Today, practically in all residential buildings, electric or gas heat-generating equipment is installed, which is located even in garden and summer houses, where people live only seasonally. Most of the buildings that are used temporarily are completed with inexpensive types of cold-type roofing. Subsequent insulation of the ceiling in a house with a cold roof is done in order to create obstacles for the heat to escape from the living rooms.

Thermal insulation of the ceiling in a house with a cold roof and warm: specificity of structures

The organization of the roofing part of the cottage and the choice of general parameters for the roof is carried out on the basis of how the building will be exploited in the future.

The general parameters of the roofing part of the cottage include:

- shape and type of roof;

- type of roofing material;

- scheme truss system;

- the specificity of the space under the roof;

- the absence or presence of a layer responsible for thermal insulation.

Note! When building country houses can be used two types of roofs: cold and warm. Each of these structures has its own characteristics. They subsequently affect the further operation, therefore, it is worth considering the choice of the roof at the stage of the design development of the building.

Warm roofing is a type of construction that provides for complete warming of ramps. Its installation is carried out in the event that a room located under the slopes, is operated as a dwelling. Today, a fairly large number of projects of modern houses include the use of an attic space for the equipment of living rooms.

Roofs of this type are recommended to be installed in cottages and houses that are operated and heated throughout the year. This will allow you to eliminate heat loss through ramps. At the same time, one detail should not be overlooked: the cost of installation work and the purchase of materials in these circumstances is significantly higher than during the construction of a cold-type construction.

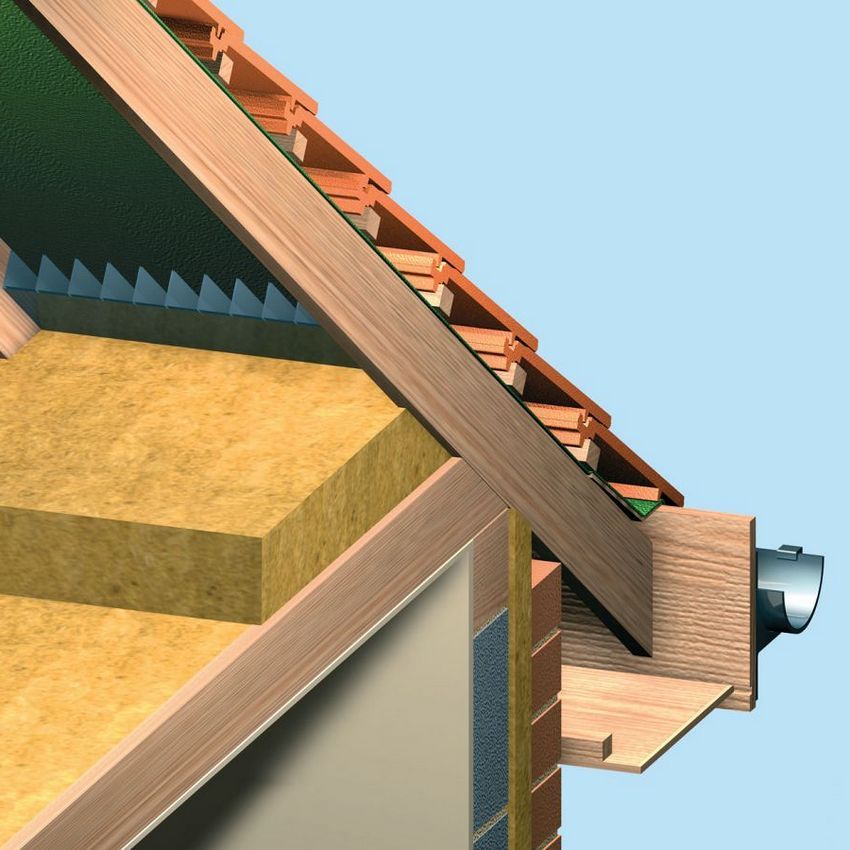

A cold roof has a slightly different structure, since its construction does not use the usual pattern, where the layering of materials is carried out in the following order:

- waterproofing;

- thermal insulation;

- roof.

