Furniture is the final element in the overall interior of the room, so its choice is a rather complicated and responsible process. Its presence, shape and placement are reflected in the overall comfort of the room. Furniture made of wood in this respect greatly benefits in comparison with other materials. About what advantages it has, what types of wood should be preferred and which models to choose for making with their own hands, will be discussed in the article.

The versatility of solid wood furniture: facts from history

Began to use wood for the manufacture of furniture for a long time. Researches of archeologists and other artifacts testify that in five centuries BC a joinery business appeared, specializing in interior items. A real discovery for our ancestors was the fact that a tree is much better treated than a stone, and various objects can be made from it. Then there was no technology for the production of individual parts, so it was practiced to make furniture from solid wood by carving from a piece of wood.

Gradually, the production of furniture turned into a separate craft and even an art form. For example, interior items in the Renaissance period were somewhat moved away from their main destination. Masters began to saturate them with carved details, paintings and even jewelery made of precious stones. Then valuable types of wood were discovered, for example, mahogany furniture, which is still considered the most expensive.

In modern furniture production, wood has gradually begun to yield to other materials that are cheaper, and the manufacturing process is simpler. When abandoning a tree, they are guided by such stereotypes as:

- vintage antique wooden furniture, does not fit into the modern style;

- cumbersome and heavy weight;

- high cost.

At the same time, neither plastic, nor wood-shaving, and even more metallic household items, are unable to give the room warmth, coziness and comfort, which is created by wooden furniture. Not to mention the smell that wood radiates. These factors contribute to the preservation of a large number of fans of wooden furniture.

The favorable atmosphere of comfort and coziness created by wooden furniture is a weighty, but not the only, advantage.

Helpful advice! For the manufacture of furniture made of wood is better to take the wood of the same species. If mixing is unavoidable, then a material with the same structure should be selected to prevent uneven drying.

There are a number of advantages of wood in the production of furniture in comparison with other materials, in particular:

- Durability and strength. The material is durable and resistant to various atmospheric influences, and if properly processed it will last for more than a decade. There are models that have been used for over a hundred years.

- Beauty and attractiveness are achieved through special carving or inlay.

- Naturalness and environmental friendliness. The tree does not contain harmful substances that threaten human health.

- Ergonomics and ease of use. Furniture is made to order, taking into account the wishes of the owners and the dimensions of the room.

- The possibility of restoration and repair. Due to the use of special tools and technologies, the original appearance is easily returned to the item.

- Versatility. Wood furniture will fit into any style.

- Exclusivity and uniqueness. A custom-made or hand-made model will become a well-deserved object of attention.

- Sustainability. Due to the large weight of wood furniture is not easy to budge, but also hard to overturn.

Wooden furniture is produced in two ways:

- solid wood shields made of solid wood;

- from pressed or glued shields, where thin wooden plates are interconnected, forming a holistic sheet.

Shields come in different shapes. The color of wood for furniture depends on the type of wood and is represented by a rich palette – from dark to light colors. Thus, you can easily choose the option for a particular interior. Shields are ideal for the production of a variety of cabinet furniture in the kitchen, hallway, bedroom, living room or nursery. The type of material depends on the texture of the selected tree.

Natural wood panels are expensive. Therefore, in order to save in the manufacture of furniture with their own hands using chipboard. The material is quite popular, but in terms of reliability, durability and durability is significantly inferior to solid wood. Furniture made of chipboard can not withstand shifts and crossings.

If the question of saving on material is not worth it, then it is better to take as a basis shields from the array. It is necessary to use only high-quality material, which is determined by the absence of knots, close placement of rings. The denser they are, the stronger the material. It is especially important to consider the quality factor in the case of choosing a pine. It is necessary to check the wood for the presence of fungus, which is manifested in its uneven color.

Helpful advice! If the high cost of material scares, you can make wooden furniture from improvised means. Snags, and remnants of building materials, and even pallets will do. It is enough to connect ingenuity and fantasy to get the original furniture made of wood. Photos of such interior items can be found in sufficient quantities on the Internet.

For the manufacture of wooden furniture using different tree species. The main thing that must be considered when choosing them is the degree of hardness of the material. Solid wood is needed to create load-bearing structures designed to withstand heavy loads during operation. In this case, the arrays of oak, beech, elm, as well as apple and sycamore trees are perfect.

Soft wood is used for facades and furniture decoration. Since it is easy to process, it gives an opportunity to get a figured detail of the desired size. Such breeds include cedar, pine, birch. Also used poplar, alder, willow. In addition, you need to take into account the texture and texture of wood. Beech and linden have a smooth surface. Walnut, oak and ash give a certain relief.

Below we consider in more detail the most popular breeds used in the manufacture of furniture:

- Pine is a soft rock and a popular material that is subject to strong mechanical stress. Used in the manufacture of carved furniture made of wood and accessories.

- Birch is a wayward material related to soft breeds. After painting it becomes more attractive. Used to create interior items that are not under great load.

- Willow in furniture production is valued by its vine. Wicker tables, chairs and baskets give the interior a special flavor. Particularly original willow country furniture made of wood.

