One of the common and important problems of a private wood house is a cold floor. This is due to the outflow of cold air streams from the ground, which penetrate through the gaps. In order for the room to be warm and comfortable it is necessary to carry out the floor insulation in the wooden house below. How to do this, what materials are used for this and the main points of the installation work are described in this article.

Why do you need to make floor insulation in a wooden house below

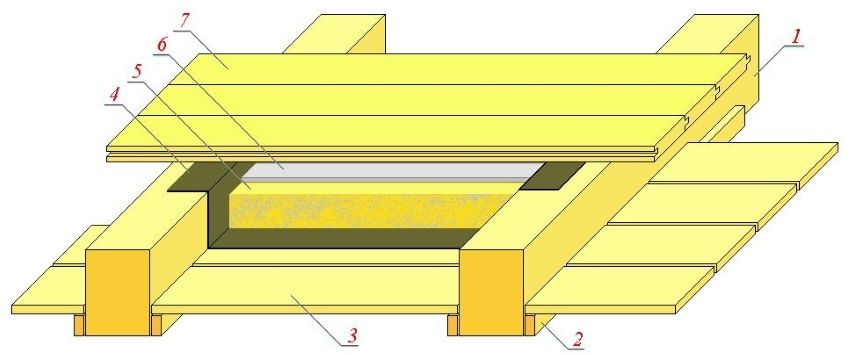

Warming of wooden floors in a private house is technically correctly carried out from below, due to several reasons:

- this avoids resizing the room to a height on the ground floor;

- no need to choose a hard insulation that can withstand the weight of furniture and home appliances;

- in this way, the owner protects the entire hardwood floor from freezing;

- the line of condensate settling out of the construction limits is reduced. This helps prevent rotting of the whole house.

The choice of materials and methods of warming the floor in the house completely depends on the design features of the structure, individual capabilities and preferences of the owner. Be sure to take into account the nuances of installation and the specific operation of the wood itself.

Wooden houses can be:

- frame type;

- on screw piles;

- on the tape base;

- on the pile foundation.

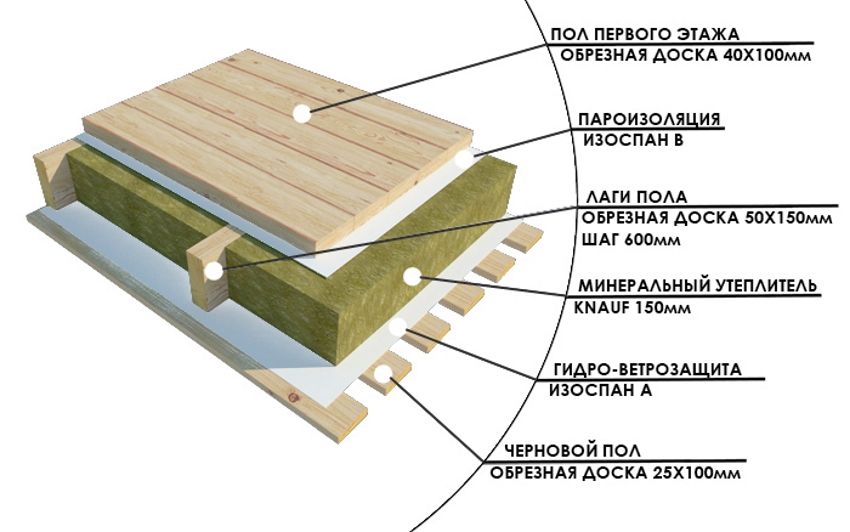

Regardless of what type of building has, insulation of a wooden floor in a private house has common specific nuances:

- the use of waterproofing is a must. This will prevent the boards from swelling. The best material for waterproofing is a one-sided fiber;

- to provide heat in the room, it is necessary to do a two-layer insulation of the wooden floor in the bottom of a private house. In such buildings, flooring consists of tightly fitted boards. This material is constantly exposed to changes in temperature and moisture. Therefore, wood for the floor must be treated with special means;

- The performance characteristics of the insulation should not change when in contact with wood.

All these points must be observed when carrying out floor insulation in the country and in a private country cottage.

The construction market offers a wide range of materials for floor insulation. They differ in cost, installation technology, optimal operating conditions, etc.

Materials used for floor heating in a wooden house below:

- mineral wool;

- ceramisite;

- penofol;

- polystyrene or polystyrene foam;

- sawdust;

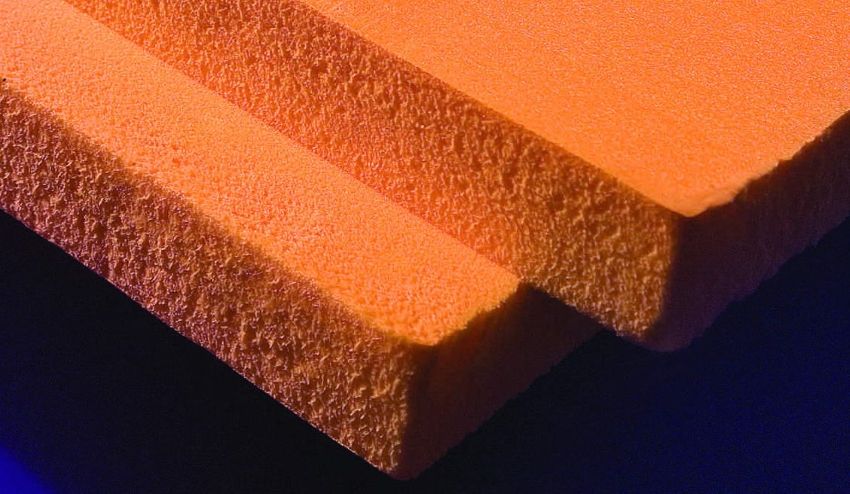

- penoplex;

- ecowool

Each of the materials has its own advantages and disadvantages. Its choice as a heater depends on the characteristics of the house, the financial possibilities of the owner and the type of flooring.

