Without hot water it is difficult to imagine comfortable living conditions. But the work of the water supply there are many complaints. In the apartments of high-rise buildings in large cities, hot water is often supplied intermittently. In this case, indirect heating boiler will help out: the principle of operation of this unit is quite simple, and it is possible to create it even with your own hands. But immediately it must be said: that such equipment provides for connection to the heating system.

What is an indirect heating boiler and what is it for?

The boiler is called the heater or tank, supplying an apartment or house with hot water. In general, there are 2 types of such units: direct and indirect heating. The main difference of the last version of the water heater is that this boiler produces heat produced by the heating system. The appearance of the tank indirect heating causes the association with the barrel. But in the modern market you can find models that have the shape of a cube or parallelepiped. The former, being made with a boiler of indirect heating in the same style, are usually installed directly below it. This solution saves space in the back room.

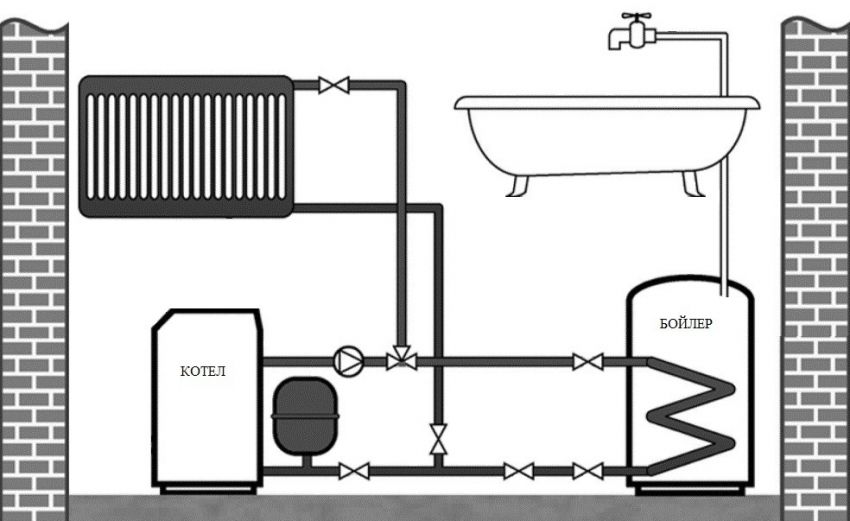

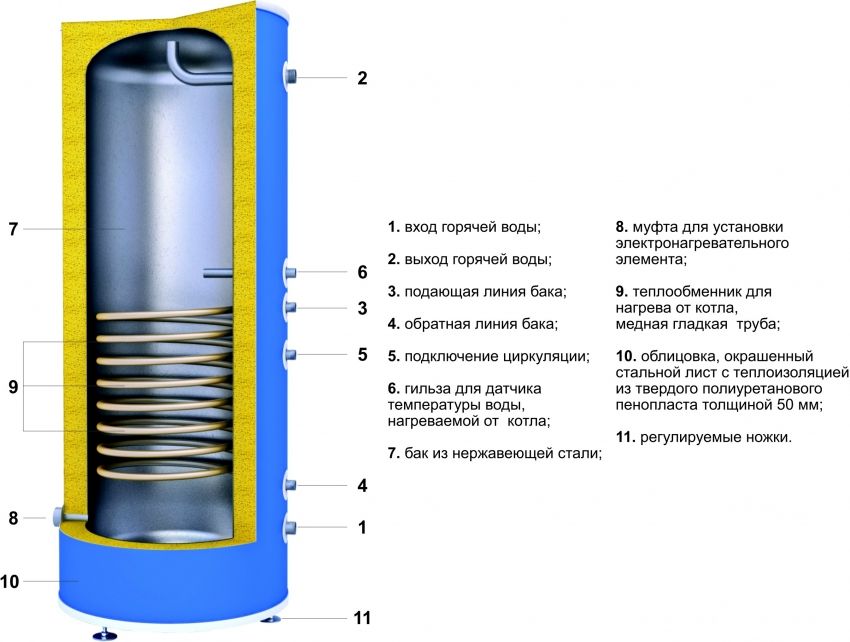

Water is fed into the unit on 2 circuits. The first is heating, which is connected to the heating system of the dwelling. In the second, the water is heated, coming from the water supply and subsequently distributed to the water intake points.

