Coordinated and very fast seem actions of machines on a large construction site. Yesterday, a huge ladle bit into the ground, and today there is already the first level of the future building. This is a large-scale construction sites. But even if you need to put a country house, the principles are the same: first, preparation of the soil, its tamping is necessary. Buying expensive mechanisms for non-durable use is inappropriate. Do-it-yourself vibrating plate is a real and affordable solution.

Scope of application and technical characteristics of vibrating plates

The vibrating plate is a unit, the main function of which is tamping. It is used in various fields: for soil compaction during construction, landscape planning, for tamping bulk materials (sand, pebbles, gravel), for laying asphalt, paving slabs, paving stones.

The machine has a small size, so maneuverable. It can be used both in open areas (when tamping a land plot, parking, pavement, floor in large industrial premises, etc.) and in confined spaces (in ditches, trenches, near buildings, near curbs, wells, hatches etc.).

The vibrating plate for consolidation of soil and other bulk materials is recommended for use on the areas which are not exceeding 1000 m? On large-sized sites, large-size and more powerful equipment is used for these purposes.

Each model of the vibrating plate has its own performance indicators, which determine the features of its use and scope. So, when choosing a plate, you should pay attention to the following specifications:

- base plate dimensions, mm;

- vibration frequency, Hz;

- the depth of the seal, mm;

- amplitude of vibration, mm;

- power, kWt;

- unit weight, kg;

- consumption of electricity or fuel, kW / h or l / h;

- maximum productivity, sq.m / h;

- overall dimensions of the device, mm.

Vibrating plates are divided by several indicators. The first one is the type of engine. Depending on which engine is installed on the unit, the plates are:

- petrol;

- diesel;

- electric.

The vibrating plate electric 220 V is the cheapest and available option. According to technical criteria, it is slightly inferior to the two other types, as it has a small weight and a low degree of tamping. Most of all, this model is suitable for use on a private plot, in agriculture, in landscape works. The disadvantage of it is the mandatory availability of a power source and limiting the range of the cord length.

In the absence of a source of electricity or the inability to connect to the mains, it is worth buying a gasoline vibrating plate. It is more expensive than electric, but has no restrictions on operating conditions. It is easy to transport and move. Diesel fuel is cheaper than gasoline, but the engine itself is more expensive. Diesel units are the most powerful, they are often used on construction sites. The disadvantage of a diesel plate is a significant level of noise during operation and high cost.

Helpful advice! Engine power directly affects the movement of the plate. At high rates, the unit moves by itself. If the power is low, then the stove can burrow. This disadvantage is exacerbated if the layer of fine-grained material is rammed.

Vibrating plates are also divided by purpose: for tamping asphalt and soil compaction. The former are distinguished by the presence in their design of a device for the supply of water irrigation. It is necessary for wetting, wet surface eliminates sticking to the base. The surface of such a vibration plate is smooth, the edges are rounded.

The unit for soil tamping is heavier, the surface texture of the plate is embossed.

There are cars with progressive movement and reverse. Progressive move in one direction and have one debalance. The second type of vibrating plates reciprocating direction of movement. They have two unbalance, so they can move in different directions. Vibrating plates are controlled manually or remotely. The last option is convenient and safe, but the price is much higher.

Along with power, an important technical indicator is mass. It is on her need to pay attention when choosing a device model or when creating a tamper with your own hands. According to this parameter, vibrating plates are divided into four types:

| Type of plate | Weight | Features and scope |

| Lungs | Up to 100 kg | Low compaction, used in agriculture, landscape planning |

| Universal | 100-200 kg | High-frequency, low-amplitude, used for thin soil layers of fine-grained fractions and asphalt pavements. |

| Moderate | 200-500 kg | Used for thick layers of coarse-grained soil |

| Heavy | More than 500 kg | Have a high amplitude of vibrations, are used when a high degree of tamping is needed |

Helpful advice! When choosing a plate, you should consider that a heavy device is less maneuverable, but more efficient. If the mass does not match the thickness of the soil and is less than the recommended one, it will take a lot of time to compact and additional amount of fuel or electricity will be consumed.

To buy a vibrating plate, the price is recommended to choose by reviewing the characteristics of the units and the prices of any trading organization. But the right to use and even more so to make a car with your own hands is possible only if you know her device.

