Sandwich panel – a three-layer structure, which is used in the construction of buildings. It consists of two outer layers and insulation between them. These products appeared on the construction market not so long ago, but they have already managed to gain popularity among customers. This article will discuss the main characteristics of the sandwich panels: dimensions and prices, as well as other parameters.

Sandwich panel: what is it

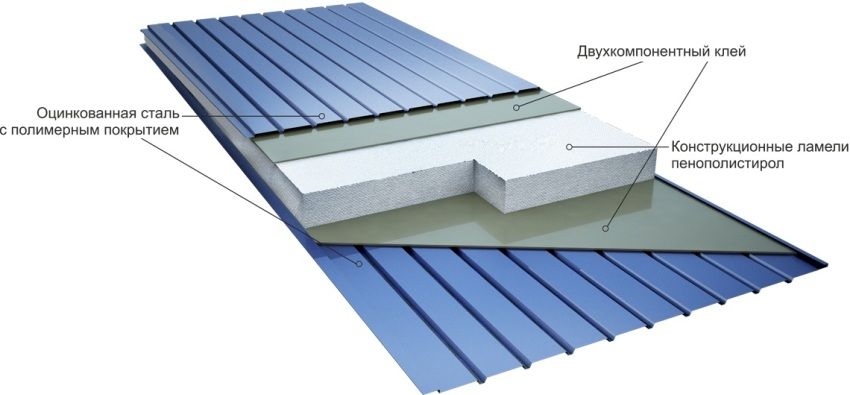

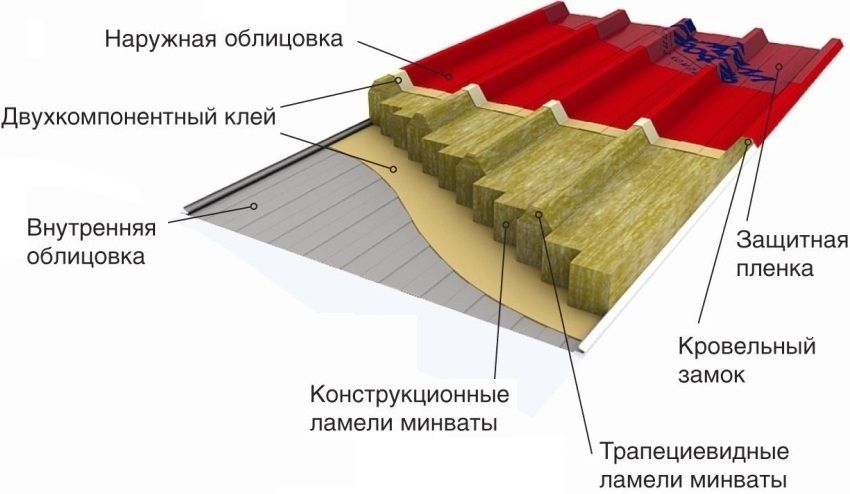

Sandwiches used in the construction of houses consist of three layers. The two outer layers are made of the same material, with galvanized steel being considered the most popular. This is due to the high technical characteristics of galvanizing, including: excellent corrosion resistance and resistance to high temperatures. Sandwiches made of aluminum and oriented strand board (OSB) are also common.

The most common insulation used in the manufacture of sandwich panels: polystyrene foam (PPS), polyurethane foam (PUF) and mineral wool. Polyurethane foam products have high thermal insulation performance and moisture resistance.

Note! In some cases, the panels are made with the addition of a fourth layer, which serves as drywall. Adding the latter to the sandwich structure allows you to enhance the fire resistance of the structure.

The main advantage of such plates is that the structure of the sandwich panels can be erected even in difficult climatic conditions. Domestic companies, in the production of such building materials, are guided by technologies used in the USA and Canada.

These building elements are practically devoid of flaws, which leads to their high popularity. Consider which buildings are built using sandwich slabs:

- residential buildings;

- athletic facilities;

- office and administrative buildings.

Such products are divided by purpose into 3 main varieties:

- for walls;

- for roofing;

- for windows.

In the first case, the installation of building elements is carried out on a metal frame. Wall plates are used to organize the outer box of the house, as well as internal partitions. Roofing and window sandwiches are also used in the installation of various structures and differ from wall models in technical characteristics and cost.

The use of sandwich plates allows you to complete the project in a short time for minimal cost. Due to the small weight of such panels, eliminating the need for a high-strength foundation.