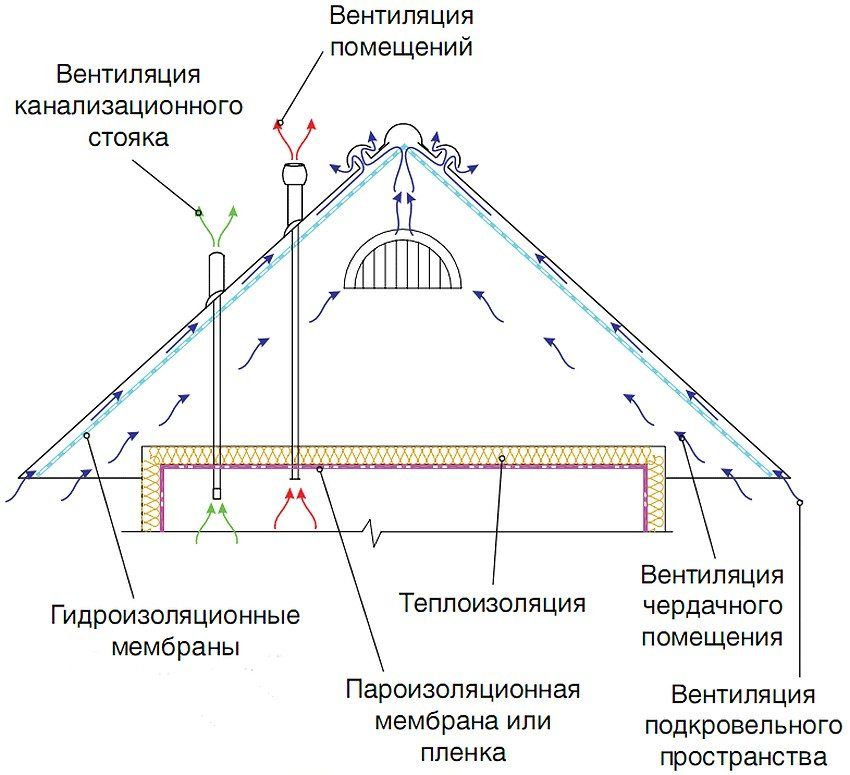

The cold type of construction is used in those houses in which the space under the roof is not residential and is not heated in winter. In fact, the cold roofing structure is a truss system. Over it installation of a waterproofing layer and roofing material is carried out.

This type of roof has a lightweight, accompanied by low construction costs, and the installation system is much simpler than with the arrangement of a warm version of the design. Therefore, a cold roof can be considered as a practical and budget way of organizing a roof for a country house.

Note! If there is no heating in the attic room, the air in this zone serves as a kind of buffer that ensures the reduction of heat losses. In accordance with the principle of action of such a phenomenon as convection, warm air that rises from the heated premises below is subjected to gradual cooling. As a result of this, internal heating of the slopes does not occur, which excludes the probability of ice forming on them.

To save heat and reduce fuel costs, the insulation of a ceiling placed under a cold roof is most often carried out by installing heat-insulating materials of fibrous or backfill type. This procedure can be considered the most effective, since the flow of heated air always rush up.

Of course, the issue of insulation should be addressed at the design stage of the building. However, if necessary, this procedure can be performed after construction, for example, if the house is old and it does not have thermal insulation.

If you make the ceiling warming in a house with a cold roof (especially for wood constructions), you get a certain benefit:

- Insulating material will provide additional sound insulation, so residents will not feel discomfort if it is noisy outside, it is raining heavily, or there are sudden gusts of wind.

- In the summer, insulation will prevent heated air from entering the house from the street. This will allow to maintain a comfortable microclimate in the premises.

- In winter, the insulation material will prevent heat from escaping to the outside.

To insulate the ceiling area in a wooden house, you can seek professional help from specialists. However, the most profitable option with respect to price and quality is to perform this procedure with your own hands.

Helpful advice! Work on the insulation of the cottage can be done independently. The main thing is to study the question well: to familiarize yourself with the properties of various materials, their disadvantages and advantages, to study the specifics of the insulation technology with their use, to arm yourself with step-by-step instructions and video materials.

Effective insulation can reduce the costs of heating a country house by almost 30% by reducing heat losses. This procedure will significantly save money from the family budget.

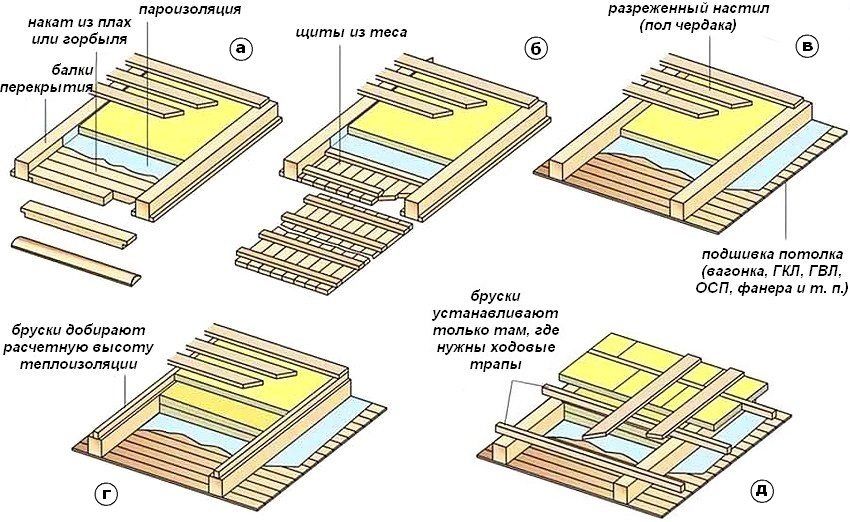

Installation of insulation can be carried out in two ways: from the floor to the bottom or from the attic area.

The most correct and effective technology for insulating a ceiling zone under a cold roof is the method of installing insulation material from the attic. In most cases, the ceiling structure is made of wood, which has thermal insulating properties.

