Heated floor in recent years has gained deserved popularity. What pipes for underfloor heating better take when building such a system? Asking this question, it is necessary to study all their types and compare the characteristics.

What pipes are used in underfloor heating

Making the decision to start work, we go to the store to buy components. The main component of this design are pipes. They will offer us several options:

- Metal-plastic.

- Copper.

- Polyethylene.

- Polypropylene.

If we do not understand what the difference is, it will be difficult for us to make a choice. To focus only on the price is not entirely correct. Therefore, you need to know all the main properties of each type and decide, what pipes for a heat-insulated floor is better for us in a current situation.

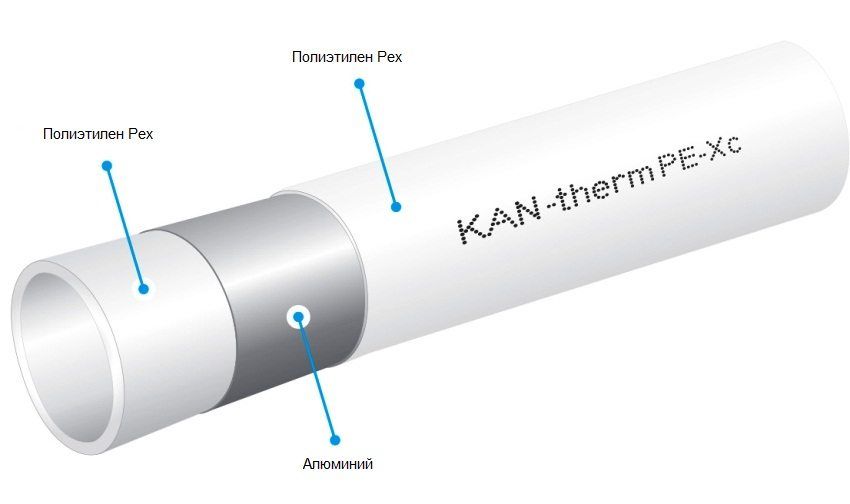

Metal-plastic is a modern composite multilayer material. Outside and inside of polyethylene of different thickness, a strip of aluminum connects them. Such pipes have an optimal heat transfer per 1 m2, which gives good performance when heating the floor covering. The metal contributes to very fast heating and good heat capacity, and also provides the necessary strength to the product. The design features of the pipe led to the following properties necessary for it:

- Very long service life. Manufacturers assure us that plastic pipes will last 50 years or more.

- Such pipes are very convenient in laying. Their ability to bend, allows you to make any contour on the floor: a spiral, a snake or other forms.

- Anticorrosion resistance provides immunity to salts and chemically active impurities.

- A completely flat surface inside the pipe ensures stable pressure in the system.

- Good strength allows the pipe not to be distorted when heated to even 95 degrees, and also to keep the pressure at 10 bar.

This type of pipe has a number of drawbacks, which are simply necessary to know about:

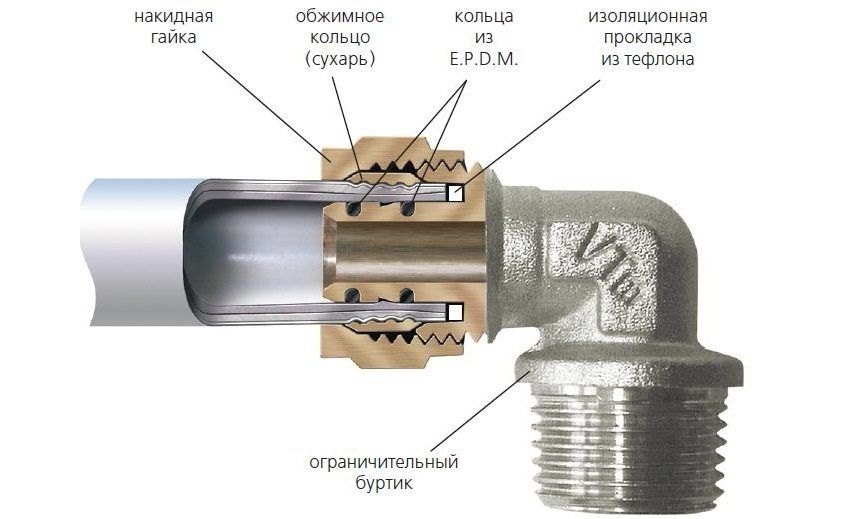

- The pipes are connected to each other using a special fitting, which is able to absorb scale on itself. In the end, the fitting may collapse and a leak will appear.