Sandwich panels are often used in the organization of various kinds of fences, as well as for carrying out reconstruction work on various construction sites. Rigid slabs, which are distinguished by a ribbed outer layer, are used for the construction of light frame structures. Such constructions include, for example, garages and kiosks.

When choosing a material for building a house, it is necessary to pay attention to all its characteristics. Consider the main advantages of using sandwich panels:

- high speed of construction, which allows you to implement the project in the shortest possible time;

- favorable cost;

- the possibility of organizing not only mechanical protection, but also thermal insulation;

- no need for additional building insulation;

- a small mass of slabs, which allows to reduce the load on the foundation of the building. This item greatly simplifies the construction of a house of sandwich panels;

- for the installation of such plates there is no need to use special construction equipment;

- facade panels are not only material for the construction of buildings, but also a decorative element, so do not need to spend time on the exterior of the building.

Useful information! Sandwich panels are used not only as the main building material, but can also be used for cladding of a building. In this case, they act as additional thermal insulation.

Like any other construction product, they have some drawbacks that should be noted:

- a finished building made of such slabs cannot withstand considerable mechanical loads;

- during the interior decoration of rooms it is necessary to take into account the fact that overloading the sandwich plate can lead to its destruction.

Sandwich plates consisting of several layers are divided into several varieties, depending on the purpose. As already mentioned above, wall, roofing and window models of plates are distinguished. Fixing these products is made on special screws, which are distinguished by their length.

There are also PVC panels, which are used for slopes when installing windows. The installation of these building elements allows to warm the structure. You can buy a sandwich panel for slopes in any specialized store, building hypermarket or order it online. Price sandwich panels for the slope on average is 300-400 rubles.

These panels are used in facing the walls of the house and for the organization of internal partitions. With the help of them are installed and supporting structures, as their technical characteristics allow the use of plates for this purpose.

To increase the index of rigidity and strength, wall modification is reveted with sheets of steel. And also such plates have a high coefficient of thermal insulation and are fire resistant.

