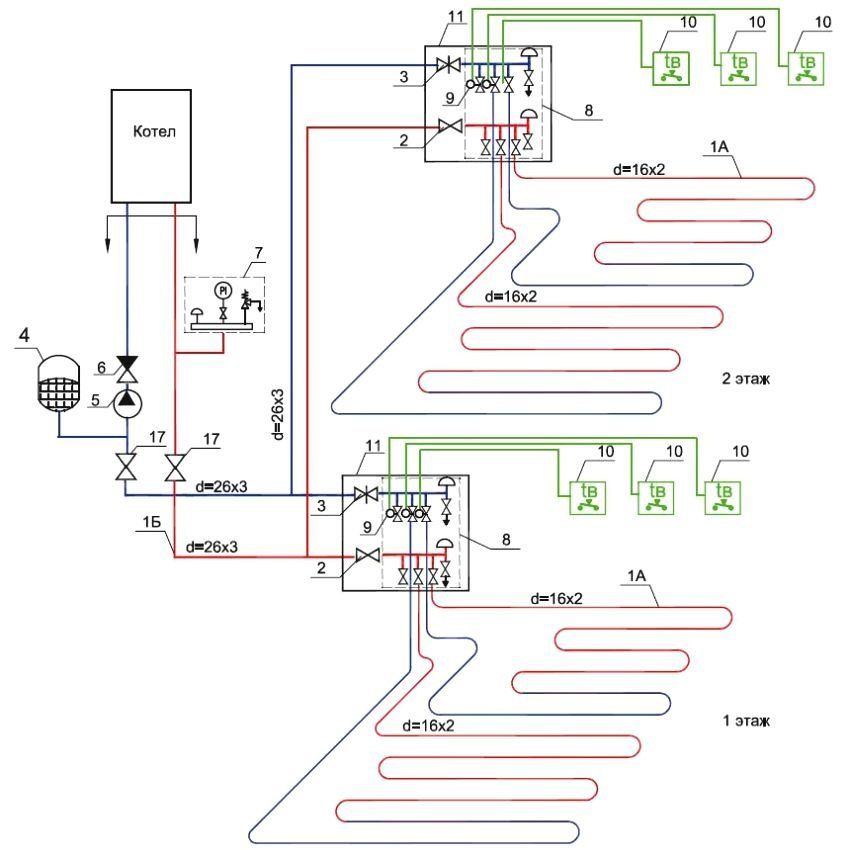

- floor heating system consists of parallel functioning circuits. The length of one heating circuit depends on the heat load, the useful area of the room, the method and pitch of the pipe;

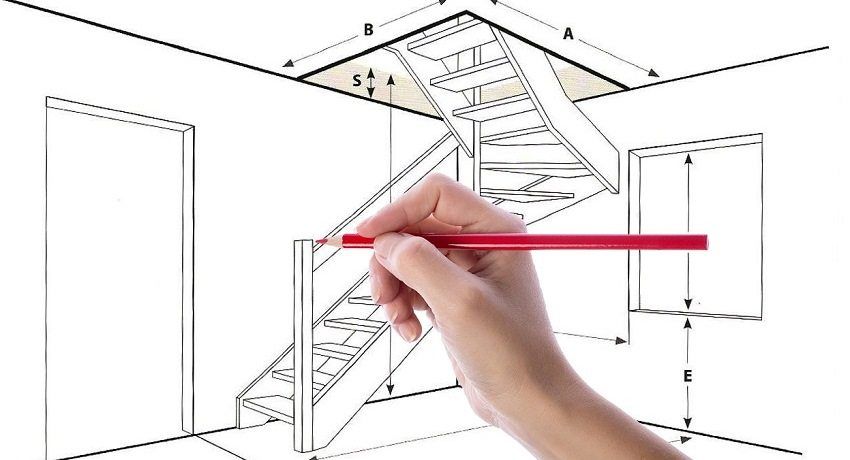

- the construction area of the premises does not coincide with the surface occupied by the heating floor circuit. The effective area takes into account the free space, which does not include the installation sites of the built-in furniture and the distance from the internal (0.3 m) and external (0.1? 0.15 m) walls;