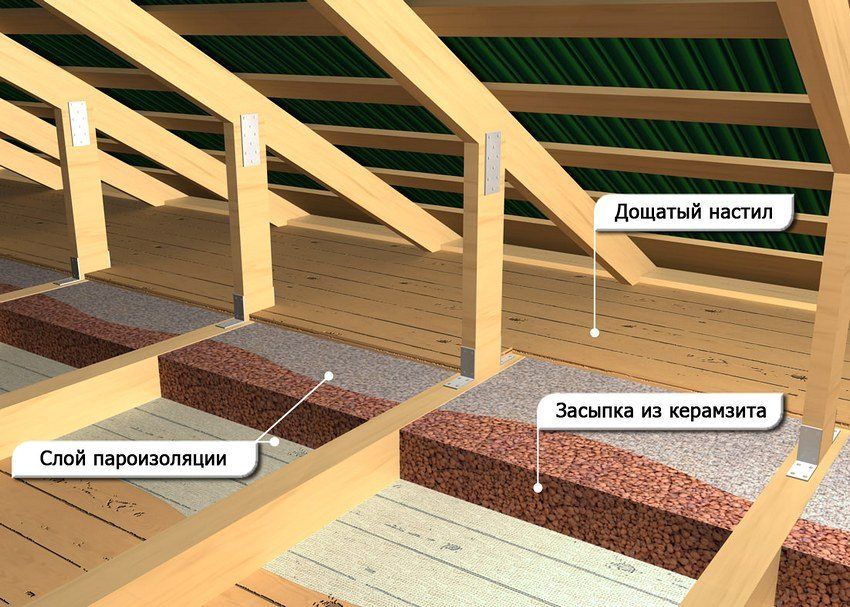

After the installation of insulation on the attic floor, the surface of the subfloor is formed above this area. At the warming which is carried out indoors from an attic, materials of zasypny type or rolled can be used.

Insulation from the floor is carried out in the event that:

- reconstruction of old buildings with finished attic floors;

- no access to the attic.

Technology implies installation:

- frame construction of wooden slats or metal profiles;

- insulation material in the form of plates;

- drywall as plating.

This method has a significant drawback. By installing the frame and cladding, the amount of free space in the room is significantly reduced (the ceiling height is reduced). Moreover, the installation work at the top of the room requires more time and effort.

Helpful advice! High-quality and effective thermal insulation can be achieved only in a complex. To solve problems with the loss of heat in a building with a cold type of roofing, it is recommended to perform warming of all openings, including door and window, as well as the floor. Using a thermal imager, you can identify the most problematic areas. Areas painted in yellow and red should be carefully insulated, since it is through them that the heat goes outside.

Considering the fact that this method of insulation is less effective, experts recommend performing it only when it is not possible to reduce heat loss by another method. For example, to avoid dismantling the ceiling.

The market of building materials offers a lot of insulation for private homes. To determine the choice of material, it is necessary to analyze the range of heaters for compliance with the basic requirements.

Criteria for selection of materials:

- Thermal conductivity (materials with the lowest thermal conductivity are considered the best).

- Moisture resistance (this parameter is of particular importance if the installation of insulation from the outside is carried out, and the roof covering is already worn out).

- Durability.

- Environmental friendliness (materials should not bear danger to human health).

- Flammability level (in the process of insulation works, non-flammable or slightly flammable materials should be used).

The most running insulants are:

- expanded clay;

- small chips or sawdust;

- all types of stone wool;

- cellulose-based ecowool;

- polystyrene foam;

- Styrofoam;

- polyurethane foam (sprayed type of material).

Warming of the ceiling zone from the attic is carried out by laying the insulating material on top of the ceiling or inside its voids (if any).

The choice of material and technology of its installation completely depend on the type of overlap, which can be concrete or wood. Concrete is insulated with the help of dense materials in the form of slabs or mats and heavy insulating materials of the filling type. For wooden lag-based ceilings, lightweight filling or rolling materials should be used.

In addition to insulants made on natural and artificial basis, materials of natural origin are used for insulating works.

Such materials include:

- sawdust;

- clay;

- seaweed;

- reeds;

- needles;

- hay;

- old foliage;

- straw, etc.

Note! These types of materials (with the exception of sawdust) are highly susceptible to rotting. Therefore, the insulation with their use will be short-lived.

Warming with small chips or sawdust is considered one of the most ancient methods of improving the microclimate in a residential area. In those regions where the woodworking industry is developed, this type of material can be bought for a penny, and in some cases even get completely free if agreed with the factory. Often, woodworking companies themselves do not know how to get rid of sawdust, so there should be no problems with the purchase of insulation.

Sawdust is recommended to use for the organization of the insulating layer on top of wooden floors. The only disadvantage of this heater is its flammability. But this disadvantage can be compensated by applying different installation methods.

Warming of sawdust will be effective only if the correct thickness of the layer. This indicator is calculated based on temperatures characteristic of the winter season in your area.