The heating circuits in the unit under consideration are implemented by two methods:

- “Tank in the tank.” From the name it is clear that this is such an indirect heating boiler, the design of which provides for the formation of a contour by accommodating a smaller steel tank in the main tank;

- in the main tank is mounted coil.

Both circuits are connected in parallel to the housing heating system. The coolant enters the boiler from it through the pipeline. To organize the effective circulation of the coolant, such a pipeline is necessarily equipped with a pump-mixing system.

Helpful advice! When buying a boiler for a gas boiler, estimate the capacity of the last unit. It should be enough to ensure simultaneous operation of the heating system and the boiler switched on for heating.

Cold water is supplied to the tank for heating, and hot water is collected by consumers. It should be borne in mind that many manufacturers produce such an indirect heating boiler with several heat exchangers. This design works more efficiently, but is extremely rare in sales.

The advantages of the technical solution implemented by this device include:

- during the heating season, the wiring is not overloaded, since the device does not work from the mains;

- and the heat transfer fluid and the internal heater system do not come into contact with tap water. It follows that such an indirect heating boiler will last for a long time;

- hot water will begin to flow into the faucet immediately after the unit is started, because its work is based on the recycling process;

- A water heating system well-designed on the basis of this device will work efficiently with an optimal amount of expenses at the operation stage.

But it was not without flaws. From these experts emit:

- the installation of indirect heating boiler with recycling requires significant preparatory work, requiring considerable financial costs, which will adversely affect the family budget;

- there is a boiler of this type much more than electric or gas analogues;

- the initial heating of the water takes about 1-2 hours. During this period of time, the quality of the heating system may noticeably deteriorate;

- having bought at a reasonable price a 100-liter boiler of indirect heating, for its installation you will have to allocate a separate room. The fact is that even with, it would seem, not such a large amount of internal capacity, the external dimensions of such a device are quite impressive. Not to mention the 200-liter indirect heating boiler. But the industry even produces 300-liter samples;

- Providing hot water at home depends on whether the heating system is currently working. But for obvious reasons, in the summer time there is no need for it. There are two ways out of this situation: the installation of an individual coolant supply system that serves only the boiler, or the installation of a combined indirect heating boiler with electric heating elements.

The last option will dwell a little more. The most inexpensive and for this reason, which has become traditional in the boiler is the copper heater. However, due to the intensive formation of scale at high temperatures in hard water, it quickly fails. In addition, these deposits reduce the degree of heat transfer in heating elements, as a result of which power consumption increases.

Helpful advice! The purchase of a combined indirect heating boiler with a “dry” heating element will save on the payment of electricity bills.

Such an electric heating element is made of ceramics. And they called the heater “dry” because it is enclosed in a steel flask. That is, direct contact with water is absent, and, accordingly, scale does not form. The presence of such a frame leads to an increase in heat transfer area and to a decrease in the intensity of cooling. That is why the electricity for operation of a combined heating boiler with “dry” heating element is required less.

It is possible to heat water in the unit under consideration using a gas or solid fuel boiler, a solar water heater or a heat pump. Moreover, his work is possible in conjunction with the heating equipment of two types: single and dual circuit.

