The familiar fences of wooden picket fence are fading into the past. Increasingly, residents of holiday villages and town houses use metal structures for fencing their plots. And it is quite reasonable. Profiled – material is durable, resistant to deformation and in the form of fencing has a very aesthetic look. Moreover, the fence from a professional flooring with hands with columns can be mounted by every more or less masterful technician.

Decking: universal qualities

Due to the high anti-corrosion performance, versatility in the application, easy and quick installation of profiled sheets are becoming increasingly popular.

The term of operation of a professional flooring with a polymeric covering makes up to 50 years. Designs made of metal, look aesthetically pleasing, stylish and modern. Corrugated sheets are widely used in construction: hangars, supermarkets, warehouses, roofs, fences, canopies, sheds and much more.

Do it yourself gates. Drawings, photos. Video materials installation process. The advantages and disadvantages of swing and sliding gates, especially their installation. Schemes with sizes and photos.

Due to the fact that the profiled sheeting is made from rolled raw materials, sheet sizes can be ordered individually. Profile width – from 0.98 m to 1.85 m, depending on the manufacturer. The thickness of the profiled sheet affects its resistance to damage and durability. The most commonly used thickness is 0.5 mm or 0.7 mm. For wall cladding and the device of the fence do-it-yourself use sheets with a wave height of 8-20 mm.

One more advantage of a professional flooring is a variety of colors of performance (about 30). You can choose a color according to the RAL color standard scale, based on your taste. You can always buy a can of paint of the appropriate color at the places where the metal profile is being made to handle places of accidental damage or scratches.

When choosing a professional flooring for installation with your own hands, it is necessary to focus attention on the manufacturer in order not to doubt the quality of the material.

For the device of a fence from a professional flooring with the hands with columns, you will need materials:

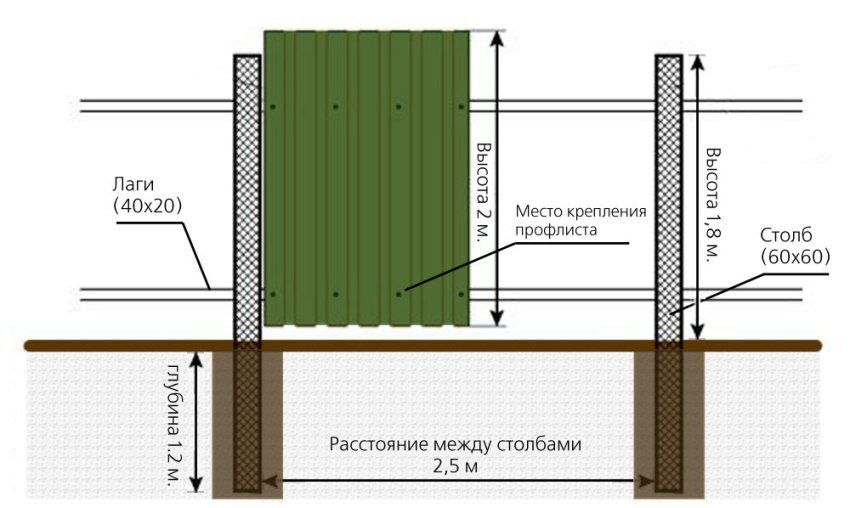

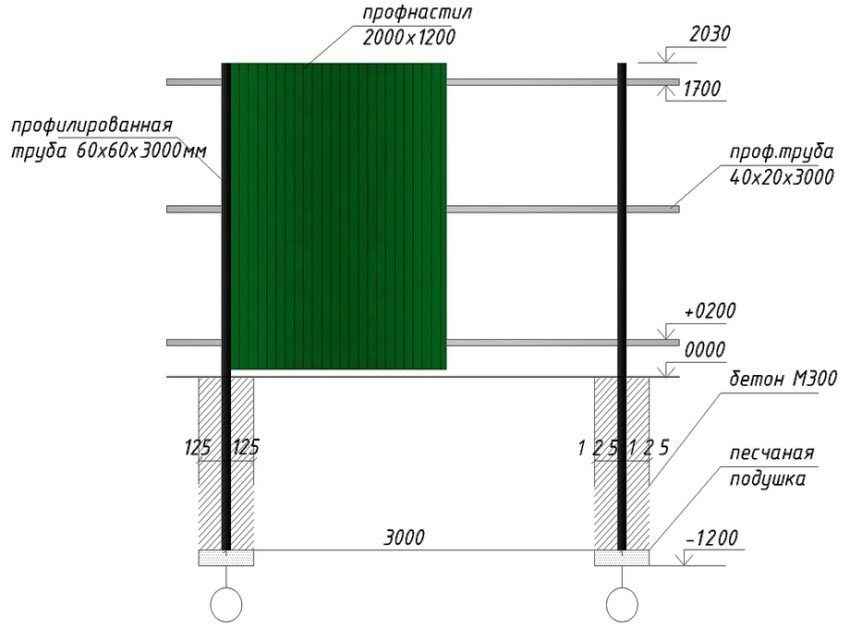

- metal pipes with a square or rectangular section having dimensions of 4×6 cm or 6×6 cm, metal thickness not less than 2 mm. Pipes will be used for support pillars;