Table for determining the thickness of the sawdust layer:

| The name of the material | The thickness of the layer (cm) depending on the temperature indicator (? C) | Weight, c / m? (1 q = 100 kg) | ||

| -15 | -25 | -20 | ||

| Small chips | 6 | eight | 7 | 3 |

| Sawdust | five | 6 | five | 2.5 |

In some cases, pellets made of small sawdust in the form of granules can be used as insulating material. To reduce the level of flammability, sawdust is recommended to be mixed with flame retardants (specialized fire and biological protection means).

In addition to sawdust and shavings, more unusual materials of natural origin can be used for insulation.

Table of thermal conductivity of materials:

| The name of the material | Conductivity coefficient | Weight, c / m? (1 q = 100 kg) |

| Felt (different type) | 0.031-0.05 | – |

| Foliage (dry) | 0.05-0.06 | – |

| Tow | 0.037-0.041 | 1.8 |

| Moss | 0.04 | 1.35 |

| Needles | 0.08 | 4.3 |

| Straw mats | 0.05-0.06 | – |

| Vata | 0.037 | 0.8 |

| Fine chips (packing) | 0.05-1 | 1.4-3 |

| Bonfire (different type) | 0.04-0.065 | 1.5-3.5 |

| Sphagnum (peat) | 0.05-0.07 | 1.5 |

| Sawdust | 0.05-0.08 | 1.9-2.5 |

| Straw (stuffing, cut) | 0.04 | 1.2 |

Helpful advice! For safety reasons, perform additional insulation on electrical cables. For this it is recommended to use corrugated tubes of the appropriate diameter.

According to this method, the elimination of gaps that may be in a wooden floor is carried out using clay. Its consistency should be slightly thin. After coating, the surface is sprinkled with a small layer of sand, as from excessive temperature after drying, the clay can crack, disrupting the integrity of the insulating layer. In such circumstances, the sand gets inside the cracks and seals the gaps.

Sawdust is a favorite habitat for small rodents. To avoid damage to the insulation by mice, a layer of carbide with slaked lime is poured. After that, a layer of sawdust is formed. Depending on the climatic features characteristic of your region, the thickness of this insulation may be different. The minimum layer is 15-20 cm, but it is better to perform the mound height of 25-30 cm.

Since the sawdust is quite easy to burn, they should be lightly sprinkled with spent slag on top. This should be especially carefully done in the area where hot communication systems, such as the chimney, are located. On top of the insulation is not required to lay anything. For convenience, if you use the attic, you should put boards.

Other technology requires protective measures to prevent moisture from damaging the floor. To do this, you can take a waterproofing film that is laid over a wooden floor, or treat the entire surface with clay.

Helpful advice! Use a waterproofing film that is capable of passing vapor particles from the living room.

After that, sawdust mixed with cement and diluted with water according to this recipe:

- sawdust (10 parts);

- cement (1-2 parts);

- water (1.5 parts).

To cement stuck to sawdust, they need to get a little wet. The resulting mixture covers the entire surface of the floor in the attic, or you can fill the space between the floor beams with it. The thickness of the layer – 20 cm. It is recommended to perform this type of work in the spring, since the sawdust will need all summer for proper drying. To check the quality of drying, you should walk over the embankment. If the sawdust is completely dry, they will emit a light crunch, and the surface of the insulation will not wrinkle.

There is another technology of insulation using sawdust. This method is similar to the above method, only the cement in the recipe is replaced by clay.

And finally, the latest technology. It involves the implementation of insulation in the simplest way. Slag is excluded from the equation and does not need to be sprinkled with sawdust In this case, the insulation is smeared with clay. The mixture should not be too liquid to avoid leaking into the mound of sawdust.

Clay is the oldest material used in construction. Pure clay is not used as an independent heater, because to ensure a full level of thermal insulation, you will need to form a layer with a thickness of about 50-80 cm. The wooden ceiling is simply unable to withstand this amount of material, therefore special mixtures of clay and sawdust are used .

Helpful advice! First you need to cover the floor with a film with vapor barrier properties and the ability to not pass moisture.

Preparation of clay-sawdust mixture:

- A large barrel is taken and filled with water.

- Clay in the amount of 4-5 buckets is added to the water barrel.

- The liquid is mixed until the clay is almost completely dissolved in it, and the water does not get a dirty tint.

- Part of the mixture is poured into a concrete mixer.

- Sawdust is added, mixing is performed.

- In the process of mixing water is added to the clay-sawdust mixture.

As a result, you need to achieve a solution with an optimal consistency, which will not be too thick or liquid. It is necessary to cover this ceiling with a layer of 15-20 cm with this mixture. After applying the surface is leveled. Then she needs to be given time to dry. As the mortar dries, cracks may appear on the insulation layer. They are removed by smearing with clay.

Expanded clay is an environmentally friendly material. Natural clay is used as a raw material in its production. This type of insulation is not flammable at all, and does not emit toxic substances when heated.

