The UWB slab foundation is very popular now. It makes it possible to complete construction in a short time and ensure the durability of your building..

The content of the article

- What is UWB

- Areas of use

- Pros and cons of UWB

- Construction technology on the USP slab

- Conclusion

What is UWB

The insulated Swedish plate is the most modern base for the construction of private houses. This design includes a floor heating system that can completely replace heating. Pipes, cables and other communications also pass through it. In addition, it has a smooth surface, allowing you to lay the flooring without additional preparation. Such a base is ideal for frame buildings, as well as buildings made of logs, aerated concrete and others. At the same time, construction can be carried out on almost any soil..

This product can replace other types of foundations. In addition, it retains heat in the room, which significantly reduces heating costs. And it is also one of the factors in which, even with high humidity, your home will always be dry and comfortable. If you are interested in the question, the foundation of UWB, what it is, then in this article you will find out the answer to it. It is a multi-layer reinforced concrete slab that has the following layers:

-

gravel and crushed stone pillow;

-

waterproofing;

-

insulation;

-

metal carcass;

-

channels for laying communications.

Such products are made in various sizes, which must be selected depending on local conditions and the type of building. In order to withstand the load of the bearing elements, stiffeners are installed under them.

Areas of use

This technology is most popular in Estonia and other Baltic countries. It is ideal for regions with cold climates and even with a close location of groundwater. The fact confirming the effectiveness of the USHP-type foundation is its use on the Scandinavian Peninsula, where the climatic conditions are rather severe. Currently, this technology is actively used in Russia..

It provides a rigid structure that successfully resists the movement of the soil in different directions. There is a high-quality layer of insulation under it, which eliminates all the problems associated with freezing. Even in the most severe frosts, such a base does not lose its properties and does not deform. It is advisable to use the insulated plate in the following cases:

-

in cold regions to minimize heat loss;

-

at a high level of groundwater, where it will protect you from flooding;

-

for individual construction, if you plan to use a warm floor system;

-

on unstable and soils prone to heaving.

Pros and cons of UWB

Arrangement of this type of base can be done independently, however, there are many nuances that must be observed to ensure high quality. Among the advantages of the Swedish monolith are the following:

-

saving on special equipment, since its installation does not require digging a large pit;

-

a layer of thermal insulation applied from all sides not only retains heat in the room, but also increases the service life of the base;

-

no need to build additional channels for pipes and wiring.

-

any construction sites are suitable for installation, while groundwater does not have a negative impact on the future construction.

-

high level of tightness and thermal insulation;

-

not afraid of mold, mildew and parasites;

-

does not require additional processing during finishing work;

-

fast installation time;

-

built-in underfloor heating system maintains a comfortable indoor climate throughout any season.

Despite the use of the most advanced construction technologies, such a component, like any other, has its drawbacks. Most often, tenants and builders distinguish the following:

-

despite the ease of installation, the cost of erecting such a structure is quite high;

-

it is impossible to arrange basements and underground garages;

-

there is no exact information about the service life of the products, since they began to be used relatively recently;

-

there are restrictions on loads (UWB is suitable only for low-rise buildings)

However, this design holds great promise. Numerous advantages overlap all disadvantages.

Construction technology on the USP slab

Despite the fact that such a system can be made on your own, you still have to seek help from specialists. It is better to entrust the implementation of the necessary calculations and study of the soil to professionals in their field. This will save you from many problems during installation and further operation of the facility..

To get started, you should do the following to investigate the groundwater and determine the composition of the soil and the likelihood of its movement. Based on this data, the following calculations are performed:

-

pit dimensions and planning of other land activities;

-

drainage device;

-

dimensions of the pillow and concrete layer;

-

reinforcement system;

-

pipeline and underfloor heating project.

It is recommended to make drawings at each stage, they will greatly simplify the construction of a house on the USP foundation. Since UWB is a multi-layer architecture, calculations must be made for each individual component..

Excavation

Any construction activities begin with the preparation of the land. When installing the Swedish stove, at the first stage, you should dig a pit, having previously cleaned the area from the fertile layer. This is easy to do with a shovel. If you put it on vegetation, then in the process of decay, the cover will shrink. To ensure that no grass grows, you can treat the area with special compounds. It is important to dig it to the depth corresponding to the design documentation. As mentioned above, for these purposes no deep digging is required, it is enough to move 50 cm in depth, which can be easily done manually.

