Recently, metal roofing has become increasingly popular on the roofing materials market. Installation of the roof of it is relatively simple, and performance are at a high level. When choosing this material an important parameter is the size of the sheet metal roofing: the price of which may also depend on a number of other factors, such as the type of sheet coating, their shape and many others.

What to consider when choosing a sheet size

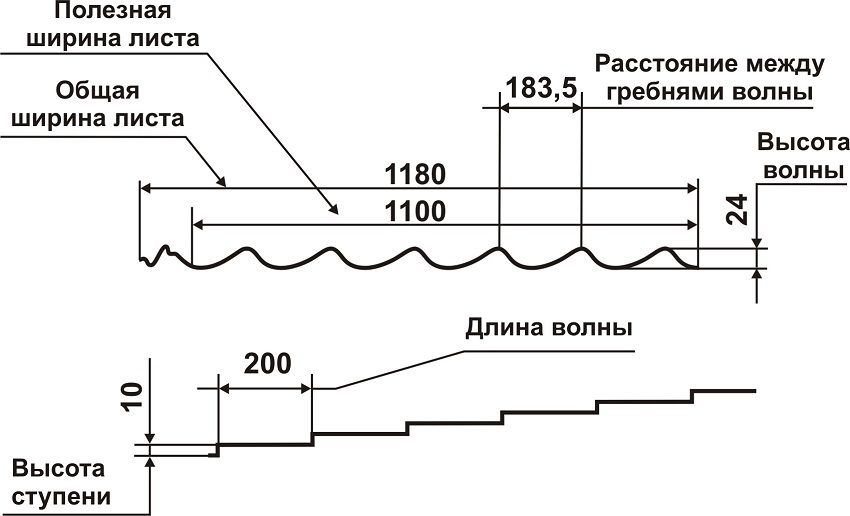

At standard sizes, the price of sheet metal for the roof is slightly higher than that of slate or roofing tin, but this is offset by the high performance characteristics of the material. Choosing a sheet, you should understand that its area can be full or useful. Overall length and width is the distance from one edge to the other. Usually, length varies from 40 cm to 8 m, and width – 1.16-1.19 m.

The useful size of the sheet should correspond to the size of the roof, but not be too large, otherwise the process of mounting the roof can become much more complicated. The most convenient for installation width is 1.16 m, and a length of 4.5 m. It should be borne in mind that the sheets of material are mounted overlap, that is, the edge of one sheet overlaps the adjacent one. This is done in order to eliminate the possibility of leakage and increase the service life of the entire coating.

The optimal size of metal roofing is the full size minus overlaps. In standard cases, the size of the overlap is from 6 to 8 cm in the transverse direction and from 10 to 15 in the longitudinal direction. Also, the amount of overlap depends largely on the brand of the chosen material.

In addition to the length and width of the sheet of roofing material, the choice must take into account a number of important parameters:

- sheet thickness. This parameter ranges from 0.45 to 0.5 mm, with the latter being the most popular. The thickness is indicated in the parameters that the manufacturer claims, but it is better to check it manually when purchasing. If you buy too thin metal tile, then it will be quite difficult to transport and install, and it will withstand a small load;

- profile height. Standard height is 1.8-2.5 cm, if you need a sheet of greater or lesser height, then its production can be ordered individually;

- wave step. For standard models it ranges from 35 to 40 cm, but profiles with other characteristics can be made to order.

The most popular among buyers is metal with a small wave height – up to 50 mm. This is because it is cheaper than other types of profile and easier to install. If the wave height exceeds 50 mm, such sheets are considered elite and are more expensive than usual.

Helpful advice! Profile wave can also be asymmetric or symmetric. The first option is more common and cheaper. Sheets with a symmetric wave are not produced by all manufacturers and are several times more expensive.

One of the features of the material is the presence of a distinct top and bottom of the sheets. This means that it is impossible to turn them over. If your roof is of complex shape, and you use shingles of complex configuration for the roof, this feature greatly complicates installation and increases its cost due to a large amount of waste.