The embankment formed from expanded clay can have a different level of density, since the material is produced by manufacturers in the form of fractions with different sizes. From the smallest particles the densest heat-insulating layer is formed.

Table with density parameters:

| The size expanded clay granules, see | Indicator strength at compression, MPa | Density level (volume), c / m? (1 q = 100 kg) | Density level (bulk), c / m? (1 q = 100 kg) |

| 1-3 | 0.9-1.1 | 4.5-6.5 | 2-2.5 |

| 0.1-0.4 | 2-3 | 8-12 | four |

| 0.4-1 | 1.2-1.4 | 5.5-8 | 3.35-3.5 |

For insulating the ceiling zone, it is recommended to use expanded clay with a granule size of 0.4-1 cm.

Note! After installation, clay does not become a source of dust and is not able to cause an allergic reaction. It has a long service life and does not lose its properties and characteristics throughout this time.

Expanded clay granules are characterized by a high rate of heat resistance, so this material is used to separate the wood from the chimney. For this, a special box is constructed around the chimney pipe, which is filled up with granules.

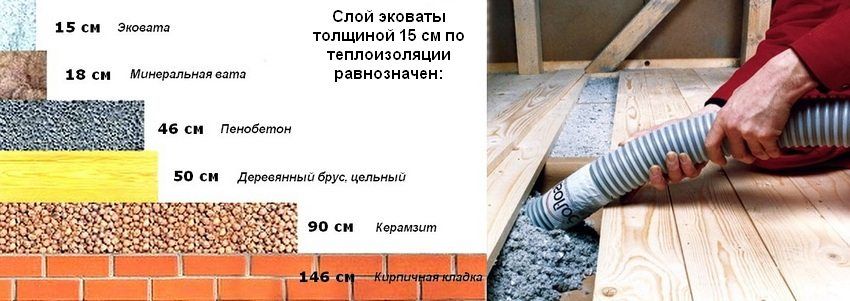

To more fully assess the properties of expanded clay, you can compare its characteristics with those of another environmentally friendly material – ecowool.

Comparative characteristics:

| Material property | Cellulose wool | Expanded clay |

| Level of density, c / m? | 0.42-0.75 | 2-4 |

| Level of chemical inertness | – | is neutral |

| The percentage of water absorption in relation to weight | 15 | 18-20 |

| Thermal conductivity | 0.037-0.040 | 0.10-0.15 |

| Interlayer density | High density and crack filling | Granule size: 1.5-2 cm – voids; 0.5-1 cm – high density |

| Vapor permeability | 0.67 | 0.3 |

| Flammability level | low (due to flame retardant treatment) | incombustible |

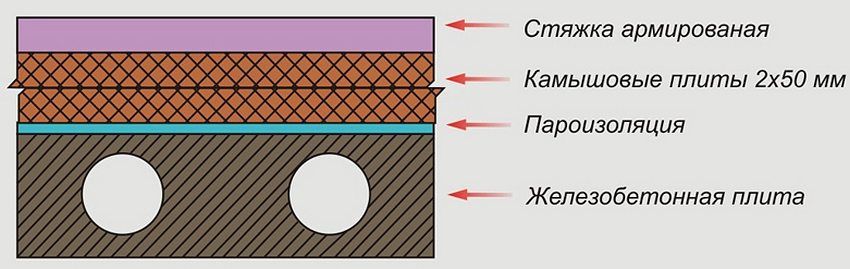

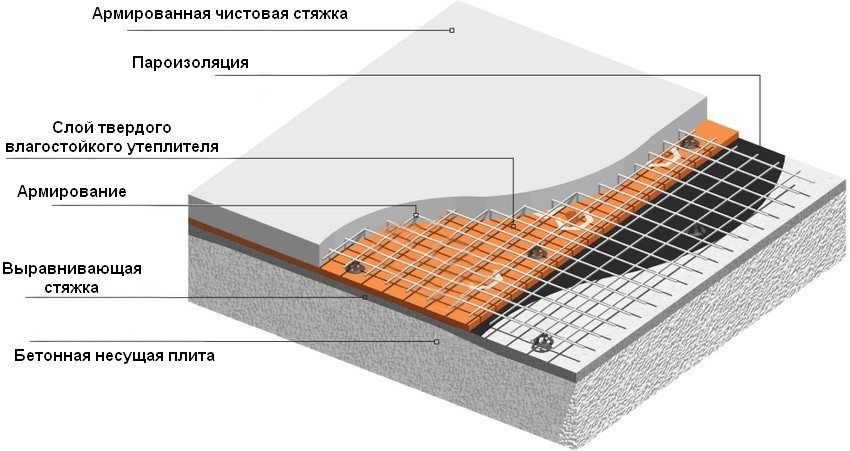

In the technology of insulation using fractions of expanded clay, a significant role is played by the weight of the material. Due to its severity, it is not recommended to use this insulation when working with wood floors, since the flooring under pressure of large weight can fail. Therefore, expanded clay is applicable exclusively on concrete structures.

