Modern canopies, due to the use in their designs of the newest building materials, can have the most diverse configuration. Owners of their own homesteads and country houses especially liked polycarbonate sheds to a private house with their own hands: photos of convenient and practical structures convince of their extraordinary versatility. Having covered a large part of the courtyard with a polycarbonate shed, you need not worry that a sudden rain will catch you by surprise, forcing you to collect garden tools, shoes and equipment left outside. The construction attached to the house will cover the car from the scorching sun, and if there is a dinner with friends in the open air, the meeting will not have to be postponed due to bad weather.

Types of canopy structures attached to the house

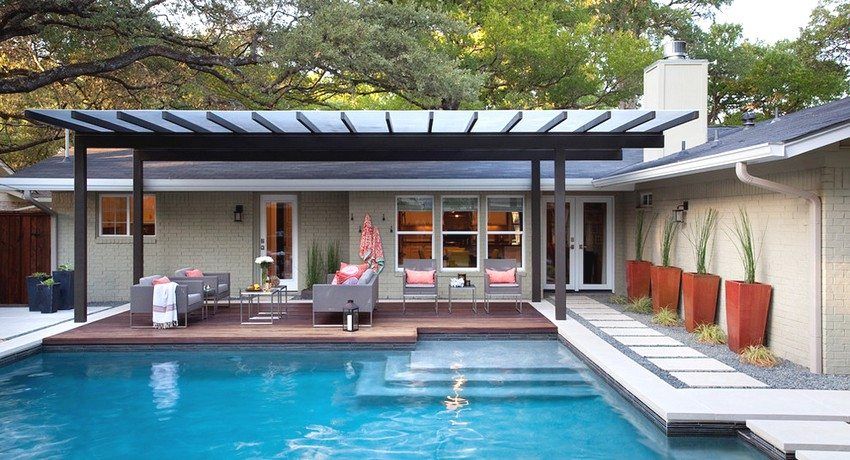

As for the canopies, installed in isolation, and for the structures adjacent to the house, there is a single rule: the structures must be combined with existing architectural forms and fit into the overall landscape design. Attached to the house canopies of one side based on the rack, and the other statically attached to the wall of the house, garage or fencing. There are several types of frames for such structures:

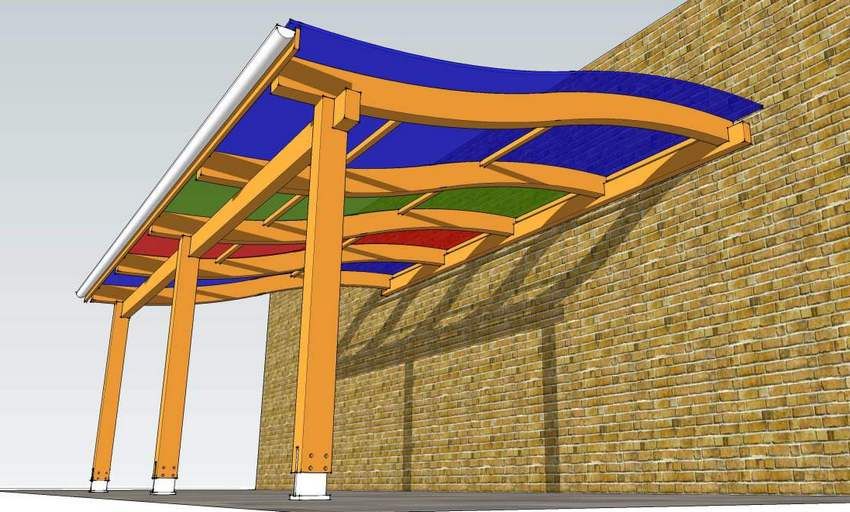

- canopies with a lean-to roof – the most familiar simple structure. Installation technology is quite simple. When calculating the angle of inclination of a flat roof, the possibility of a rapid descent of snow cover in wintertime is taken into account;

- gable structures – common forms of the roof, having two slopes. The angle of inclination in such structures is 35-45 degrees, which ensures the descent of snow under its own weight and the absence of rainwater stagnation. Recently, gable canopies with concave and curved slopes are gaining in popularity;

