Corrugated pipes are quite popular, and the scope of their use is quite wide. Most often they are used to connect hoods with a ventilation system. Positive qualities are due to high performance, and the main advantage is ease of installation. Corrugation for exhaust can be used for the arrangement of chimneys or installation of air ducts. This article will tell about its types, characteristics, installation features.

What is a corrugation for the hood: structural features

Corrugation gained its popularity due to its high efficiency as a connector between the ventilation duct and the ventilated device. It is characterized by ease of installation, which can be done even by an inexperienced master without special tools. The desired size and shape are easily created due to the flexible features of the corrugated pipe.

The corrugated pipe for ventilation has a rather simple structure: it consists of metal rings that are covered with a thin layer of insulating material. Most often, this wrapping is made of several layers of laminated foil. The pipe in most cases has a cylindrical shape. There are types of products where the strips of the base material are simply twisted spirally. Depending on the type of model, the thickness of the strips can be 100, 120, 150 ml. Between themselves, they are securely connected with special locking seams, forming a tight connection.

Due to the compression of the links, the flexible outer layer is folded into an “accordion”, and when they are stretched, the pipe may increase several times. The softness of the frame allows not only to stretch the structure, but also to bend it at the right angle. The long pipe can be given a serpentine appearance, which makes it possible to use it in the most inaccessible places. Corrugation – an ideal option for inconvenient placement of the ventilation system or in a small apartment.

Corrugated pipes are made from a variety of materials of different lengths, base shapes and diameters. Plastic pipes are available in different colors. The price range is also quite wide. These main differences underlie the classification of the corrugations. Manufacturers of the product offer a variety of models – from colored and thin transparent plastic to special stainless steel conduit pipes. When choosing, it is necessary to be guided not only by external features, but also by the production characteristics and purpose of the product.

Scope of corrugated pipe is very wide. Models with a large diameter (more than 3.5 m) are placed under the motorways and under the railway, where they perform the function of fortifying walls on the culvert canals below the embankments. Radically opposed thin models are used as insulation or for diverting water. Such an example could be a corrugation for air conditioning.

Helpful advice! Choosing a corrugation, you should pay attention not only to the color and its harmony with the interior, but also to the appropriate type of pipe, which has a narrow purpose.

On the external structure of the corrugation may be in the form of a circle, rectangle or square. In the manufacture of corrugated pipes using a variety of materials. Their list is very wide:

- galvanized steel;

- stainless steel;

- aluminum foil;

- textile fiber;

- polyethylene of different degrees of pressure, HDPE;

- polyvinyl chloride sheet.

Each of the types deserves separate attention, since its direct purpose depends on the structure of the material and the dimensions of the pipe. The most popular in this list of corrugations made of stainless steel or aluminum, which is most often used in the installation of home ventilation. On the basis of production methods, corrugated tubes are divided into the following types:

- Frame. Represent a frame made of metal, covered with foil or film. The flexibility of such ducts allows restoring the original undeformed look.

- Spiral-wavy. Have the appearance of metal tapes with medium flexibility. The product can be stretched twice as much, but the original position after that will not be returned to him.

Polyethylene or plastic corrugation is applicable in the arrangement of plumbing, for example, to supply water to various types of household appliances. In addition, the corrugation is widely used in the installation of sewage internal apartment passages, in particular under the bathroom or sinks.

Different materials from which the product is made, and the dimensions of the corrugations indicate its wide use in various fields. Thin, small, but long plastic or polymer pipes are used in the installation of various networks. It can be electrical, telephone, television wires, power and fiber-optic Internet cables. For insulation of electrical wires use corrugation with a diameter of from 15 to 40 mm.

Less flexible metallographic equipment is used in heating systems, because such pipes are fast and easy to install. The segment of the desired length is easy to bend in the right place without changing the diameter inside, which makes it possible to create a heating system in difficult and hard-to-reach areas.

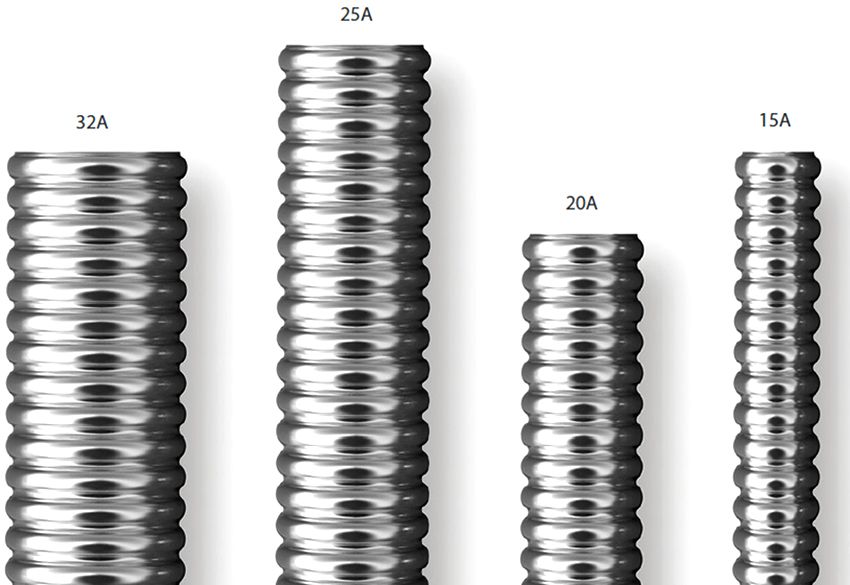

For ventilation systems suitable pipes with great flexibility. The diameter of the corrugations for the hood corresponds to sizes from 10 to 15 cm. Sometimes these figures reach 20 and even over 30 cm. Such options are rather the exception, although they can be easily found in the commercial field. As the material for the manufacture of corrugations used in the kitchen ventilation system, the most common aluminum foil. Less commonly, in domestic conditions, plastic or stainless steel pipes are used.

