The basement is one of the most important parts of the building. This is a kind of support, which is subject to constant negative influence of the environment. Finishing the basement of a private house not only gives it an aesthetic look, but also protects it from adverse factors. Therefore, finishing materials must be moisture-resistant, frost-resistant, reliable and durable.

Why do I need to finish the basement of a private house

Most of the building foundation is below ground level and hidden from view. The speaker, above ground level, is called the base. According to the norms, the height of the base from the ground must be at least 20 cm. It is usually made of brick, stone or concrete slabs.

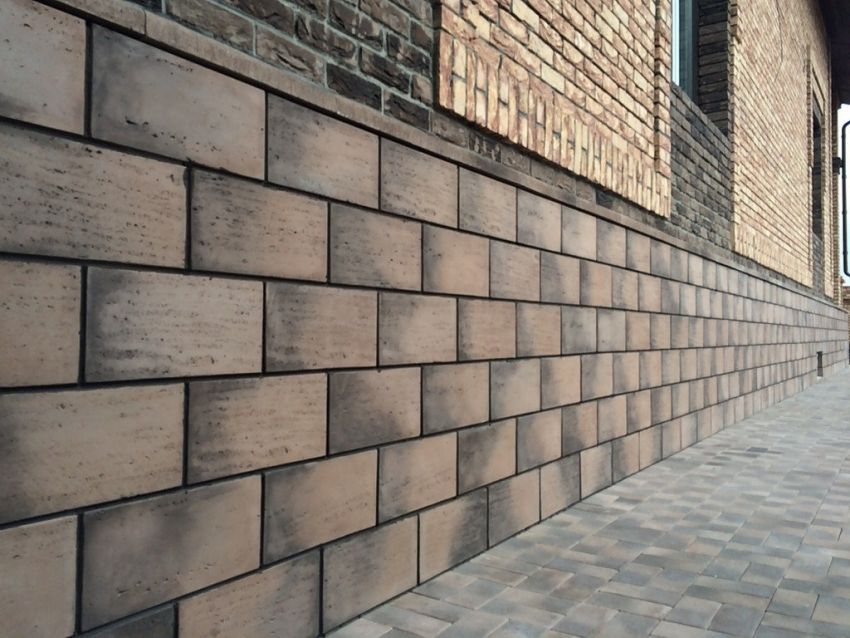

The construction of the stone base is the most practical solution, since the design does not need additional finishing. However, it is worth considering that this is the most expensive way. Brick masonry is more accessible. This material is environmentally friendly, has a low thermal conductivity and good strength characteristics.

Facing the basement of the house is not only aesthetic character. This is a reliable protection of the building from external influences. Finishing materials that will be used for plating the plinth should have a high level of strength. Together with the plinth, its lining will take the load that is created by the wall structures of the building and distribute it evenly throughout the building foundation. It must withstand pressure and protect the basement from the effects of external factors, such as precipitation, sunlight, humidity, temperature fluctuations.

Finishing material protects the foundation of the structure from damage by mold, fungus and various types of insects. Facing the cap is performed with the aim of insulating the building. It is also necessary to protect the foundation from severe frosts, under the influence of which its strength decreases and the process of erosion develops.

If you leave the surface of the base without plating, it will contribute to its slow destruction as a result of constant exposure to dry or liquid dirt containing aggressive chemical and mineral substances.

Various options for finishing the basement of a private house, the photo clearly confirms this, turning the building into a masterpiece of design art, making it look complete and unique.

There are basic variations of structures that are used for projects of houses with a base:

- protruding beyond the surface of the walls;

- flush with the building;

- falling away from the wall.

Most often during the construction of a private house, the photo of the base of the house clearly confirms this, using the first two options. The protruding basement is recommended to be used when the house is being built using thin outer walls, a warm underground is used, or a basement is provided in the building. In these cases, this type of basement will provide the building with additional thermal insulation.

If you make the basement part flush with the building, when thin walls are used for its construction, dampness and condensation in the interior are inevitable. Here it is most problematic to install the insulation and perform the finish.

Important! Choosing these types of base, you should take care in advance about the arrangement of the ebb.

The falling base is less affected by precipitation. Here you can easily hide the waterproofing, equip the insulation and veneer the necessary materials, which contributes to a longer life. This type of basement is recommended for buildings without a basement. Finishing materials for the basement will perceive the pressure of the soil, performing a support function, thereby maintaining the safety of the entire structure.

All work on the lining of the socle structure is carried out at the final stage of production – exterior decoration of the building. Works better in warm, dry weather. Cap plinth consists of the following actions that are performed in a certain sequence:

- A trench is being dug, 20 cm deep and 50 cm wide, all around the building.

