Plastic air ducts for ventilation are used to provide residential and industrial premises with a stream of fresh air, eliminate unpleasant odors and remove harmful fumes. Nowadays, plastic-coated channels have become especially popular because of their practicality, durability, ease of installation, and relatively low cost. The article discusses in detail the issues of calculation, selection and installation of ventilation ducts.

Plastic air ducts for ventilation: types, dimensions and classification

A wide variety of duct applications in ventilation systems causes a wide range of types and versions. There are several parameters that underlie the classification:

- sectional shape: elliptical, rectangular, round;

- execution material: plastic, metal-plastic, steel;

- rigidity;

- size or diameter of the section;

- method and type of connection;

- constructional execution.

In order to satisfy wide consumer needs and to foresee possible variants of constructions, manufacturers offer a wide choice of plastic ventilation ducts. So, for rectangular flat air ducts, typical sizes range from 100×55 to 204×60 mm, the diameter of round ones is 100-200 mm.

The most commonly used section types are round and rectangular. In some cases, when the design imposes strict restrictions on the size and shape of the channel, use the elliptical version. This cross section is achieved by processing a round product on special machines.

For the manufacture of plastic ducts of round shape, a smaller amount of material is required, and the technology of their production is more simple. In the case of a rectangular version, costs increase on average by 20-30% when moving from a circular section. The complication of the manufacturing process is due to the fact that such air ducts are made up of several separate parts.

The main arguments in favor of choosing a round shape are the best tightness (which is ensured by a solid construction and the absence of welds), high speed of the air flow, reduced noise, lower weight and ease of installation.

As an advantage of rectangular channels should be allocated optimal placement in space. This form takes up less space, it is easier to adapt to the peculiarities of the layout, for example, when combined with suspended ceilings.

Helpful advice! If the location of the proposed location of the ventilation system imposes restrictions on the lateral dimensions of the ducts, you can use transition elements to change the shape of the section. In this case, the transverse area of the combined parts must be the same.

The material used for the manufacture of air ducts of different types depends on the area of their use and possible restrictions imposed by the existing ventilation system.

Widespread in the conditions of transfer of aggressive air flow, and for use in all types of residential premises received plastic or PVC type. Plastic is light and smooth material resistant to moisture, acids and alkalis. Due to its tightness, various connecting elements (knees, tees, bends) are made of it .4.

Air ducts made of galvanized steel are used in ventilation systems that operate in a non-aggressive environment (temperatures up to 80? C). The protective coating has anti-corrosion properties and significantly increases the service life of products, however, it increases the cost of installing ventilation ducts per m2.

Metal duct type is made using two metal layers (often made of corrugated aluminum) and a layer of foamed plastic. This type has high strength with a small mass. Products have an aesthetic appearance and do not need additional thermal insulation. The disadvantage is the increased cost.

Helpful advice! In living conditions (especially when organizing ventilation in an apartment kitchen), it is preferable to use plastic wires due to less noise, weight, ease of installation and lower cost.

Other types of ducts include polyethylene, vinyl plastic and glass fabric. These types are characterized by high rates of corrosion resistance, low weight, the ability to bend in all planes at an unlimited angle.

Since today the most common are rigid air ducts – the main part of all ventilation equipment on the market is focused on this type. Often rigid boxes have a round or rectangular cross-section. For the manufacture of used sheet material. Basalt wool may be used as external insulation.

Flexible air ducts for ventilation are presented in the form of corrugations (corrugated sleeve), which is made of polyvinyl chloride (PVC). It should be noted excellent ease of transportation and installation. Before you buy a flexible duct, you should consider the disadvantages of this type. Thin walls have low noise insulation. Also, the embossed surface of the corrugations adversely affects the speed of air flow along the wire.

The latter type is semi-rigid. It is an intermediate link between flexible and rigid products, combining in itself high strength and elasticity. The disadvantages of such ducts should include reduced air flow rate, which imposes restrictions on their use in branched systems.

Helpful advice! You should not limit the choice of only one type of duct. A wide range of connecting elements makes it easy to combine rigid and flexible channels. Such a combination does not affect the performance of the ventilation system as a whole.

The most common ways to connect duct sections are flanged and flangeless connections. The basis of the first is the installation of flanges that are attached to sections of the ventilation channel with rivets or self-tapping screws. Tightness at joints is achieved using rubber and other seals.

The flangeless connection is made with a band of thin sheet steel and metal slats.

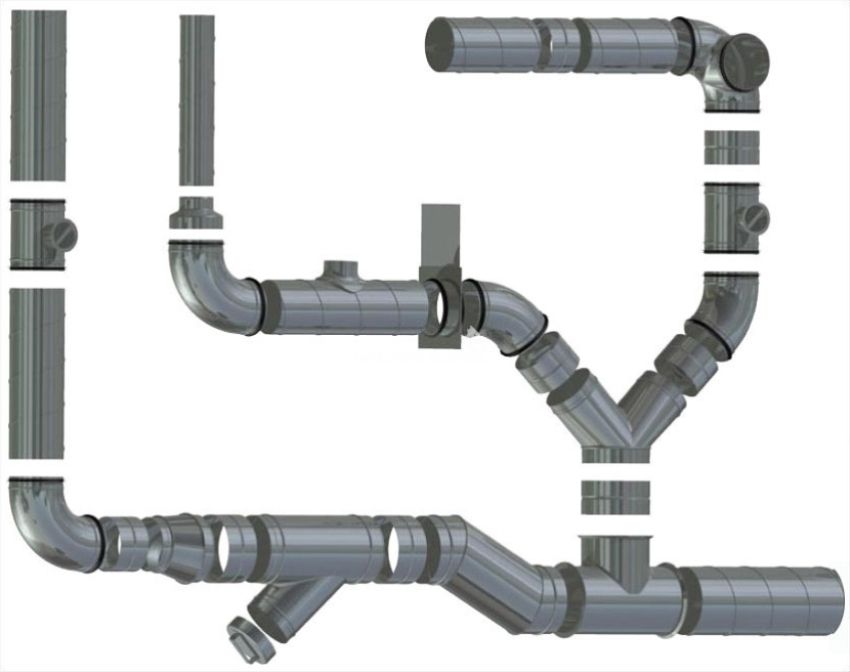

The main types of air duct connections are:

- tees (in places of pairing or ramification of the system);

- knees and bends (in places where the channel turns);

- adapters (for switching from a round duct to a rectangular or, conversely, the connection of parts of different sections);

- confusors and diffusers (in places of transition to another size). The first narrow the channel, and the second – expand.