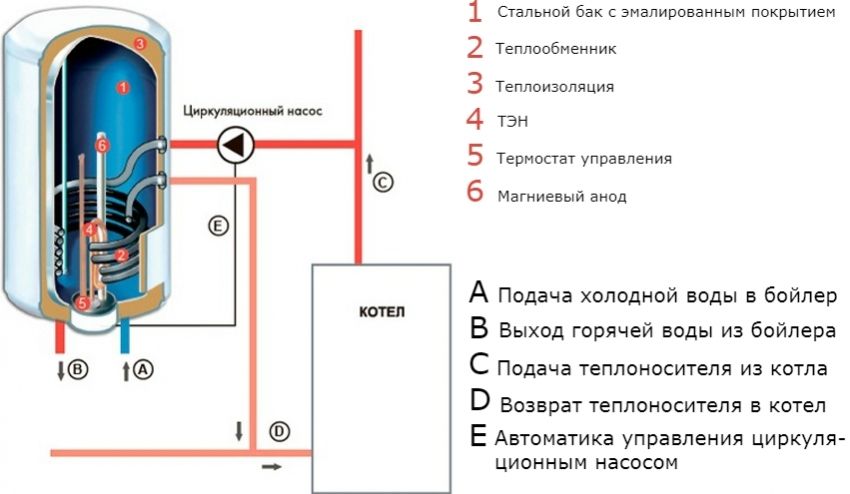

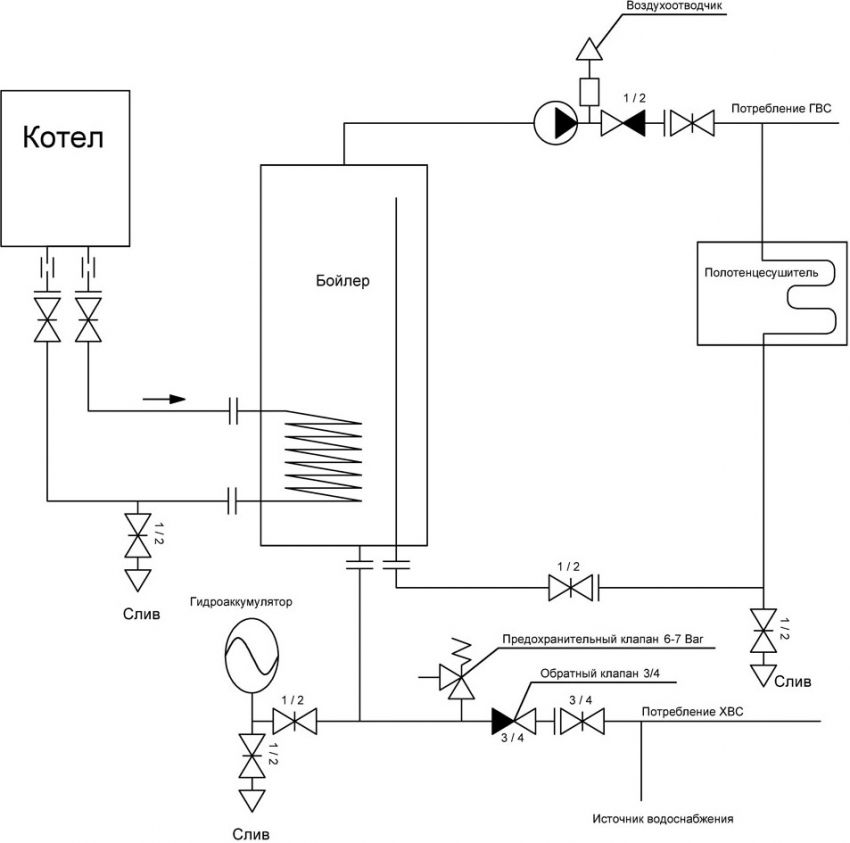

According to the standard scheme of the boiler indirect heating, it is connected to the heating system, as well as to the branches of hot and cold water supply. Cold water comes from the bottom, hot water is discharged from the tank located on top of the tank, but the recycling point is located in the middle of the boiler. The direction of movement of the heated coolant is reverse – from top to bottom. That is, from the gas boiler, it enters the water heater branch pipe on top, and returns to the heating pipeline through the lower branch pipe of the unit.

Thanks to this scheme of connecting the indirect heating boiler, the efficiency of this device is increased. After all, heat is first transferred to the heated layers of water.

In order for the boiler to work successfully in tandem with a heating unit having a hot water supply circuit, a three-way valve is used. It distributes the flow of coolant between the additional water circuit and the main heating circuit.

A thermostat is installed in the storage boiler of indirect heating. It is he who generates the three-way valve control signals. When the temperature of the water in the tank drops below a certain level, the valve, on command from the thermostat, turns on and redirects the flow to the hot water supply from the heating pipeline. Signals from the thermostat will return the valve to its original state if the temperature of the water in the heater exceeds the pre-set mark. The flow of coolant in this case is directed to the heating pipeline.

In the warm season, the unit works differently: the flow is not redirected, but the combustion modes of the gas boiler are controlled. When the temperature of the water in the boiler decreases, the thermostat sends a corresponding signal to the three-way valve. With this “command”, the last device “ignites” the main burner of the heating unit. When the water temperature exceeds a certain value, the gas supply to the burner stops.

Important! When setting the maximum water temperature in the tank (it is also the temperature of the automatic thermostat triggering), the user should take into account that its value must be less than the value of this parameter set for the automatic boiler.

