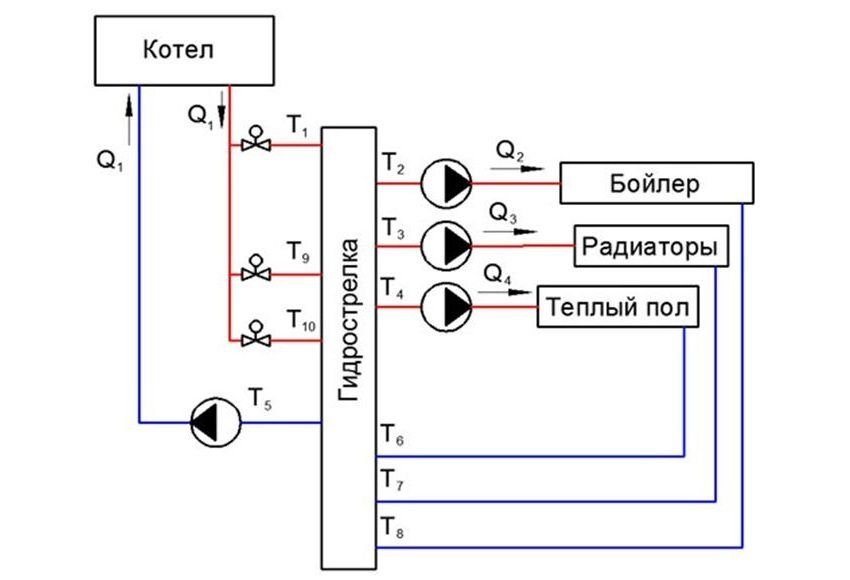

What is a hydraulic needle in the heating system? The hydraulic and temperature buffer that provides the correlation of the supply / return temperature and the ordered maximum flow rate of the coolant is called a hydraulic needle. The article on the topic: “Hydro Arrow: principle of operation, purpose and calculations” reveals the essence of the hydraulic separation of the heating circuits.

Why do we need a hydraulic needle in the heating system?

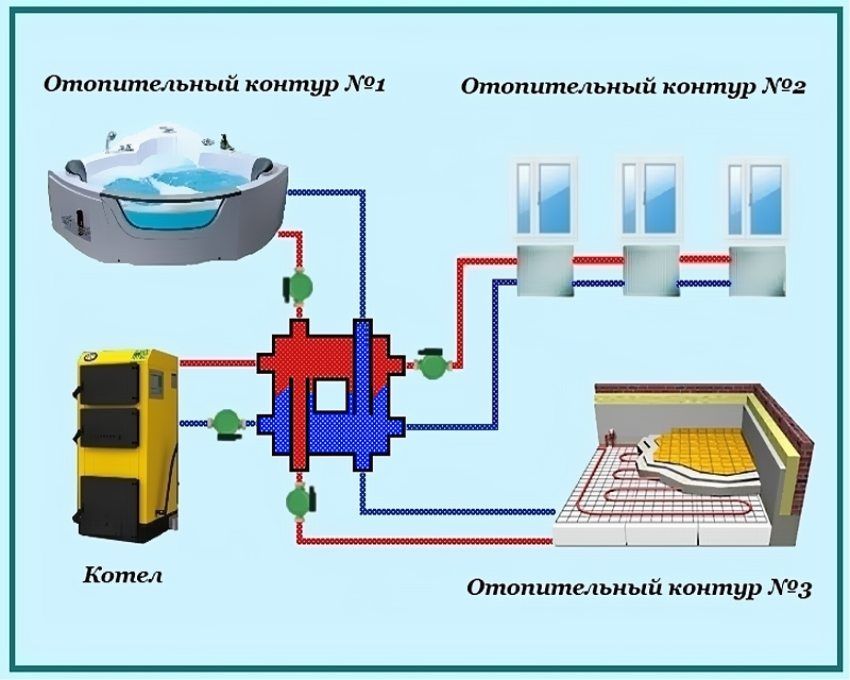

It is very easy to explain why a hydraulic needle is needed for heating. The processes of unbalancing the heat supply are familiar to the owners of private houses. A modern boiler has a smaller circuit than a consumer’s circulation flow. The operation of the heating water-gun allows separating the hydraulic circuit of the heat generator from the secondary circuit, increasing the reliability and quality of the system.

