Blacksmithing is a difficult physical work that requires special equipment in conjunction with the relevant knowledge and experience of the master. However, for the manufacture of some artistic elements, you just need to bend the workpiece at the right angle. The deformation of the metal can be performed without mechanical heating; for this, cold forging machines are used. What features have such units – it will be discussed in this article.

Cold forging machines: advantages of their use

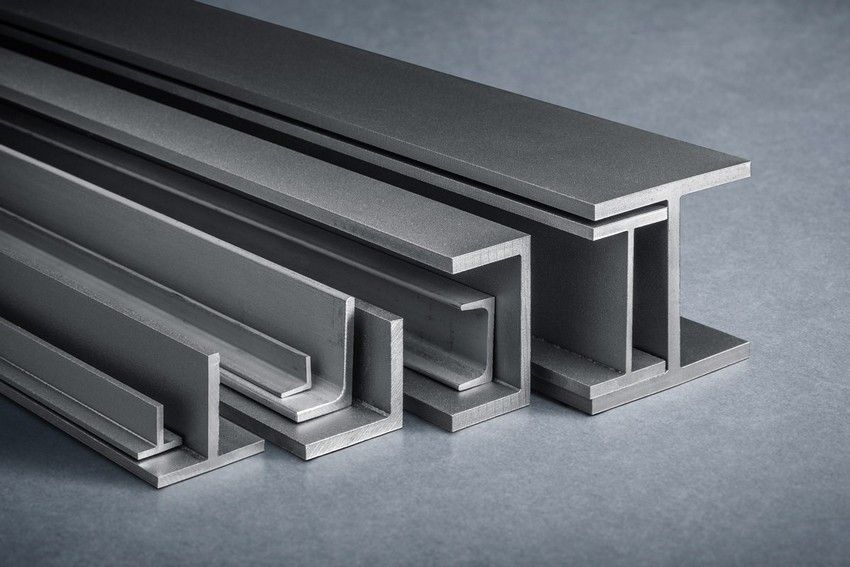

The method of cold forging uses a metal property such as ductility, that is, during mechanical actions, the initial shape of the workpiece can be changed within specified limits. Therefore, soft metals are suitable for this process, for example: low carbon steel, copper, aluminum, etc. For use as blanks can be used:

- rods of any section: round or square;

- metal strips of various cuts;

- pipes;

- rolling profile.

Products that are produced by a blacksmith during hot forging metal are unique and unique in their own way. If you need to create a set of identical elements that are then assembled into a ready-made structure, then uniqueness will only interfere. It is for this purpose that the method of cold forging is used: it guarantees the formation of a large number of identical elements.

Professionals who have experience in the application of this technology and are able to masterly handle a complex instrument work with hot metal. With cold forging, the highest skill will not be needed – everything is much simpler. Manual forging machines allow you to obtain a sufficient number of products without significant physical effort to carry out a particular project.

In addition, the time spent on the preparation of elements is significantly reduced when working on special machines, not to mention comparing this method with hot forging technology: a few minutes to produce one element is an indisputable advantage.

A machine of any purpose is used to facilitate manual labor. For cold-type forging, different equipment can be used, minimizing the master’s physical efforts and allowing the following basic operations to be performed:

- profile bending at the desired angle or radius;

- making spirals or curls;

- longitudinal twisting blanks.

The variety of the parts obtained allows them to be built in combinations and intricate designs, to create a neat artistic canvas for fences and arbors, a symmetrical decor for park benches, as well as other objects for various purposes.

Note! Decor-machines help to create elements of the same shape and size in a short period of time, reduce the cost of each of them and reduce the duration of the manufacturing process.

Cold forging machines can be specialized (to perform only one operation) and universal. There are such types of special machines:

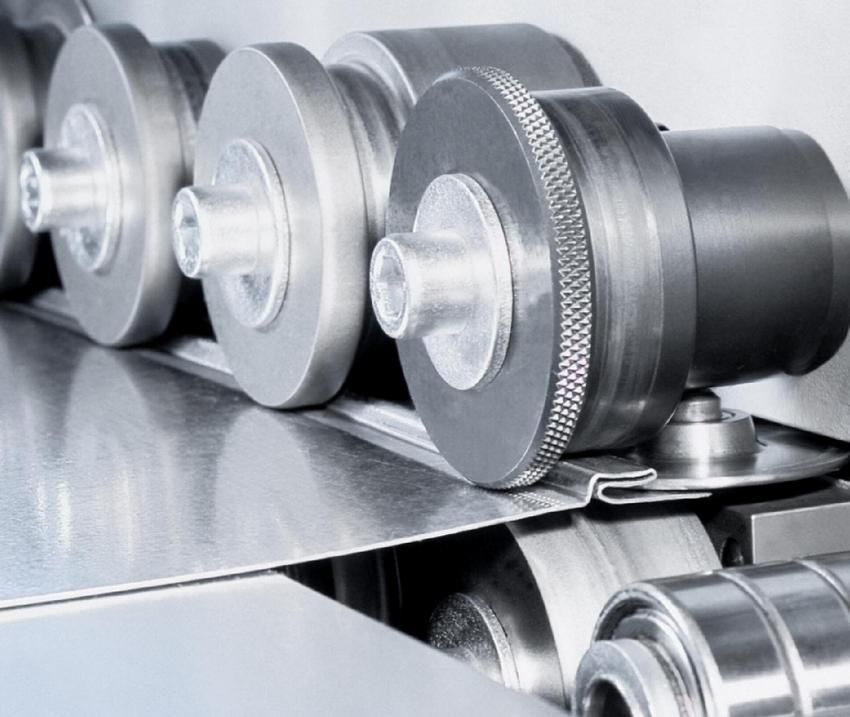

- knuckles (bending machines) – allow you to bend the workpiece at an angle or a given radius (wave);

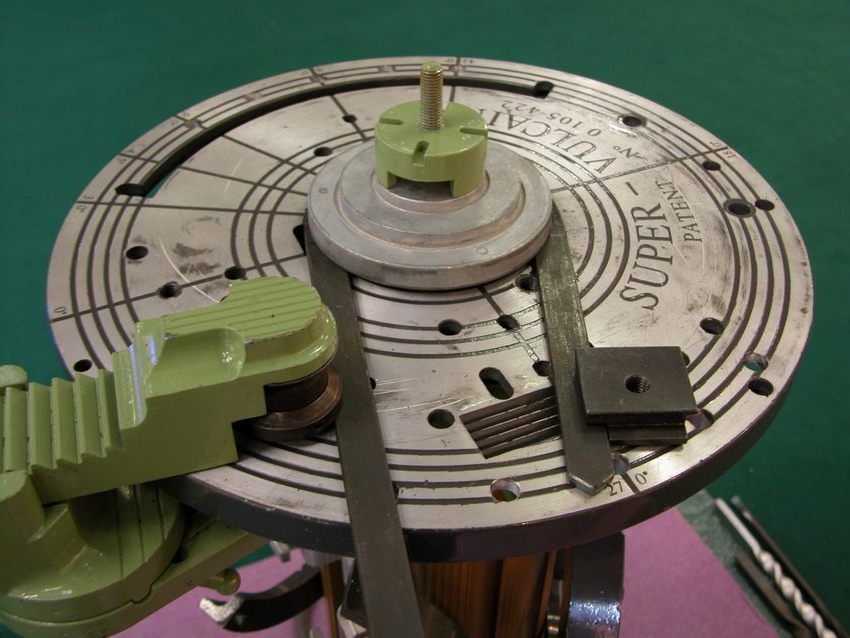

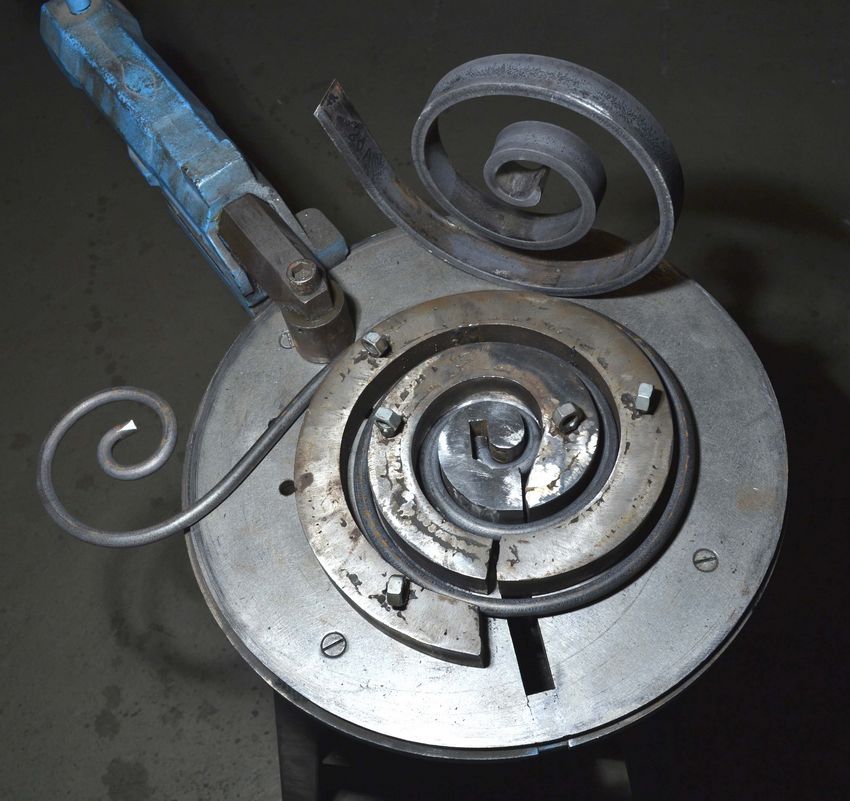

- snails – twist the workpiece in a spiral and curls;

- torsions – help longitudinally twist the workpiece or several such parts at the same time;

- stamping machines – with their help make decorative collars, shaped tips, wave with a small step.