The above scheme works most effectively when using gas boilers equipped with automatic equipment and a circulating pump. In this case, the heating unit itself can control the valve according to the signal received from the thermostat of the heater. You should know that when the water heating system works with a three-way valve, the priority of the heater circuit is higher than the heating circuit.

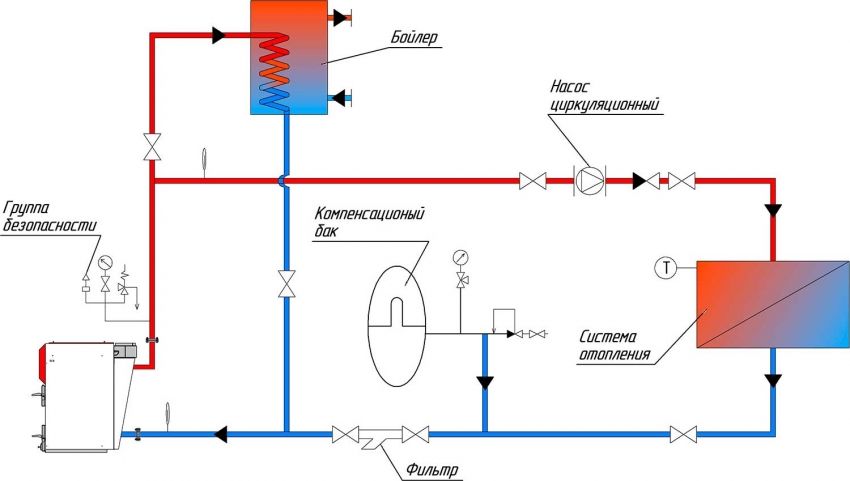

To ensure effective joint operation of the indirect heating boiler with a single-circuit gas boiler, a scheme with two circulation pumps is used. A connection of this type is actually capable of replacing the above scheme with a three-way valve. The separation of coolant flows using pumps through different pipelines is a key feature of this type of connection. The distribution of the priorities of the contours is the same as in the previous case. However, a higher priority of the water supply circuit over the heating circuit is ensured only by a special setting of the pump activation algorithm.

Alternating switching of the pumps is also controlled by signals from a thermostat installed in the tank. Before each unit must be installed check valve. The creation of such binding of the indirect heating boiler prevents mixing of the coolant flows.

This scheme works like this: turning on the DHW pump is accompanied by turning off the heating pump. That is, the heating system will begin to cool. However, a noticeable decrease in the house temperature will not be observed for the reason that heating the water in the indirect heating boiler with a gas boiler will last for a short period of time. Inhabitants of the house will feel it only at initial start-up.

Sometimes the owners use several heating units in the construction of a large area of comfortable temperature. Then an additional pump is installed in the storage water heater.

If the hot water is not taken a long time interval, it will begin to cool. It may take several minutes to wait until the hot stream reaches from the boiler to the end user. Reducing the time of discharge of the cooled water is provided by using the scheme of the boiler indirect heating with recirculation. This is realized by organizing the forced movement of a heated stream through pipelines closed in a ring.

Helpful advice! When choosing a piping scheme for heating and DHW circuits (with or without the possibility of recycling), it is necessary to take into account the specifics of the heating system, as well as to make accurate calculations of equipment capacity and the level of demand for hot water.

The technical solution with recycling provides almost instant delivery of hot water to any connected sanitary fixture. It stipulates that another circuit is mounted to the boiler of indirect heating, equipped with its own circulation pump, and additional structural components are installed:

- safety valve (designed to protect the water heater from overpressure);

- automatic air vent (prevents airing of the pump);

- expansion tank (performs the function of pressure compensation in the DHW circuit when the valves are closed);

- non-return valve (prevents the return of water in the pipeline).

| power, kWt | 69 |

| Volume, l | 400 |

| Productivity (maximum) in the flowing mode, l / min.,? T = 35 ° С | 28.3 |

| A heating element | 1 coil |

| Accommodation option | Floor |

| Ode pressure (maximum) | MPa 1 |

| Weight, kg | 145 |

| Sizes, mm | 1832X670 |

In conclusion, it is necessary to say that the selection and installation of a combined boiler for a house is a responsible and complex task, which can be solved by familiarizing with connection diagrams, advice and expert opinion, as well as feedback from users of such systems.