- premises with a useful area of more than 30 m ?, divided into sectors. Each section heats an independent circuit connected to the distribution manifold. The length, pitch and diameter of the links connected to the combs of one distributor must be equal. An exception is made for contour reinforcement zones along external walls;

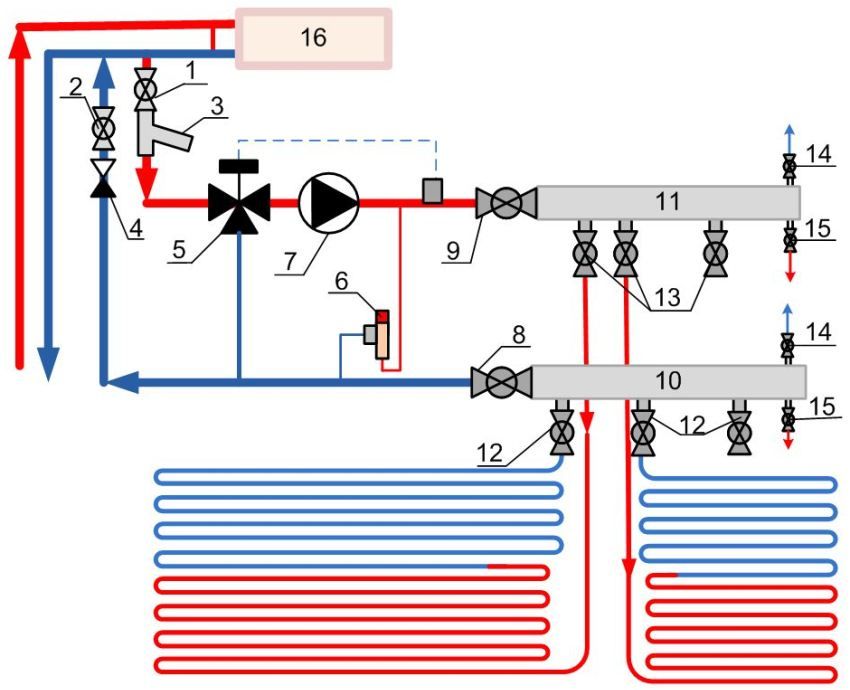

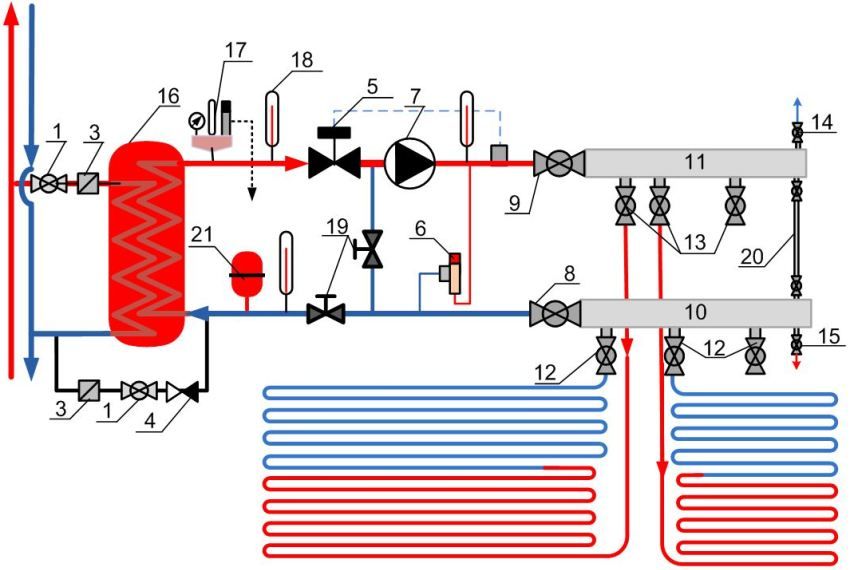

- water floors – an element of the volatile heating system. The large length and complex configuration of the low-temperature circuit requires the installation of a common or several circulating pumps. The preset pressure in the heating system of a small house can support a boiler with an integrated pressure pump. The installation of circulation pumps and control valves in each circuit is necessary for balancing the underfloor heating of a large house (more than 150 m?);