Penoplex is a common foamed polymer. It is distinguished by high strength, ability to maintain shape. For the production of penoplex extrusion method is used. This allows you to get a solid structure with a large number of small cells inside for better heat transfer. Moisture does not penetrate into the openings, so the material does not need additional waterproofing. Penoplex does not load the foundation of the structure. Due to this peculiarity of the material, it is most often used to warm the floor in a frame house on piles.

Minvat as a heater is used most often. It has a low weight, does not burn, has a high degree of protection against extraneous sounds.

There are three types of this material:

- glass;

- slag;

- stone

This material is produced in the form of a thick slab or flexible mat. For ease of installation on the plates is marked with a blue stripe. This allows you to place sheets in the right direction.

A big disadvantage of this material is the ability to absorb moisture. Therefore, when we warm the floor in a private house with your own hands, you need to have a good vapor barrier.

Helpful advice! Working with cotton requires special protective clothing for the body, gloves and glasses. This is due to the fact that during the installation work, small fibers are separated from the plates. They can cause irritation and itching of the skin.

Expanded clay is a small round porous balls of slate or clay. They are obtained by roasting materials in a furnace at high temperature. Expanded clay is considered safe and environmentally friendly material. Among its advantages should be highlighted:

- high sound insulation;

- resistance to low temperatures;

- environmental safety for humans.

A noticeable disadvantage of this material is compaction under its own weight. Balls of claydite are pressed together. This leads to an increase in the weight of the substance and a decrease in thermal insulation properties.

Helpful advice! You should not choose this material for warming the floor in a wooden house on screw piles. An increase in the mass of the flooring can lead to a subsidence of the building foundation.

Sawdust is a waste product of the woodworking industry. They have good steam and sound insulation characteristics, retain heat, are environmentally safe for humans. Sawdust differ in low cost. The resulting heat effect is not worse than that of expensive materials. Thanks to the cement component, they are also well suited for flooring in the ground floor apartment. Subsequently, such a screed can be used for laying laminate, linoleum, tile, etc.

Before use, sawdust is subjected to special treatment. This helps prevent rodents and beetles from appearing in them. After that, they are mixed with cement and water and evenly applied over the entire floor area.

Helpful advice! Instead of a solution, you can use clay. This material is environmentally safe and has better thermal insulation characteristics than cement.

Sawdust is ideal for warming floors on the ground, especially if the building does not have a solid and solid foundation.

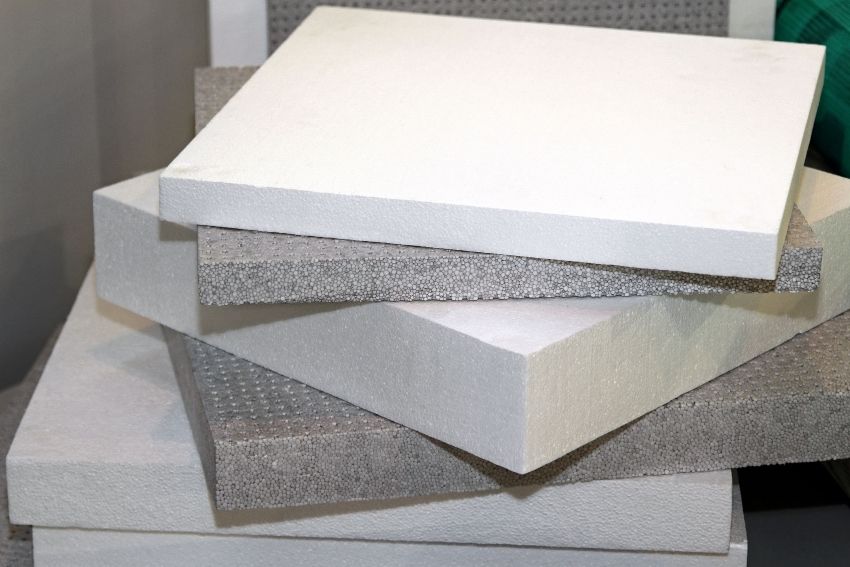

Popular is warming the floor foam board. Most often, this material is called foam. The advantages of this heater:

- low vapor and sound permeability;

- high thermal conductivity;

- not afraid of exposure to fire and high temperatures;

- resistant to external factors and chemicals;

- does not lose its properties for a long time;

- easy to install.

A significant disadvantage of the foam is its exposure to moisture. He can absorb it. This adversely affects the basic performance characteristics. But simple and inexpensive polystyrene floor insulation technology is a significant advantage. That is, in most cases, the owner of the house.

Helpful advice! If your cottage or private house is located on the ground with close groundwater storage or high risk of flooding, you should not choose foam as insulation. If the choice has already been made, you should take care of good waterproofing.

Polyurethane foam (ecowool) is a great way to solve the problem of floor insulation in an apartment on the first floor and in a private house (cottage). This material is blown into free space with a compressor. So he fills all the voids evenly. The fine particles that make up the ecowool provide excellent vapor barrier. The material is not exposed to moisture, so when installing it, additional waterproofing is not needed. This reduces the cost of insulation.

To the floor in the house turned out to be warm, it is necessary to take into account many nuances. The correct choice of insulation plays an important role in this. Selecting material for yourself, you should not make a start from the price or technology of installation. Consider the type of building, the nuances of the landscape and especially the operation of the house (permanent or seasonal). Based on this, you can choose the perfect insulation for the floor.