Having chosen the fence of corrugated board, you get a decent elegant design that will not only mark the perimeter of home ownership, but also protect the yard from prying eyes. A variety of colors allows you to choose a material consonant with the existing facing and roofing coatings. A light weight and simple installation method makes it possible to install a fence from a professional sheet with your own hands, with even minor skills in construction.

Properties and advantages of metal sheets for the fence

The appearance on the market of corrugated sheeting contributed to the widespread use of this material in various areas of construction. It is successfully used for fencing the territory of private, public and industrial use. The material has a number of unique properties, allowing to give preference to the device of fences from a professional sheet:

- high strength and durability – thanks to the stiffeners, wall profiled sheet has the strength with low weight. The strength of the panels is influenced by the thickness of the sheet, the shape and height of the ribs. The polymer composition of the coating prevents corrosion and provides the material with a long service life, which can be 40-50 years;

- resistance to wind load – depending on the strength of the wind prevailing in your region, you can choose the required sheet thickness able to withstand such a load;

- wide range of colors – professional sheet is available in various colors, which can be selected on the RAL scale (color standard) based on individual preferences and maintenance of the architectural composition;

- universality – the material can be used not only for fencing, but also for the construction of small outbuildings and sheds;

- sufficient noise insulation – the fence is able to delay street noise and the hum of passing cars;

- simplicity and ease of installation – lightweight corrugated material, it can be installed even by one person, fastening is carried out using special self-tapping screws with polymer coating;

- ease of care – profiled sheet is well washed in the usual way, does not require periodic repair. If random damages form during the installation process, they can be quickly eliminated by treating the scratches with paint of the corresponding color from the cartridge;

- attractive price – sheets of metal profiles for fences have an acceptable cost in comparison with materials such as traditional metal, brick or stone.

Helpful advice! When choosing decking for fencing, give preference to wall sheets that have a lighter weight and a variety of profile shapes. Such material has a lower cost than the roofing counterpart and as a fence can easily cope with the wind load.

Wall profiled used for fences, characterized by the shape of the profile with a small trapezoid height – 8-25 mm and is characterized by simplicity and elegance of the coating. It can be used as an independent fencing structure and as a background, for example, for a wrought fence.

In order to correctly calculate the required amount of material when installing the fence from a professional sheet with your own hands, as well as correctly plan the step between the support posts, you need to be aware of its basic dimensions and markings.

Sheets of sheeting, given the configuration and the height of the profile, are classified into separate groups:

- C marking – wall profiled sheet used for the construction of walls, partitions and enclosing structures, as well as for decorative surface cladding and wall insulation;

- H marking – bearing professional sheet used for the construction or strengthening of supporting structures;

- NS marking is a universal metal profile, which has found application in roofing, wall and ceiling finishing. Differs in considerable height of a leaf with a small thickness and height of a wave.

The main difference of the wall profile from the carrier is the height of the trapezoid and the presence of additional stiffeners. Such a difference is explained by the use of H-grade profiled sheeting in structures where the load on the material is much higher.

The length of the sheets varies depending on the manufacturer of the metal profile and varies from 0.4 to 12 m, however, a height of 2 m is considered standard. The following are the parameters of the most used professional flooring grades.

Table 1: Professional sheet for the fence: sheet sizes:

| Sheet parameters mm | Brand profiled sheet | |||||

| From 8 | From 10 | From 18 | From 20 | From 21 | CH 35 | |

| Total width | 1200 | 1150 | 1150 | 1150 | 1051 | 1060 |

| Working width | 1150 | 1100 | 1100 | 1100 | 1000 | 1000 |

| Metal thickness | 0.4: 0.8 | 0.4: 0.8 | 0.6: 0.7 | 0.45: 0.7 | 0.4: 0.7 | 0.5: 0.9 |

| Wave height | eight | ten | 18 | 20 | 21 | 35 |

| Edge spacing | 62.5 | 45 | 91.67 | 137.5 | 65 | 70 |

Helpful advice! The installation of profiled sheets is overlapped, it is necessary that the larger edge of the rib completely covers the edge with a smaller edge.

The cost of the profiled sheet depends on several factors: the thickness of the metal, the shape of the profile and the type of protective polymer coating. With increasing thickness of the metal increases its value. For example, the price of profiled sheeting with a thickness of 0.7 mm will be higher than a similar sheet of 0.4 mm by about a third.