- metal pipes are square or rectangular, the dimensions of the section 4×2 cm, metal thickness 2.5 mm. Serve for the device transverse lag;

- profiled corrugated sheets, it is desirable that the wave height does not exceed 21 cm, and the thickness is in the range of 0.4 – 0.7 mm;

- special self-tapping screws with gaskets – for fixing corrugated sheet to the frame. They are equipped with a polymer coating that prevents corrosion of fasteners, are selected in the color of the sheets.

Surely everyone in the house has a certain set of tools for doing their own hands. But so that the work does not stall due to the absence of any device, the following is a complete list of the necessary tools and equipment:

- welding machine – you will need to connect the supports with cross tubes;

- building level – to determine the vertical and horizontal of the mounted elements;

- measuring tape – preferably up to 50m in length (for data accuracy);

- metal shears – in the case of cutting professional sheets;

- Kapron thread – necessary for marking the perimeter of the fence;

- Bulgarian – with the help of which the pipes are cut and the joints are ground;

- screwdriver – used for screwing screws during installation;

- a gas drill for wells or a hand drill – if it is planned to use pipes for fencing supports.

How to make a fence of corrugated correctly and accurately? This is for those who love to equip the territory with their own hands. You can do without the involvement of master specialists, save money and enjoy the process. A fence made of corrugated flooring with your own hands, the video of which you could see on the Internet is quite a doable task.

Having decided to install the fence out of corrugated flooring with their own hands, first of all, the space around the perimeter of the territory is freed. The size of the future fencing is determined. In the corners of the intended fencing pins are clogged, which are subsequently connected with a nylon cord.

With the help of roulette is extremely accurate measurement of the sides of the site and the total length of the fence. Outlined installation site support pillars, gates and wickets for passage. To give the structure strength, it is recommended that the supports be positioned so that the distance between them does not exceed 2.5 – 3 m.

