Proper arrangement of the ventilation system in the kitchen is the key to a healthy indoor climate. The system consists of an exhaust device and an air duct made of various materials. Due to the low cost, ease of installation and durability of plastic boxes for ventilation are the most popular. Everything you need to know about this product is detailed in the article.

What are plastic boxes for ventilation?

Each modern apartment has natural ventilation, which is provided from the common ventilation duct, passing through all the floors of the building. Very often there are kitchens with a ventilation box in the corner. The design of the room in this case should be properly designed to ensure that this element was almost imperceptible, and ideally fit into the overall concept of the interior.

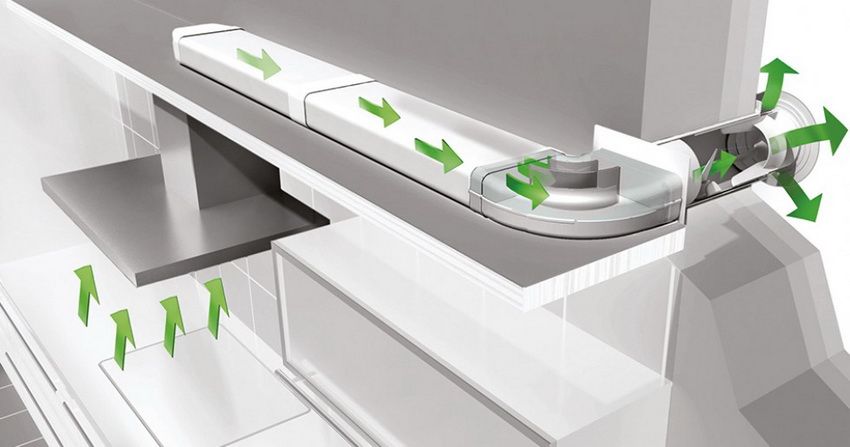

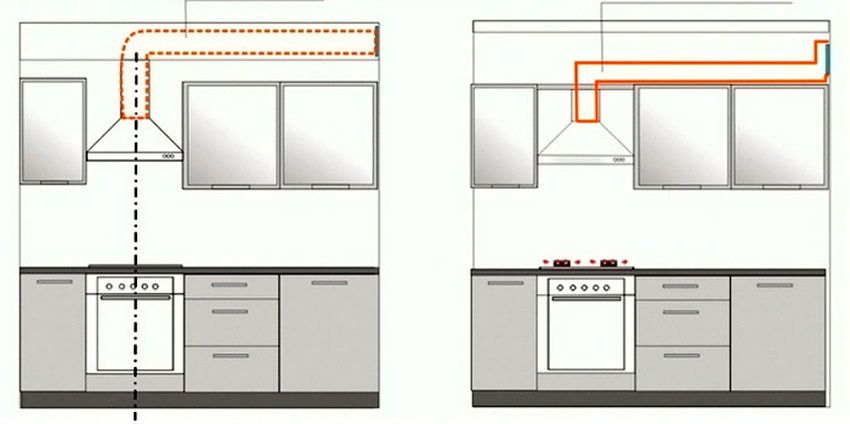

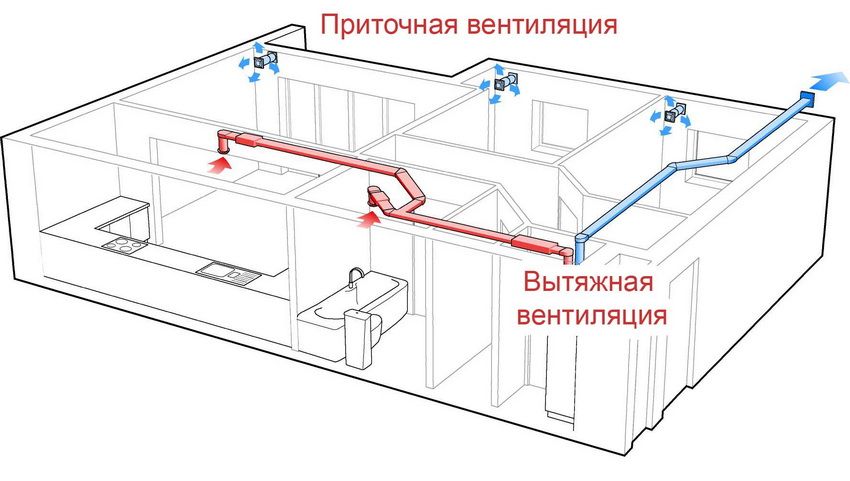

Often the capacity of the ventilation system is not enough to provide the required air exchange in the room. This especially applies to kitchens. For the organization of a favorable, healthy microclimate in a room with high humidity, it is important to equip the forced ventilation system. It is able to continuously clean the air from smoke and odors, which are formed as a result of cooking. This system consists of an exhaust and a metal or plastic exhaust duct. It connects to the ventilation duct in the kitchen.

