Processing of wood blanks is performed on special turning equipment. Using this type of apparatus allows you to perform various operations with high accuracy. If necessary, you can make a lathe on the tree with your own hands. This will save finances. For the manufacture of this device, you must familiarize yourself with its design features and use the advice of experts.

The device of the lathe on a tree

This unit includes several major nodes. Each of them performs a specific function. For the manufacture of homemade device will need to learn more about the structure of these elements.

The bed. The basis of any machine, including woodworking. This node ensures the stability of the structure on the working surface, and also contributes to the fixation of individual elements of the machine. Thanks to the bed all the components are located in the right places.

It is important to remember that stationary devices have a more overall frame, equipped with legs. In turn, desktop units have a more compact basis, which makes them mobile. In the manufacture of the machine on the tree with your own hands, you need to pay special attention to this node, since the accuracy and efficiency of the construction as a whole depends on it.

Headstock This node performs a very important function: it ensures the rotation of the wooden block during its processing. The workpiece is fixed in the chuck located in the spindle shaft. It is worth noting that some small-sized machines include the headstock, which can move along the guides of the base (bed). Its movement allows you to adjust the location of individual parts relative to each other.

When the part is machined, the headstock of the lathe is securely fastened. Models that are stationary often combine this element with the frame, which makes it completely immobile.