- Since aluminum and polyethylene have completely different coefficients of expansion when heated, then through many cycles there will be a separation of the constituent parts of the pipe. This is an objective reality that must be considered when answering the problem of which pipe for a warm floor is better.

Helpful advice! When installing a system of water heating floors made of metal-plastic pipes, it is not necessary to bury the connecting fittings in the screed. It is better to mount them near the walls, in order to cover them with baseboards.

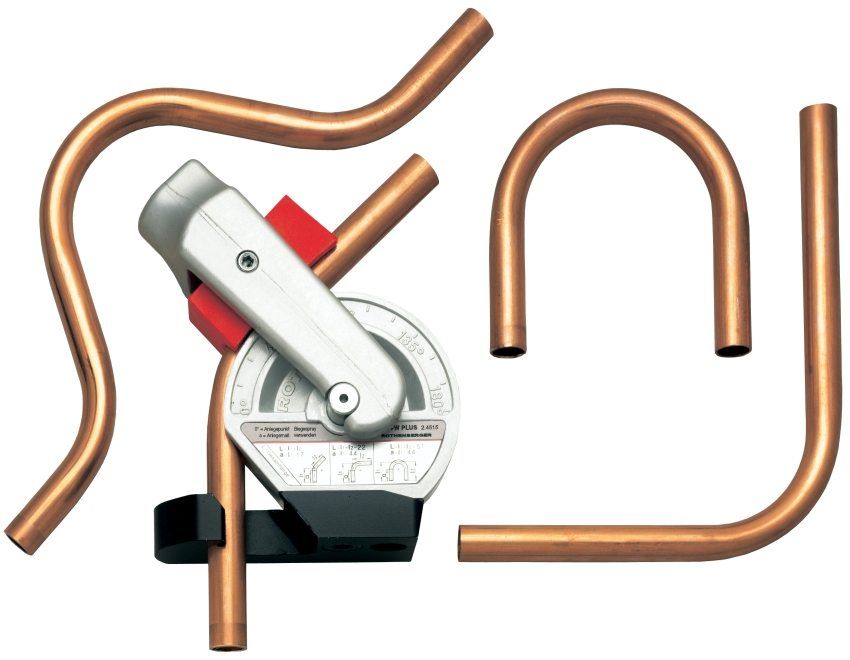

Copper is a fairly expensive non-ferrous metal, which affects the price of pipes from it. But despite this, copper pipes are often used in floor heating devices, because it is difficult to argue with the fact that this metal has better qualities than polymeric materials. It is superior in many important ways:

- On durability of material and reliability when using.

- According to the level of thermal conductivity and heating rate.

- By flexibility, because the copper pipe is very easy to twist into any desired shape, as well as cut.

In addition, such pipes are able to transfer even freezing, not to mention the high temperature. A significant drawback is the cost of these pipes, since you have to pay for fittings, which are also made of copper, because there should not be contact of different metals. In addition, it is unlikely that it will be possible to mount a heated floor made of such copper pipes, due to the fact that high-temperature brazing is used to connect the pipes, which implies the ability to operate with a special tool and its presence.

Helpful advice! Choosing copper pipes for a warm floor is better, whatever expensive they are, hire a professional for installation. This will provide high-quality styling and will eliminate unnecessary problems.

Many experts say that pipes made of cross-linked polyethylene are suitable for a heated floor better than others. Indeed, this material from polymers has unique properties:

- Its heat resistance is very high. The pipe can withstand temperatures up to 120 degrees, which is an absolute record among all types of plastic pipes.

- The material has the ability to restore its geometrical parameters during cooling. Numerous cycles of raising and lowering the temperature do not affect it, unlike other materials.