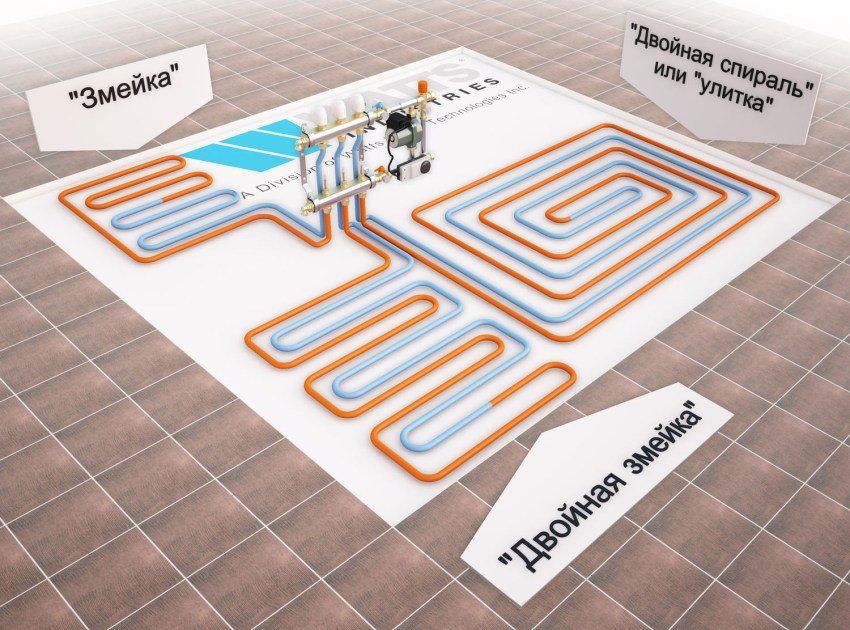

- Laying schemes of a warm water floor (simple, angular, double loop or spiral) depend on the method of heating and the geometry of the room. Additional heating allows simple single loops with a step of 0.2 ± 0.3 m. Basic heating with warm water floors is arranged with double loops or spirals (step 0.1 ± 0.15 m);

- the pitch and length of the individual chains determines the diameter of the selected pipe. The larger the internal cross-section of the pipe, the greater the allowed length of the contour. The distance between the axes of the supply and return pipes must maintain an optimal thermal condition. Standard indicator of temperature difference in adjacent areas of 5 ° C;