If you choose a model with a complex wave configuration, then you should understand that it will not just be more expensive than the standard one, but its installation will take more time and effort from you. Therefore, if you do not have professional skills in the field of roofing, it is better to stay at a simpler and cheaper option. Photos of the roof of metal show that it looks good even if you mount the most common roofing material without frills.

If you want to understand what the already mounted material will look like on your roof, then you should visit the specialized stands where manufacturers demonstrate ready-made pieces of the roof.

When choosing the size of a sheet of metal for the roof it is worth considering that the material itself consists of several layers, each of which has its own special purpose:

- Zinc layer – protects sheets of metal from corrosion, high humidity and other types of negative effects;

- polymer layer – gives the sheet of material the necessary color, acts as an additional protection from external influences. In the photo of metal, colors depend on the top polymer coating.

- passivating layer – does not allow static electricity to accumulate on the sheets of roofing material;

- priming layer – serves as the basis for applying a polymer coating.

Choosing a roofing material with a polymer coating, you get a guarantee of durability for 10-15 years, and with proper installation and maintenance, and for a longer period.

The common sizes of sheets of metal tile are summarized in the table:

| Size (length x width), mm | Overlap in length, mm | Overlap in width, mm |

| 705×1190 | 45 | five |

| 3600/2200/1150 / 450×1185 | 100 | 85 |

| 3620/2220/1170 / 470×1140 | 120 | 90 |

| 3620/2220/1170 / 470×1160 | 120 | 60 |

| 3620/2220/1170 / 490×1160 | 120 | 80 |

| 3630/2230/1180/80×1180 | 130 | 80 |

| 3630/2230/1180/480×1190 | 130 | 90 |

| 3650/2250 / 850×1153 | 150 | 28 |

| 3650/2250/1200 / 500×1190 | 150 | 90 |

Various manufacturers of roofing materials are used to create the top layer of tile different materials:

- Pural – a relatively new version of the coating based on polyurethane. With a thickness of only 50 microns, the material boasts a high level of resistance to temperature extremes, mechanical stress and corrosion. Pural coated roof tiles are usually used in cases where the roof must withstand very high or very low temperatures;

- polyester – based on polyester gloss paint, 25 microns thick. From its advantages we can distinguish a steady, saturated color that does not fade in the sun, and the possibility of installation and operation under any environmental conditions. In addition, the polyester coating is characterized by the lowest price of metal tiles per square meter;

- Matte polyester is the same as the previous version, but featuring a matte sheen and slightly thicker – 35 microns. It is also characterized by color stability and the fact that it maintains a high level of operational characteristics under any environmental conditions. If you choose between a matte and glossy metal tile – which one is better, then the choice here depends solely on your individual preferences in terms of roof design;

- PVDF is a glossy coating consisting of 80% polyvinyl fluoride and 20% acrylic. Its thickness is 27 microns, and the main advantage is a high level of resistance to exposure to ultraviolet radiation and aggressive media. Tiles with such a coating is good to use when installing the roof of a house, for example, on the coast. In addition, PVDF is self-washing, and it can be mounted not only on the roof, but also on the walls. Most often, metal with such a coating comes in metallic color and boasts color stability and durability;

- Plastisol – the thickest version of the polymer coating, its thickness is 200 microns. The material is based on polyvinyl chloride, and its main advantage is the highest level of resistance to mechanical and atmospheric effects as compared to others. The only drawback of plastisol is that it can dull and burn out when heated, so when installing in hot climates it is recommended to use light colored sheets.

Helpful advice! The main criterion for selecting the option of polymer coating sheets – is the environmental conditions.

Price per square meter of metal tiles manufacturer Ruukki:

| Profile type | Thickness of steel, mm | Coating | Price, rubles |

| Decorrey | 0.45 | Polyester | 498 |

| Finnera | 0.5 | Purex | 567 |

| Finnera Plus | 695 | ||

| Monterrey | Polyester | 450 | |

| Purex | 493 | ||

| Pural | 584 | ||

| Pural Matt | 584 | ||

| Adamante | Purex | 725 | |

| Armorium | Pural Matt | 815 | |

| Elite | 830 |

The choice of the size of the metal roof also affects the type of slope. It may be as follows:

- single or dual roof;

- gable;

- hip;

- mansard;

- chetyrehskatnaya.