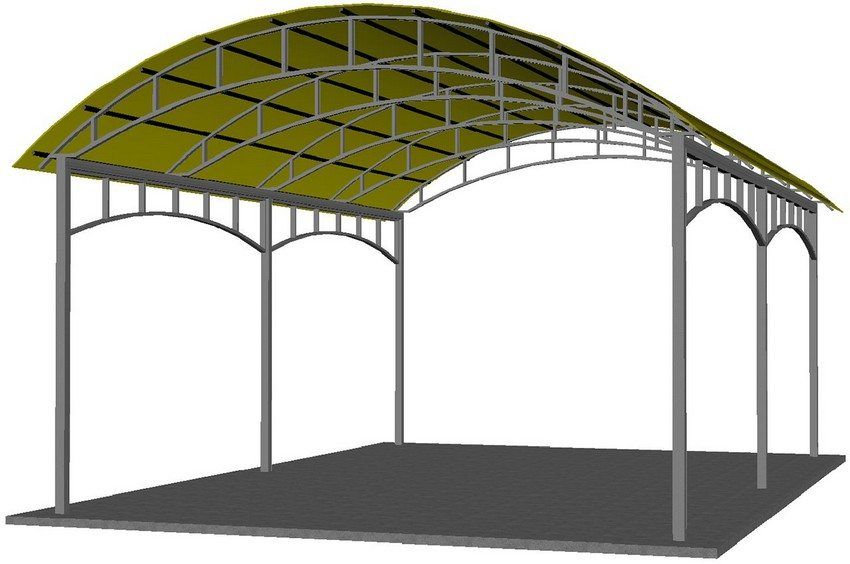

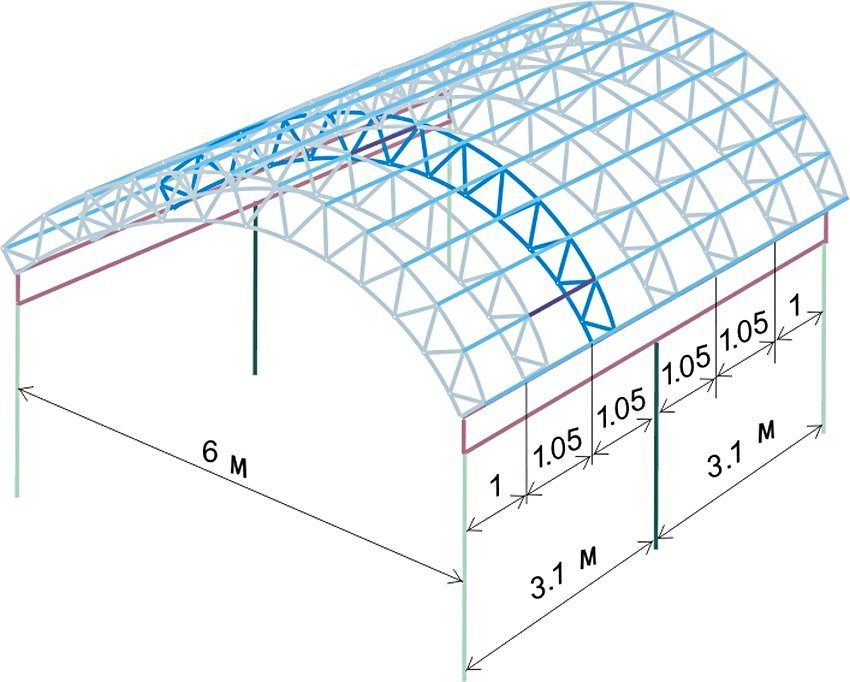

- arched (semicircular) shape of the roof is an actual construction from the standpoint of functionality and originality. The emergence of new materials with plastic properties made it possible to successfully use such structures for sheds, canopies and other structures. Semicircular roof contributes to the timely removal of snow. The bend radius of the arch depends on the minimum allowed by the manufacturer for the material used;

- wave and dome structures – used as a protective and decorative element;

- multi-level sheds – structures with several tiers. In such sheds can be used as a sloping roof and arched.

For independent production and installation of a polycarbonate shed, especially if the work is done for the first time, it is recommended to choose a structure with a single-sided roof. It is quite simple to manufacture and to cope with the installation can not possessing special skills.

It will be much more difficult to design, manufacture and install dome or arched canopies of polycarbonate to a private house with your own hands (photos on the network demonstrate the complex structures of such structures). Here it is necessary to take into account the directions of the channels in the panels of cellular polycarbonate, the permissible bending radius, the thickness of the material and other aspects that require certain knowledge and skills.