The answer to the question: “Why is a hydraulic needle in the heating system needed?”, Is a list of advantages of heating with a hydraulic thermal separator:

- a separator is a prerequisite of the equipment manufacturer to guarantee maintenance for a boiler with a capacity of 50 kW or more, or a heat generator with a cast iron heat exchanger;

- the node provides the maximum flow with the laminar flow of the coolant, maintains the hydraulic and temperature balance of the heating system;

- parallel connection of the heating hands and the consumer circuit creates minimal pressure loss, performance and heat energy;

- the knee arrangement of the supply-return connections provides the temperature gradient of the secondary circuits;

- optimal selection and calculation of the hydraulic arrows for heating protects the boiler from the difference between supply and return temperatures, protects the equipment from heat stroke, evens out the circulation volume of water flows in the primary and secondary circuits;

- the node increases the efficiency of the boiler, allows the secondary circulation of part of the coolant in the boiler circuit, saves electricity and fuel;

- podmes maintains a constant volume of boiler water;

- if there is an urgent need, the separator compensates for a shortage of consumption in the secondary circuit;

- a hollow separator reduces the effect of pumps with different kW power on the secondary circuits and the boiler;

- additional functions of hydraulic separator – reduces hydraulic resistance, creates conditions for the separation of dissolved gases and sludge.

The principle of operation of the heating water gun allows stabilizing the hydrodynamic processes in the system. Timely removal of mechanical impurities from the coolant will extend the service life of pumps, valves, meters, sensors, heating devices. By separating the flows (heat generator circuit and independent consumer circuit), the hydraulic needle ensures maximum utilization of the heat of combustion of the fuel.

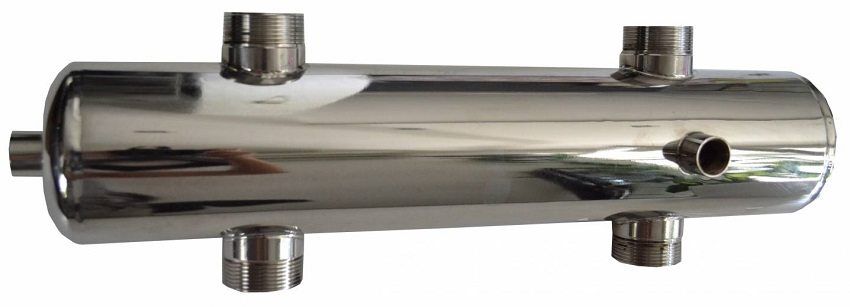

The hydraulic separator is a vertical hollow vessel made from large-diameter pipes (square profile) with elliptical plugs at the ends. The dimensions of the separator are determined by the power (kW) of the boiler, depending on the number and volume of circuits.

Heavy metal casing is mounted on support legs in order not to create linear stress on the pipeline. Compact devices are fixed to the wall, placed on the brackets.

The hydraulic needle pipe and the heating pipe are connected by flanges or threads.

Automatic valve vent is located at the top of the housing. The precipitate is removed through a valve or a special valve, which is embedded below.

The material for the manufacture of hydraulic arrows – low carbon or stainless steel, copper, polypropylene. The body is treated with an anti-corrosion compound, covered with thermal insulation.

Important! Polymer models are used in the system, which is heated by a boiler with a capacity from 13 to 35 kW. Hydraulic separators made of polypropylene are not used for heat generators that run on solid fuels. Making hands with their own hands from propylene requires experience and skills to work with a professional plumbing and hand power tools.

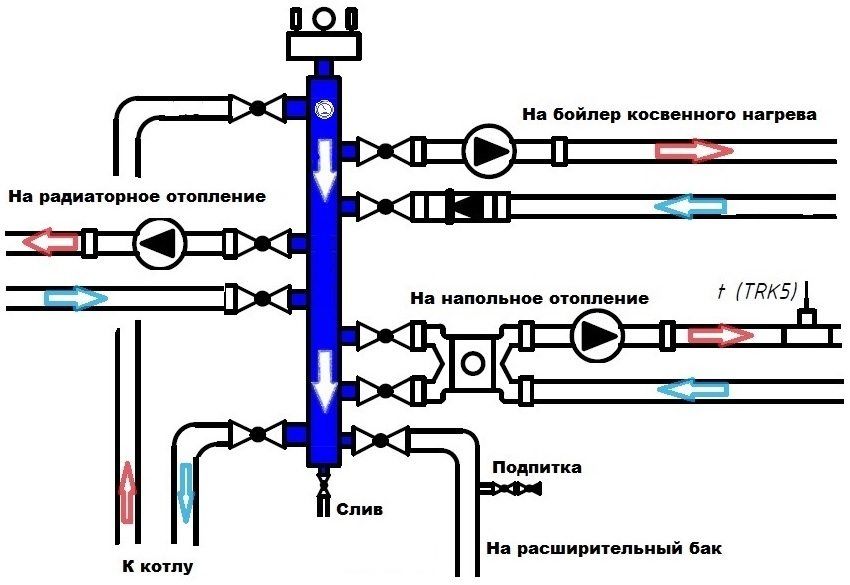

Advanced models combine the functions of a separator, a temperature controller and a separator. The thermostat valve provides a temperature gradient of the secondary circuits. The release of dissolved oxygen from the coolant reduces the risk of erosion of the internal surfaces of the equipment. Removal of suspended particles from the flow extends the service life of the impeller and the bearings of the circulation pumps.

