The list of modern materials that create a water-repellent layer is very wide. Among them, a place of honor rightly takes liquid glass. For waterproofing it is used on different objects. The unique properties of the product create protection against moisture not only on the floor, foundation, but also on car headlights, as well as in structures that have direct contact with water, in particular, in pools or wells. This article will tell this.

Features, characteristics and composition of liquid glass

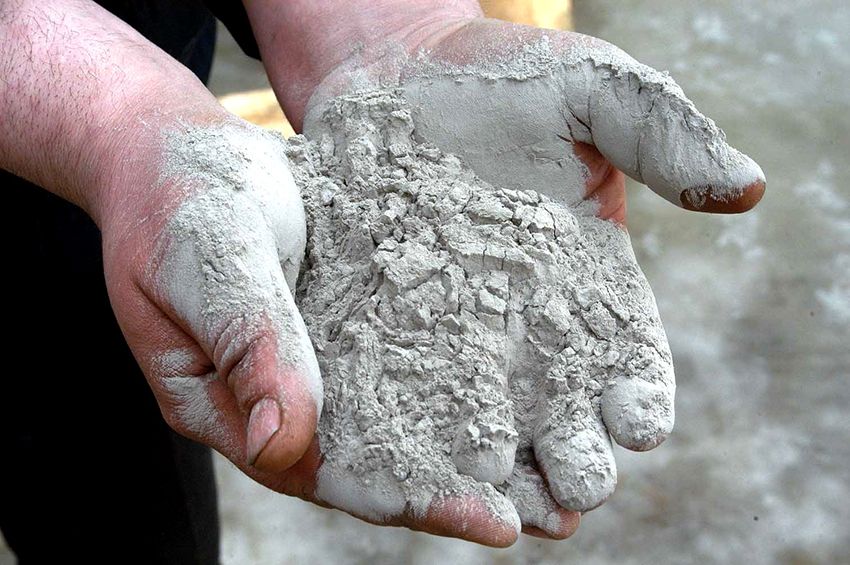

Popular in construction, life and work means called liquid glass, is a viscous homogeneous substance. According to the chemical formula, it is an aqueous solution of sodium silicate or potassium silicate. The composition includes microcrystals, which after application are well absorbed, penetrate into the middle of the porous material, where they increase in size. Hardening, they create excellent hydroprotection and make the surface airtight.

Because of the high penetrating power, the material is also called soluble glass. It consists of molten silica sand or soda, potassium or sodium silicate. The technological process of creating a means involves burning, crushing and thorough mixing of its components. The universality of liquid glass due to its characteristics, including:

- water-repellent properties, that is, water repellency;

- antiseptic effect that prevents the formation of bacteria, fungi and mold;

- antistatic – after coating with a means of the surface is not electrified and less covered with dust;

- high degree of solidification, which contributes to the creation of additional strength of the material;

- protection from alkalis and acids;

- fire resistance

The versatility of the tool involves its widespread use in various areas of production. Most often used in construction. Processing with liquid glass is performed in cases where it is necessary to carry out the following types of work:

- basement waterproofing;

- creating a waterproof layer on walls, ceilings and floors in underground rooms;

- waterproofing pools and wells;

- adding to concrete to enhance water repellency and strength properties;

- dedusting of flooring concrete surfaces;

- waterproofing wood;

- the creation of bactericidal grout;

- fast gluing of different materials;

- use as a quick-drying substance;

- creation of fire protection coating;

- protection of tree trunks after cutting;

- use as sealant in plumbing;

- cleaning surfaces and utensils;

- decorating walls and creating self-leveling floors.

Helpful advice! A wide list of positive qualities, as well as environmental friendliness and harmlessness of liquid glass, suggest its use not only in construction, but also in everyday life.

One of the ways to protect the foundation of the house from moisture is waterproofing with liquid glass – reviews from both experienced craftsmen and novice builders indicate a high degree of water resistance of the film, which covers the surface. Additional advantages are provided by other advantages of the material:

- high degree of adhesion;

- small expenditure of funds;

- reasonable price in comparison with other sealants;

- at least five years of operation of the waterproofing layer;

- possibility of use in conditions of high humidity.

Listing the advantages of the tool, it is necessary to mention the disadvantages that this universal remedy has:

- Limited in combination with other materials, since this composition can be applied only on concrete surfaces and wood products. It is impossible to use liquid glass on brick surfaces, since it will contribute to its destruction.

- The inability to use in its pure form. Waterproofing is made with the addition of other materials, the absence of which would entail the destruction of the protective layer.

- Obligatory compliance with the proportions of liquid glass in combination with other components of the solution. Otherwise, the waterproofing properties and strength characteristics of the mixture will be lost.

In addition, this composition is characterized by the complexity of the technology of application. Certain skills are required for waterproofing. Work does not tolerate sluggishness, as the mixture dries very quickly. For the same reason it is better to knead the solution in a small amount.