Without a doubt, flat plastic air ducts are very popular for use in residential non-industrial premises. Here we should highlight the following positive properties of such products:

- due to the absence of oxidizable elements in them, plastic wires do not suffer from corrosion. This feature has greatly simplified the work of designers, eliminating the need to provide additional protection systems. Resistance to oxidation makes the design itself and its installation process simpler;

- cost reduction: PVC ventilation pipes are significantly (sometimes 2-3 times) cheaper than metal counterparts;

- smooth inner surface contributes to maximum air flow and does not require periodic cleaning;

- the ability to cut pieces of wire at the installation site, and a wide range of various fittings greatly simplify the assembly and installation of the structure;

- non-toxicity and complete safety for both humans and the environment.

Along with all these advantages, flexible PVC ducts have one major drawback: low resistance to fire.

The calculation of ventilation ducts is one of the most important stages in the design of an air supply system. Before proceeding directly to the selection of the cross-sectional area of the wires, it is necessary to determine the ventilation capacity by air.

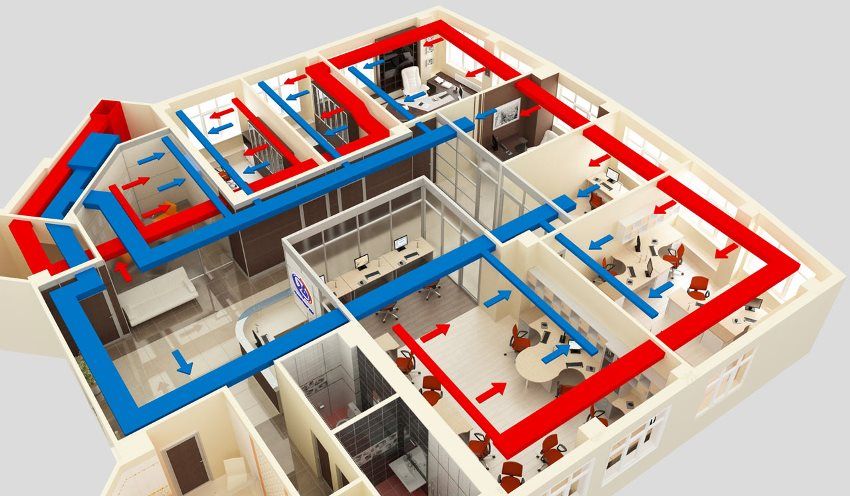

To begin, you need a plan of the object, which shows the area and the purpose of all rooms. Air supply is provided only in those rooms in which people are located for a long time (living room, bedroom, office). The air is not supplied to the corridors, since it gets there from the living rooms, and then to the kitchens and bathrooms. From there, the air flow is exhausted through exhaust ventilation. This scheme prevents the spread of odors around the house or apartment.

The amount of air supplied for each type of dwelling is calculated using MGSN 3.01.01. and SNiP 41-01-2003. The standard volume for 1 person in each room is 60 m? / H. For a bedroom, this figure can be reduced by 2 times to 30 m? / H. It is also worth noting that when calculating take into account only people who are long in the room.

Helpful advice! The calculation of the characteristics of the ventilation system can be carried out manually using the specified formulas. However, there are many online calculators that simplify and speed up the solution of this problem.

The next step is the calculation of air exchange rate. The multiplicity shows how many times per hour there is a complete renewal of indoor air. The minimum value is one. This value prevents stagnation of the atmosphere in the rooms.

Based on the foregoing, to determine the air flow, it is required to calculate two air exchange parameters: by frequency and by the number of people from which a larger value is selected.

Calculation by the number of people:

L = N x Lnorm, Where

L – power of ventilation, m? / H;

N is the number of people;

Lnorm – the normalized air flow rate per person (typical – 60 m? / H, in a state of sleep – 30 m? / H).

Calculation of the rate of air exchange:

L = b x S x H, Where

L – power of ventilation, m? / H;

b – air multiplicity (residential premises – from 1 to 2, offices – from 2 to 3);

S – area of the room, m ?;

H – vertical dimensions of the room (height), m ?.

After calculating the air exchange for each room, the obtained values are summed up for each method. Greater and will be the required ventilation performance. For example, typical values are:

- rooms and apartments – 100-500 m? / h;

- cottages – 500-2000 m? / h;

- offices – 1000-10000 m? / h

To calculate the area of the ducts, it is necessary to know the volume of air that must flow through them over a period of time (according to the previous stage of the calculation) and the maximum flow rate. The calculated values of the cross section decrease with increasing air flow rate, however, this increases the noise level. In practice, for cottages and apartments, the speed value is chosen in the range of 3-4 m / s.

The organization of the ventilation system is a relatively simple process. The described simple calculation method makes it easy to select the necessary elements, and a wide range of ventilation channels and connecting elements simplifies the placement and installation of plastic ducts in a limited space of ordinary residential premises.