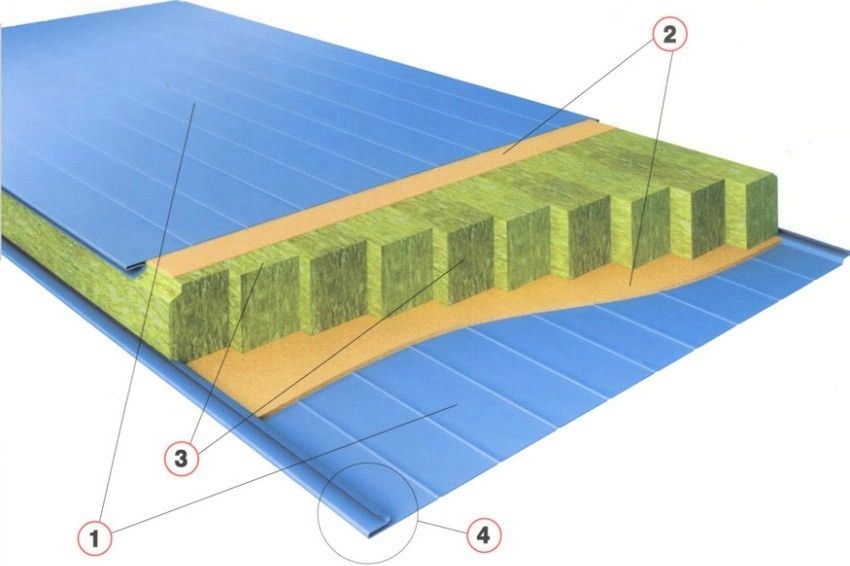

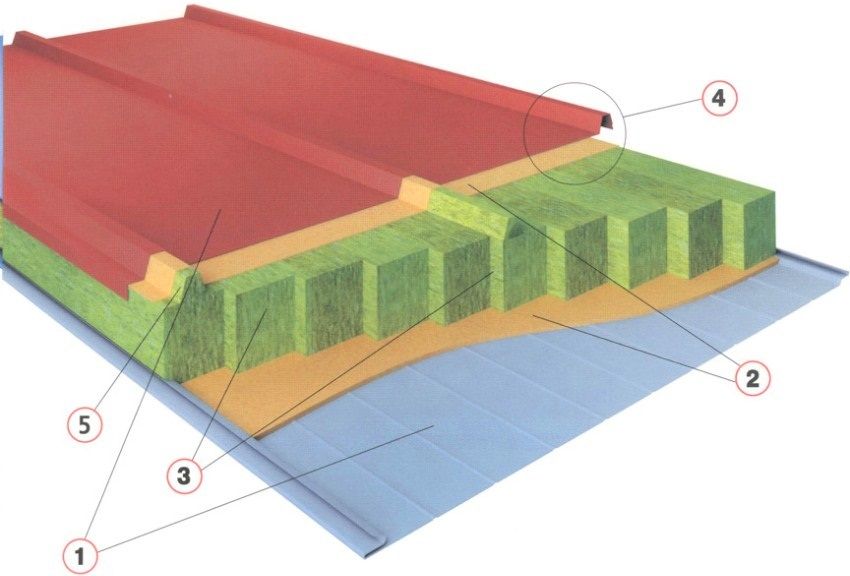

The peculiarity of the use of roofing plates affects their technical characteristics. Since roofing models are used when installing the roof, they have high moisture insulation characteristics. This property is very important, as a good roof should protect the interior of the house from precipitation.

In addition to enhanced waterproofing properties, roofing models also have insulating qualities. Sandwich panels used for the roof, keep the warm air, which tends to the top, inside the house. This allows you to reduce heat loss to a minimum. Fixing of roofing plates is made using self-tapping screws to wooden bars.

It is also worth saying that such products are noise insulating. They are equipped with special locking elements that allow for quick installation and enhance protection against precipitation. The operational life of such products is quite long. Another advantage of using roof sandwich panels is that they do not deform over time and do not lose their properties.

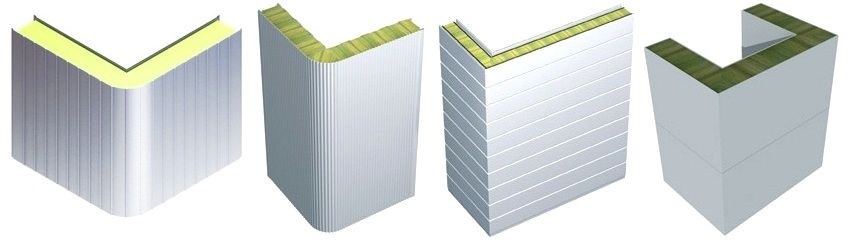

Corner sandwich elements are used to design and protect the corners of the building from the effects of low temperatures. Very often, residents of houses are faced with the fact that poorly insulated corners of the building are frozen in the winter season. Such plates can have one of two forms:

- rectangular;

- rounded.

The corner plate can have a thickness of from 60 to 250 mm, and the length and width of the sandwich panels are in the size range of 0.4–3 and 1–1.2 m, respectively.

The cost of corner panels with basalt fiber insulation varies between 1,500–2,500 rubles. for 1 m.

The outer facing layer of the sandwich panel can be faced with various materials. They perform not only protective, but also decorative function. Consider what materials are used for facing sandwich plates:

- porcelain concrete;

- ceramic tiles;

- gypsum plasterboard;

- OSB;

- MDF;

- DSP;

- Hardboard;

- aluminum;

- stainless steel;

- galvanized steel.

Note! Metal cladding at the production stage is equipped with a protective coating – zinc-coated or polymer layer. This is necessary to enhance anti-corrosion properties and the stiffness index of the plate.

Consider the composition of the exterior cladding in more detail:

- steel sheet, which has a thickness of up to 0.5 mm;

- zinc layer or decorative layer of polymer material (thickness up to 0.25 mm);

- varnish or paint.

- Before installation, check the plate locks. Minvat should not be located behind the inner shelf of the lock, otherwise it will make installation impossible.

- Installation of panels is performed from the ridge of the roof.

- At this stage it is necessary to fix the first plate (open wave to the end of the house).

- Next, the panel is aligned.

- Then you need to check how much the panel overhang acts. It is very important that during installation the design distance is maintained.

- At this stage, you need to stretch the cord (on the ridge of the roof). The edge of the product is mounted parallel to the axis of the house.

- The panel is fixed by special screws.

- At the end, you need to seal the joints of the locks.

Sandwich plates are an innovative modern material and are available in different variations. Every year the design of such panels is improved. Their cost decreases, and technical characteristics, on the contrary, increase, which guarantees a steady increase in demand for this product from customers.