Quite a budget is considered to be a galvanized sheet. The zinc coating makes the material resistant to the formation of corrosion in comparison with ordinary sheets. In turn, the professional flooring with polymer coating has a greater degree of protection, but its price is 30-35% higher than galvanized.

Fences from a grid giter, fences from a grid of the chain-link. Photos of good options. Photos of structures, their features. Mesh giter for fences. A fence from a grid the chain-link with own hands. Plastic mesh fencing.

As for the shape of the profile, the higher it is, the stiffer the larger and higher the bearing capacity of the sheet. Accordingly, the cost of such material will be more. The number in the marking of the metal profile indicates the wave height in mm. For the device of a fence from a professional leaf, they mainly use a wall profile, which is considered to be the most economical, and less often, roofing sheeting is used.

Below are the estimated prices for popular types of professional sheets from different manufacturers.

Table 2: Price of metal sheets for the fence “:

| Brand, manufacturer | Mark | Type of cover | Metal thickness, mm | Sheet width, mm | Length sheet, mm | Price per m ?, rub. | |

| full | working | ||||||

| Grand Line Optima, Russia | C08 | not | 0.4 | 1200 | 1160 | 500-8000 | 209 |

| Grand Line Optima, Russia | C08 | polyester | 0.35 | 1200 | 1160 | 500-8000 | 232 |

| Grand Line Optima, Russia | C08 | polyester | 0.4 | 1200 | 1160 | 500-8000 | 239 |

| Grand Line Optima, Russia | C10 | not | 0.5 | 1180 | 1150 | 500-8000 | 318 |

| Grand Line Optima, Russia | C10 | polyester satin | 0.5 | 1150 | 1110 | 500-8000 | 350 |

| Grand Line Optima, Russia | C08 | polyester | 0.4 | 1200 | 1160 | 2000 | 577 |

| Grand Line Optima, Russia | C21 | polyester | 0.5 | 1051 | 1000 | 500-12000 | 698 |

| Grand Line Optima, Russia | C10 | polyester | 0.5 | 1180 | 1150 | 500-3000 | 742 |

Helpful advice! In order not to overpay for the brand when buying a corrugated board, you can purchase material from lesser-known, but producing quality products manufacturers. Pre-worth reading reviews and recommendations.

Given the huge choice of color performance, the profiled sheet for the fence can be selected in any shade you like. The most commonly used colors for fences are brown (chocolate), green (moss green), cherry (red wine), fences of these colors look three-dimensional and aesthetically pleasing. Very popular profiled sheets, made with a texture that imitates wood or granite.

A separate group can be identified fences of corrugated board, which are combined with wood, stone, brick or metal. The ability of the metal profile to combine gives unlimited possibilities for the manifestation of designer imagination. Often in the fences use a combination of several types of material, for example, bricks, forged elements and profiled sheet.

The classic option includes a fence made of corrugated flooring with pillars of natural stone or brick, depending on the architectural development of the infield. Due to the construction of the concrete base, the ground part of which is faced with the appropriate material, such a fence has a majestic appearance. It should be noted that it is necessary to build a foundation for a fence with brick pillars. For example, you can see the photo of the fences from the profiled sheet with brick pillars.

For a brick or stone construction to look appropriate, it is important to choose the color of the professional flooring correctly. For example, a professional sheet of an oxide-red color group or a shade of terracotta perfectly combines with a burnt brick. If the pillars and the parapet are lined with gray natural stone, the composition can be supplemented with a sheet of light aluminum color or profiled with a dark gray coating.

Quite interesting are the solutions of fences, where the profiled flooring is enclosed in a metal frame or framed with a special strip along the upper edge. The profiled sheet covered with such a lath is more reliably protected from corrosion. The presence of edged sections in the fence makes the construction of gates and wickets almost imperceptible. Such fences have a neat finished look.

Not so long ago, professional flooring for fences with a curly upper edge appeared on the market. Figure sections of these fences has the shape of a wave or peak. The design of this fence is as close as possible to the traditional version of wooden fences. It should be noted that the integrity of the corrugated sheet in such a fence is not violated.

The metal profile fences decorated with carved metal or forged elements look elegant. Lace patterns of metal plates can decorate not only the sections of the fence, but the gate with a wicket. The chosen beautiful color of the background sheeting will favorably emphasize the forged compositions and will make the fence unique, keeping the shape of the structure.

