The issue of registration of tracks on the site sooner or later rises before all owners of the sites. The option of using for this purpose paving slabs, one of the most simple, reliable and beautiful. Therefore, for self-production and installation will require instructions on how to make a vibrating table for paving slabs with your own hands. This article will consider all the nuances of the assembly of the device, as well as the recommendations of specialists in the manufacture of the frame and the choice of engine.

What is a vibrating table and what is it for?

The vibrotable, or as it is called, vibropress is a special device designed for the manufacture of paving slabs. The main advantage of this device is the ability of its working surface to make oscillatory movements. In addition, the vibrating table can be used for other purposes, for example, for the manufacture of monuments, sections of concrete fences, etc.

As for self-manufacturing of the vibrating table, this is most often resorted to when they want to independently engage in the manufacture of paving slabs for the decoration of their own yard. Although in some cases, this method is used to organize your own small business.

Of course, using a vibrating table, it is impossible to produce on an industrial scale, but given that it can be made from scrap materials, and with its main functions – eliminating air bubbles and sealing the composition of forms, such a device will cope perfectly.

As possible in more detail we consider what is needed in order to make a homemade vibrating table, as well as step-by-step instructions for its manufacture.

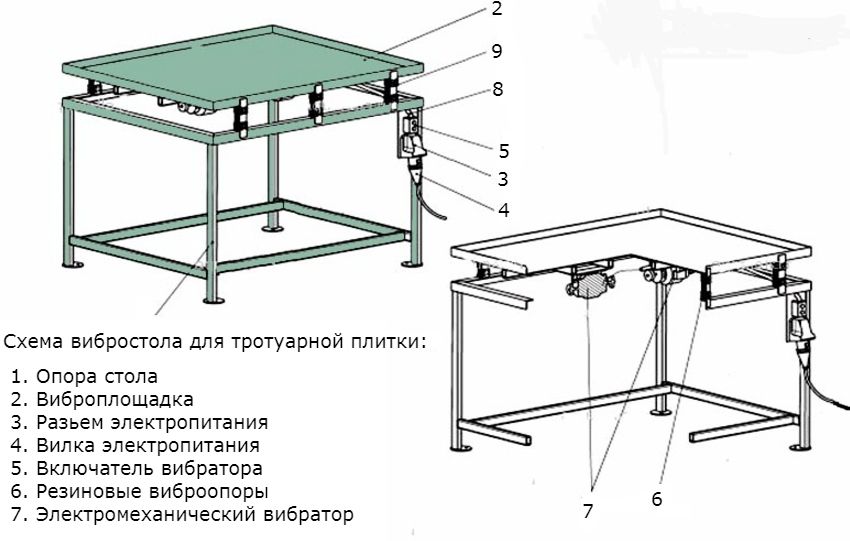

Vibrating tables are different, and before proceeding to manufacture, it is necessary to determine the appropriate option and its features. So, depending on the direction of vibration, these types of devices are distinguished:

- Models with horizontal vibration.

- Models with vertical vibration.

These types of devices are divided depending on how exactly the rotor is located in them. In this case, the first option (table with horizontal vibration) is more popular.

Depending on the installation method, the vibrating tables can also be divided into two types: stationary and portable (mobile). But depending on the specialization of the devices, they distinguish those that are intended for the formation of products, as well as those that are designed to extract the finished product from the mold using vibration.

Externally, the molding and shaping tables are virtually indistinguishable, with the exception of a special nozzle with holes, on which the mold is installed, from which the finished product is to be removed.

If you want to make your own machine for the production of paving slabs, it will be enough to make a vibrating table with horizontal vibration. At the same time, it is possible to extract the tile in two ways: manually (usually in the conditions of the home workshop, flexible forms are used) or by installing the shaping nozzle.

In order to understand how to properly make this or that device, you need to understand the technology of manufacturing those elements for which it is designed. Therefore, we consider the principle of operation of the vibrating table and what each of its component parts is designed for.

