What are the pros and cons of dry floor screed and what is the technology of its creation. All this interests people who have dismantled the old floor and are preparing to lay a new one. The technology of dry screed construction is fundamentally different from other ways of leveling the base of the floor. It does not use a single drop of water and does not require a large number of assistants for installation. For this reason, everyone is able to make a dry floor screed with his own hands. Videos of how experienced masters do this can be viewed in order to visually study the whole process.

What are the features of dry screed

Probably, no method for creating screeds is as original and, at the same time, as simple as a dry screed floor. The pros and cons of such a leveling foundation we have to consider further. This method was invented not so long ago, but already enjoys great popularity, especially among owners of private houses.

And it is not surprising, because in them most often the overlappings are wooden, which excludes the use of liquid leveling compounds without the use of an impressive layer of waterproofing, which incurs additional costs.

From the name it is clear that all components of the dry screed do not contain liquids. It is also sometimes called “precast floor”, which is not without sense. After all, it consists of two independent components:

- the filling part, which can be, for example, crumbs of expanded clay, about 5 mm in size. It not only levels the surface, but also has excellent sound insulation and poor thermal conductivity. There are other bulk materials with similar qualities, which will be discussed further;

- hard sheet coating made from gypsum-fiber boards that are laid on top of the backfill. They put the finish coating of any type.

There are various bulk materials that can be used to create a floor screed using the dry method. Features all have different, but they can be considered in more detail:

- expanded clay or crumb out of it. It is heated to a high temperature and foamed clay. Due to the very low density – almost weightless, but it has excellent thermal insulation characteristics;

- Foamed vermiculite, which is a natural material with a very small weight (1 m? weighs only 160 kg). Sometimes its use is more justified than the use of expanded clay;

- expanded perlite (heated to 1000 degrees). A volcanic material devoid of all moisture by heating.

Helpful advice! Perlite is so light that it can be blown away by a small draft. For this reason, when working with him, the windows should be completely closed.

- polystyrene in plates. This material is not backfill and it is necessary to apply it only on a flat base, when there is no need for additional alignment. Expanded polystyrene plates have excellent sound insulation properties.

The top layer can be made of various sheet materials. We list those that are most suitable for creating a dry floor screed. Pros and cons have their own each:

- wood-chipboard (chipboard) – the well-known old material, obtained by pressing and impregnating wood chips with resins. It has a moderate cost, easy to install, but is afraid of moisture and contains not entirely harmless substances;

- gypsum plasterboard (gypsum board) – the usual drywall from a layer of gypsum between two layers of thick paper. The material is convenient to process, it is cheap, but also afraid of moisture;

- gypsum fiber boards are similar to gypsum board material, but it has a reinforcing mesh that increases strength. There are moisture resistant. Their surface is covered with a waterproof material. The coupler with such sheets can be arranged even in the kitchen and bathroom;

- gypsum chipboard (GSP) – is a mixture of gypsum and chips, bonded with resins;

- moisture resistant plywood with very good waterproof properties.

Helpful advice! It is necessary to choose sheet material taking into account in what room it is planned to do a dry coupler of a floor. The pros and cons of each need to be considered in the context of how well it is protected from moisture and what are its strength characteristics.

Today, there are many video instructions on how to make a floor screed with your own hands. The video, including, shows in detail and the dry method. As in any business, in the course of carrying out work on the device of dry screed, you first need to prepare the base.

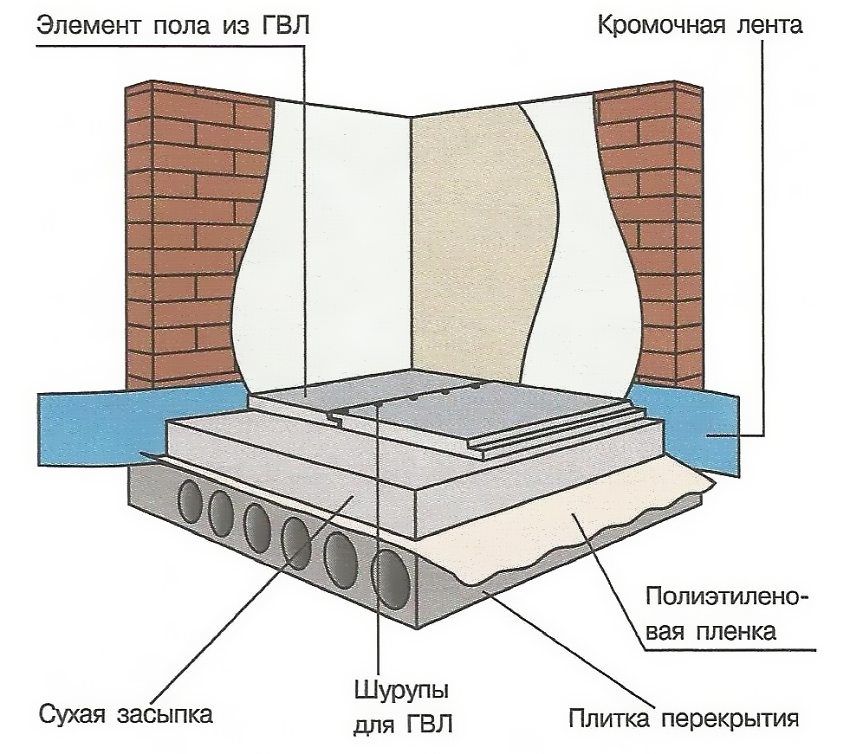

To do this, make demolition work: free the room from the old floor, remnants of cement and other structures. Holes near utilities close up with foam or cement mortar. After that, they make a waterproofing film that extends over the walls to the level of the finishing coating. The room must be completely dry.

Using a laser level, lighthouses are installed to the height where it is planned to level the upper layer, and around the perimeter of the walls it is necessary to fix the tape, compensating for temperature expansion. Its top edge should also reach the surface of the topcoat.

Pros and cons of the semi-dry floor screed and the technology of its device. The technology of creating a semi-dry floor screed with their own hands, its features and properties. Algorithm for semi-dry floor screed.

Bulk material is poured between beacons and leveled using rules or slats on them. The layer can turn out to be of various thickness, from 30 to 60 mm, which is normal, as it is needed for alignment.

Helpful advice! If it turned out that in some places the layer thickness exceeds 80 mm, then the plates should be put in two layers. This will strengthen the screed and will not let it sink over time.

Gypsum-fiber sheets are laid directly on the backfill, displacing them relative to each other by 40 cm. I paste the sheets together with ordinary PVA construction glue. After that, the screws attach the sheets to the beacons, rigidly fixing them on the horizon. On top of the sheets, you can mount any decorative finish.

Dry screeding device – the process is very fast and relatively cheap. In addition, there are other pros and cons of dry floor screed:

- absolute purity when performing the whole process;

- as a “side effect”, an additional heat insulation layer is created on the floor;

- the ease of the whole structure, allowing you to create it even in dilapidated wooden houses;

- simplicity of laying various engineering communications;

- reduction of repair time, as there is no need to wait for drying. Installation of the topcoat can be started immediately.

As with everything else, the dry screed has one, but significant minus. This is the fear of abundant moisture. If a sufficient amount of it gets on the surface of the plates and is not immediately removed, then the material will swell with damage to the finish coating.

Having considered all the nuances of laying dry screed, it can be concluded that its use is justified in areas where water is little used, and the risk of flooding or other emergency is minimal. The device of this type of screed in bathrooms and bathrooms entails certain risks, even with the use of plates with moisture resistant coating.