Today you can buy ready-made forged ornaments in building outlets. Having chosen the picture to your taste, you can independently weld these elements to the metal frame of the fence section from the profiled sheet. Use for your inspiration photo fences from a professional sheet with your own hands.

For a complete picture of the stages of construction, read the video fences from the professional sheet with your own hands.

To learn how to build a fence of professional sheets with your own hands, you need to study the main characteristics and properties of corrugated flooring, to get acquainted with examples of installation of enclosing structures. On the Internet are numerous stories about how to build a fence of professional sheets with their own hands. The video provides comprehensive information about the stages of work.

Before starting the construction of the fence, it is necessary to make a correct calculation of the required material taking into account the main parameters of the fence: length, height and design of the fence as a whole. When calculating the required amount of profiled sheeting is taken into account the method of fastening them with an overlap, the size of which ranges from 3 to 10 cm.

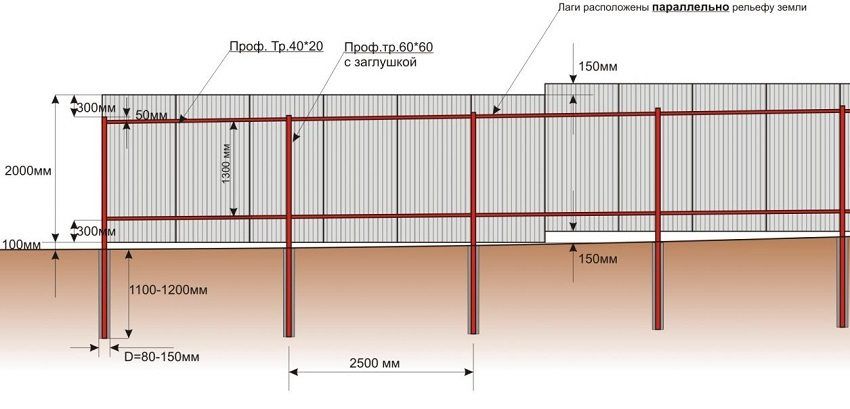

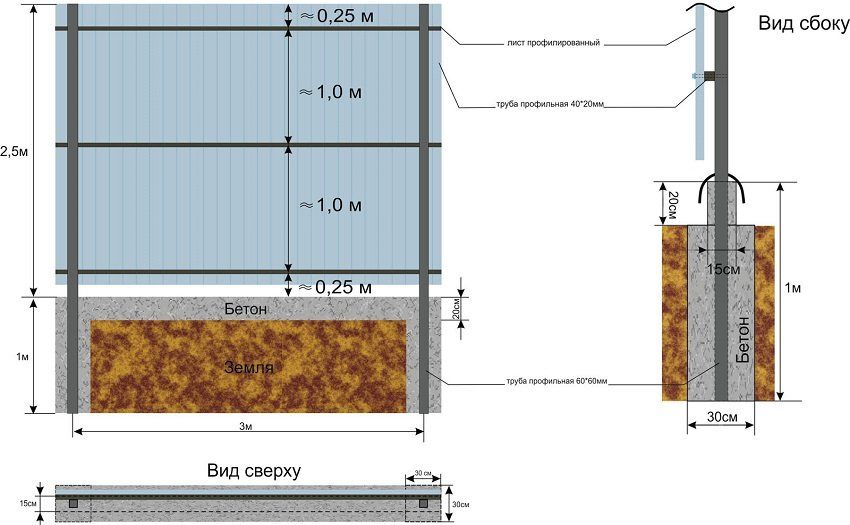

The perimeter of the site is cleared of vegetation, debris and leveled. Wooden stakes are driven into the corners of the plot, between which the cord is fixed. Marked the installation site of the gate and the gate, determined by the step between the supporting pillars. Traditionally, it ranges from 2-2.5 m to 3 m. In these places, intermediate pegs are driven in.