- Oak has maximum hardness and durability. Despite this, it is easily processed, resistant to moisture, invulnerable fungi and insects. Oak furniture is large and sturdy wardrobes, dressers, tables and beds. Products serve many decades and even centuries.

Even before work begins, it is necessary to take care of the availability of the necessary amount of material, the entire arsenal of equipment and tools. To create furniture you will need a woodworking machine, with which you can easily create parts of various shapes and sizes. But using this equipment requires certain knowledge and skills. You also need to prepare for the processing of wood planer and jigsaw; for connecting parts – screwdriver, hammer, screwdriver, hardware; for decoration – paint, varnish, brushes, accessories, furniture stapler and knife.

Helpful advice! To create a project, it is best to use special computer design programs, in particular Google SketchUp 2018, T-FLEX Furniture Elekran, Software – 3D-Constructor, SketchUp.

The direct production process includes the following steps:

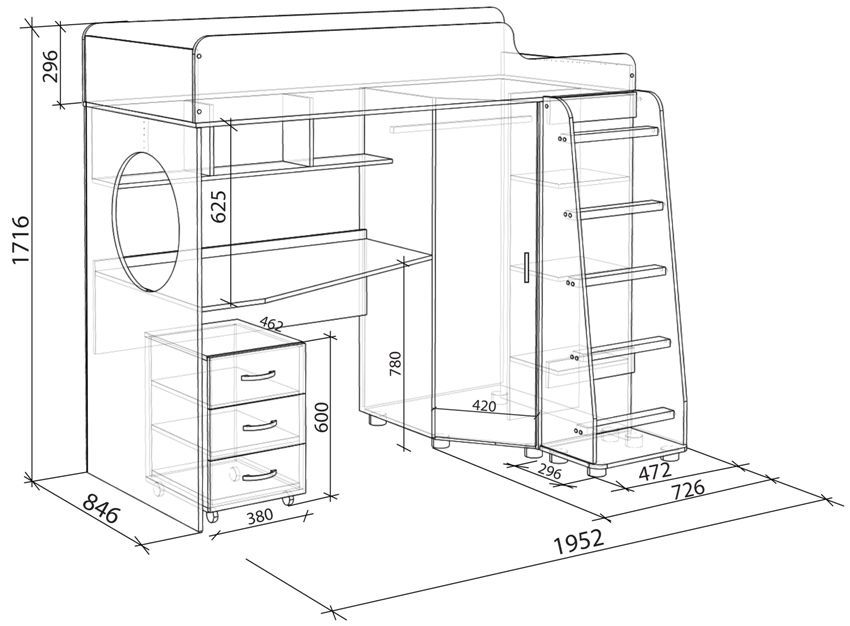

- creating a project. At this phase it is important to foresee the future location of the object, its functional purpose and, consequently, the shape and size. All details should be considered in the drawings;

- markup The draft is transferred to the material. It is important to maintain accuracy up to a millimeter;

- sawing parts. To do this, use a saw, hacksaw, jigsaw or machine. It all depends on the size of the future part;

- treatment of the material with special means that will provide moisture resistance and bioprotection from fungi, mold and insects;

- cover with a decorative layer. You should use special varnishes and paints for furniture made of wood. It is important to paint before joining the parts into a single design so that the coating is applied in all places;

- assembly Details of future furniture are interconnected in various ways using glue, dowels or slats. It is important to the minimum use of metal hardware. This affects the value of wooden furniture.

Independently create a drawing is quite realistic, but it is easier to use ready-made schemes and sketches, which are numerous in the network. Own original project has indisputable advantages, as it guarantees the receipt of a unique household item in accordance with the requirements and characteristics of a particular family, the place of its future location and destination.

If you decide to implement your original idea, then you should consider the following nuances:

- material used;

- options for connecting parts;

- the size and shape of the future subject;

- estimated location;

- purpose and conditions of use of furniture;

- the need for protection;

- finishing options.

Working on the knurled pattern, you can avoid mistakes that were made, and then corrected by predecessors and tested on the finished product. For this purpose, you can search for interesting ideas on professional websites, special forums and even in groups of social networks. Typically, beautiful drawings and photos of wood furniture with their own hands are accompanied by detailed instructions, diagrams, master classes and video recommendations. If you follow the phased advice, the process of making furniture is greatly accelerated, and it also becomes possible to avoid a number of mistakes.

Remove contamination from the polished surface of wooden furniture with gasoline. To do this, just wet the rags in gasoline and wipe the stain. If, after drying the surface, the stain is still present, the action must be repeated. After that, you need to wipe the base with a clean, dry cloth and apply denatured alcohol or linseed oil, which will help restore the damaged polish. Stains from hot objects can be eliminated with vodka or alcohol.

The wooden furniture is not only a subject for functional use, but also an important element of the general interior. For lovers of the beautiful, exquisite, natural and exclusive as well as possible in the setting fit wood furniture. Its price can be quite high, given all the advantages, in particular strength and durability. Solve the issue with the cost will help self-production of household items. In the presence of certain skills, equipment and tools will have to spend only on quality material.