Thus, the material itself is indeed a universal tool used to impart water-repellent properties to different surfaces. The success of its application depends on strict adherence to the rules for performing the work and the proportions of liquid glass for waterproofing.

There are various ways to use a silicate solution to impart water-repellent properties to objects. They need to be familiar with before using liquid glass for waterproofing in order to choose the most efficient and suitable technology in a particular case. The main methods of application of the tool:

- coating method;

- penetration technique;

- adding material to concrete.

The coating method helps to create the most effective surface protection, in particular, it is used in waterproofing the foundation as a preliminary layer, which is applied under roll insulation. For this purpose, this means (in its pure form) covers the concrete surface in two layers. After complete drying of the liquid glass, the main stage of the insulation works is carried out.

Helpful advice! Applying a coating layer on a concrete surface not only provides additional waterproofing, but also protects it from the appearance and development of harmful organisms, fungi and mold.

The penetrating technique is irreplaceable when it is difficult to reach the surface to be treated. In this case, do not use clean liquid glass, and mix it with water in a 1: 1 ratio and add another part of the dry building mixture. The solution is thoroughly mixed and immediately applied, as it dries very quickly. It is recommended to prepare a small amount of the mixture.

It is important to thoroughly clean the treated surface before applying the solution. In this case, the adhesion of materials will occur faster and will be more reliable. The mixture is applied with a spatula and the surface is covered with a wet cloth, which prevents the coating from cracking.

The addition of silicate solutions to concrete in order to increase its water-repellent properties is the most popular method of using liquid glass in construction. This method allows you to create a solid foundation and provide reliable waterproofing. These two factors explain in the best possible way why liquid glass is added to concrete. The procedure for preparing the mixture is simple. This can be done independently.

The main thing in this process is the sequence in adding components and respecting the proportions of liquid glass and cement for waterproofing. To prevent cracking and destruction of concrete, it is important to consider the conditions in which the ready-made mortar will be used. To do this, follow these rules:

- Soluble glass is not added to the finished cement mortar. First, prepare a dry mixture, then it is gradually diluted with a stream of liquid glass mixed with water, while thoroughly mixing the solution.

- When adding a silicate mortar to cement, it is important to clearly follow the instructions recommending strict adherence to the proportions of liquid glass in concrete. For waterproofing, this figure is only 3%, although in other cases it can reach 25% (of the total mass).

- When adding a sodium-silicate mixture, the concrete solution quickly hardens. The work is simplified by adding water or making minimal portions.

- It is not recommended to prepare the solution in a concrete mixer, since it will begin to solidify during the mixing process.

There are a number of subtleties in mixing cement-sand mortar with liquid glass for waterproofing. The proportions of concrete and silicate are generally 10: 1. In rare cases, a different ratio of materials may be used.

Attention! In no case should water be added to the finished mixture of concrete and liquid glass after the solution has been kneaded.

The process and duration of its hardening depend on how much glue is added to the composition:

- if in a solution of 2% liquid glass, the process of setting will begin in approximately 45 minutes, and complete solidification will occur in a day;

- adding 5% of the product to the cement-sand mixture will result in an accelerated process of solidification, which will begin in half an hour, and the final result will be noticeable after 16 hours;

- 8% of the soluble glass in the solution will cause it to set in a quarter of an hour, and the concrete will completely dry after 7 hours;

- the process of setting at a proportion of 10% will occur in 5 minutes, and complete solidification in just 4 hours.

When deciding whether it is possible to add liquid glass to concrete, it is important to consider the type of cement. In this case, the applicable brand M300 and M400. To achieve a waterproof effect, the amount of glue is increased, but at the same time its maximum value should not exceed 25%. To prepare the solution, it is best to use a construction mixer, adhering to the following principles:

- need to use clean drinking water, without impurities and salts, the maximum amount per batch is 10 liters;

- add water glass to the water and mix;

- the liquid is poured into a more voluminous dishes;

- gradually, a sand-cement dry mix is added to the water-silicate solution;

- the solution is stirred until a homogeneous mass.

The use of liquid glass with cement for waterproofing is popular in different cases, which is primarily due to the reliability of waterproof protection, reasonable price of materials and a number of other factors that allow the use of the tool in various fields:

- liquid glass can not be used for waterproofing brick surfaces, as quickly hardening the mixture can lead to the destruction of the brick base;

- it is necessary to prepare and apply the composition in small portions, since liquid glass sets very quickly;

- in the preparation of the solution important conditions are compliance with the proportions and consistency in mixing the components, otherwise this tool will simply lose all its properties;

- liquid glass based on sodium has a higher adhesion and perfectly combines with mineral materials, and potassium liquid glass can be used in an environment with high acidity.

Thus, liquid glass is virtually indispensable and truly universal means for waterproofing. By consuming it in the right proportions with other materials and applying the minimum dosage, you can get high-quality and durable hydro protection. The solution can be used on different surfaces and objects. Simplicity and ease of use make it possible to do their own hands.