In this case, the width and length of the pit should be 1-2 meters larger than the base itself. This indentation will be used to equip the drainage system. You will also need to apply special markings with marked lines for the exit of utilities. You need to mark along the contour of the future foundation pit. This can be done with special equipment or with a stretched rope. When the pit is dug, you need to pour dry sand on its bottom, which will then need to be moistened and tamped.

Waterproofing

A cushion of crushed stone with a thickness of about 15 cm is equipped in a dug pit.Gravel must be selected with a fraction size of at least 20 cm and no more than 40 cm.After filling the stone, a layer of sand is laid on it up to the mark established in the project, which is then compacted using special equipment.

Then everything is covered with sealed roll materials that provide high-quality waterproofing. To prevent moisture from seeping from the bottom of the canvas, it is necessary to lay with a slight overlap on each other. Then all joints are closed with a gas burner. When laying this layer, it is required to provide protection from water and on the sides of the monolith..

Sewerage, drainage, blind area

The insulated Swedish plate as a foundation should never get wet. For these purposes, a trench is arranged around the entire perimeter for laying drainage pipes. They will remove water, which can later be used for household needs. When arranging this system, it is worth considering the possibility of cleaning it in case of blockages. Wells installed in several places will help for these purposes..

To drain rain and melt water from the walls of the structure, a blind area is made around the entire perimeter at an inclination of 4 degrees, which ensures the natural movement of liquid. Also at this stage, the installation of water pipes, sewerage and electrical networks is carried out. All communications must be laid below the level of freezing of the ground. In order to be able to repair damaged networks, they must be placed in large cases. Necessarily need additional wells to carry out repair work.

Before the filling stage, all wires and pipes must be taken outside for further connection. It should be remembered that components embedded in monolithic concrete will no longer be available. Therefore, it is recommended to create a redundant system. If the first breakdown occurs, you can easily switch to the spare.

Formwork

UWB production is impossible without high-quality formwork. It is usually done in two ways:

-

The most common method, used for many decades, is the use of planks or wood sheeting as a frame. They rest against the walls of the waterproofing layer from the outside. This prevents concrete from getting on the wood, which allows it to be used for other needs in the future..

-

a more modern and effective way is to use special heat-insulating materials. Such a structure can be operated without subsequent insulation..

Reinforcement

Installation of USHP is impossible without installing a reliable frame made of reinforcement. Plastic clips will help you position the metal bars at the desired distance from each other. The first line of reinforcing material should rise at least 5 cm from the surface. The distance between the elements is calculated during the design process. In general, the technology for creating a reinforcing frame should be performed in several stages:

-

the creation of stiffeners from thick reinforcement, it is important to pay special attention to the places where the supporting structures will be located;

-

reinforcement of a product in the form of a mesh.

The thickness of the rod depends on future loads and must be calculated by specialists. The fittings can easily damage communications and thermal insulation. Therefore, it is recommended to assemble the cage separately and then put it in the right place. It is recommended to fasten metal components with a special gun, which will ensure high structural strength.

