Today, I-beam is very popular in construction and other areas of industry, which is distinguished by its unique durability and reliability. The product is able to withstand a load that is several times greater than the value characteristic of structures with a square, round or rectangular section. The range of I-beams is distinguished by a wide range of products, each product being made in accordance with current standards.

GOST-regulated I-beams: characteristics and features of structures

What is a double tee? This design is a metal profile having an H-shaped section. The standard sizes of the product, its shape and maximum permissible deviations in the technical parameters are strictly regulated by GOST 26020-83 and GOST 8239-89. The standards indicate the types of I-beams and the order of their marking.

Against the background of other types of metal, for example, a channel, the assortment of which is normalized by GOST 8240-97, an I-beam (GOST 26020-83 defines a unique shape of the product section) is characterized by the greatest degree of specific rigidity and strength. The voltage is evenly distributed over the entire area of the beam, which can significantly reduce the amount of material used.

If we compare the temporary resistance to rupture of the H-shaped profile and the solid beam, we get the same value, while the mass of the I-beam is 10 times lower. The strength of adjacently placed products is determined by summing, and located on top of each other – by an increase of 4 times.

Important! The use of I-beams will ease the weight of the structure by reducing construction costs.

I-structures are widely used in the construction of hydraulic structures, floors of high-rise buildings, supporting structures. This is due to the resistance of products to increased loads and their immunity to mechanical stress. Profiles are quite common in industrial construction.

Due to the high bearing capacity, which is evenly distributed throughout the product, it is advisable to use such structural elements for spans longer than 7 m. One cannot do without an I-beam in the construction of overpasses and bridges, which is associated with the ability of profiles to perceive increased vertical loads.

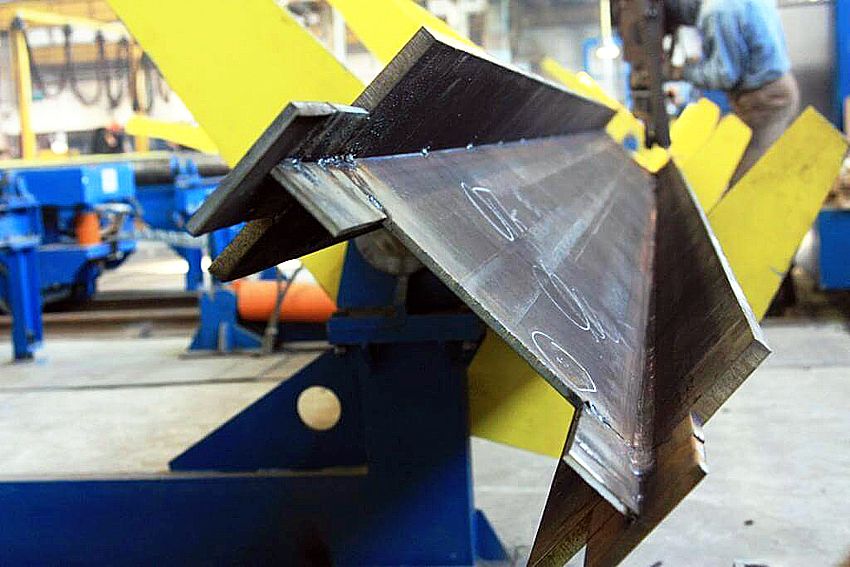

GOST standards for I-beams determine that products can be made in two ways. The first option involves the manufacture of profiles by rolling from blanks of a length of 3-12 m, which are processed at a temperature of 1200 ° C. This process is carried out on special machines. In the production of structural steel is used, which does not contain alloying additives.

This technology contributes to the rapid production of monolithic products. Such elements exhibit increased resistance to various types of mechanical stress. The technology allows the use of building parts without the use of additional ribs.

The unique shape of the product allows you to reduce the mass of the structure, while increasing its carrying capacity. Shelves, which evenly distribute the load, eliminate the possibility of tilting the structure.

The H-profile can also be made of three elements using welding. This technology allows to obtain a detail of a smaller cross section in comparison with monolithic structures.