To begin with, preparatory work should be carried out: clean the concrete surface and cover it with a film with vapor-insulating properties.

Helpful advice! Laying film layer is overlapped to get a solid coating. The joints are glued with adhesive tape. Do not forget to overlap the walls with a margin of 0.4-0.5 m. With a film coating, you need to process the chimney and the truss system of a wood roof.

After that you should knead the clay and lay it on the film layer. On top of it is expanded clay. To ensure a high level of thermal insulation, experts recommend making a mixture consisting of large and small granules. As a result, the embankment will be homogeneous.

If the cottage is located in a region with a cold climate, the layer thickness of 150-200 mm should be increased to 500 mm. Otherwise, insulation works will have no effect. For this reason, mounds of expanded clay are rarely used for warming houses, since the weight of the insulation is large.

On top of the granules is a screed consisting of a cement-sand mortar 50 mm thick. The mixture should be thick, so that the particles of the screed do not spill into the insulation. As a result, you will have a sufficiently strong floor surface that allows you to store massive things in the attic or install a boiler. A great advantage would be the environmental friendliness of this technology and the fire safety of the material.

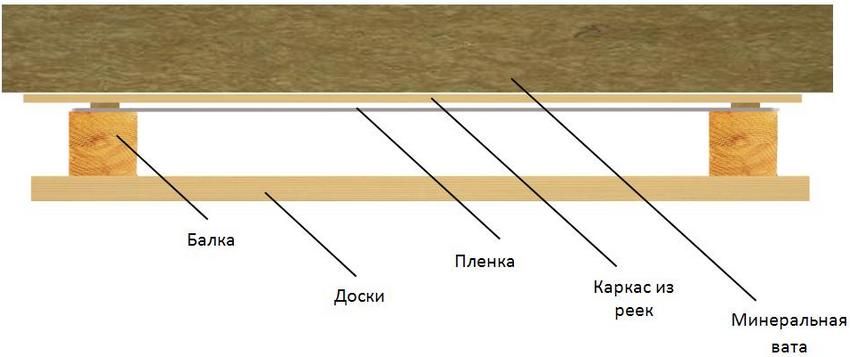

Minvat is considered one of the most used and popular heaters. This material processes the attic area, since its characteristics are optimal for carrying out such types of work.

Various materials are used as raw materials in the production of mineral wool:

- cullet;

- sand;

- blast furnace slag;

- stone rocks (basalt).

For this reason, the range of insulation is quite wide:

- slag wool;

- glass wool;

- basalt cotton wool.

Note! The group of mineral wool insulating materials has one major drawback. The production uses phenol-formaldehyde resins as a binder. During operation, insulants release substances harmful to human health into the air. This carries a danger to all tenants.

Slag is made on the basis of blast furnace slag. As a heater for residential premises of the house it is of little use. In the attic area, the humidity level may be elevated. The probability of the formation of such conditions increases during the transition period (autumn, spring).

Due to the high hygroscopicity of the material is subjected to rapid wetting, which greatly reduces its thermal insulation characteristics. Acidity, which is formed when wet, even after removing slag wool, has a negative impact on other types of building materials. This effect is especially noticeable in ferrous metals.

Slag is made of caustic fibers. For this reason, this type of insulation is not recommended to be laid in residential premises. The slag structure is extremely fragile. In case of any damage, small particles are formed, which are so light that they can be suspended in the air. And it is dangerous to health.

Slag has only one advantage – low cost in comparison with other types of insulation materials.

Glass wool refers to a group of materials referred to as mineral wool. The technology of its manufacture is based on the use of molten glass mass. On production, thin fibers are drawn from this mass. After that, a canvas is formed from them, which is converted into rolled material by rolling. In the range there is another form of glass wool products – mats.

Note! The thermal conductivity of glass wool is much lower than that of a material made from slags. The level of water absorption is 0.55-0.8 kg per 1 sq. Km. m

Glass wool can not be called the most suitable material for insulation, however, it is often used for processing attic floor. Often, the material is combined with other heaters.

For the same reason as in the case of slag wool, glass wool can only be stacked from the attic space. Small particles of fibers cause irritation of the mucous membranes and skin, so you should protect the living quarters from contact with this type of material.