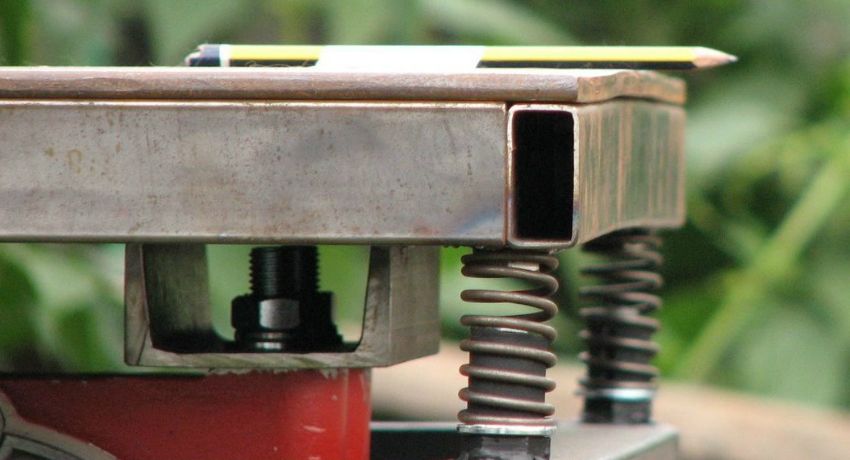

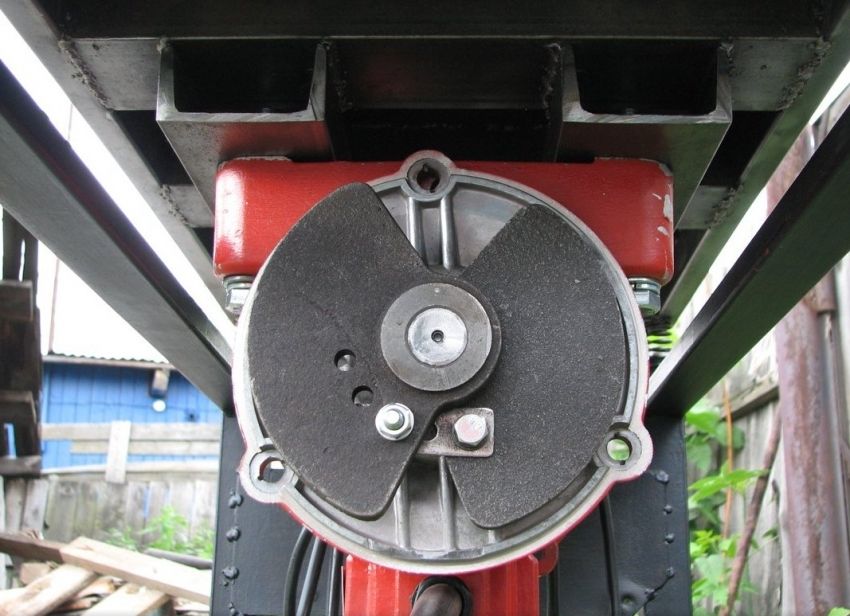

The working surface of the table is attached to the frame with the help of a special spring system, if we are talking about the device of horizontal vibration or with the help of suspensions, in the case of vertical devices. Due to the work of the motor rated power, on the shaft of which the eccentric, tabletop is set in motion. Due to the fact that the eccentric shifts, the center of gravity changes, resulting in the desired vibration.

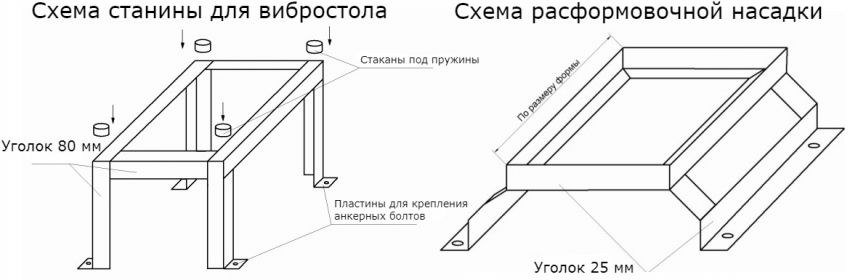

A general idea of the device vibrating table can be obtained by reading the sketch. But for self-production of such a design, a full-fledged drawing will be required, which will allow to take into account all the nuances and pre-define the required dimensions of each of the elements.