The photo shows a model of hydraulic arrows for heating in the section:

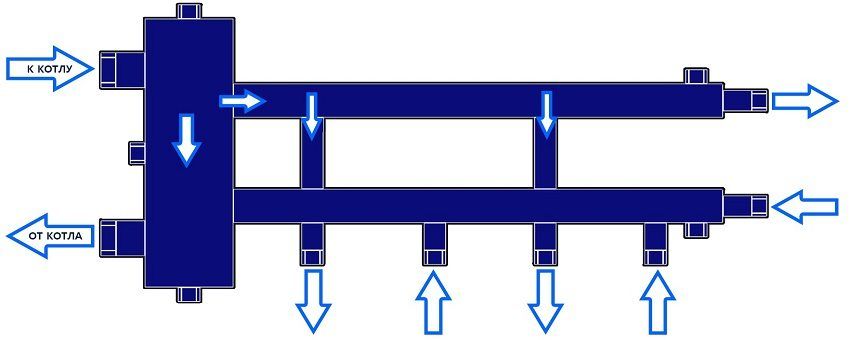

Horizontal perforated partitions divide the internal volume in half. Flows of supply-return contact in the zone of the “zero point” and slide in different directions, without creating additional resistance.

Above, in the high-temperature zone, are located porous vertical deaeration plates. Sludge collector and magnetic trap (magnesium anode) are located in the lower part of the housing.

The design options of the hydraulic arrows: a pressure gauge, a temperature sensor, a temperature control valve and a line for powering the system at start-up. Complex equipment needs adjustment, regular inspections and maintenance.

The coolant flow passes the separator at a speed of 0.1-0.2 m / s. The boiler pump accelerates hot water to 0.7-0.9 m / s. The recommended speed limit gives an idea of what a hydroarrow is needed for heating.

The change in the volume and direction of movement dampens the rate of water flow with minimal loss of thermal energy in the system. Laminar flow movement leads to the fact that the hydraulic resistance inside the body is practically absent. The buffer zone separates the boiler and the consumer circuit. The pump of each of the heating circuits operates autonomously, without disturbing the hydraulic balance.