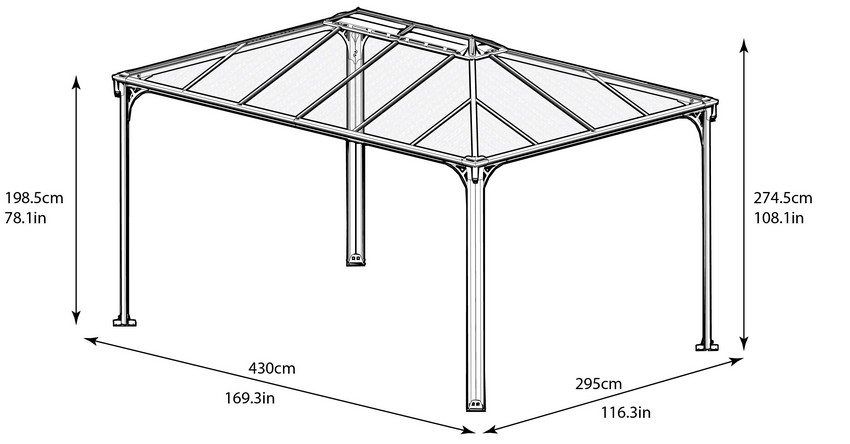

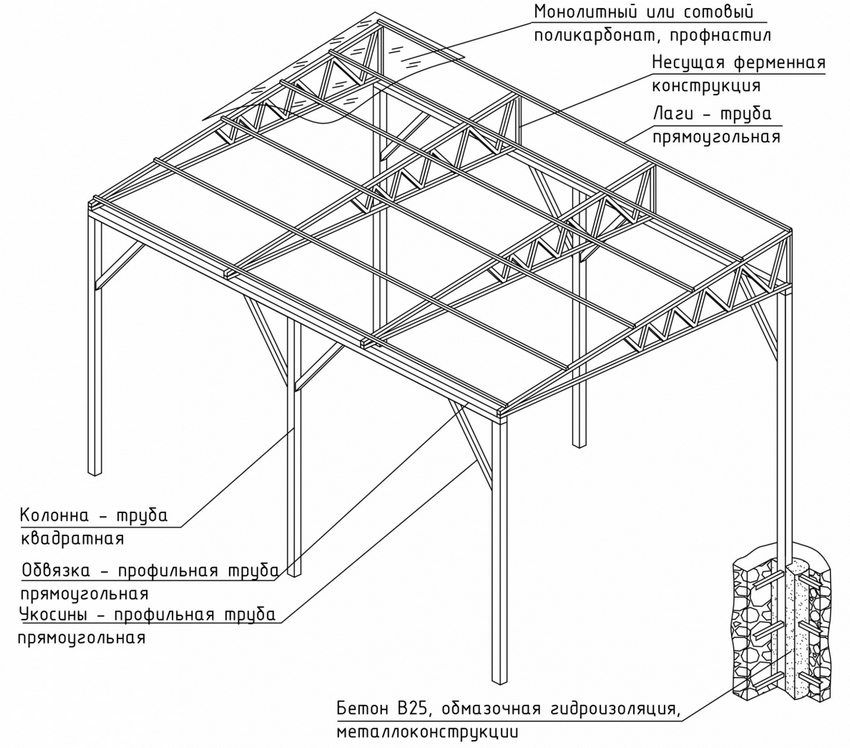

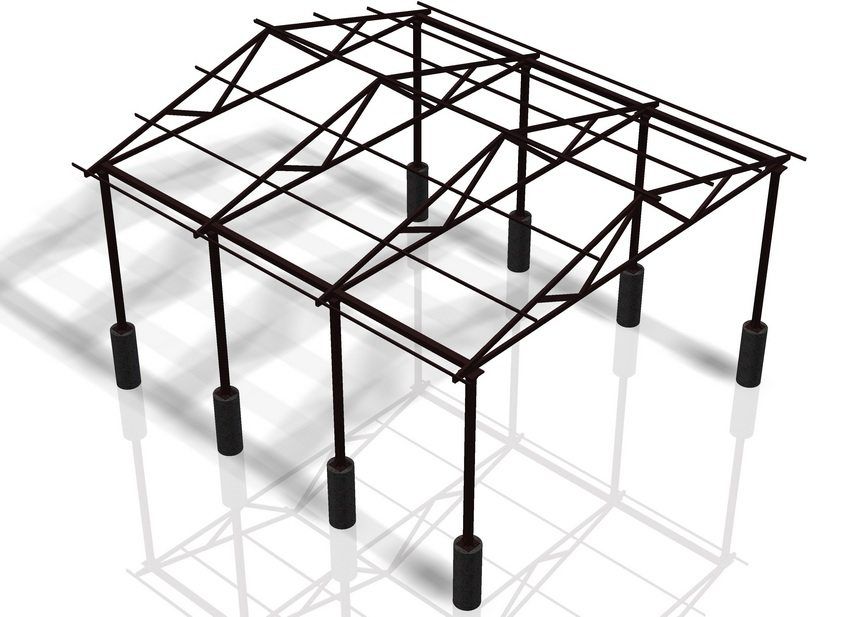

The canopy is a simple construction in the form of a roof mounted on support posts. For supports, you can use wood (logs or bars), a metal shaped tube with a different section, as well as brick posts. The metal profile and wooden beam are also used to assemble the frame, only the cross section is chosen smaller than for the supports.

Can be varied material to cover canopies. It is the roof that gives the structure a certain appearance. It can be plastic slate, asbestos cement slate, metal tile, copper sheets, corrugated board, polycarbonate.

Due to a variety of unique properties, polycarbonate is the most sought-after as a coating for sheds. This material is much superior to metal and glass, not inferior to them in environmental friendliness and strength. High resistance to cellular polycarbonate loads in comparison with glass is determined by the presence of longitudinal stiffening ribs of the cellular structure.

Although monolithic polycarbonate is stronger than cellular, each of them has its own advantages. The choice to cover one or another type directly depends on the requirements for the structure.