Shed option – the simplest in terms of design and is characterized by the smallest number of parts. A single-sided roof does not have a ridge, additional ventilation elements and other unnecessary parts, respectively, when calculating metal tiles on a single-sided roof, you can count on a minimum amount of waste. In addition, it affects the price of work.

How much does it cost to cover with a metal tile a single-sided form? Considerably cheaper than other roofing options. But the durability of such a roof will be at its height, even if you use the thinnest version, since the load on a single-pitch roof is less than the roof of a different configuration.

For a gable roof sheets of metal size of a standard size are also suitable. With a gable roof made of metal, photos of houses look very attractive, regardless of the manufacturer of the roofing material or the type of polymer coating. In terms of economy in terms of material used, this option is a bit more expensive than in the case of a single-pitch roof, but also does not require large financial expenditures.

Hip roof – one of the most difficult and costly in terms of the use of roofing materials options for roofing. What is the best metal tile to use in this case depends only on you, but you should take into account the fact that a sufficiently large amount of material can go to waste due to the complex configuration of the structure.

Regardless of the size of the sheet, the price for a sheet of metal, the installation of the roof of this material is carried out in a certain sequence and in compliance with a number of important nuances.

After you have decided on a metal tile – which one is better to choose for the roof, you need to make sure that the surface of the roof itself is even. All defects found must be eliminated, otherwise you risk getting a short-lived construction with low quality hydro and thermal insulation and other performance characteristics.

After all defects of the roof are eliminated, it is necessary to make measurements of each of the ramps and the entire roof as a whole. The size and price of metal tile depend on it.

Helpful advice! Metal roofing as a roofing material should be chosen if the roof slope is not less than 14 degrees. Otherwise, it is recommended to give preference to another material.

If there is already some kind of roof covering on the roof, it must be dismantled. Also, before starting work, it is necessary to remove all supposed ventilation, chimney and other penetrations through the roof. It is not recommended to carry out installation of the material in parallel with the facing work.

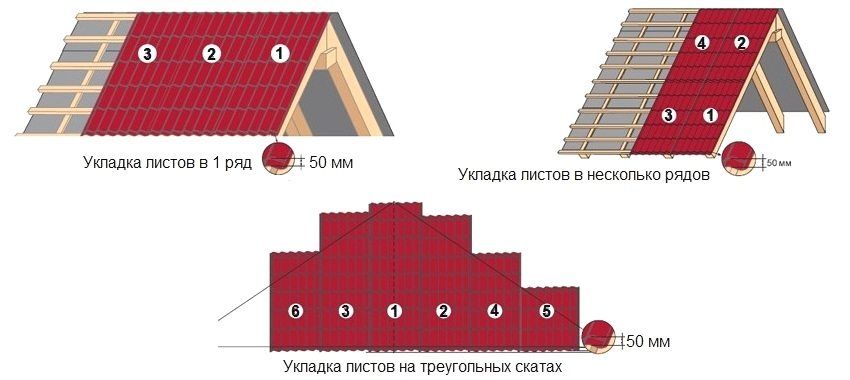

Sheets of metal tiles of standard size should be laid with an overlap of 10 cm. If the length of the slope exceeds 6-7 m, then the sheet should be divided into 2-3 parts.

The lathing is the base of the roof of metal tile. Its installation should be carried out in accordance with the following recommendations:

- The step between rafters should not exceed 900 mm. When using metal tiles of a standard size, it is recommended to take rafters with a cross section of 150×50 mm, boards – 100×25 mm.

- The first batten board should be tied strictly along the overhang. However, it should not protrude beyond the eaves, and its thickness should be 10-15 mm more than the other boards of the system.