- Filling the space with gravel to ensure drainage. Additionally, the trench can be strengthened using a reinforcing mesh.

- The surface of the wall with a height of 50-70 cm for the future basement is cleaned of dirt and treated with water repellents. If necessary, eliminate all irregularities.

- Arrangement of thermal insulation.

- Decorative facing plinth.

The choice of facing material and method of its installation depends on the design of the base and the method of its ebb.

To protect the basement from the negative effects of precipitation, an ebb should be installed, which is fixed above the protruding part of the basement, and is a kind of demarcation between the base of the building and the wall structure. One part is in contact with the wall at some angle, and the other, hangs over the foundation, blocking it, collecting rain and melt water.

Ebb tides for the base are strips of 50-400 mm. Select the color, size and shape of the castings should be depending on the finishing material of the foundation. The water-repellent design can be made independently using waterproof materials, and you can buy castings for the foundation base in finished form at any hardware store.

Today, the industry produces several varieties of ebb:

- plastic;

- metal;

- concrete;

- clinker

The type of reflux is selected based on the finishing material for the facade of the building. Plastic sills are most successfully combined with vinyl siding, which is used for cladding the building. Due to the wide range of colors, you can choose the most appropriate option. The use of concrete or clinker for basement is preferable for buildings that are lined with natural stone or brick. Metal canopies can be used with any kind of finishing material.

The most cost-effective option is to use plastic PVC drips. The cost of the product is 50 rubles. for 1 rm Despite the high rate of water resistance, the ebb show an increased sensitivity to physical impact, especially in the winter, when they can crack and crack from the slightest blow.

Helpful advice! Due to the fact that plastic shells have increased brittleness, you should give preference to more durable and expensive products.

The most durable and durable are the ebb, made of metal: steel, copper or aluminum. Installation of products is convenient and simple, and is determined in fastening the metal strips to the walls of the building using self-tapping screws and dowels. When choosing this material from a wide range of species, special attention should be paid to the aesthetic appearance of the product so that it creates the completeness of the overall design of the building. The price of the product starts from 100 rubles / pm.

Helpful advice! Assembling the basement ebb, the slats should be placed overlapping one after the other by at least 30 mm. In order to avoid damage to the protective layer of the product, which will lead to the formation of corrosion and destruction of the material, you should not trim the strips.

Metal shells are made from high-quality and frost-resistant cement M450 brand with the addition of river sand, crushed granite and plasticizers. The solution is poured into silicone molds of various geometrical parameters. The result is an even and smooth product. These outflows are fixed on a special solution.

The ebb for the basement of the foundation, the price of which is the highest and starts from 200 rubles. for 1 rm, These products are made of clinker tiles. This material has high strength properties, reliably protects the building from the negative effects of the environment and successfully emphasizes the design of the cladding.

After selecting low tide, you can proceed to its installation. Here it is necessary to take into account not only the material from which the ebb is made, but also the structural features of the building. So, for a wooden house suitable elements that will be fastened with screws or other fasteners. Since wood has low adhesion and is afraid of dampness, the use of adhesives is impractical.

For buildings made of brick or facing stone, you can apply the ebb, which will be fastened with polymer or cement-glue solutions.

Helpful advice! When using concrete or ceramic castings, their installation should be carried out simultaneously with the lining of the basement and walls.

If it is necessary to install ebbs on a building already trimmed with a facing material, then it is better to use metal or vinyl elements.

Before mounting the ebb, it is necessary to seal the joints of the walls with the base. All cracks and crevices should be treated with a water-repellent mixture, or sealed with a sealant. Further it is necessary, using a level, to make a wall marking. The highest point of the basement is determined and a horizontal line is drawn along which the upper part of the outflow will be mounted. Part of the foundation that stands, it is necessary with the help of a cement screed to compare with the horizontal plane. The bottom of the low tide will rest on it.

Important! The ebb plane relative to the wall should be located with a slope of 10-15%.

Installation of the ebb should be started from the corner using special corner elements that can be purchased together with strips of the same width and color. Next, you need to finish all the protruding parts of the building structure: columns, pilasters and others.

In case of finishing the base of a pile-screw foundation with the help of brickwork, it is necessary to install the base in the form of a tape made of reinforced concrete or a metal profile. Masonry bricks with bandaging. To connect the elements used cement-sand mortar. The thickness of the seams is 10-12 mm.

Facing the cap of a private house is important, so you should pay attention to the choice of material for work. It acts not only as a decorating element, but also is a reliable protection of the entire building from the effects of atmospheric and mechanical factors.