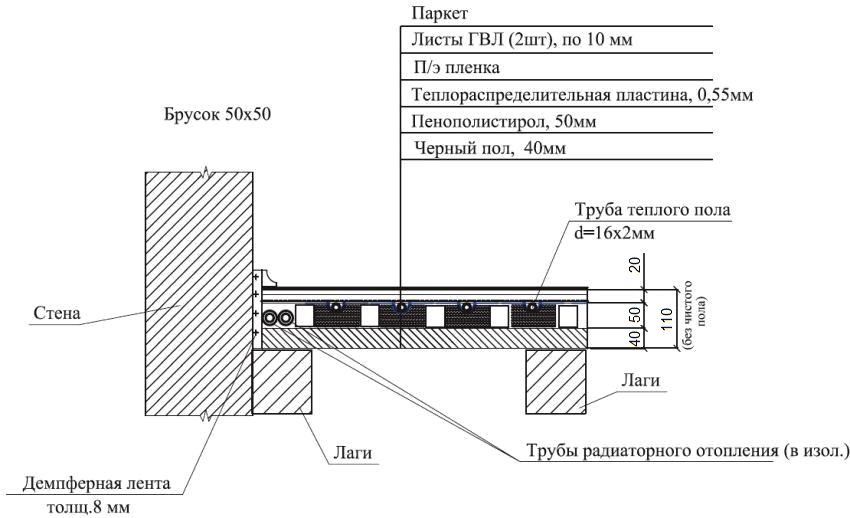

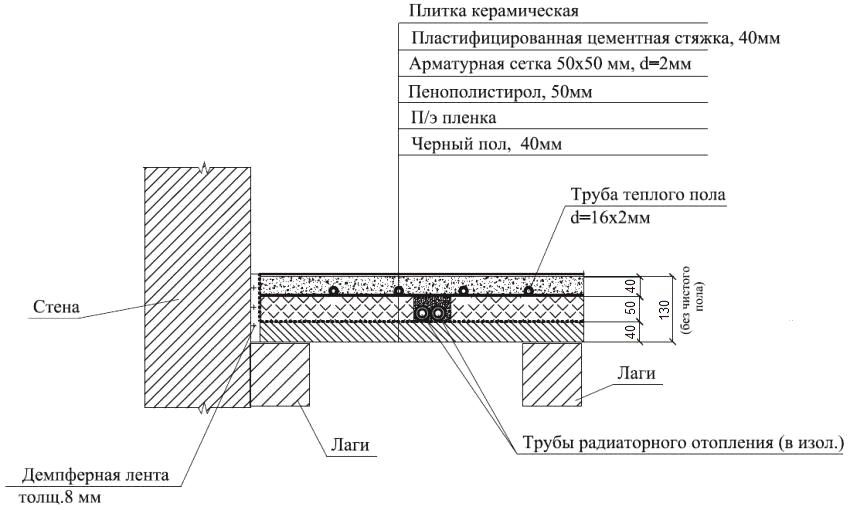

- The height of the cake warm floor into account when you make door and window openings, installing fasteners for heating appliances. The passage of pipes through the doorway is performed in a metal casing. Places pipe laying is fixed in a certain position, so as not to damage the eyeliner when installing the door unit.

The technology of installation of warm water floors is distinguished according to the principle of the device of the base of the heating circuit. The basis for warm water floors is chosen taking into account the bearing capacity of the interfloor overlap and the intended flooring. Watching video of wiring diagrams of warm water floors in a private house will help to get a clear idea of the sequence of operations and technology of work.