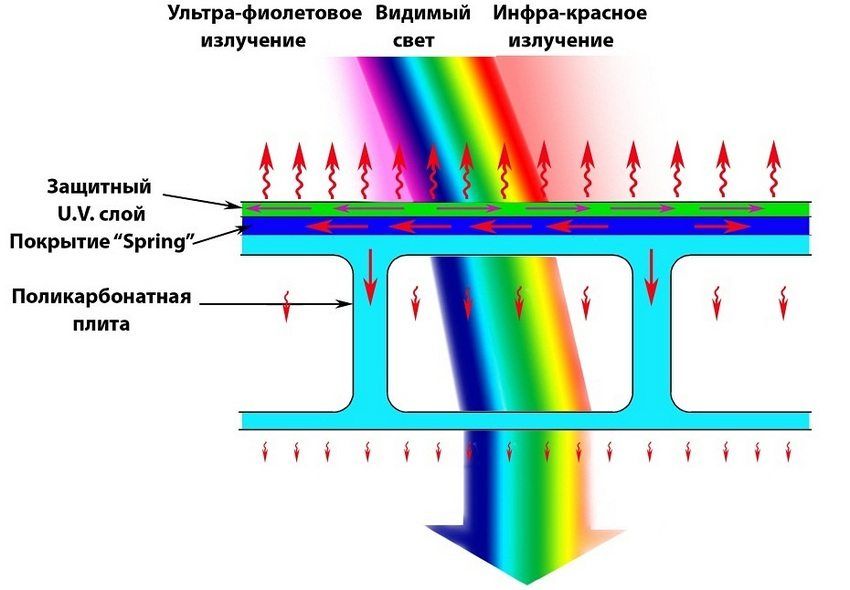

Solid polycarbonate has an incredible light transmission ability, reaching 90%. Cellular samples have somewhat lower translucent qualities, but at the same time they perfectly diffuse light and create a barrier to ultraviolet radiation. Use for canopies of sheets of cellular polycarbonate due to such properties:

- high structural strength – several layers interconnected by stiffness walls at different angles form a cellular structure, providing high strength;

- stability, ability to withstand strong wind and snow load;

- impact resistance – the material not only does not form fragments at rupture, but is almost not deformed by mechanical effects;

- flexibility – it is possible to give the material any desired shape without deteriorating its characteristics;

- high percentage of light transmission with protection from UV rays;

- resistance to temperature fluctuations – can be operated at a temperature from -40 to +55? С;

- light weight – allows for installation without resorting to the use of special mechanisms (the material is 15 times lighter than glass of the same size);

- simplicity in cutting – the material is perfectly machined with cutting tools, drilled, with no fragments;

- fireproof – flame-resistant material, when contact with a source of fire is terminated, it self-extinguishes. The opening formed during melting allows the smoke to be expelled, eliminating the risk of suffocation;

- resistant to chemical and weathering;

- durable – retains its properties throughout the entire period of operation of 10-11 years;

- it is easy in leaving – does not demand additional processing, quickly gives in to clarification.

As for the aesthetic component, manufacturers produce not only colorless transparent sheets, but also samples with a variety of colors. This allows you to give the structures of cellular polycarbonate a spectacular appearance.

Helpful advice! Choosing the color of polycarbonate to cover the canopy, you should give preference to tones that do not distort the natural colors of the objects located under the building. When using panels of red and orange color, all objects will have a corresponding characteristic shade.

The characteristics of polycarbonate are largely determined by the structure of the material: cellular panels are hollow, their specific weight is much less than that of solid sheets. Consequently, their cost is lower.

The parameters of choice of polycarbonate for sheds are: its decorative features, geometric shapes, purpose, economic indicators.

Helpful advice! If the style of construction provides plastic, similar to silicate glass, apply solid polycarbonate, which can also have different colors.

It is recommended to use for carports polycarbonate with a thickness of 4 mm or more. You can analyze the parameters of various types of panels on the basis of their operational properties:

| Parameters and properties of polycarbonate panels | Units | Cellular structure | Monolithic structure |

| Standard width | m | 2.1 | 2.05 |

| Leaf length | m | 6/12 | 3.05 |

| Material weight | kg / cm? | 1,3 | 7.2 |

| Allowable minimum bending radius | m | 1.05 | 0.9 |

| Thermal resistance | m ?? S / W | 0.28 | 0.2 |

| Duration of operation | year | 12 | 25 |

| Degree of translucency | % | 82 | 90 |

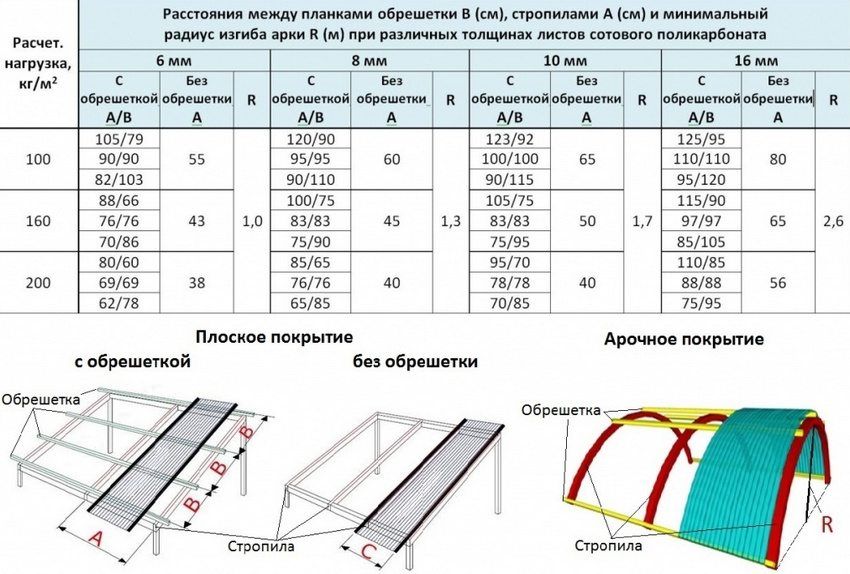

Determining the optimal thickness of the honeycomb panels, they take into account the purpose of the canopy and the degree of load on the structure. For sheets with a honeycomb structure, consider the following:

- polycarbonate with a thickness of 4 mm is used for small canopies with a maximum rounding (canopies, greenhouses);

- with sheets with a thickness of 6-8 mm, they cover structures of considerable size that can withstand the impact of strong winds and snow loads (sheds for the yard, parking lots, swimming pools);

- a sheet thickness of 10 mm is used to operate the structure in environmental conditions close to extreme.

The thickness of monolithic polycarbonate panels can vary from 4 to 12 mm. This material is twice as strong as the cellular counterpart. The most commonly used thickness of the solid sheet for canopies is 4-6 mm, which can quite guarantee the strength of the structure in any climatic conditions.

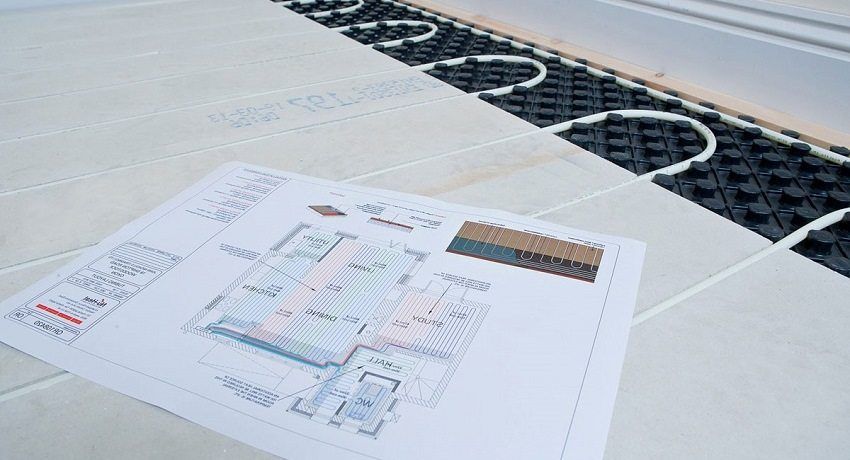

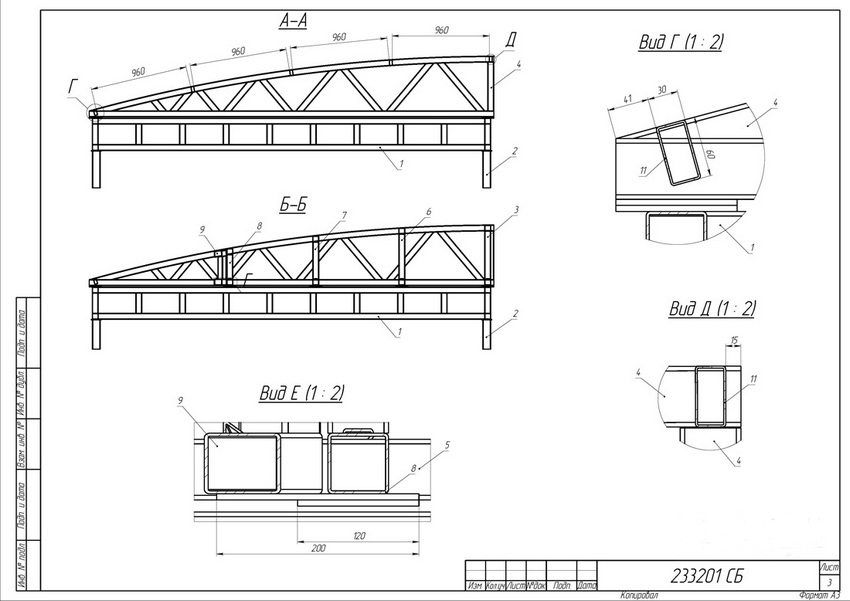

In order to manufacture, assembly and installation of the structure was carried out without any unexpected difficulties, it is necessary to develop with your own hands a polycarbonate canopy drawing. This will allow you to properly prepare all the elements of the frame and to avoid possible waste of materials. Sketches of future construction should take into account the design features of the selected form of a canopy. If possible, the parameters of the adjacent structure are chosen so that when cutting pipes and cutting plastic there is as little waste as possible.

If an arched structure is chosen, the skeleton of which is made of a shaped pipe, special bending equipment is required. Not everyone has such a tool at hand, but, even with a pipe bender, it is rather difficult to give the material a correct bend.

Cutting polycarbonate for a semicircular construction is also associated with some difficulties. Therefore, for work done independently, it is recommended to stop the choice on a lean-to canopy made of polycarbonate. For a framework of this construction, it is much easier to calculate the number of profiled pipes and cut out the polycarbonate sheets required by size.