It is very important that the common channel work properly. Otherwise, in order to ensure effective ventilation in the apartment, it will be necessary to restore the ventilation duct. That will require additional costs to attract specialists. The effective operation of the inlet ventilation system depends on the correct extraction and proper installation of the duct.

Ventilation ducts vary in manufacturing, size and shape of the section, flexibility and degree of elasticity. The most popular for the arrangement of household ventilation systems are plastic ducts. Unlike bulky galvanized ventilation ducts, they can successfully complement any kitchen interior. They are made of high-quality polymeric materials such as polyethylene, polyvinyl chloride and propylene, without harmful impurities to human health.

The manufacture of ducts for ventilation from polymers is carried out using simple technology of hot pressing, which makes it possible to obtain a product of various shapes and sizes. Using, for example, flat ducts, you can create an almost invisible ventilation system that hides behind the ceiling fabric or the upper wall of the hinged kitchen cabinets.

Today, manufacturers produce various variations of polymer ducts that provide normal air circulation and fit into any interior.

Polymer ventilation ducts are divided into:

- rectangular products;

- a box with a round section;

- oval-shaped products.

The most popular are rectangular plastic ventilation ducts, which successfully fit into any interior. This duct can be hidden under a stretch ceiling or positioned inside a kitchen cabinet. It can also be revetted with finishing materials or painted in a suitable color. Installation of rectangular boxes is quite simple, even in remote places, and does not require special skills.

