Expanded clay in its numerous positive characteristics is a versatile material. Due to the high degree of sound insulation and heat saving, it is used to warm the floor, walls and even the ceiling. Most often it is used as a component for screed when it is necessary to create a warm and strong base. This article will tell you about the advantages and disadvantages of the material, how to use it and how the floor screed with expanded clay is made.

Screed floor in the apartment: features of the process and its need

Replacing the old floor or laying a new one in a newly built home is a very important and time-consuming stage of repair work. After all, on how the floor will look, to a large extent depends on the overall type of housing, comfort and coziness. It is very important that the surface is smooth. Therefore, before flooring any kind of flooring, it is advisable to produce a screed.

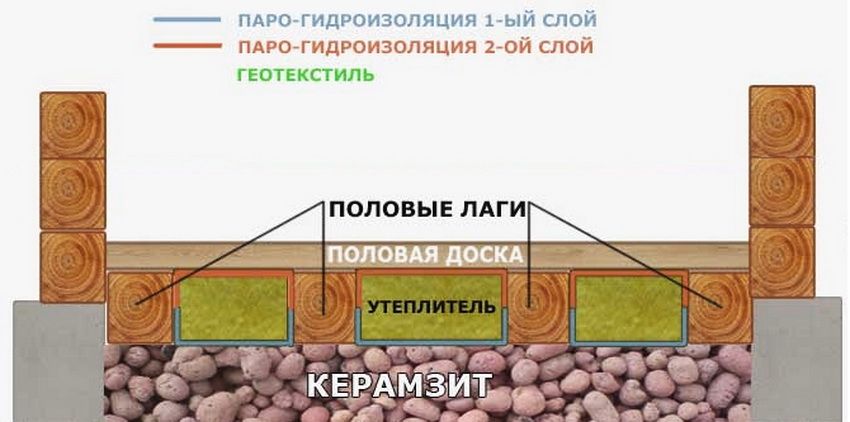

There are two traditional types of screeds – wet and dry. The first option involves a relatively large amount of work. The process is lengthy, time consuming and dirty. In this regard, recently builders prefer dry technology screed with expanded clay. This installation is relatively simple and consists in filling in the lags or between the walls of the ceiling of a special granular material. Further, special sheets are laid.

When choosing a screed option, you should consider the condition of the surface and the characteristics of a particular room. Self-styling requires precision technology to make the floor as strong and durable as possible. One of the most effective and common methods of leveling the surface – floor screed with expanded clay. The technology is not easy, even in the case of the use of ready-made mixtures.

Expanded clay – a material characterized by ease, practicality and environmental friendliness. Positive qualities include a high level of heat and sound insulation. It is made by burning clay at a very high temperature, therefore, in translation from Greek, the word “clay” sounds like burnt clay.

The production technology itself involves exposing the prepared clay to intense heat. As a result, the raw material swells and becomes porous. In this case, the outer part of the shell is melted, which leads to sealing and high strength of the material.

Sedimentary clay rocks are most often used as raw materials, less often – metamorphic rocks. They are distinguished by a complex composition, which includes hydromica or kaolin, as well as feldspar, carbonates and other impurities. The clay most suitable for expanded clay contains no more than a third of quartz. The raw materials are supplemented with special additives that provide the best swelling of the expanded clay. To do this, use diesel fuel, fuel oil, ferrous substances, perlite and the like materials.

Helpful advice! Choosing claydite, you should give preference to certified products. Special GOST 9759-76 includes the parameters of granules, the requirements for weight and strength of expanded clay. It is the strength – the main indicator on the basis of which the material is allowed to be used.

Raw granules of a certain size are subjected to special treatment, including drying, roasting and cooling. Next, the clay is sorted and, if necessary, crushed into fractions of smaller sizes. After that, the material is packed and prepared for transportation.

Expanded clay screed floor is resistant to high temperatures and frost resistance at the same time. This feature allows its use in different temperature conditions. In addition, it is resistant to fire, it does not develop putrefactive bacteria and mold. One of the main advantages is the low specific weight. The ease of the material simplifies its delivery. In addition, leveling the floor with expanded clay will help eliminate any flaws that other materials cannot cope with (or their application is simply unprofitable).