Before you start creating a drawing, you should consider the two most popular options: for beginners and for craftsmen. In the first case, the vibropress has a simpler design, but it allows you to perform the main task – to form products. Assembly, maintenance and care of such a device are carried out quite simply and quite by force even to a novice master.

Helpful advice! Over time, additional functions, such as a sand sifter, can be added to this simple design. The main thing is to correctly carry out all the necessary calculations so that the addition of new functions does not become a reason for the failure of the main elements.

More complex designs designed for masters, initially combine a vibropress and a sifter for sand. In the assembly, such a construction is more complicated, however, it is convenient in that it facilitates the process of obtaining the components of the desired fraction.

The first thing you should pay attention to before starting work is the size of the table top. It is believed that the minimum size of the surface should be 600×600, since with narrower sides, the forms will fall in the process of movement. In addition, a narrow design will have less stability.

Helpful advice! If in the process of making paving slabs at home, the forms still fall off, you can try to reduce their number. This will adversely affect the performance of the device, but in this case the number of tiles damaged due to the fall will decrease.

In many ways, the size of the vibrating table is determined by the required volume of production. It can be said that there is a direct relationship here – the more elements must be made at a time, the larger must be the area of the tabletop. Naturally, for a large vibropress will require a more powerful engine, and the materials from which the structure will be assembled, must be very durable.

As for the height of the vibrating table, then everything depends on the individual data of the person who is to work for him. The standard height, optimally suitable for a person of average height, is 90-100 cm.

Important! Determining the height of the table, it is necessary to take into account the method of installation, which will be used. For example, if a stationary device needs to be dug into the ground and cemented, then the length of the legs of the table must be taken into account in advance.

In order to independently assemble the structure, a grinder, a welding machine, a drill, and the ability to handle them are required. Consider the list of necessary materials, which can be found among the commissioned materials.

For tabletops, you can use plywood or a sheet of metal of suitable size. In this case, the sheet of plywood should be 14 mm thick. This will allow to transmit a greater amount of vibration due to the small thickness, but at the same time provide the necessary structural strength. In addition, in this way it is possible to significantly reduce the noise level during operation of the device. If a metal sheet is used, its thickness should be in the range of 5-10 mm.

The cost of a plywood sheet of the required thickness, made of birch veneer, will be about 650 rubles with a standard size of 1525X1525 mm. But the sheet of hot-rolled metal with a thickness of 5 mm will cost more, about 1000 rubles.

Helpful advice! If a metal sheet of lesser thickness is available, it can also be used by strengthening the structure with metal corners or pipes welded to the center of the sheet and around the perimeter.

Metal corners with a size of 50×50 mm. They will be required to create a tabletop edging and during operation the vibrating table will not allow the forms for the production of paving slabs to move from the surface as a result of vibration. Their cost will be about 140 rubles per 1 mp

Channel for mounting the motor (about 210 rubles / mp). It will need to be welded to the center of the back side of the tabletop, pre-drilling holes that will be used for the bolts holding the motor.

Metal tubes for the legs of the table. Usually for this purpose, elements of 2 mm thickness and size 40X40 are used. The price will be 107 rubles per 1 mp

Pipes for forming the upper and lower parts of the frame. Since the main load will fall on these elements, you should choose a fairly durable material – 40X20 and 2 mm thick for the upper part and at least 20X20 of the same thickness for the bottom. The cost will be 84 rubles / mp. and 53 rubles / mp. respectively.

Plates of metal that will be used as a sole for supporting legs. For this fit pieces of metal with a size of at least 50X50 and a thickness of 2 mm.

- put a round pulley on the shaft, in which a part of the circle is drilled or ground;

- experimentally choose a nut that is suitable in size and weight, and weld it onto a pulley;

- put the clutch on the shaft, pre-welded on its end face a bolt with two nuts, placed across. Due to the fact that the nuts can be moved along the thread, unbalance is performed.

As you can see, self-production of paving slabs for the dacha is quite a feasible task if you spend time and effort studying the issue and assembling the necessary device. Although it should be noted that using such a vibrating table it is possible to organize, for example, a small production of polymer-sand paving slabs.