From the materials required:

- profiled sheet – usually for the construction of fences using sheets of corrugated grades C08 – C21. Such foxes are used when the planned fence will have a height of up to 2-2.5 m. If the future fence is supposed to be higher than 3 m, then it is recommended to use the material with marking C20, C21. Experts advise to give preference to professional sheet with a polymer coating;

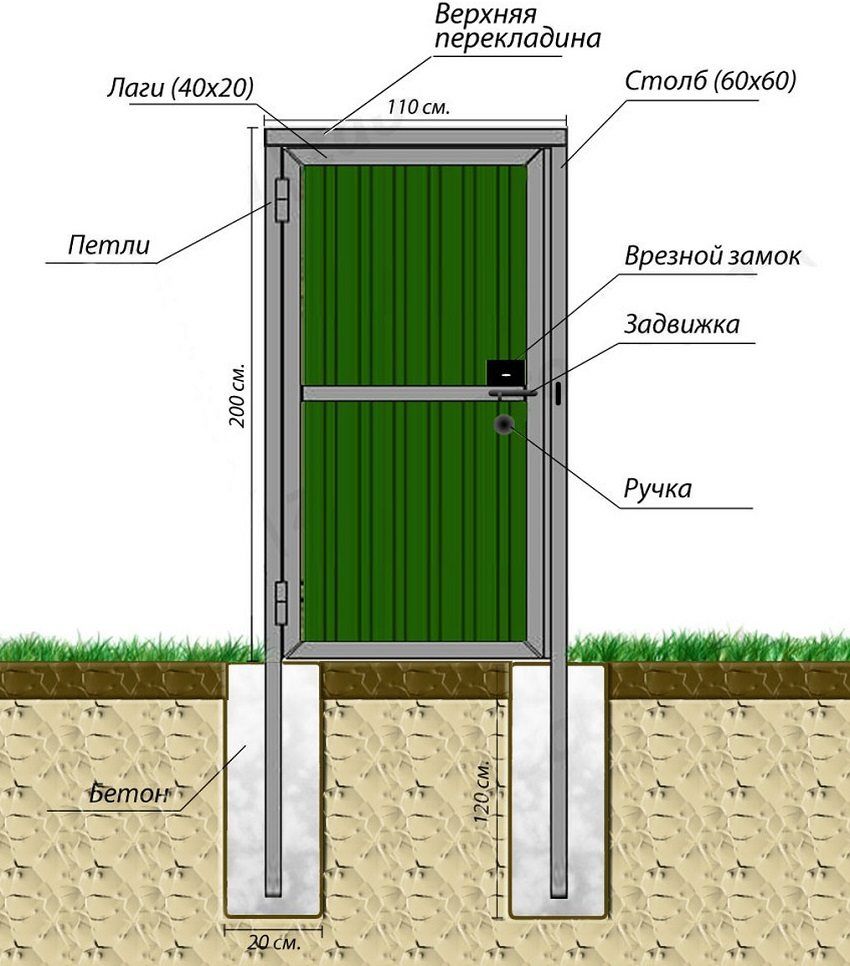

- metal supports – for holders, a profile hollow tube of square (rectangular) section 60X60 mm, 60X40 mm is used. Wall thickness is chosen not less than 2 mm. The pipe for the posts on which the gates will be supported is used with a large section of 80X80 mm;

- horizontal guides – for transverse lags to which the profiled sheet will be attached later, a profile tube of a smaller cross section is used than for vertical supports, 20X20 mm or 20X40 mm with walls of 2-2.5 mm are suitable. For the height of the fence 2-2.5 m lags are attached in two rows at a distance of 1.5 m;

- screws – for fixing sheets use roofing screws with sealing rubber washers, it is desirable to use galvanized fasteners. The pitch of the self-tapping screws is taken at a rate of 1 pm of material – 12-14 attachment points.

Helpful advice! Sheets of corrugated sheeting should be fastened to the frame with self-tapping screws with thermo-washers, screwing in the place where the lower wave of the profile passes.

When installing supports, two types of base can be used: a tape under which a trench is arranged along the entire perimeter or a separate (local) base for each support. To find out at what depth to bury the pillar for the fence, you must have an idea about the type of soil on the site. In the case of clay soils make a hole of 0.9 m, if the soil is loose – 1.2 m.

How to install poles for fences? Before installing the supports at the corners of the perimeter, the bottom of the pits is covered with roofing felt. When all the pillars are installed along their upper edge, they tighten the construction cord, thus checking the correctness of their installation in height. Intermediate supports are placed between the corner posts, keeping the distance between the fence posts of 2.5 m.

After installation of the supports in the pits, they are covered with crushed bricks, stones, they are well tamped, poured with water and concreted. Then stand for two weeks to complete setting. While the solution has not yet stiffened, check the verticality of the installation of each pillar and, if necessary, align the position of the racks.