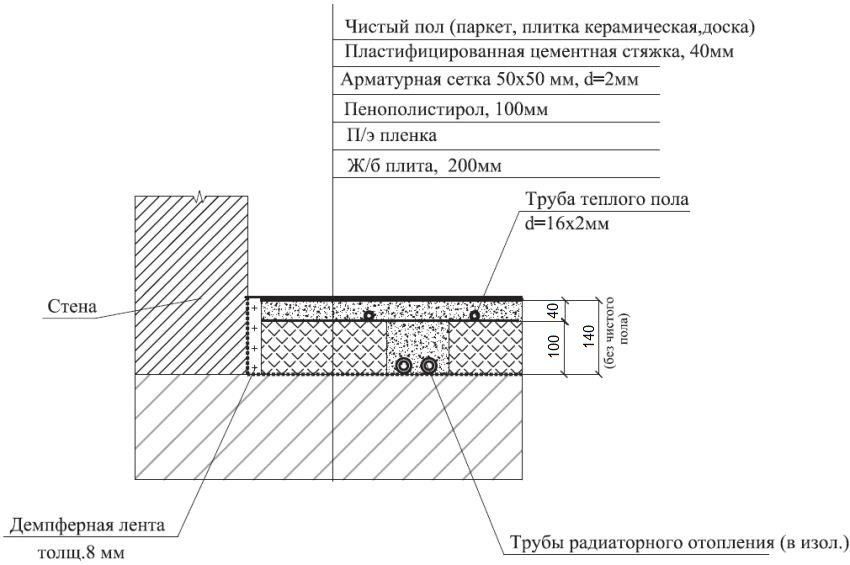

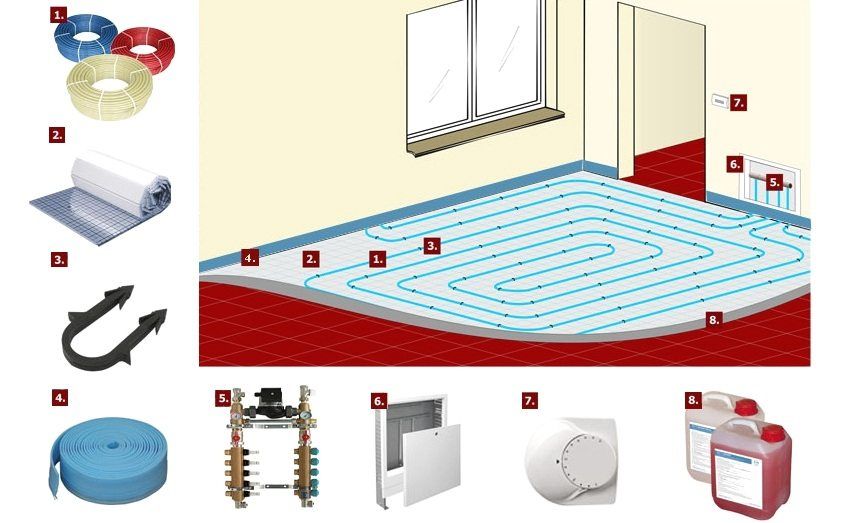

Experts call warm water floors floating. Damper tape width of 12? 18 cm mounted on the perimeter of the room and each circuit, if the room is divided into independent sectors. Edge film on the height of the screed plays the role of a temperature weld. A shock absorber ensures the safety of the flooring and heating circuit during temperature expansion, vibration and movement of building structures. The tape reduces heat loss at the joints of the heating plate with external walls.

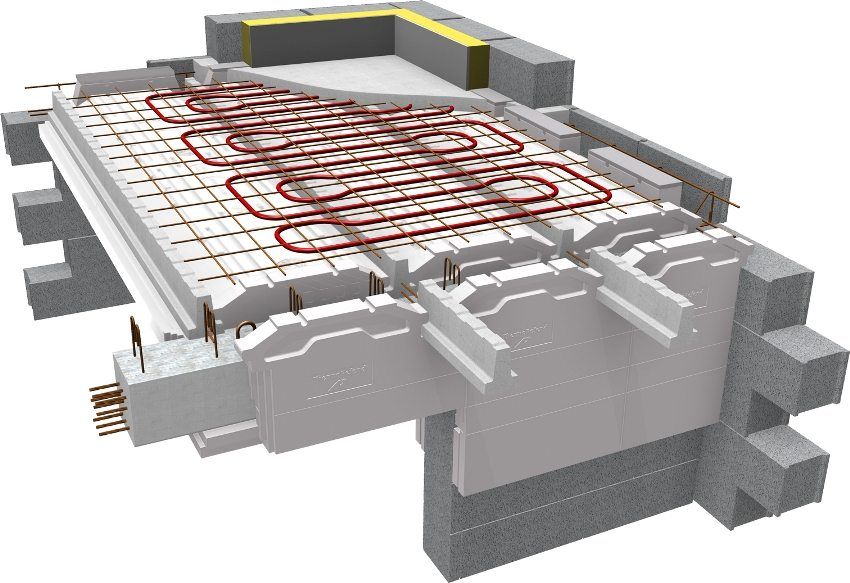

On concrete slabs arrange warm water floors in bulk cement screed. Concrete basement is lined with waterproofing, laying a layer of insulation and reinforcing mesh. The pipes to the cells of the frame are fixed with clamps, special clamps or steel wire. On top of the pipe contour, to evenly distribute the operating load of the floor covering, if necessary, also arrange a reinforced screed.

