From this article, you can find out what technical characteristics a wood milling machine used in home workshops has. The text describes the main types of this tool with regard to its functionality and other parameters. Using this information, you can choose high-quality equipment for the workshop, which will meet all the requirements and will be able to perform the necessary operations.

Wood milling machine: general tool information

Milling machines – a popular category of joinery equipment. They are used for milling relief parts and profiles, cutting and processing workpieces in order to give them the necessary configuration. With the help of these woodworking machines it is very convenient to make a selection of grooves and process the edging part of the products, cut spikes and even make small interior elements, for example, baseboards.

Using additional devices, it is possible to significantly extend the functionality of the milling machine to produce parts with a complex configuration. In most cases, such equipment is installed in private workshops, as well as in small industries. Desktop tool options are applied by craftsmen who work at home.

Note! Before you buy a CNC milling machine for wood, you need to check the availability of the certificate. This document guarantees the compliance of the instrument with all standards established by the state, as well as the safety of its use.

Most milling machines have the same structure. The standard construction of a woodworking tool consists of:

- milling table;

- caliper;

- beds;

- spindle for milling machine with CNC;

- cutting element.

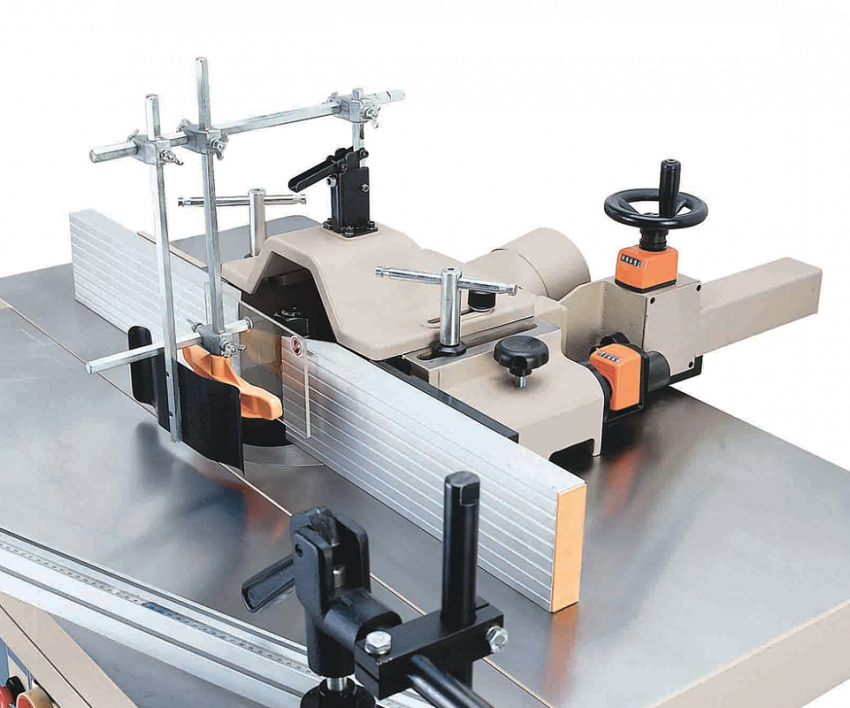

In the additional equipment of some models included a carriage. This element allows the processing of workpieces from different angles.

The bed of the milling machine on a tree represents a monolithic detail which differs in stability. It is not affected by vibrations and vibrations arising during the operation of the tool. The shaft is mounted on the caliper, the upper part of which is displayed through a hole in the table. If it is necessary, you can always adjust the height of this element, adjusting it to the requests of the wizard. A spindle with a plug-in construction and a cutting part are mounted on top of the part. The type of the cutting element is selected based on the task.

As a cutting part can be used:

- cutters;

- discs;

- knives;

- drilling-cutting elements for milling on wood.

The greater the rotational speed of the spindle, the higher the quality of material processing. This nuance should be taken into account when performing operations that need precision. The tool has a special structure, providing the ability to safely and quickly change the cutting element.