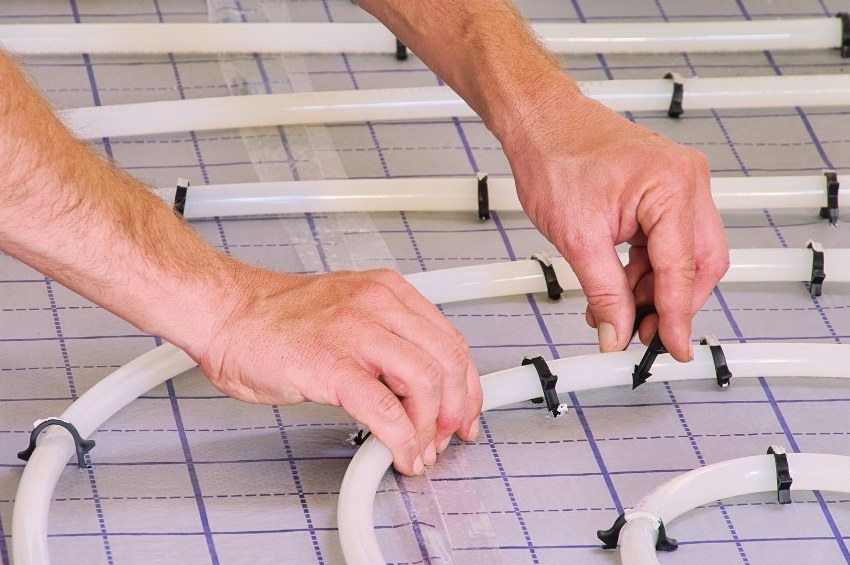

Due to the fact that the molecules of polyethylene, by the standards of the microworld, are simply huge and even connected to each other in addition, the pipes made of this material are very flexible, which makes it possible to bend them, they are environmentally friendly, not subject to corrosion and durable. These properties allow, without doubt, to take pipes from cross-linked polyethylene for a heated floor.

Not deprived of polyethylene pipes and minuses. Suffice it to say that polyethylene is able to gradually pass oxygen. This leads to an oxidative reaction in the environment surrounding the pipe. Fortunately, we learned how to deal with this by spraying a special composition onto the pipes.

Helpful advice! In the process of installing a water-heated floor, polyethylene pipes need to be fixed with special brackets or laid into special grooved rails. This is done due to the fact that polyethylene badly keeps its shape.

Usually use 16 mm pipes made of cross-linked polyethylene for floor heating. They give optimum heat transfer, with a small thickness of the screed. In addition, they are easier to lay a snake on the bottom of the floor.

The use of polypropylene pipes for the installation of a heating floor is not advisable, since such pipes bend very badly. Play the installation process of polypropylene pipes do it yourself, video which you can see, spiraling in increments of less than 13 cm is simply impossible, which creates problems with floor heating in certain conditions. Laying them on a given contour is very difficult. They are not designed for heat at all, more than 80 degrees.

If you stopped to make a warm floor of these stubborn pipes, then you should know that they are polypropylene pipes of different diameters, which have a layer for reinforcement of aluminum foil. It reduces the expansion of the material when heated. Polypropylene is strong enough and reliable. In addition, pipes from it are cheaper than others. When installing a heated floor, it is necessary to maintain the temperature in the room above 15 degrees. Only under this condition will it be possible to install the polypropylene pipes by hand. Video of this process always focuses on this circumstance.

In order to begin the construction of a heated floor, it is important to get a welding machine for welding polypropylene. Learning to use it is not difficult. On this account you can find a lot of instructions and manuals. Since this type of pipe bends very badly, laying can only be done in a spiral. For installation it is better to take a 16 mm pipe. They have the best combination of thickness and flexibility.

In addition to the welding machine, you will definitely need special connecting fittings and stop valves for the installation of polypropylene pipes with your own hands. Video soldering of all parts of the pipeline is easy to find online. Laying spiral is made on top of waterproofing using special mounts or grooved bars. After the whole structure is soldered, water is pumped into it from the heating system. If everything works and there is no leakage, then you can fill the screed.

Having considered all the options, it is still difficult to make a conclusion about which pipes are better for floor heating. Clearly, polypropylene is the worst for this role. Excellent quality in copper and polyethylene pipes, mediocre in metal-plastic. If you make a choice between copper and polyethylene, then it is fundamental what amount of repair is included in your budget for this type of expenditure. After all, copper is much more expensive than polyethylene, although for the purposes of a warm floor, the latter is not inferior to many in terms of its characteristics. That is why polyethylene pipes are the most popular today, and many different designs are made of them.