Important! Due to the use of elements from various steel grades, it is possible to reduce the cost price of the welded product.

The process of welding the I-beam occurs in the following sequence:

- execution on CNC machines cutting sheets of steel;

- welding of metal blanks in automated installations using hydraulic clamps;

- Editing of constructions on the basis of parameters prescribed by the standard.

Using the method of welded technology, it is possible to get I-beams, the price per 1 meter of which depends on their geometrical parameters, different widths and thickness of the shelves. You can order a product of a certain length with cutouts and holes for fasteners in the profile body.

If I-beams are made on modern equipment, the products are not inferior in their technical characteristics to hot-rolled counterparts. When using outdated equipment and low carbon steel grades, building elements will be characterized by low operating performance.

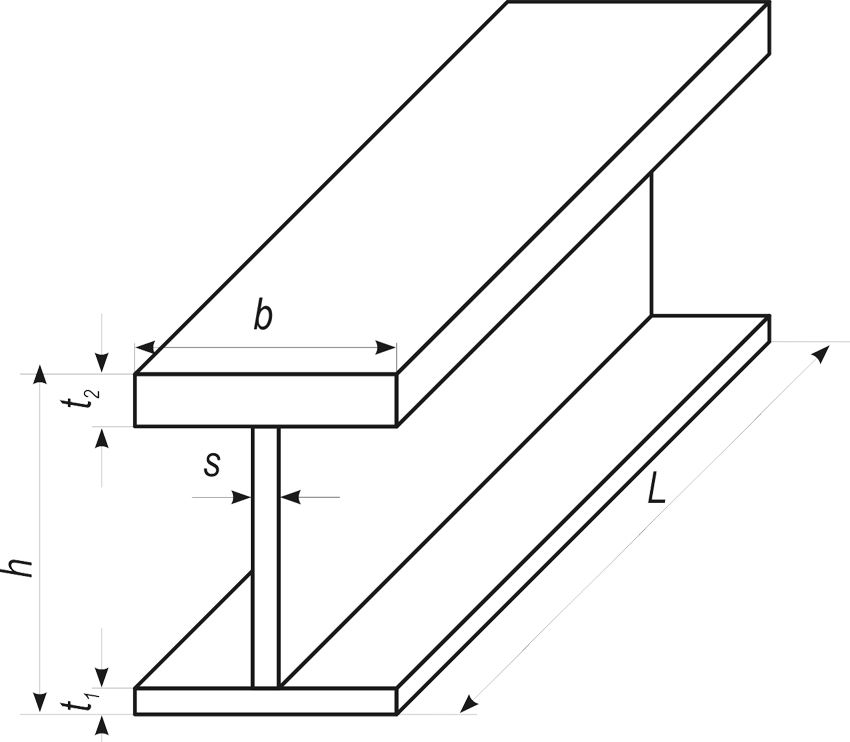

Selecting I-beams to perform a certain kind of tasks, you should consider their main parameters:

- height – the distance between the flanges of the I-beam;

- width – the size of the gap from the base of the product to the end of the shelf;

- wall thickness, which is calculated from the base of the product and determines the strength and bearing capacity of the structure;

- average shelf thickness, determined by subtracting the wall thickness from the shelf width, dividing the result by 4;

- the radius of the inner rounding formed by the fit of the shelves, which assumes the greatest load, determining the charge of rigidity and strength of the product.

Important! Shelf should not be adjacent to the wall at right angles. The radius formed at the junction contributes to an increase in the strength of the product.

To designate I-beams in the design documentation, an inscription is used that is composed in a certain way. The letter indicates the type of product, which can be normal, column or wide. The letter “D” denotes an additional series of profiles with specified parameters regulated by the standard.

The numerical value in front of the letter corresponds to the height of the I-beam in centimeters. The number after the letter determines the modification of the element. The larger the number indicated, the thicker and heavier the product. The number of the standard according to which the I-beam is made is indicated below. At the end of the prescribed material manufacturing design. For example, the beam 35SH1 is a wide-I-beam with a height of 350 mm.