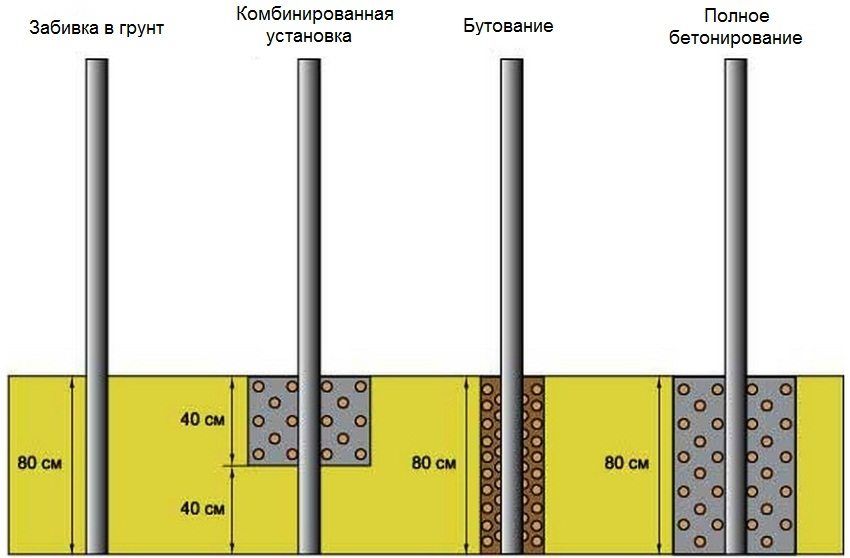

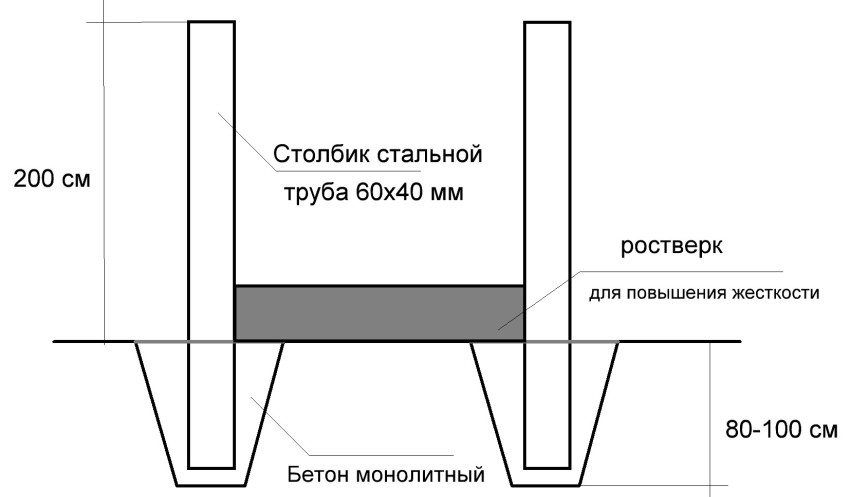

Support metal pipes are installed in prepared pits. In the locations of the marks for the supports, holes are drilled to the depth of the pillars. The length of the support pipes is determined from the calculation of the height of the fence and taking into account the depth of immersion. For reliability, a third part of the total pipe length is lowered into the ground. Pits are arranged with a drill around the perimeter at the same distance.

Helpful advice! In order not to measure the distance between the supports with a tape each time, you can use a cord, the length of which will be equal to the distance between them. This will speed up the process and eliminate measurement errors.

The installation of the pillars on the same line of the site must be done only vertically and make sure that they do not get out of one plane. To control the position of the supports, you can use a level or plumb. The first pipes are installed at the end points of one row. With the help of a cord stretched at the top between the two end supports, the height of all other pipes is fixed.

You can adjust the height of the pipes by pouring the right amount of soil to the bottom of the pit. Pipe supports bursting with wedges, avoiding their displacement. At the bottom of the pit is laid a cushion of rubble, and then poured the pits with concrete columns. It is very important to remove air from the solution using a splicing. In this state, you need to leave the support for three to four days until the concrete sets completely. Correct installation of pipe supports affects the entire structure of the corrugated fence (photo examples confirm this).

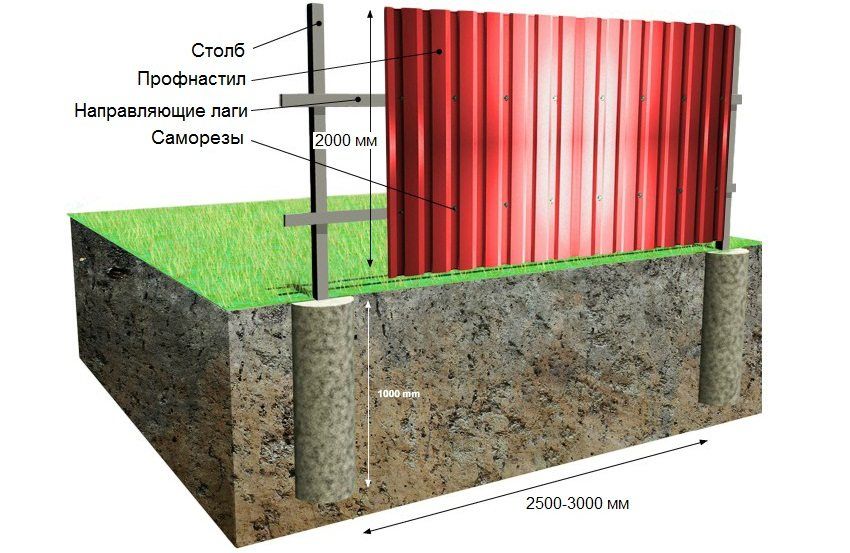

For the installation of transverse lags do square or rectangular pipes with their own hands. Cut the pipe into pieces of the required size. The number of transverse rows is set on the basis of the height of the fence itself. For a two-meter fence it is quite possible to do in two rows. Make sure that the transverse pipes are located at a distance of 200 mm from the ground and from the edge of the support.

Fastening lag is made by welding strictly at an angle of 90 °. You can check the horizontal of the pipes using a level, and this should be done along the entire perimeter of the structure. After the installation of the entire frame is completed, it is necessary to grind the attachment points and treat the entire structure with a primer or paint. The video will tell you how to fix transverse lags.

Once the frame is ready, proceed to the installation of corrugated sheets with their own hands. Decking for the fence, with dimensions of sheets 2.0×1.2 m of type C8, is most suitable for the construction of barriers. Sheets are attached to the transverse tubes with self-tapping screws for the metal profile of the corresponding color. The profiled sheets overlap, covering the previous sheet on one wave.