The material has the following positive characteristics:

- high degree of thermal insulation;

- good level of noise insulation;

- sufficient strength;

- low cost in comparison with other materials;

- it is durable;

- Easy to carry.

Among the disadvantages, it is necessary to note weak moisture resistance in the case of using the dry-screed method, therefore in some cases it is better not to use claydite. The material itself will not suffer, but moisture will linger under the concrete. Subsequently, this will lead to increased humidity in the room. This factor is favorable for the development of fungi and mold. The disadvantages of the material should also be attributed to the fact that for insulation you will need to make a coupler of great thickness. A layer less than 10 cm will be ineffective.

Ceramsite screed in many points wins over other fillers. In addition to the maximum level of heat and sound insulation, it has good breathability, is durable. The material is suitable for any floor covering. The maximum effect of all the listed positive qualities can be achieved only if all the requirements of the technology of laying expanded clay are met.

For insulation of the floor, walls and floors of buildings using different materials. In addition to the expanded clay, among the most popular materials also belong polystyrene foam, foam plastic and mineral wool. They are characterized by qualities such as lightness, high thermal insulation and low price. However, due to their versatility, claydite or mineral wool is most often used. Warming the floor with these materials is most effective.

Expanded clay, as an eco-friendly material, does not pose a threat to health and serves for several decades. It is inexpensive, multifunctional and resistant to fire, moisture and rodents. However, its use requires a number of preparatory work, so it is not suitable for creating “warm floors”.

Helpful advice! Mineral wool is more effective as a thermal insulation material, but it is not as durable and durable as expanded clay. Therefore, it is advisable to use for wall insulation. While the expanded clay is more suitable for sex.

Insulating walls with expanded clay outside the house is a rather laborious and inconvenient process. It is in this that clay is inferior to mineral wool, which is suitable for warming facades, roofs and pipes in hard-to-reach places. From it it is easy to cut the necessary shape using a knife.

It is unambiguous to say which material is better, it is impossible, and even more so to make a categorical choice in favor of one of them. Choose insulation should be based on the specific conditions of construction and material capabilities. Most often, experienced builders combine mineral wool with expanded clay, which has a positive effect on the cost of work and increases the degree of insulation. Both heaters are distinguished by simplicity of the installation process and low cost, giving an excellent result at the output.

For the expanded clay screed use different types of fractions. In the modern construction market there is a material with different levels of density. The weight of a cube of expanded clay varies from 260 to 600 kg / m ?. The specific weight of claydite is the weight of the cube of the material. It depends on the grain size: the larger the grain, the lower the specific gravity will be. It is exactly 1 m? Claydite and its density underlie the classification of the material below:

- Ceramsite crushed stone has a size of 10-14 mm. Such material is taken for the manufacture of concrete.

- Expanded clay gravel used in the installation of floors of varying degrees of strength. Apply most often to thin, but durable decking. These are expanded clay of a fraction of 5-10 mm, 10-20 mm and 20-40 mm.

- Expanded clay sand – the smallest material. The maximum fraction of expanded clay – 0.5 mm, it is used in the process of creating thin screeds.

The table will help to demonstrate the specific and volumetric weight of expanded clay, depending on the type and fraction,

| View | Fraction, mm | Specific weight (g / cm?) | Expanded clay weight in 1 m3, (kg) |

| expanded clay sand | 0-5 | 0.5-0.6 | 500-600 |

| expanded clay gravel | 5-10 | 0.4-0.45 | 400-450 |

| expanded clay gravel | 10-20 | 0.3-0.4 | 300-400 |

| expanded clay crushed stone | 20-40 | 0.2-0.35 | 200-350 |

In accordance with the table, the approximate weight of 1 m3 of claydite fraction 10–20 is 350–400 kg.

The specific gravity also depends on the brand density. According to the existing GOST, the higher the density of expanded clay, the greater the weight of the material.

It is impossible to determine the specific weight of haydite, but the average value is quite simple to establish. The average value is 400 kg / m? (0.4 g / cm?). In addition, each fraction has its own specific indicator. For example, expanded clay 10-20 in bags weighs approximately 16.8 kg.