If the milling needs to be performed in a straight line, one cannot do without the use of a guide bar with a movable structure. For fixing of an emphasis of the tool special grooves are provided. Many modern models of devices, regardless of whether there is a carriage in the configuration, are complemented by an industrial vacuum cleaner. It effectively and quickly removes chips and dust from the work area.

The structure of the milling machine varies depending on the type of construction and model. Therefore, the master has the opportunity to choose a tool that will meet his needs.

The most popular types of designs:

- turning and milling machine for wood;

- CNC router;

- manual unit;

- copying;

- desktop;

- household milling cutter;

- vertical;

- horizontal;

- double sided etc.

Each of these devices performs certain functions and has its own characteristics. Therefore, before you buy a manual milling machine for wood or a unit of another type, it is advisable to get acquainted with its capabilities in more detail.

Note! Before starting work, you need to make sure that the wooden blank is securely fastened. Otherwise, the cutter with force will throw it to the side.

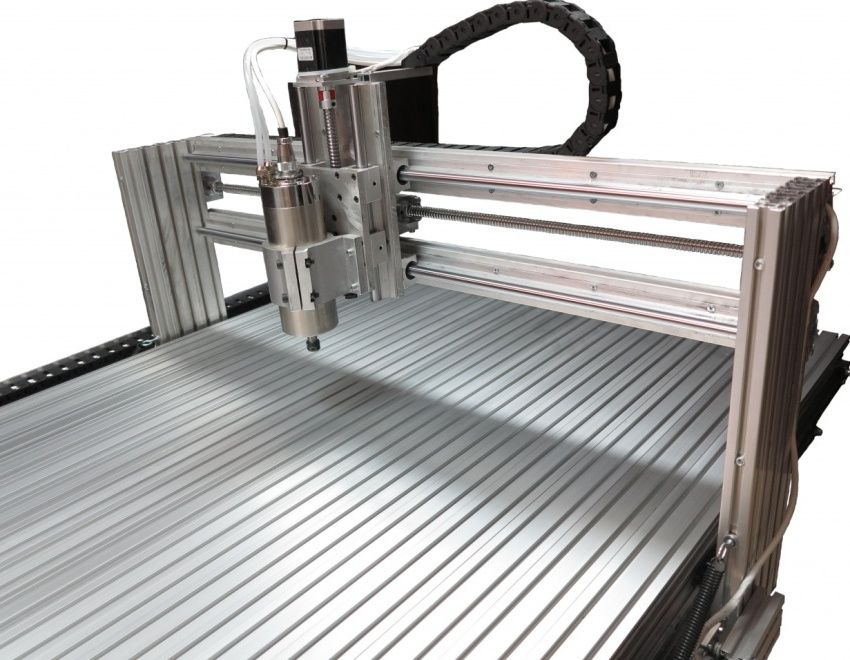

CNC devices are considered relatively new equipment. Such universal milling machines are additionally equipped with electronics. In the design there is a microprocessor, which greatly simplifies the processing of wooden parts and improves its quality.

Work on the CNC machine is carried out in the following order:

- With the help of specialized software program is compiled.

- Wooden blank is mounted on the desktop.

- A program is entered and a test run is performed.

- In the prescribed mode, the processing of wooden blanks.

- If the need arises, the program is adjusted.

The described process requires minimal participation from the operator. This is the main advantage of CNC milling mini-machines used in home workshops. Large units are used in production. They perform complex technological tasks. Milling cutters of this type are console and beskosolnymi.

In console machines, the block with the cutting element is fixed and does not change its position during processing. In this case, the desktop moves, which moves in the transverse and longitudinal direction. This type of mill is mainly used for machining metal parts, since the size of the blanks is limited.

In beskonsolnyh models the cutter offset is provided by a carriage with transverse and longitudinal guides. In this case, the processing unit can be given both vertical and horizontal position, depending on the tasks.