Helpful advice! In the design diagrams, such a distance between the transverse elements of the batten should be provided so that the line of junction of the panels falls on the core tube of the frame. Thus, the polycarbonate coating will be rigidly fixed.

When covering the roof with polycarbonate, you should take into account the installation features of this material:

- typical polycarbonate panels are produced with a length of 6 or 12 m and a width of 2.1 m. Based on these parameters, the dimensions of the structure are calculated, which allows to get as little waste as possible;

- the panels are interconnected using end profiles (their length is 6 m), which can be matched to the color of polycarbonate. They are securely fastened and do not require additional fixation;

- the length of the end profile, closing the final cut, is 2.1 m;

- To cover semicircular roofs, a polycarbonate sheet is positioned so that the bend is in the transverse direction of the air channels;

- The arrangement of the sheets of polycarbonate should be such as to ensure the smooth discharge of condensate from the internal channels. Otherwise, the cells inside the plastic will become moldy, which will affect the light transmittance quality;

- in pitched structures of canopies, the upper end of cellular polycarbonate is closed with a continuous self-adhesive tape in order to avoid ingress of moisture, dust, and insects. The lower end is processed by a perforated tape, which allows moisture to be displayed outside. In arched canopies in both ends, a tape with micro-perforation is used;

- The mounting holes are created with a slightly larger diameter, which allows the polycarbonate to expand or contract freely, depending on the temperature effect. Do not make the holes too large;

- when mounting panels use self-tapping screws with thermal washers, which are selected in the color of polycarbonate.

Helpful advice! The use of thermo-washers of appropriate colors gives the coating a neat aesthetic look and prevents moisture and dust from entering the polycarbonate panel through the mounting hole.

The project also provides for the thickness of polycarbonate, corresponding to the selected design:

- impressive canopies with an inclined shape – sheets 10 mm thick;

- arched and semi-circular canopies – a panel of 8 mm will fit;

- for adjacent canopies of a single-sloping design with a gentle slope, polycarbonate with a sheet thickness of 16 mm is chosen that can withstand the possible snow load in winter.

All these nuances should be taken into account before installing a polycarbonate shed to a private house with your own hands. Photos of self-made structures will serve as an example for the manufacture of its unique structure.

Sheds adjacent to the house, as a rule, cover most of the yard. Some prefer to close the entire house territory. This approach contributes to the universality of the use of structures:

- it is easy to place a car under it, protecting it from rain, hail, snow;

- the canopy will save paving slabs in the yard from premature destruction and cracking;

- thanks to the canopy, the porch and steps will always remain dry, which will exclude the possibility of slipping;

- the design will exclude wet garden tools and equipment, various items left outside;

- due to the transparency of polycarbonate, mini flower beds can be placed under a shed;

- very convenient is the conclusion of the water pipe into the courtyard. Thanks to the hinged cover, it is possible to do household chores during the whole summer period in any weather, without going into the house: wash dishes, vegetables and fruits, preserve food, etc .;

- a functional structure is a shed for a dacha: those who like to engage in the harvesting and drying of fruits may not be worried that direct sunlight or moisture will get on the raw material;

- with the arrival of autumn, the courtyard protected courtyard will not have to be constantly cleaned of falling foliage and branches, and in winter it will take a lot of time to clear snow.

Canopies attached to the house are a more acceptable option in comparison with a stand-alone structure, since their construction will require less financial investments, and they are mounted much faster.

Using canopies of polycarbonate for cars, you save him from many negative influences:

- polycarbonate coating protects the paint layer of the car from the ingress of sunlight, keeping it in perfect condition;

- roof canopy will become an obstacle to falling on the body of rain, small items. In winter, protects from snow drifts;

- a car parked under a carport is well ventilated, which protects body elements from corrosion;

- it is much more convenient to unload or load things into the car, especially in inclement weather, under a shed;

- the space protected by a carport can be used for servicing and repairing a car, regardless of weather conditions;

- even if there is a garage in the courtyard, it is often more convenient to leave the car under a carport, if after some time you need it.

These and many other functions allow attached to the house carports for cars to be a worthy alternative to a major garage. Photos of carports made of polycarbonate, presented in large quantities on the net, demonstrate the various forms of these structures.