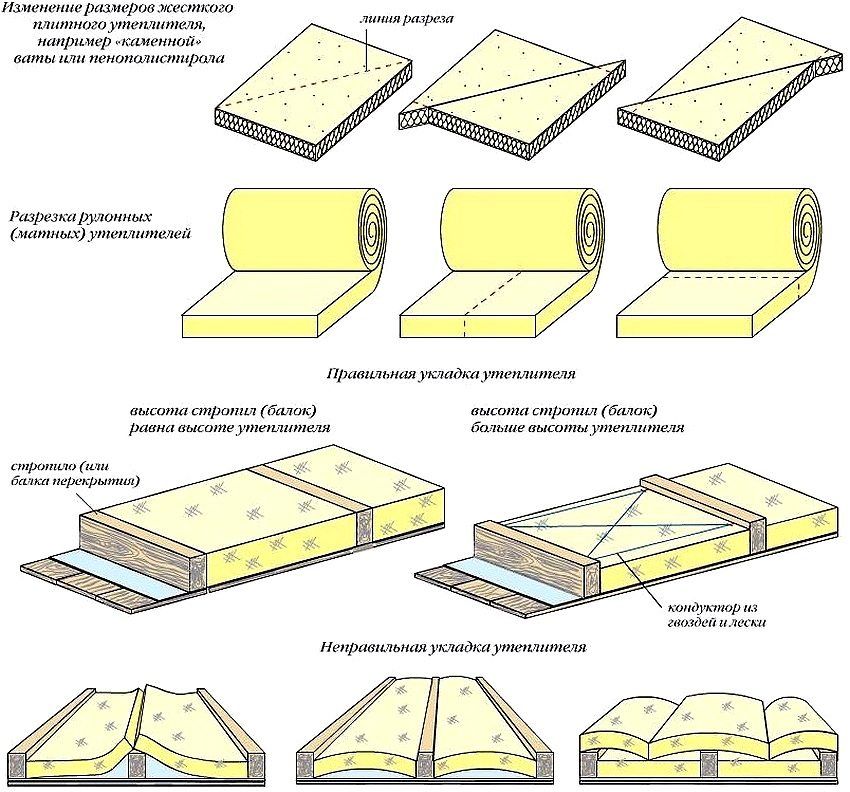

Gabbro-basalt rocks are used for the production of basalt insulation. This material is optimal for work on the insulation of the ceiling plane from the inside of the room. Basalt wool fibers are the most plastic of all, so the level of their fragility is extremely low.

The material is marketed in the form of tightly pressed mats with high strength characteristics. Since basalt wool is invulnerable to external factors, insulation can be done even from the attic. In addition to rolls, you can buy slabs of gabbro-basalt rocks with different density indices.

Some manufacturers equip basalt wool with foil interlayer, which is aimed at strengthening the insulating properties. The shiny foil coating perfectly reflects the heat back into the room, preventing its exit.

The URSA company offers consumers the most demanded type of insulation – mineral wool. This manufacturer specializes in the manufacture of materials for thermal insulation based on fiberglass and minerals. Mineral wool “Ursa” has two forms of release: hard plates and rolls.

Helpful advice! It is better to use rolled products for warming rooms with wooden floors, placing the material between the beams. Plates are more suitable for carrying out heat insulation works in cottages with concrete floors, although their use in timber structures is allowed.

To insulate the surface of concrete floors, the plane should be carefully leveled for further work. This zone is covered with a film coating, after which you can begin to lay the plates. Installation is carried out vrazbezhku.

The surface is covered with flooring, which can be formed from plywood or wooden boards. The permeability of concrete is very low, so you do not need to perform a screed on top of the slabs. This procedure will reduce the insulating properties of the material.

The scheme of warming the wool produced by the company URSA wood floors:

- the space between the beams is covered with a material with vapor insulating properties. This stage should not be missed because mineral wool loses its beneficial properties when wet. The laying of the film is overlapped, and the joints are sealed by sticking tape. Mandatory lapping on the wall is 150-250 mm;

- A roll of mineral wool of appropriate thickness is laid over the film. This indicator depends on the level of heat loss in the house and can be in the range of 10-25 cm. Installation is carried out in such a way that the material is placed in the space between the beams with little effort. To ensure the necessary fit density, mineral wool should be cut with a margin. The size of the segments should exceed the size of the space between the beams by about 20 mm;

- floor covering is formed. Of course, you can not cover the insulation, but in this case, the attic will not be able to walk. It is recommended at this stage to install the wooden floor. Laying boards is carried out so that between them and the insulating material left a free space of 3 mm.

Note! Mineral wool in relation to fire safety is very convenient, so the organization of a wooden floor on top of insulation will be the right decision.

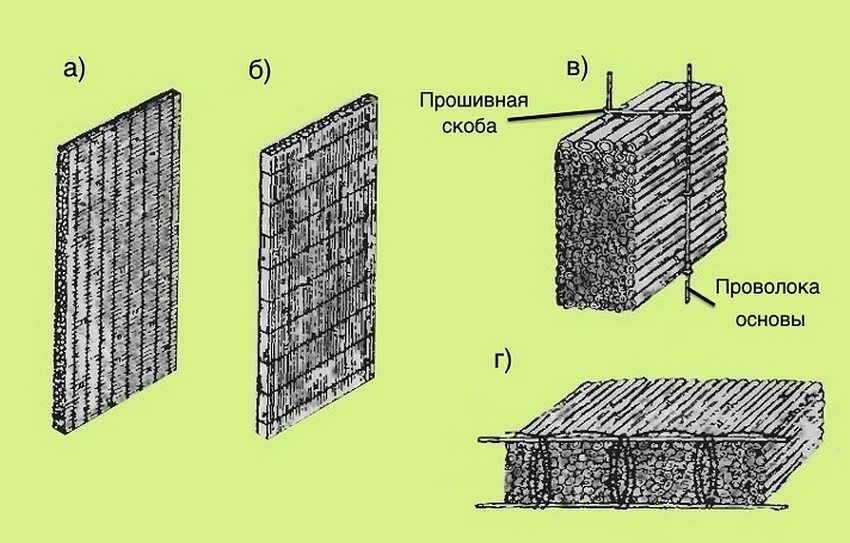

Mats formed from reeds will be an excellent insulating material. Products are tied with wire or twine. Installation of insulation is carried out over the ceiling so that the seams are placed in a razbezhku.