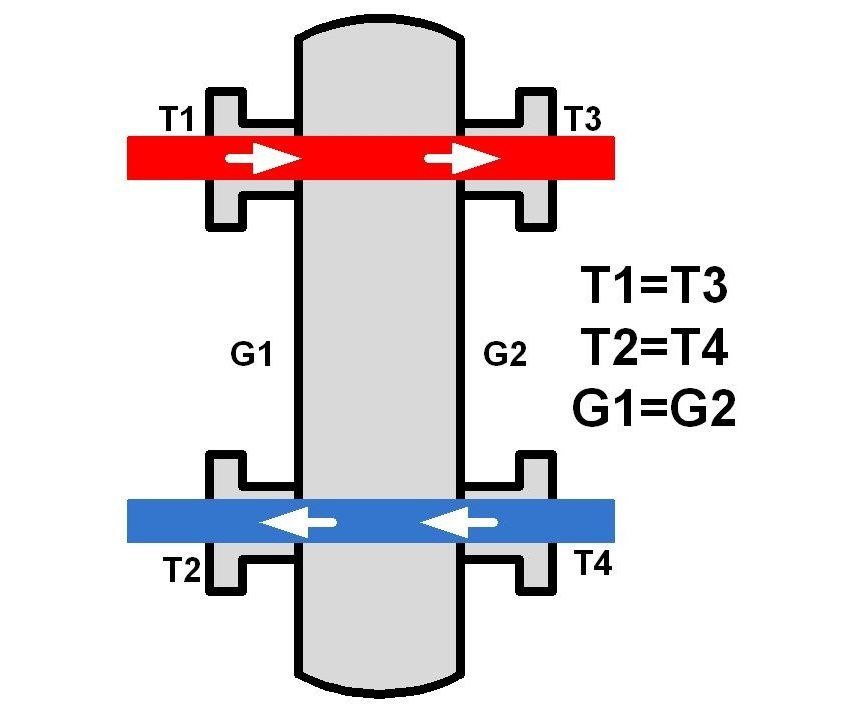

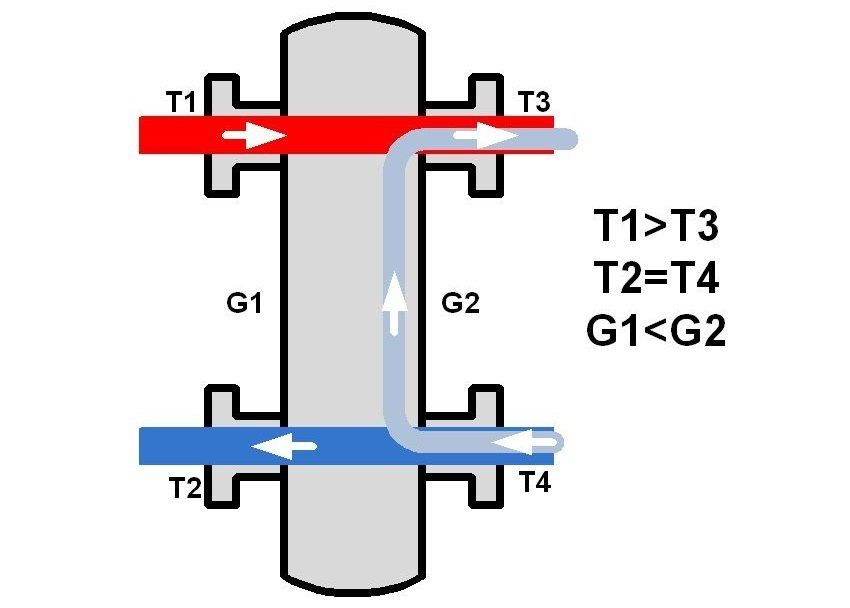

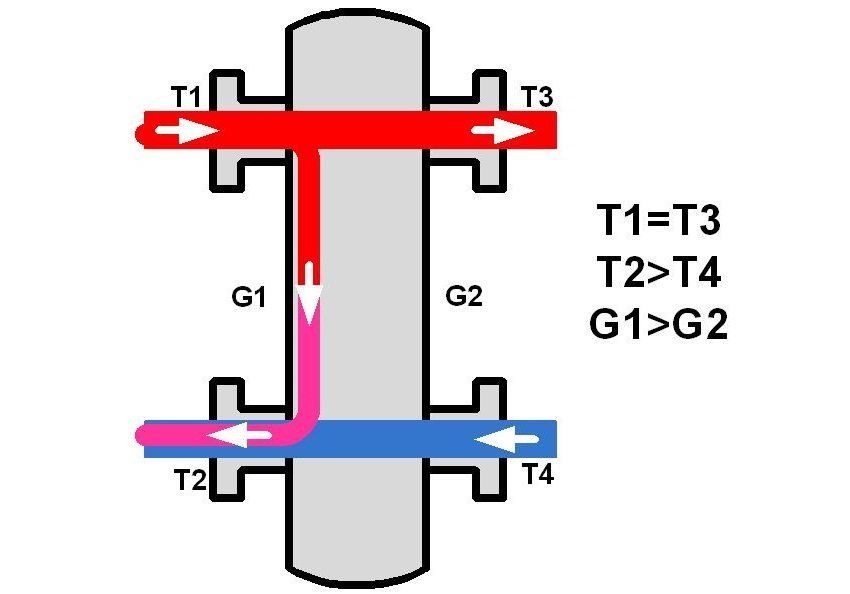

Hydraulic arrows for heating (operation mode):

- The neutral operating mode of the hydraulic separator, at which the pressure, flow, temperature and thermal energy of the supply and return flow correspond to the design parameters of the system. Pumping equipment has sufficient total capacity. Laminar flow movement in the hydraulic needle provides the processes of deaeration and sedimentation of suspended particles.

- The scheme reflects the principle of operation of the heating hands, in which the boiler does not have enough power to ensure consumption in the secondary circuit. The lack of consumption leads to a mixture of cold coolant. The difference in supply / return temperatures leads to the triggering of thermal sensors. Automatic equipment will bring the heat generator to the maximum combustion mode, however, the consumer does not receive enough heat. The heating system is unbalanced, there is a threat of heat stroke.

- The volume flow of the primary circuit is greater than the dependent coolant flow rate. The option in which the boiler operates optimally. During ignition of the unit or parallel shutdown of the pumps of the secondary circuits, the coolant circulates through the hydraulic needle along the primary (small) circuit. The temperature of the return flow that enters the boiler is equalized by mixing with the feed. A sufficient amount of coolant comes to the consumer.