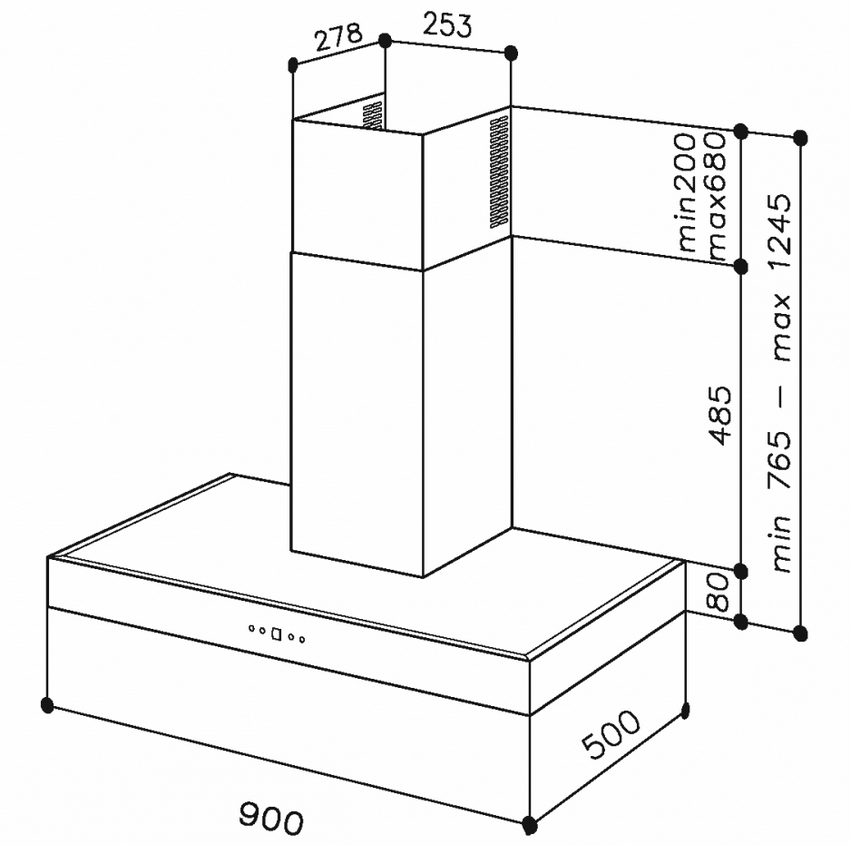

The cross section of polymer ducts is selected on the basis of the power of the ventilation system. Manufacturers mainly produce plastic rectangular ventilation boxes with dimensions of 110×55 mm, 120×60 mm, 204×60 mm with a wall thickness of 3-4 mm.

For a large ventilation system, you can buy a ventilation box for a rectangular section with a size of 220×90 mm and a round shape with a diameter of 200 mm.

For laying of long ventilation systems, round ventilation ducts of 50–150 mm in size are used predominantly. Here, due to the fact that the circle, as a geometric figure, has the smallest perimeter, internal resistance in the duct is minimized, which has a beneficial effect on the performance of the entire ventilation system.

Helpful advice! Long sections of the ventilation system is better to perform their flexible boxes of round or rectangular shape, which have a length of 15-20 m.

Today, many prefer the design of the kitchen with a ventilation duct made of polymers. Plastic boxes have become a worthy alternative to bulky unattractive metal products. They have a number of indisputable advantages, which makes them more popular among consumers:

- high operational and technical parameters;

- durability of the product;

- wear resistance;

- increased resistance to mechanical damage;

- products are not subject to deformation;

- resistance to temperature fluctuations and exposure to aggressive substances;

- low weight, which simplifies installation of the product;

- have an attractive appearance;

- the presence of different color variations;

- low cost of the product.

The ventilation system of plastic boxes is very easy to install on the principle of a pipe-bell. Thanks to this simple wiring diagram, the structure can later be easily dismantled for maintenance and cleaning, and reassembled. The number of such cycles is not limited.

Among the wide range of plastic fittings, you can choose the necessary composition of components with which to lay the duct of any configuration and length without the use of welding machines, rollers or soldering irons. Numerous photos on the Internet show how to beat the ventilation box in the kitchen so that it fits perfectly into the interior of the room.

Due to its low weight, the polymer duct can be easily fixed to the ceiling or wall using ordinary dowels.

If it is necessary to assemble a ventilation system that will collect and discharge hot air saturated with vapor, then it is advisable to use a ventilation duct made of galvanized steel. He is able to withstand high temperatures and not lose shape. Polymer box, in contrast, can quickly deform and lose tightness.

The polymer has good thermal insulation properties, which reduces the risk of water condensation and reduces the oiling of the inner surface of the plastic box to organic compounds. And thanks to the smooth, polished surface of the plastic, unobstructed discharge of polluted air containing fats, organic compounds and soot that do not settle on the walls of the box is ensured. These characteristics reduce the risk of accumulation and development of pathogens in the ventilation system.

Before you buy plastic boxes for ventilation, you should decide on the purpose, type and capacity of the ventilation system. Polymer air ducts are selected on the basis of the power of the exhaust, the specific layout and design of the room. The efficiency of the entire system depends not only on the correct installation with all the main criteria, but also on the correct choice of cross-sectional area and channel shape.

The pipe section for the plastic box is selected on the basis of the maximum volume of polluted air that must pass through the system at a speed of 3-7 m / s. This value should be equal to or slightly larger than the size of the exhaust fitting.