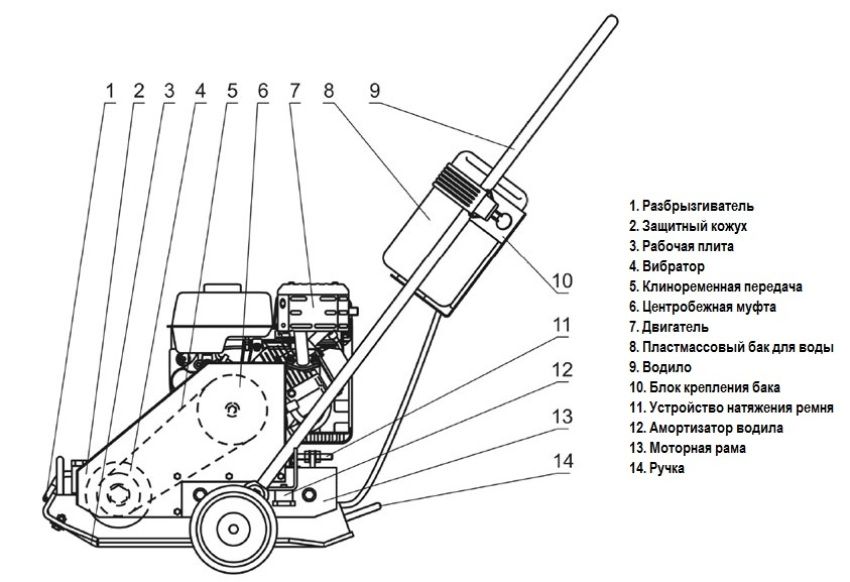

The design of the vibrating plate consists of the following main components:

- engine;

- vibrator;

- plates;

- centrifugal clutch;

- motor frame;

- control knobs;

- protective covers.

A vibrator is installed on the heavy platform, the basis of which is the unbalance shaft, placed in the bearings and the cylindrical body. The design is fixed with clamps, bolted to the plate. An important detail in the device of the vibrating plate, which also joins the platform, is the motor frame. It is attached with shock absorbers.

Above the vibration exciter is the engine. The motor and the vibrator connect the clutch and the V-belt drive. In the process, the engine creates a rotational motion, which is transmitted to the vibrator, which converts them into oscillatory. These movements are communicated to the slab, and then to the surface layer, which is compacted.

If the function of a vibrating plate includes tamping paving slabs or pavers, the model should be equipped with a softening nozzle made of plastic or a special support surface made of polyurethane.

Working mechanisms have a shock effect on the surface of the plate, which produces a certain number of movements in contact with the ground – this is the basis of the principle of operation of this device. Kinetic energy is converted to other forms of energy upon impact. The pressure on the surface instantly increases, and then the same instantaneous decline occurs. Consequently, in addition to the impact force, speed and frequency are effective. As a result of this action, small particles fill the voids, as a result of which a very dense even coating is obtained.

For the manufacture of plates used two types of material: cast iron and steel.

Helpful advice! When choosing a unit with a cast-iron plate, be sure to pay attention to the metal grade. Low-quality cast iron stove may crack during prolonged use on gravel.

The size of the plate is also important during operation: the smaller its area, the better its tamping qualities. Vibration indicators determine how well the surface will be compacted. If the plates have the same mass, but different vibration forces, then a unit with higher rates will be better tamped.

For non-scale works it is recommended to buy an electric vibrating plate. It is lightweight, has a folding handle that allows you to move and transport it to the desired object. The unit has an adjustable frequency converter that allows you to change the frequency of vibration, limit the starting currents, save electricity, set the optimum mode of operation for these conditions. It is possible to buy an electric vibrating plate, the price of which is several times less than the species with fuel engines, from any manufacturer, where similar products are presented.

The most demanded and, therefore, are widely represented vibrating plates with gasoline engines. The most popular are the units of the Swiss company Ammann, whose plants have been operating throughout Europe for a long time and have already gone beyond its limits. The range of units includes almost all types (from ultralight to the heaviest) diesel rammers.

The appearance of vibrating plates has accelerated the process of compacting surfaces hundreds of times. A variety of modifications allows you to choose the necessary mechanism for high-quality and comfortable work. The ability to manufacture self-made vibrating plates made available the use of the unit by people with different material capabilities.