Prerequisite: the performance of the circulation pump of the primary (boiler) circuit is 10% more than the total maximum pump head in the secondary circuit.

How to calculate the hydro arrow of a private house heating system independently? You can calculate the required dimensions by the formulas or choose the diameter by the rule “3D”.

- The formula determines the diameter (D) according to the maximum capacity of the hydraulic separator (calculations based on the passport data for the boiler):

- The formula determines the diameter of the hydraulic needle on the power of the heat generator. ΔT flow / return temperature difference – 10 ° C:

- The diameter of the nozzle entering the hydraulic needle or distribution manifold:

| Designation | Character decoding | unit of measurement |

| D | The diameter of the body of hydraulic arrows | mm |

| d | Nozzle diameter | mm |

| P | The maximum power that the boiler has (passport data of the boiler) | kw |

| G | Maximum flow (throughput, flow) through the hydraulic separator per hour | m3/hour |

| ? | Constant value (3.14) | |

| ? | Maximum vertical velocity of the coolant through the separator (0.2) | m / s |

| ?T | The difference in temperature flow – return (passport data of the boiler) | ° C |

| C | Heat capacity of water (relative unit) | W / (kg ° C) |

| V | Coolant velocity through secondary circuits | m / s |

| Q | Maximum consumption in the consumer circuit | m3/ h |

Important! The formulas according to which the hydroarrows are calculated for heating are obtained empirically. The diameter of the inlet to the hydraulic separator corresponds to the diameter of the outlet of the boiler.

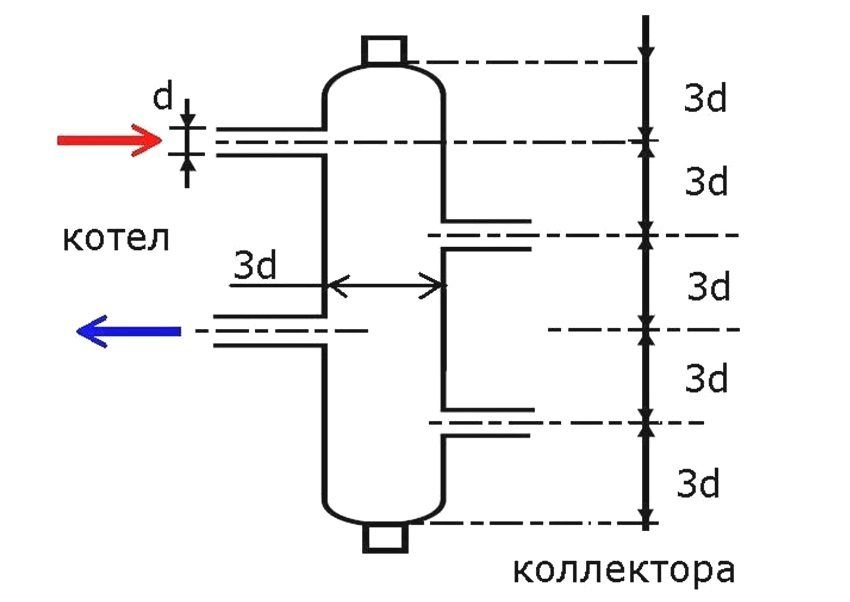

- Determination of the parameters of the hydraulic needle practical method

The approximate size for small dividers is chosen according to the diameter of the inlet (outlet) nozzles. The distance between the inserts is at least 10 choke diameters. The height of the body is much greater than the diameter.

The crank diagram of the hydraulic arrows for heating is used in the selection of the installation of large sizes. According to the “3d rule”, the diameter of the body is three times the diameter of the nozzle. The 3d distance determines the proportions of the structure.

- The distribution of frames by the height of the column separator:

If the system does not provide a distribution manifold, then the number of tie-ins into the separator is increased. The pipeline connecting the first (boiler) circuit with the hydraulic needle is distributed in height. The method allows to adjust the temperature gradient in the dynamics. The condition is necessary for the qualitative selection of the coolant secondary circuits.

Small houses are heated by a boiler, which has a built-in pump. Secondary circuits are attached to the boiler through a hydraulic needle. Independent contours of residential buildings with a large area (from 150 m2) connect through a comb, hydro separator will be cumbersome.

Theoretical knowledge will help draw up diagrams and drawings of the heating hydro arrow, make an individual order of equipment in a specialized organization, monitor the work of the contractor. Trust the manufacture of critical nodes of the heating system to non-professionals is dangerous for life and health. It should be remembered that the equipment damaged by the owner’s fault is not subject to warranty repair and return.