It is recommended to lay the mats in two layers. This is done in such a way that the second layer overlaps the joints that are formed between the mats of the first layer. This pattern of laying is aimed at eliminating the formation of cold bridges.

Natural materials for warming include algae. In the cities of the coastal region, this type of raw material can be purchased for a pittance, or you can order delivery to almost any part of the country.

Seaweed ladders have many advantages:

- hypoallergenic;

- therapeutic effect on the human body due to the large amount of sea salt and iodine in the composition (in the course of operation, useful pairs of algae are released);

- the absence of such a problem as damage to the insulation by small rodents;

- the material is not capable of supporting the combustion process and does not emit any smoke at all;

- the material is not afraid of insects and does not have the conditions for the development of microorganisms.

Note! The installation of algae ladders does not require prior organization of the vapor barrier.

Laying ladders carried out directly on the floor or overlap. The optimum layer thickness is 20 cm. Board should be placed over the algae or a full wooden floor should be organized.

The second name ecowool – cellulose insulation. This material of the modern generation is less popular than mineral types of insulation, however, it is more environmentally friendly and has a natural origin.

The advantages of products made on the basis of cellulose:

- when applied to the insulation, the treated surface seems to be preserved – there is not the slightest chance for the development of microorganisms and mold under it;

- Laying of layers of any thickness is allowed, because the material has a low weight, even under the condition of dense tamping. As a result, the overlap in the attic will not become heavier due to the large amount of ecowool, while the level of insulation of the ceiling will be very high;

- long service life with full preservation of properties throughout this period;

- insulation is completely environmentally friendly, and its operation is not accompanied by the release of toxic fumes;

- if necessary, the layer of material can be further compacted. The installation of thermal insulation is carried out fairly quickly, especially if specialized equipment is used for its installation;

- when installing insulation, a seamless and completely hermetic coating is formed that does not let the heat or cold through;

- The low flammability of cellulose wool is supplemented by the possibility of self-extinguishing. These properties are obtained by treating the material with flame retardants directly in production. When arson does not produce a large amount of smoke, and the insulation does not emit hazardous to human health products of combustion;

- the breathing structure of the material makes it possible not to linger in moisture inside the insulation.

Note! The recoupment of the procedure for insulating ceilings with this material comes after 2-3 years. This period depends on the method of laying cellulose cotton and the thickness of the layer.

The structure of ecowool is made up of fine cellulose fibers. The process of installation of insulation is carried out in two ways: “dry” and “wet.”

The basis of the “dry” technology is the scattering of the material, followed by distribution and tamping in the space between the floor joists. Ecowool is a natural absorbent, so there is no need to pre-lay the film.

The wet installation works are carried out with the use of specialized equipment that applies cellulose fibers mixed with glue on the floor surface under pressure.

The blown system allows you to blow all of the cracks with ecowool – as a result, a solid coating with air particles inside is formed on the surface. For most regions, a layer of material 25 cm thick is considered optimal. Houses located in cold regions need to increase the layer thickness to 0.4-0.5 m.

The scheme of installation of insulation with a spray of water has its advantages. The presence of moisture accelerates the formation of lignin. A crust hardens on top of cellulose wool 1-3 weeks after application. Taking into account the fact that over time the material is subject to caking, it is always necessary to provide a certain stock (about 5-15%).

The material, called penoplex, belongs to the category of extruded polystyrene foam. This kind of insulation is much stronger than conventional foam, although it has related features with it. Due to this, penoplex can be used for carrying out insulation works on concrete floors, before the formation of a concrete floor in the attic.

Helpful advice! Engage this material in the process of warming the first two floors in a low-rise building of a private type.

In the presence of wooden ceilings in the house from the use of penoplex better to refuse. The surface of the products completely does not allow air, which will entail the accumulation of moisture, which creates comfortable conditions for the development of mold.

The surface to be treated should be checked for any irregularities. If defects have been identified, they must be eliminated by leveling. Only then can you take up the installation of a vapor barrier material.

The next layer is the foam plates. The layout of their placement on the surface is scrambled. Fixing insulation to the surface is carried out using special dowels, equipped with a mushroom-type hat.

The joints between the plates should be processed using foam, carefully filling all the free space. After the sealant has completely dried, the cement-sand screed is cast. The minimum thickness of the layer – 50 mm. When the solution hardens, you get a solid base surface on the second floor or in the attic.