If the section is chosen too large, a working ventilation system will create an extra hum. In addition, this will lead to inappropriate investment and labor-intensive installation work.

In the case of a small section of the duct, the extraction performance will be reduced, due to the increasing load on the mechanism. This will lead to a decrease in air exchange cycles in the room, the occurrence of vibration in the system and an increase in the cost of electricity.

The choice of the shape of the ventilation box depends on personal preferences and kitchen design.

Important! Round air ducts provide a quieter operation of the ventilation system.

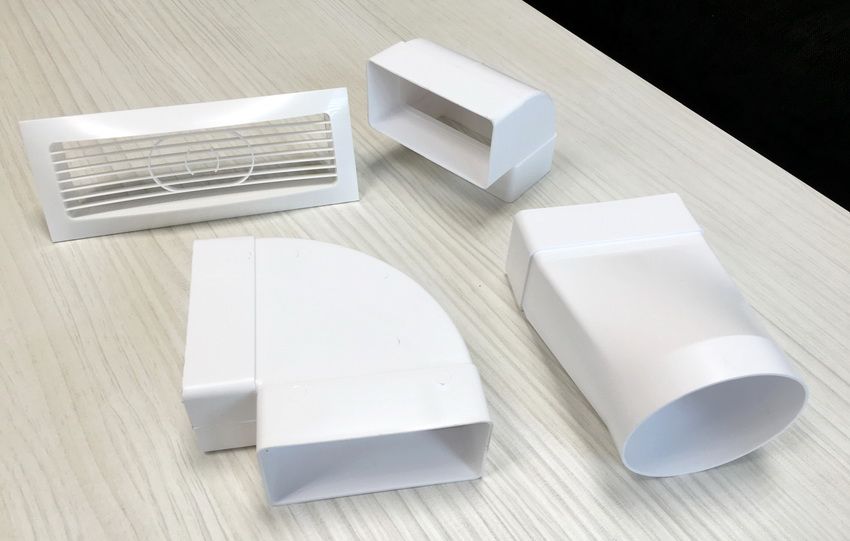

The device of the ventilation system should begin with drawing up a drawing indicating the types and sizes of parts and points of fastening elements to the wall or ceiling. Depending on the design of the room and the location of the furniture, the ventilation box may have a different configuration. This is done with the help of special plastic shaped elements, which are connected to the straight sections of the ventilation duct using the “landing rim – socket” system.

Today, you can buy ventilation boxes of round or rectangular cross section with a length of 0.35 to 2 m. You can cut off a section of the required length using a grinder or a hacksaw. If the length of the straight section exceeds 2 m, it can be mounted using several elements of standard length, connecting them together with the help of special elements for polymer channels.

Rotate the duct 45? or 90? carried out by the knee. If a rectangular box is used, the change of direction can be performed both horizontally and vertically.

Helpful advice! If the duct must be rotated to a value not a multiple of the angle 45 ?, use a multi-angle knee, in which one of the sides, depending on the angle required, is cut off.

If it is necessary to change the shape of the box from rectangular to round, special adapters are used. Products may have a straight or angular shape.

Manufacturers produce the following types of transitions:

- from the diameter of 100 mm to the size of a rectangular box 110×55 mm;

- from the diameter of 100 mm to the size of a rectangular box 120×60 mm;

- from a diameter of 125 mm to the size of a rectangular box 204×60 mm.

To make the transition to a plastic box of a different size, gearboxes should be used. For polymeric products of round cross-section of any size, a special universal adapter is used.

Helpful advice! Despite the fact that all the plastic elements of the ventilation system fit snugly together, it is better to process all the joints with acrylic or silicone sealant, which will prevent the ventilation duct from depressurizing after some time.

Plastic air ducts are a good solution for arranging a reliable, highly efficient ventilation system in a house or apartment. A properly selected fittings, fasteners and sealant give the design not only an attractive appearance, but also significantly prolong the service life of the system.