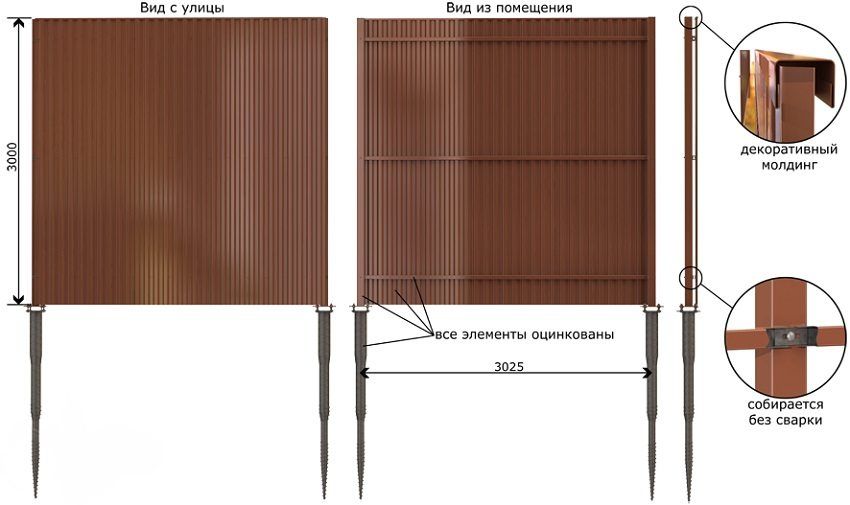

Establishing a fence from a professional sheet with their own hands, many prefer the use of screw posts for the fence. The upper part of such supports is a square tube, and the lower part is made in the form of a screw pile. Thus, this support is easy to install, twisting until the round part enters the ground. And with the square top of the pipe it is convenient to dock any elements of the fence.

If you plan to fence with brick pillars, after the supports are installed and concreted they are covered with bricks. It should be borne in mind that if the tape foundation was not arranged, then a separate foundation must be made for each brick column.

Fastening the guides of the lag to the posts is made with the help of a welding joint. The number of horizontal guides depends on the height of the fence, and the distance between adjacent crossbars is 1.5 m. After all the logs have been welded, you need to carefully clean the joining points and paint the finished metal frame.

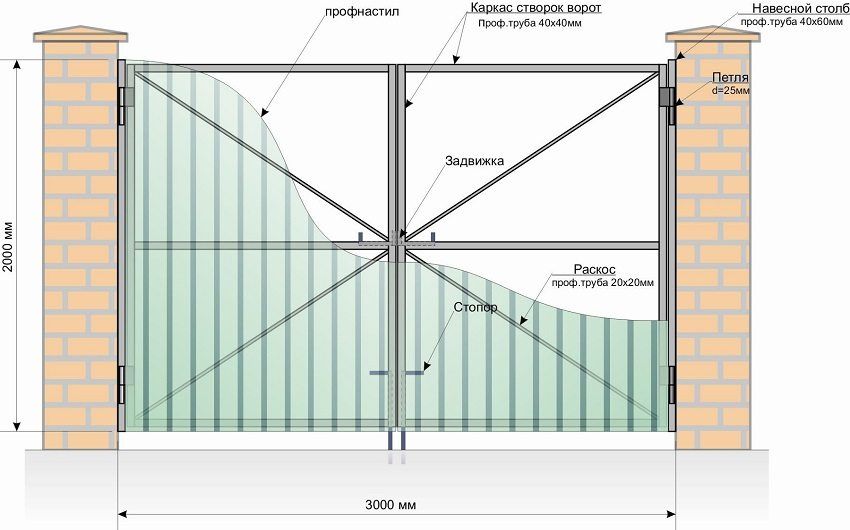

The assembly of the gate and the entrance gate begins with the manufacture of frames, the structures of which are reinforced with diagonal bridges. To give the structure stability of the gate and the gate is connected to each other by a transverse beam. The finished door frames and wickets are fixed on the supporting pillars and sheathed with a profiled sheet.

Fastening sheets profiled using self-tapping screws of the appropriate color. Overlap the sheets, covering each subsequent sheet with one wave of the next. Cladding start from the gate in both directions. The recommended step between the self-tapping screws is two profile waves.

Helpful advice! Save time installation and rational use of materials will help pre-drilling holes in the metal guides in all places where there will be screws.

Using the advice of professionals and videos on the installation of fences of corrugated board, you can independently mount a beautiful and durable construction of the fence on your backyard.