Lightweight base, which combines the functions of insulation and frame – folding or special profile mats of extruded polystyrene foam. In the first case, the pipe on the substrate surface is fixed with special clamps with harpoon tips or mounting rails. On the profile mats loop loop tightly fix the boss, no additional fasteners are required. An improved version of the profile mats is covered with a layer of waterproofing and equipped with a system of locking projections.

Important! Installation of a polystyrene system requires care. Precast under floor covering is performed immediately after pipe laying. The surface of the elements made of foamed plastic can withstand distributed loads, but it is easily squeezed under a heel or a fallen instrument.

Modular systems of wood or wood composite are laid on a subfloor. Wooden rack type systems form logs. Rotary and straight grooves flooring systems made of wood are designed for laying heat distribution plates made of galvanized steel or aluminum.

Pipes that are used for laying a warm water floor (cross-linked polyethylene, metal-plastic, copper, stainless flexible corrugated with internal polymer coating, less often polypropylene) are produced using a seamless technology. Contour lay out a solid pipe. Butt joint with standard fittings in the body of the screed is permissible only for contours of corrugated pipes. The surface of the pipes must be resistant to oxygen corrosion, a reserve of temperature and mechanical strength, and have a smooth internal surface.

Coils for warm floor pipes do not dissolve in advance – careless handling can lead to the formation of creases. Installation begins from the feed manifold combs. Gradually unwind the bay, perform the intended layout, and return the whole pipe to the distributor. The circuit is connected to the twin pipes of the collector combs.

After installation of all floor heating circuits, the system is checked for strength and tightness of the connections. After testing and successful trial start pour cement screed. The finish flooring is mounted after the complete drying of the screed.

A self-contained heat generator in a private house heats water up to 95 ° C. The optimum temperature difference between flow and return is 20 ° C. However, the maximum allowed coolant temperature in the system of underfloor heating is 55 ° C, heat removal is 5 ° C. In practice, the operating range of the coolant floor circuit does not exceed 40? 35 ° C.

The temperature is regulated by means of forced mixing of the flows: part of the coolant from the return flows into the supply pipeline. Mixing units are installed between the boiler and the distribution manifold.

There are models of gas units, which have a built-in contour of underfloor heating: automatic in the “warm floor” mode of operation limits the flow temperature at the outlet of the boiler to 45 ° C. The operation of a conventional gas boiler in underfloor heating mode reduces the efficiency of operation of the unit.

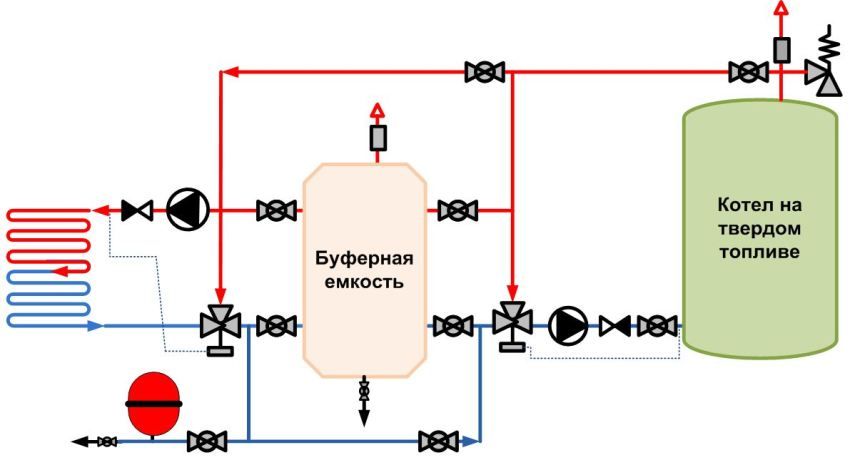

Solid fuel boilers long burning on the wood is distinguished by a complex adjustment of the combustion mode. The device of warm floors in heating systems with a heat generator on solid fuel, in addition to a circulation pump, requires the installation of a buffer tank. The heat carrier in the underfloor heating system is taken directly from the hydraulic accumulator.