The current standard defines several varieties of I-beams having different dimensional characteristics, weight and shape of the section, which is determined by the nomenclature of materials.

H-shaped metal is characterized by a different shape of the section. In the steel hot-rolled I-beam, regulated by GOST 8239-89, the shelves with the wall form an angle of 8-12 °. The product is used as a supporting crane for telpher lines. Normal I-beam (according to GOST 26020-83), indicated in the design documentation by the letter “B”, is made with parallel edges of the shelves. This simplifies the production process, while simultaneously reducing the resistance to deformation of the profile.

The wide shelf I-beam (GOST 26020-83 designates a product with the marking “Ш”) has the width of the shelves increased by 1.5 times in comparison with the above types of rolled metal. This has a positive effect on the rigidity, strength and durability of the structure. Because of this, it is able to withstand a load of 40% more than a normal beam.

I-columns in accordance with GOST 26020-83 are designated by the letter “K”. Products have a maximum width of shelves with increased thickness, which allows to obtain a high-strength product. The double tee is applied at construction of especially responsible designs.

To create ladders, floors, supports, trusses, bridges and various hydraulic structures, a normal I-beam, regulated by GOST 26020-83, is used. Wide-beam beams are used in the supporting structures of floors and staircases. In industrial construction mainly used column structures.

In accordance with GOST 8239-89 and GOST 26020-83, the range of I-beams contains the following range of materials that are used to make I-beams:

- carbon steel of ordinary quality, regulated by GOST 380-2005, can be calm, boiling and semi-resistant, characterized by an optimal ratio of strength, technical characteristics and price;

- building steel, in accordance with GOST 27772-88, is distinguished by increased requirements regarding the content of harmful impurities in the raw materials;

- aluminum alloy (according to GOST 4784-97) is used to create lightweight profile products, which are characterized by high aesthetic and corrosion properties;

- High-strength steel for bridge construction, meeting the requirements of GOST 4784-97, is used in the construction of particularly important structures and has increased resistance to the influence of cyclic loads.

Requirements of GOST 26020-83: a range of hot-rolled steel I-beams

This standard defines hot-rolled steel H-shaped profiles having parallel faces. The dimensions of the I-beam are strictly regulated by this GOST. The height of the shelves of the product is in the range of 100-1000 mm, and the width is 55-400 mm.

Unlike the dimensions of the channel, made according to GOST 8240-97, the I-gauge range is characterized by a wide range of thickness values, which is in the range of 100-600 mm. Such I-beams can be normal – indicated by marking “B”, wide-shelf – “Ш”, columned – “К” and additional – “Д”.

The wide-range I-beam assortment defines profiles with a height of 193-718 mm, which can be used without additional fastening. Such products are used as the basis for laying reinforced concrete slabs or steel sheet.

This type of elements is able to withstand significant loads, so it is often used in the construction of high-rise buildings. Wide-beam I-beams 50SH1 perform T-profiles for lattice structures.

Important! Due to the increased width of the shelves, I-beams of the wide-shelving type have maximum rigidity, which allows them to be used as independent supporting elements.

The beams are produced in the following length: measured, unmeasured, measured with a segment, multiple measured, multiple measured with a segment from 6 to 24 m. This value is defined as the maximum length of the conditional cut profile with ends perpendicular to the longitudinal axis.

The segment is a profile parameter of not less than 3 m for products with a linear density of up to 20 kg / m and not less than 4 m – with a density higher than 20 kg / m. The standard allowed the production of I-beams, having a limited length, which is within the unmeasured, which is most typical for beams 30Sh1.

If the letter “L” stands next to the marking, it indicates that the product is made of high-strength bar, giving the I-beam increased strength. The standard length of the product is 6 m. The height can be equal to 457 mm, 406 mm, 356 mm, 302 mm, 241 mm.

Possessing universal parameters, I-beams are widely used in various areas of construction. In order to obtain the maximum service life of the structure, it is necessary to correctly determine the load, relative to which the type of H-shaped profile is selected according to the product mix.