Textile channels serve for arranging communication systems in industrial premises, because they do not interfere with the free circulation of air. They are widely used in meat processing plants or catering establishments.

Aluminum, galvanized corrugations or stainless steel pipes are used for arranging air ducts both in industry and in living conditions. This is due to the reliability and durability of the metal.

Helpful advice! Aluminum corrugation is much cheaper than their counterparts from galvanized metal or stainless steel, but solid pipes have a more presentable appearance.

The most popular of the metals in the list of corrugated pipes is aluminum, which is achieved due to its high resistance to temperature differences. It withstands frost -30 ° C, does not burn and does not melt even at +250 ° C. This is a major advantage, allowing the use of corrugations for the gas column, but not the only one. Other advantages of the material are listed below:

- strength and chemical resistance;

- excellent aerodynamic properties;

- ease of installation, achieved through flexibility and the ability to stretch the pipe to the desired length;

- ease of cut, as the desired length can be cut with ordinary scissors;

- wide choice of the diameter of the desired model (range from 100 to 150 mm);

- durability;

- does not require additional protection from external influences even on the front side;

- acceptable price.

Among the shortcomings of the ducts made of stainless steel and aluminum should be noted:

- catchy and rough appearance;

- excessive lightness, which leads to the formation of dents during installation;

- the inability to return to its original shape after stretching the pipe, which requires special care;

- difficulties in washing due to multiple folds on the corrugation;

- impossibility of dismantling, as tightness can be broken.

Plastic corrugation for hoods looks more presentable and less conspicuous, so there is no special need to hide it. In addition, the material is lightweight and relatively long service life – over half a century. The advantages are also attributed to corrosion resistance and aggressive means.

The lack of a corrugated PVC duct is a higher noise level, and it is also less resistant to temperature effects. Plastic burns and melts easily, so it is not suitable as a material for chimney gas columns and boilers.

PND corrugation – a pipe which is made from special polyethylene of low pressure. It serves for laying drainage systems, as well as for the protection of cables and wires. Depending on the purpose and characteristics, there are several subspecies of the product:

- Lightweight HDPE corrugated hose is a single-layer corrugated pipe. Its varieties are used for cabling or for pumping various liquids.

- The weighted corrugated hose PND has a large cross-section, which implies its use in different operating conditions. For example, let’s say installation in a cement mortar or plunging into the ground.

- Double-walled PND pipe is a ribbed appearance and a smooth middle. Such a product is usually durable and ductile, has high throughput rates.

- Double-walled reinforced corrugation also has two layers of HDPE, but between them is built a special layer of metal that enhances its strength characteristics. Such a pipe can withstand severe loads and is characterized by high ring stiffness.

Helpful advice! PND corrugated pipe can not be installed as a transport channel of hot water.

Choosing the right pipe model requires an individual approach and a careful study of all the features. This should take into account the following basic criteria:

- the dimensions of the pipe, in particular its diameter and length;

- production material based on corrugations;

- product quality;

- the cost.

In order not to make miscalculations with the diameter of the connecting pipe, you must carefully study the instructions that are attached to the hoods. For greater certainty, you can measure the diameter. Non-compliance with recommendations can have irreversible consequences when even very expensive equipment will not function properly. Standard diameters of pipes installed on the hoods are 10, 12, 12.5 and 15 cm. Other sizes are much rarer, but they are still on sale. Manufacturers of hoods most often provide for parameters corresponding to 100 and 120 mm, and they are indicated in the installation and operation manual of the equipment.

Often, the manufacturer together with the ventilation equipment in the kit sells and duct. This is ideal if the length of the pipe fits the size of the kitchen. Otherwise, you will have to buy a product of the appropriate size. The length is desirable to measure before buying a pipe. For this purpose, the usual roulette fit. Measurement produced from the exhaust pipe to the entrance to the ventilation shaft, observing the strict trajectory of the future running of the pipe.

We should not forget that the corrugation is able to stretch and bend. For some models, this parameter corresponds to 180 °, which allows you to choose the optimal path for laying the ventilation path. It is also worth considering that the installation of the pipe is already stretched.

The material from which the ventilation passage is made is very important. In particular, the advantages and disadvantages of metal and plastic products listed above should be considered. Including it is necessary to remember about the high noise performance of plastic products, but it is also necessary to emphasize their high aesthetic characteristics, which allow the installation of the pipe when masking is difficult.

Inside the product, after 7-10 years, an impressive plaque forms that cannot be removed in any way. Therefore, at the end of this service life, the corrugation needs to be simply replaced. If the trajectory of the pipe consists of numerous bends, then the effective period of service is approximately halved. Dismantling and installation of the new system are performed according to the instructions described above.

Proper and deliberate choice of duct, as well as its consistent installation in accordance with the instructions directly affect the quality of the ventilation system and its service life. Equally important is the careful operation and timely replacement of the pipe. Even a rather long corrugated aluminum pipe will not spoil the appearance of the overall appearance of the kitchen, if you correctly organize the masking of the ventilation system. The combination of all these factors ensures the durability and reliability of such a primitive, at first glance, products such as corrugations for drawing.