Universal machines include special equipment components in various combinations.

Cold forging devices are driven mechanically (hand-held machines) or by electric drive. The equipment with the electric drive differs in the speed and ease of processing of preparations. Cold forging machine, the price of which can be quite high, is characterized by high productivity. When there is no need for performance and speed, then a manual machine will be quite enough to perform the work, especially if forging is a hobby.

You can buy a cold-forging hand-held machine at a specialist tool shop or order it online. The question is the price and solvency of the buyer. An alternative is to assemble it with your own hands. The principle of operation will not differ from the goods purchased in the trading network, and the functions performed are absolutely identical to the factory ones. Additional benefits – a gain in price, confidence that the design will not fail after the first use.

Important! Not all equipment can be made independently, some spare parts require industrial production or manufacturing to order.

First of all, you should familiarize yourself with the design features of each type of machine in order to evaluate the possibility of its self-assembly.

The torsion bar must twist the metal rods, so its design assumes the presence of two elements that hold the workpiece. One of them serves as a clamp, and the other contains a rotating spindle, which, in fact, will twist the rod to the desired frequency of the helical wave. The device is quite simple to build yourself, and some craftsmen generally manage with a vice and an uncomplicated manual collar.

The design of the bending machine is also simple, but it contains several essential elements, the assembly of which is impossible without a specialized tool. The base is a massive metal plate with a groove in the middle, into which a movable stop is inserted, moved by a worm gear. The other two cylindrical stops are fixed and mounted on the base on both sides symmetrically with respect to the groove. It is the mounting of the stops that can cause difficulties, since the holes for fasteners are drilled only on a specialized machine, such a billet of high-strength steel will not be impacted by a drill.

The machine for forging metal snail can have two varieties: with a collar or lever type. The first option allows you to vary the shape of the bend in the process, however, has a number of vulnerabilities in the design and is very picky about the strength of the materials of manufacture. The second type is more stable, but less productive. Masters consider the snail to be the simplest machine, the independent assembly of which will not cause difficulties.

It is quite simple to make convenient and functional equipment for cold forging, guided by the basic principles of its work and purpose. Any drawings, videos and photographs of designs always leave room for the author’s creativity and the perfection of the finished product. Below we will focus on the main points that are important for the assembly of machine tools.

The first and most important condition for assembling a cold forging machine with your own hands is drawings. There will be several such graphic documents:

- drawing of the base of the future machine for installation of equipment;

- assembly scheme or several schemes for each device performed;

- drawings of replacement parts, if provided for in the design.

Important! At the design stage it is worth considering how the moving parts and assemblies in the already finished product will move. This is especially necessary in the manufacture of replaceable working tools, for example, a snail or a gnote.

To assemble a homemade cold forging machine, you will need the following tools and materials:

- medium carbon steel (grade not lower than 35);

- thick-walled tube having a square or rectangular cross-section;

- a metal cutting machine (preferably portable) or a grinder;

- manual fixing tool;

- welding;

- frezer;

- bending device;

- tool for measuring and marking.

Helpful advice! In order for products made by cold forging to be distinguished by a rather good quality, it is necessary that the homemade machine parts also be of high quality. To do this, all welded joints, cut ends and finishing surfaces are carefully ground.

Some masters do simple twisting without a machine, clamping one end of the workpiece with a vice, and the other one turning with a conventional collar. With this method, the workpiece can not only twist, but also arch, especially in the area of the fixed end. To avoid this, construct a guide structure in the form of a narrow gutter, for example, from a pipe with an upper longitudinal section (U-shaped section). It is worth considering:

- the length of the gutter – it should be shorter than the workpiece, which decreases when twisting;

- chute width – it is necessary that it be 1.5 times wider than the workpiece, since it will be distributed during deformation.

You can get the desired result without a machine – for this you need to apply physical force and spend a lot of time on work. To whom this option is not suitable, it is better to engage in the project of universal equipment.

Assembling a torsion machine for self-forging is permissible in two versions: simple and universal. A simple model will be an improved method of working with vices, and on the universal there is an opportunity to additionally perform such elements as a lantern or basket.

Making a cold forging machine with your own hands, the drawing of which will help you accomplish this task, is quite simple if you understand its operation principle and design features. It is important to calculate everything carefully and take measurements. It is possible that someone will be able to come up with their own new options or improve existing models.