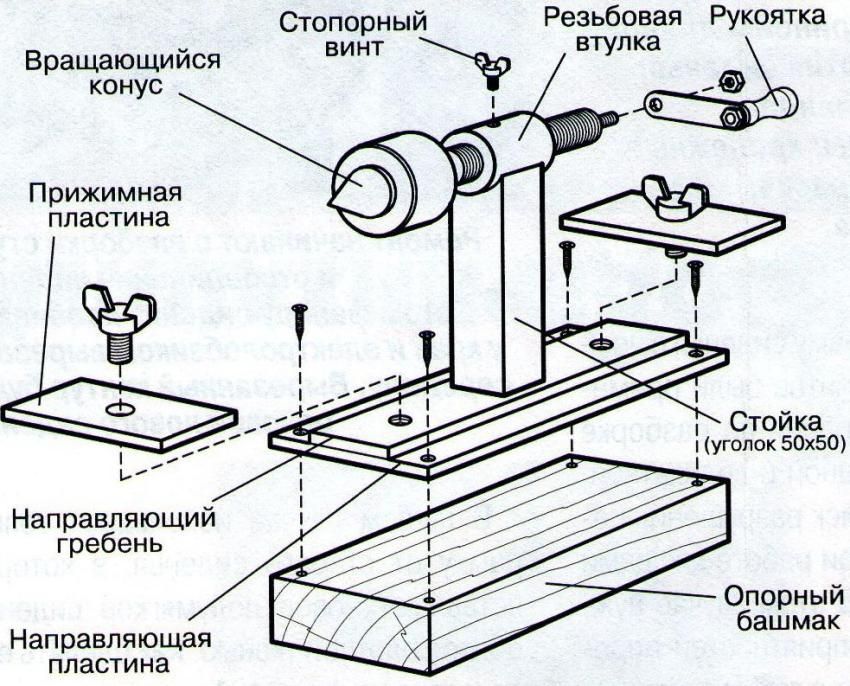

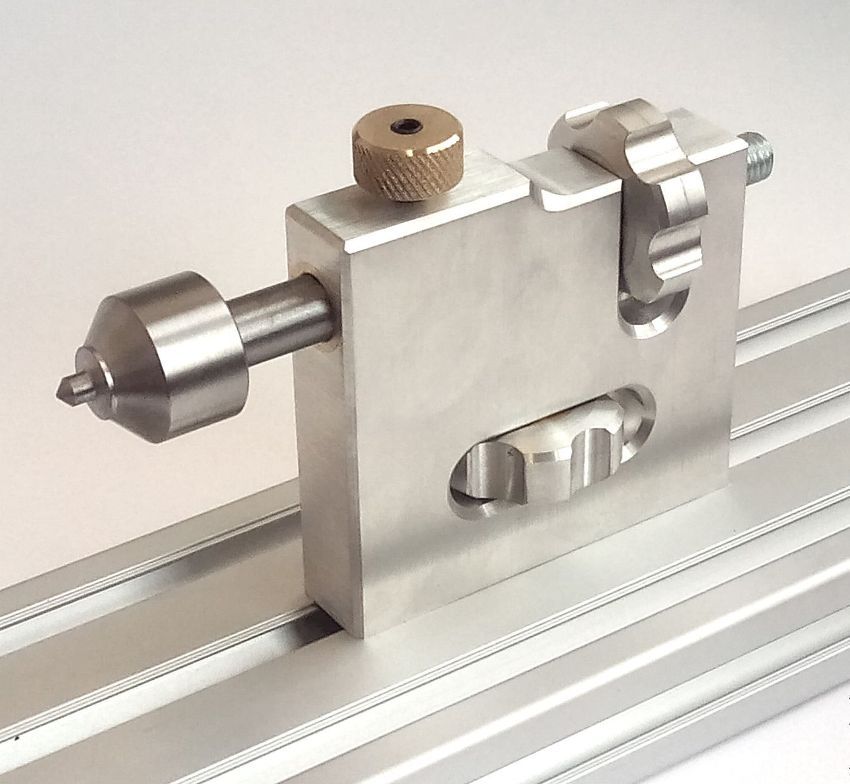

Tailstock This node, which is part of the woodworking structure, is not static. It performs a very important function: it fixes the blank in the desired position during its processing. Fastening the workpiece through the rear assembly takes into account its clamping to the chuck. Due to the fact that the tailstock is able to move freely along the bed guide elements, fixation and processing of parts of different lengths is ensured.

Note! The tailstock must be aligned with the spindle shaft.

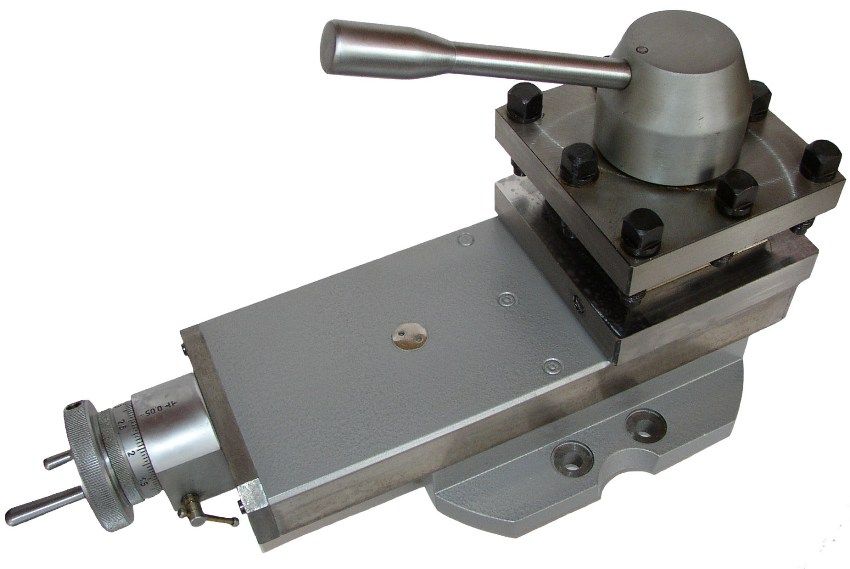

Caliper A very important element of the design, due to which the movement of the cutter is realized. Moreover, the latter may have a different location with respect to the spindle. In most self-made devices of this type, this function is performed by a handpiece securely mounted in the working position.

This part of the machine is able to move along the guides of the base (bed). Compact desktop devices, as a rule, imply the use of such an element as a stop for incisors.

Thus, both serial and homemade machine is a rather complex structure. Any unit for processing wood includes several interconnected nodes. Before you make a lathe on the tree with your own hands, you must clearly understand the purpose of its components.

In serial devices, the bed in most cases is made of cast iron. This material is distinguished by its mass. For a homemade unit should choose a less difficult option. For example, you can choose angles from rolled angular steel as the basis for a future design. The recommended length of the segments is 125 cm.

The length of the bed can be increased, but this action will require intervention in other parts of the woodworking unit. Before its manufacture is recommended to make a plan on paper. And also you can take a ready-made drawing on the profile site, which will help in assembling a lathe on a tree with your own hands.

Let us consider in stages the algorithm of actions for the manufacture of this unit. The first step is to place the corresponding corners on a horizontal surface (open side to each other). Then between them it is recommended to place calibrated inserts that will allow you to maintain the desired distance of 4.5 cm.

Next, you need to connect the guides. For these purposes, most often use the same corners, differing only in size (19 cm). The points at which welding will be performed are recommended to be marked in advance. Jumpers are located near the edges of the long corners. At the next stage, the welding itself is performed.

Useful information! The bed of any homemade machine for wood – the basis of the design, so its installation is very important. Any violation in the future will affect the efficiency and accuracy of the unit, made with your own hands.

Then you need to mount another jumper of the same size. It should have cutouts for long corners. After installation of this part must form a cell under the spike of the headstock. The dimensions of this geometric element require precise compliance. For the installation of a standard thorn of the headstock, 4.5×16.5 cm is enough

Traditionally, this detail includes two components. They are made of steel corners. Standard dimensions of welding blanks – 5 and 3 cm. The joining of these elements is done by welding (in length). The result is two segments, which must have a length of 26 and 60 cm.

The short element is used as a customizable base of the handpiece. Moreover, one of the corner shelves must be cut at an angle so that 11 cm of the intact profile remain. Before performing the same manipulation on the other wing, it is necessary to retreat 6 cm from the edge. In the second case, the angle itself remains straight.