Note! To buy a CNC milling machine that has the optimal parameters for operation, it is necessary to study the technical characteristics of the model. In some cases, the subsequent modernization of the tool without loss of performance will not work.

The most common are beskonsolnye units. Most often they are used for processing flat pieces of wood.

Choosing equipment for the workshop in the first place you need to pay attention to the following characteristics:

- permissible size of the workpiece (height, length, width of the workpiece);

- tool speed in idle mode;

- number of spindle revolutions;

- spindle cooling performance (if this feature is available);

- type of CNC (the presence or absence of the ability to replace or upgrade the block).

In addition, before buying a tool, it is necessary to pre-define the set of functions required for operation. For this, the parameters of the control unit are analyzed.

Depending on the functionality, the following types of equipment are distinguished:

- Machines with positional control – the cutter is installed on the surface of the part in a specific position.

- Contour-controlled milling machines — the program’s algorithm includes the order in which the tool’s working head performs movement within the specified trajectory.

- Universal milling machines – the program includes positional and contour functions, and also can additionally monitor the position of the cutter and the parameters of the operation that is being performed at the moment (degree of processing, depth, etc.).

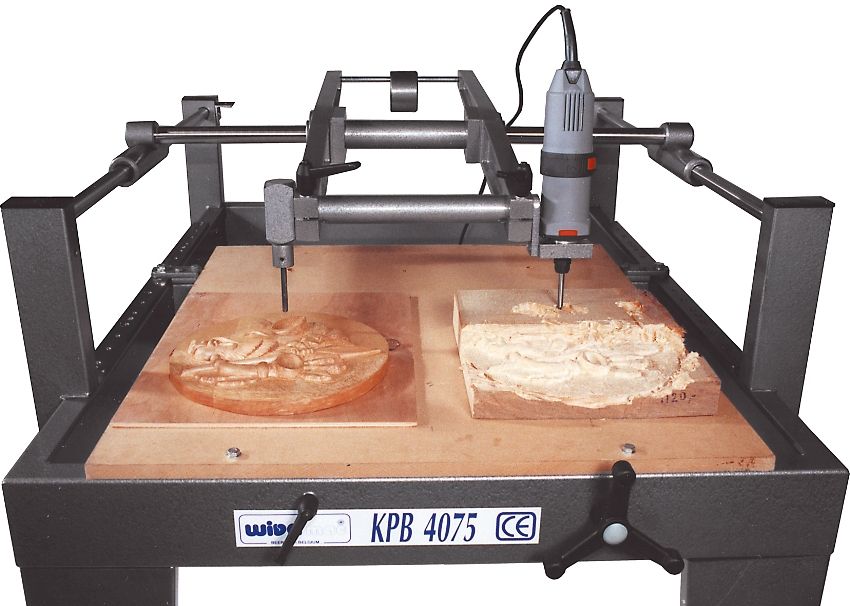

Copy equipment is designed to perform work of a high level of complexity. These woodworking machines are used for processing workpieces with a large number of carved patterns and small parts that need accurate and accurate execution.

The identity of the decorative mini-elements is ensured through the use of special templates. They can be made of wood or plastic. The wizard records the workpiece with a vacuum method, after which the tool copies the contour lines of the template. The result is identical parts with complex patterns. With the router it is possible to make volume and contour copying. These machines are compact, characterized by high strength and long service life.

Milling and copying equipment is ideal for the following operations:

- creation of ornaments and patterns;

- inscription;

- engraving of shaped profiles;

- production of complex drawings with faces located in different planes.

On sale you can find hundreds of models in different price segments. Do not pay attention to cheap milling machines from unknown manufacturers. Such proven companies as Makita, Bosch, Interskol produce reliable equipment that will last more than one year. In the event of a breakdown, spare parts for repair are always available at service centers and stores, because well-known manufacturers care for their reputation and provide warranty service for the tool.