It should be noted that bulk granules made of clay are widely used not only in construction, but also in communal and agriculture. Therefore, the range of prices for this material is quite wide and ranges from 1,000 to 2,000 rubles per cubic meter.

Helpful advice! In order to save money, you can buy expanded clay, second-hand. This material has almost not lost its positive properties, but it is worth two, if not three times cheaper.

The price policy on the market is also dictated by the producers of expanded clay. In setting pricing, they are guided by the following criteria:

- indicators of the state of raw materials from clay;

- features of production technology;

- volume and production capacity;

- storage features;

- power consumption;

- turnover rate.

Enterprises selling claydite take into account other factors in the pricing process. For example, packaging, the size of the granules and their porosity. The first criterion includes a list of additional costs for the purchase of additional equipment and the hiring of workers for the dosing, weighing and packing of material.

The size and porosity of the material determine such qualities of claydite as heat insulation, strength, and moisture absorption. All these criteria respectively affect the formation of prices. For example, the size of the granules forms a price in inverse proportion: the smaller the grain, the higher the cost. The price of fine expanded clay in bags is significantly higher, since the material itself is much heavier compared to the weight of expanded clay of large fractions of the same volume.

The cost of expanded clay per 1 m3 or per bag: which is more profitable

Trading agents in the construction market offer the purchase of expanded clay wholesale and retail, packaged or loose. It is much more profitable to buy the material by weight or per cubic meter, as during packaging, labor costs and the cost of packaging affect the pricing. If the question is about the purchase of expanded clay to insulate the floor, and not to fill the site as a decorative element in landscape design, then it is enough to purchase only a couple of cubes of material.

Packed clay is of a higher quality because it undergoes special cleaning. In addition, the packaging is more convenient to transport and protects the material from moisture, while maintaining its quality characteristics.

When buying claydite, one more important factor should be taken into account – seasonality. Usually after the end of the construction season, the material price drops by about a quarter. Thus, granulated building material in winter can be bought much cheaper.

If it is important to buy high-quality, clean, solid and certified material, you should prefer expanded clay in the package. Since it has been certified, there will be no impurities, debris and impurities in it. You can check the strength of the granules by simple compression, and the porosity is determined when the grains break.

The floor screed, carried out by the dry method, is more advantageous in comparison with other technologies. First of all, the savings means the absence of the need to attract professionals, because most of the dry screeds can be made with your own hands.

Helpful advice! If quality is more important than price, then it is worth buying expanded clay for dry floor screed in the form of a special blend “Compavit” – this is backfilling used in Knauf technology. It was developed as a heater, but in combination with gypsum-fiber sheets, excellent horizontal position of the surface was noted. The composition of “Kompevita” includes various granules (up to 5 mm) of high quality. The only drawback of such material is its high cost.

When it comes to expanded clay, the method of its use also affects the total cost. For dry screed material is taken from different factions – and its price may be low. While the bulk method requires fine-grained expanded clay, which is much more expensive.

- Before proceeding to the execution of the screed, it is advisable to take care of waterproofing. This layer will not be superfluous, but after filling the floor it will be impossible to perform it. For waterproofing, you can use liquid mastic, dense polyethylene or waterproofing;

- as beacons used ordinary metal profile or thin rails;

- the finished screed made by the wet method, you need to give time to dry. You can use the room after a month;

- so that during pouring cracks do not form, it is desirable to constantly wet the surface with water;

- cracking is prevented by a special plasticizer. It is recommended to add it to the finishing solution;

- Buying GVL, it is better to take sheets that have water-repellent treatment;

- the price of claydite does not necessarily indicate quality. Trust worth the products of well-known manufacturers;

- granules of very large size are more susceptible to destruction and threaten the base with rapid deformation;

- for fixing GVL-plates, it is better to take screws with “retractable” caps.

If all the rules and technologies are observed, it is quite realistic to make a floor screed with claydite with your own hands. Video materials, which are numerous on the Internet, will help ease the process. As a result, it is possible for a long time not to recall the repair of the floors of the house, while ensuring maximum thermal and sound insulation. In addition, you can easily eliminate all the irregularities of the floor with expanded clay. Photos clearly demonstrate how the process of laying, and the resulting positive result.