Helpful advice! Before you begin to fix the profiled sheeting to the lags, make in the places of fastening holes with a diameter one millimeter smaller than the diameter of the screws. This will help save time and consumables during the installation process.

If the area on which the fence is mounted, has an uneven surface, then this is taken into account when installing pipe-supports and pouring concrete. The depth of the holes for support columns is regulated depending on the landscape of the territory. Below is a photo of a barrage scheme on an uneven site.

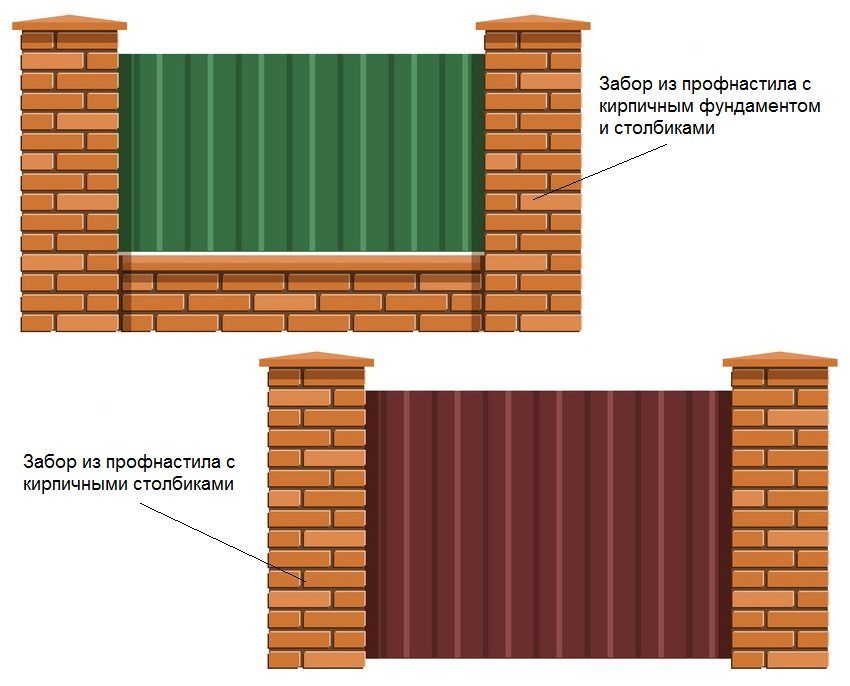

The device of a fence from a professional flooring with your own hands (photo instructions can be found on the Internet) will be more costly if you impose a metal support on a brick. But the look of such a fence will be more presentable.

With the help of pegs, the perimeter is fixed and the thread is tensioned. A trench is being dug around the perimeter for a strip foundation with a depth of 0.7 m. The dimensions of the strip foundation (side) are selected individually. The recommended size of the concrete base is 15-20 cm. The bottom is well compacted.

In order to avoid deformation of the foundation, a cushion of 20 cm of sand is arranged at the bottom of the ditch. The sand is moistened with water and compacted.

We install with our own hands a wooden formwork not less than 10 cm high and strengthen it with lintels. Then we install a previously prepared framework of reinforcement.

After installing the formwork, we place the metal pipe supports, which will later be lined with brick. Fill with concrete solution. A prerequisite – all metal supports must be in the same plane. Withstand 3-4 days.

After setting of the concrete, to the metal supports at an angle of 90 ° fasten the console. Fastening is carried out with the help of bolts or welding at a distance of 200 mm from the ground level and from the upper edge of the pipe. Later on these consoles will be mounted transverse lags. In the photo you can see how the console is mounted.

We start laying brick pillars. The post is usually laid out with the size of the sides and a half bricks. For strength, we reinforce each row of brickwork with reinforcing tape. The space inside the masonry is filled with cement mortar. We finish the finished columns with caps to prevent moisture ingress and give the structure a complete shape. The video below will allow you to deal with the technique of laying brick pillars.

Fastening of transverse lag and sheeting is done in the same way as in the case of metal pillars.

Helpful advice! If the fence of the profiled sheet is installed on the foundation, it is necessary to cover the concrete surface of the foundation with cardboard. This will save the bottom edge of the sheeting from damage.

Below is a video of the installation of a fence made of corrugated board with your own hands

If the technical technique of the device of the fence of corrugated will be observed, it will turn out smooth and accurate.

The degree of popularity of the use of wall sheeting for mounting the fence do it yourself is explained by the positive characteristics and unique properties of this material. It is equally well combined with columns of facing brick and natural stone, it can be adequately combined with a wrought fence, as well as supporting other buildings in the color scheme on the site. It all depends on your desires and capabilities. And may they always coincide with you.