Next you need to perform the response frame of a homemade woodworking machine. For the manufacture of this element suitable steel plate. The next step is to complete the guide element and its clamp. As a material for these purposes, you can use the usual inch pipe. It is necessary to make a longitudinal slot through the grinder. Masters advise not to make this item longer than 15 cm.

Then the guide sleeve is installed in a 2.5 cm corner. The section made by the grinder should be perpendicular to one of the shelves. Next, the structure must be fixed in the clip and connected with the help of welding equipment. After that, the tube is covered with the second corner and in the same way connects with it.

The finished guide part is joined by welding with a protruding corner shelf. For the final fastening it is necessary to weld a nut to the rail, and equip the second part with a screw. Also, do not forget that on the reverse side you need to perform additional fixation of the structure. To do this, a metal rod can be welded to its individual parts. It will give the structure strength and rigidity.

A podruchnik is fixed on the segment of reinforcement (smooth), which should have a diameter of 2 cm. Such a rod is fixed on the reverse side of the angle approximately at its center. At the end it is necessary to connect the fittings with a long part (60 cm).

The drive must have sufficient power to process wood products. When buying this device, it is advisable to pay attention to the standard model. Their power ranges from 1200 to 2000 watts. This is quite enough to handle all sorts of parts at home. The most commonly used drive with a capacity of 1200 watts.

Asynchronous motors are often used in home-made lathes for wood. The hands to make this device will not work. Another characteristic that is common among drives installed on their own machines, is three-phase.

Note! When assembling such equipment at home, it is quite difficult to acquire an engine that would have the necessary rotational speed. However, if desired, this indicator can be adjusted by changing the diameter of the pulleys.

When installing the drive, it is recommended to equip the frame with a special plate. It is fixed on the canopies and provides a tighter strap pressure. Some craftsmen install a pedal on the pad, which allows you to change the number of revolutions per second during the processing of wooden blanks.

For the manufacture of these sites, you must have access to the metalworking machine. In case this possibility is absent, it is recommended to buy ready-made structural elements. The headstock of the woodworking unit includes two housings that are classified as bearing.

When performing self-assembly of the machine, it is important to remember that the height of the spindle axis above the base should not be less than 12 cm. This indicator has an impact on the size of the front node. The most suitable in this situation is the bearing block, having a height of 7 cm. The shaft itself can be performed on a metalworking device. Its diameter should not be less than 4 cm.

In turn, the process of making a tailstock lathe on a tree with his own hands is less complicated. The structure of this module includes 4 elements, including:

- base;

- guide (outer);

- inner tube;

- drive screw.

The base is recommended to be made of a steel angle, the height of which should not exceed 10 cm. To create a guide, you can use a tube measuring 4×15 cm. In its back part you must install a special plug with a hole (0.8 cm). In this case, the inner tube will have dimensions of 2 cm. Next, you need to make the drive screw. A thread is applied to it under the nut in the inner tube.

It is also worth noting that the front and back headstock should be located on the same line. Otherwise, further designing of the woodworking machine will not bring any result. Grandmas are fixed to the bed in the same way as the podruchnik.

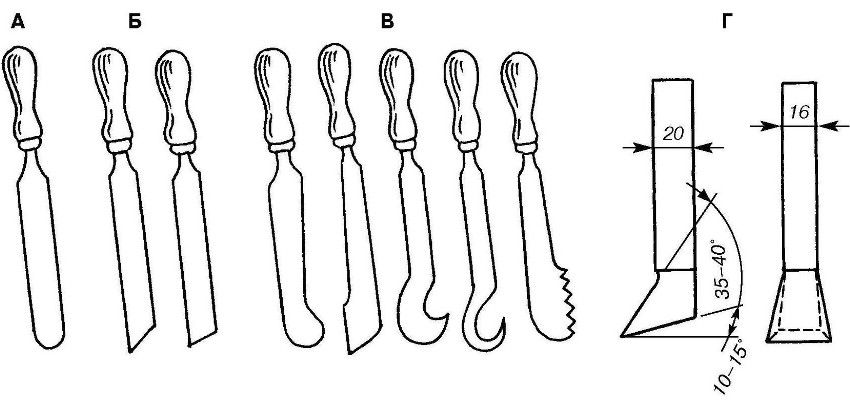

If necessary, these functional elements can be purchased in the profile shop or ordered online. However, many craftsmen prefer to make these devices independently. The most popular cutting elements today are Reyer and Meissel. They are quite simple to perform on the grinding machine.

In order to make these cutting elements, a blank will be required. As it can be used old tools (for example, a file). The metalworking unit allows you to quickly grind this disc. Molding is performed at two points: where the blade and tail will be located.

The answer to the question of how to make a lathe on a tree at home, will save you finances. Self-assembly of this unit requires preliminary calculations, charting, and care. Compliance with the instructions – the main rule that must be followed when designing such a device. A homemade unit can be a useful addition to any home workshop.