Warm floor

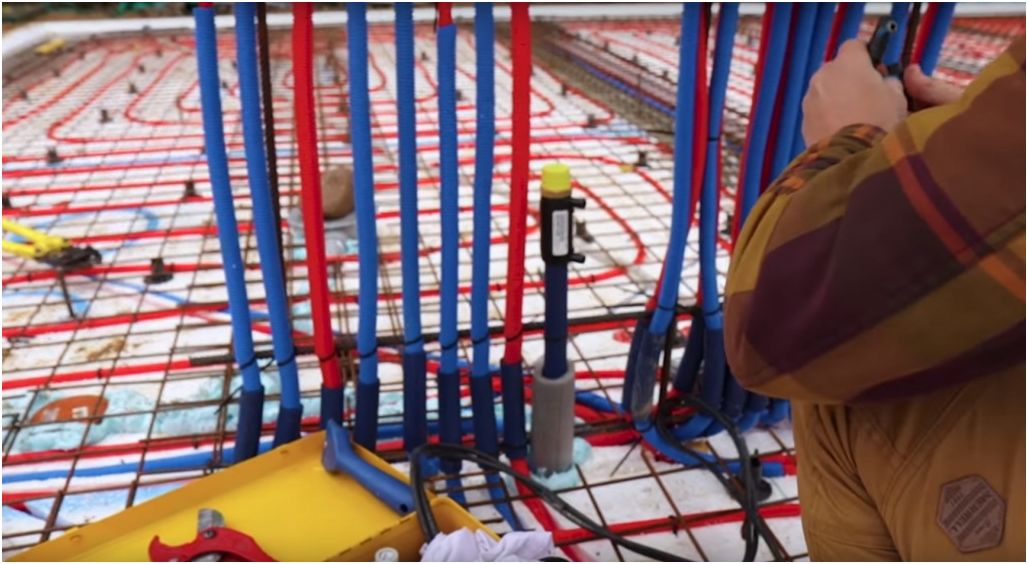

The main advantage of the Swedish stove is the possibility of laying the heating system. The pipes are installed between the parts of the armature belt, which fixes them. Sometimes special fasteners are used for these purposes, however, in most cases this is not necessary..

All components are installed at the height specified in the project. This is ensured for better circulation of the working fluid. A well-thought-out arrangement makes it possible to provide heating of the premises, taking into account the layout. After fixing the pipeline, pressure testing should be performed.

Pouring with concrete

The thickness of the concrete layer is calculated depending on the structure of the building under construction. Usually, at the location of the concrete walls, it is 2 times thicker. Thanks to such a difference in height, you will save on the purchase of concrete mortar. The technology of the Swedish insulated slab implies high-quality filling using a special concrete pump. To give solidity, all work should be carried out in one day. In this case, the maximum break between laying is allowed no more than 30 minutes..

During the filling of the composition and after completing all the procedures, vibration compaction is mandatory. It is performed superficially so as not to damage the frame and communications. In order not to perform the screed later, the surface of the structure is leveled during manufacture. Concrete is a fairly heavy material that can easily crush plastic pipes. In order to prevent this, during filling, they should be filled with air using a compressor..

To obtain a quality surface without cracks, the mortar must be properly dried. To do this, as soon as the mixture sets, it must be constantly moistened for three days. In hot weather, the foundation should be covered with polyethylene. After 3 days, it will be possible to remove the formwork, but at the same time the material is not yet strong enough and cannot be loaded onto it. The base will finally take its qualities in 4 weeks. If outside after pouring the temperature does not exceed 10 degrees, the wooden structure is removed after 5 days.

When everything is ready, you will need to sand the surface with a diamond wheel and you can start building the walls. If you do not perform high-quality grinding, then in the future you will need to perform a concrete screed. The most convenient period for the construction of such a foundation is the end of summer, when the groundwater level is minimal..

Conclusion

The USP slab foundation with the technology that we have familiarized with allows us to prepare the foundation in the shortest possible time. At the same time, you will spend a minimum of effort, and you will receive a high-strength structure that will perfectly cope with any load. In addition, you will save money when laying the flooring and during the heating season in the cold season..

It should be remembered that the durability of your home and comfortable living conditions in it depend on the quality of the construction of the base. In order not to regret later, you need to try to avoid mistakes during construction, the main of which are:

-

not using geological surveys and engineering calculations;

-

digging a pit on frozen ground in early spring;

-

not deep enough hole or preservation of the remnants of the fertile layer;

-

manufacturing by eye, without careful measurements;

-

improper arrangement of the drainage system;

-

refusal to check communications and crimp pipes;

-

skipping the surface grinding step.

Incorrectly performed work can lead to subsidence of the foundation and the appearance of cracks. As a result, not following the recommendations can lead to serious financial costs in the future and even the collapse of the building. However, with careful observance of all requirements, you can easily do everything yourself..

Such a basis is suitable for any private building and even for low-rise apartment buildings. The big advantage of such a system is the ability to make it yourself. However, if you are sorry to waste your time or you are not confident in your abilities, you can find specialists at conceptualhouseplans.com who will complete all the necessary turnkey work in the shortest possible time..

Video

Photos and videos for this article were provided by the YouTube channel of Andrey Chance.