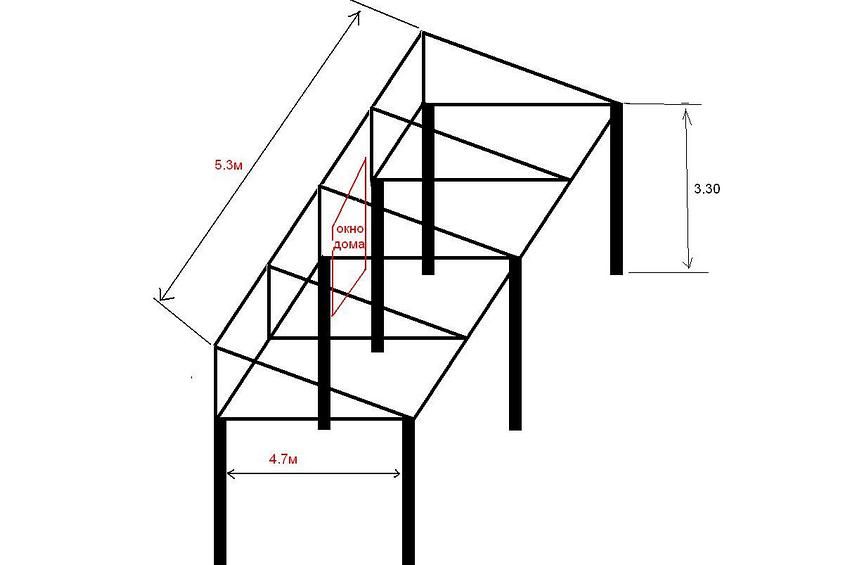

It is very convenient to use the area under a canopy for family breakfasts and dinners in the open air, especially if the design is adjacent to the wall in which the kitchen windows are located. In this case, the hostess will handily serve the dishes and cooked dishes straight from the kitchen to the street. You can also quickly deal with cleaning dishes after a feast.

The canopy that protects the porch and the entrance to the house allows you to leave the shoes used in the yard and the garden, outside the door, without fear of getting wet, which helps to keep the home in perfect cleanliness. And a carport attached to the house, the covering of which protects a balcony or terrace, will make it possible to place comfortable furniture for relaxation there.

Before proceeding to the independent production of the polycarbonate canopy adjacent to the house, it is necessary to determine what materials the racks and frame of the structure will be made of.

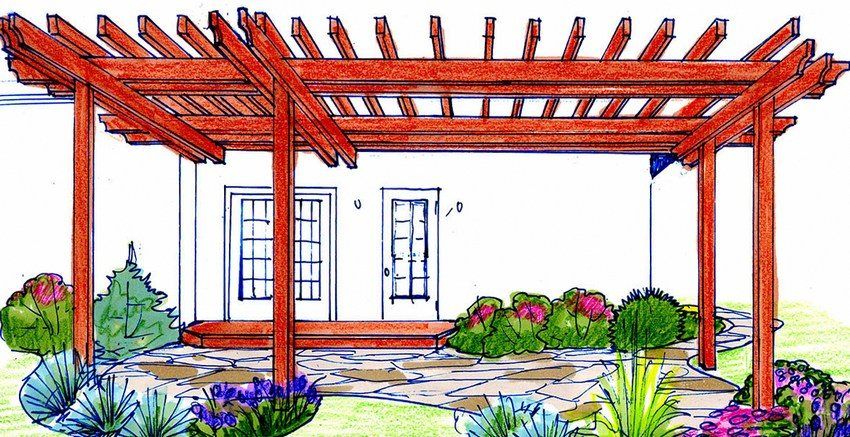

For the supporting posts of the wooden structure of the sheds, timber of various sections is used, for the batten – the board. Wood is an eco-friendly material, easy to process and long-lasting with proper care, and the construction of it will be cheaper than metal. In addition, when working with wood there is no need for a welding machine and special skills. Among the disadvantages are the ease of ignition, susceptibility to rotting. Therefore, it is necessary to monitor the design and timely treat wooden surfaces with special compounds.

In metal constructions use a profile pipe of various sections. The recommended metal thickness is at least 2 mm. Metal structures have high strength, moisture resistance, long service life. To prevent corrosion, the metal surface is primed and painted. To connect the parts using welding or bolting. You can give the canopy design a delicate openwork look, using forged elements. However, forged designs will cost much more.

In some cases, stone or brick pillars are used for carport piers. Such support legs are quite expensive, but the appearance justifies the investment, given that stone structures are not afraid of moisture, sun and temperature fluctuations.

Before making a canopy, determine the amount of material needed for the structure. All calculations are made in accordance with the drawings and sketches. It is recommended to purchase material in an amount of 5-10% more than calculated: this will allow you to quickly replace mistakenly prepared or damaged items.

For the manufacture of a wooden roof with a polycarbonate roof will require the following materials:

- beam section 150×150 mm – for supporting racks and for the horizontal beams of the frame. The required amount of material depends on the length and width of the structure;

- board for rafters, runs with a section of 100х150 mm. The quantity depends on the distance between the rafters. For polycarbonate coating, a step of 0.5-0.7 m is selected;

- fasteners, hardware;

- polycarbonate sheets.