Electric boilers – the most profitable and acceptable option for the efficient operation of underfloor heating. Automatic electrode, induction or aggregates with a tubular electric heater capable of maintaining the desired temperature of the coolant without loss of heat output of the boiler. Floor heating of small houses (up to 100m2) allows direct connection of circuits to an electric boiler. Warm floors of private houses of a large area are satisfied with the help of a coplanar distribution comb and a mixing unit.

Water floor heating with their own hands, video and description of the process. The nuances of installation. Description of the installation process of a water heated floor. Its advantages and disadvantages in contrast to other species.

The main or additional low-temperature contour of warm floors from central heating in apartment buildings is planned during project development. Independently make changes to the radiator scheme of heating an apartment building is prohibited by housing legislation. The temperature of the radiator circuit is higher than the required parameters for underfloor heating. Unauthorized change of direction, diameter and length of the whole house heating riser leads to imbalance of the system and violation of the thermal regime in a residential house.

Specialized organizations produce the installation of heated floors from central heating in apartments during the construction of the building. The principle of the device of heat-insulated floors from a central heating in the apartment is distinguished by the method of connecting low-temperature circuits. The coolant enters the pipes of water underfloor heating on a separate riser from radiator heating. Hot water for underfloor heating is prepared by a heat exchanger, which is installed in the central heating unit, the heating unit of an apartment building, or directly in the consumer’s apartment.

Theoretically, the last (in the course of the coolant in the riser) consumers can change the length of the pipes without damage to the thermal regime in the neighboring apartments. If heat is distributed from above, the warm floor on the first floor does not affect the heat exchange of the apartments located above. However, the operating pressure of the supply pipe at the lower constant distribution may not be enough to circulate in the floor contour of the upper floor.

In the absence of initial design data on the installation of underfloor heating in an apartment building, the connection of an additional circuit is agreed with the heat supplier and the management company. Resource supplying organizations issue a permit for the installation of warm semi-autonomous floors, with an adequate power reserve of the existing heating system.

Housing and maintenance companies impose a prerequisite for the design load of the foundations of warm floors, which should not exceed the permissible load on the floors in this particular case.

Traditionally, the agreement involves the installation of a heat exchanger on the radiator or hot water riser in the apartment. This requires the installation of a circulating pump, an expansion tank, a safety group, an air vent, a two-way valve, control valves, and a heat meter.

For several floor contours, a complete collector assembly is used, compatible with any floor laying scheme. A shutoff valve or thermostat should be installed at each inlet and outlet from the manifold comb. Shut-off valves provide an opportunity to turn off a separate circuit without disturbing the overall operation of underfloor heating.

Particular attention is paid to the choice of the base of warm floors in the houses of the old building. The transverse size of the cement screed depends on the degree of insulation of the floor slab. The thickness of the “cake” of warm floors above a cold basement reaches 0.15 m, which significantly hides the overall height of the room and increases the weight of the structure.

Helpful advice! A reasonable solution would be to opt for a lightweight base for underfloor heating using heat transfer plates made of stainless steel or aluminum.

The total cost of installing a warm water floor includes funds spent on the purchase of material, performing calculations, preparatory work, laying, connection and hydraulic testing of circuits for strength and tightness of connections.

Services hired professionals will cost 1500? 2500 rubles per 1 m? warm floor. The total amount depends on the number of circuits, the type of base, the cost of pipes, collector group and pump-mixing unit. Reducing the cost allows installation of warm water floors with your own hands.

Important! The quality of the material, equipment, valves and control valves must be consistent with the purpose of the system and the duration of its intended service. It is advantageous to purchase ready-made sets of warm floors, which are equipped with high-quality and compatible equipment and materials. Free calculation of warm water floors with a batch purchase is an additional bonus from major manufacturers.

Posted on the Internet video of the installation of a water heated floor with their own hands, with explanations from the authors, will help to better understand the essence of the issue. Detailed descriptions of ways of arranging and choosing materials for underfloor heating will help if there is an urgent need for underfloor heating, but there is no possibility for hiring specialists.