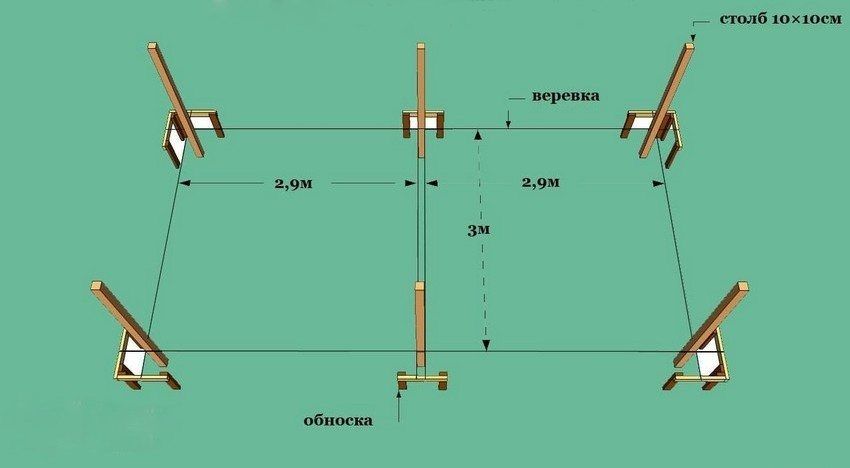

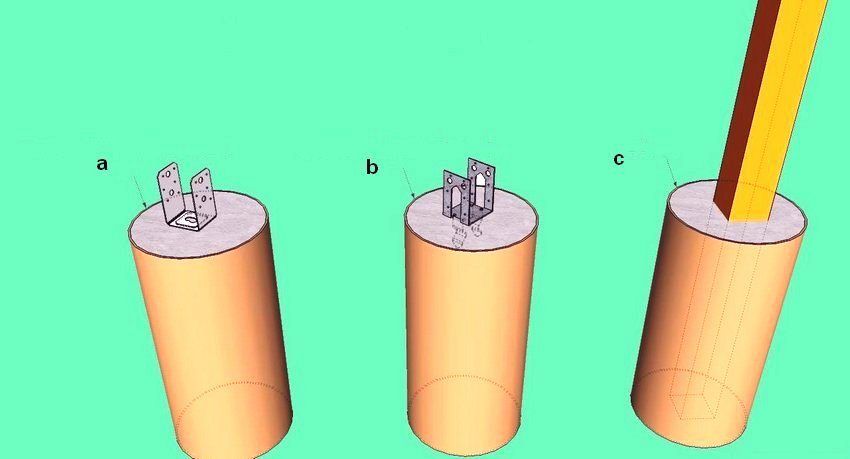

Start by marking the territory. Points are planned where the vertical support posts of the canopy will be located. The height of the supports is taken equal to the height of the canopy, taking into account the depth of the racks by 55-60 cm.

Helpful advice! When performing markings, it should be taken into account that the removal of the roof of the structure from the outside should be 15-20 cm.

Supports are usually located at a distance of 1-2 meters from each other. The pitch between the supports is selected depending on the length of the structure and the thickness of the roof covering. First, install the rack next to the wall of the house, and then a number of racks outside the structure. All supports must be located clearly opposite each other. The height of the racks should take into account the slope provided for by the project.

For concreting supports arrange pits width and depth of half a meter. At the bottom of the pits fall asleep layer of sand and rubble. Then install the support, previously subjected to antiseptic processing and wrapped waterproofing material. Check the vertical installation and pour concrete. In this form, the support is left until the concrete mix is completely set.

The construction of a wooden frame starts from the inner row from the wall. To support posts mounted wooden beams. To obtain the required length, the beams are joined to each other with the help of metal plates. The position of the beams must be strictly horizontal. The beams are fastened to the supports using self-tapping screws. In addition, the beams are additionally attached to the wall of the house through fasteners.

Helpful advice! When self-installation of a canopy, use the building level and a square to determine the verticals, horizontals and correct angles. Possible distortions can adversely affect the strength of the structure.

As soon as the horizontal beams are installed, fasteners for the transverse elements are mounted to them. In order to make the structure more rigid, it is recommended to reinforce the beams with struts on both sides of the supporting columns. The spacers are fixed with screws at an angle of 45 degrees.

Next, proceed to the installation of transverse elements. As a rule, the first beams are mounted along the edges, then the middle and then the intermediate transverse beams. As soon as all the beams are installed, the edges are closed with an end plate. For the strength of the structure, the extreme beams on the left and right are reinforced with subrafter legs. This will strengthen the structure with a possible excessive snow load.

The coating of the frame with polycarbonate begins with the cutting of plastic, the surface of which is marked with a marker. Along the outlined lines, the polycarbonate is cut by a circular saw, the blade of which has small teeth. When cutting sheets, they should be well fixed so that there is no vibration. After that, the channels of cellular polycarbonate are cleaned of chips and sawdust. When cutting the material, it is necessary to take into account the location of the channels inside the polycarbonate: they must be located in such a way that the moisture can flow freely.

Helpful advice! When covering the canopy with polycarbonate, it should be laid so that the film with the logo of the manufacturer is on top. If you place the sheet on the contrary, the material will quickly lose its properties.

After the material is cut, it is placed on the frame and mark the place of attachment. Here you need to take into account that the distance from the edge of the sheet to the first hole should be more than 40 mm, and the pitch of fastenings should be 35-45 cm. Further, in the planned places, mounting holes with a slightly larger diameter are drilled than with a self-tapping screw. When all the holes are made, the polycarbonate sheets are fixed to the frame. When attaching sheets using screws and heat washers. After mounting the screw, the plug for the hole in the cap snaps into place, which ensures complete sealing of the mount.

Between themselves, polycarbonate panels are joined with a plastic profile, which is matched to the color of the sheet. It should also be ensured that the junction line of the panels falls on the transverse elements of the batten.