High-quality insulation and decoration of the facade of the house guarantee a significant saving of thermal energy, which is especially important in the context of the constant increase in the cost of energy. In addition, integrated work makes the house more attractive from an aesthetic point of view. There are different methods of insulation and decoration of buildings, but the wet facade is considered the most modern: the technology of this method of finishing is described in detail in this article.

Warming facades wet outside or inside: features of choice

Traditional building materials used for the construction of walls, such as bricks, steno- and concrete blocks, are characterized by increased strength and a sufficiently long service life. However, they do not have a high level of thermal insulation, and therefore a significant part of the thermal energy simply disappears through the walls. To prevent this undesirable process, the walls are insulated.

Warming can be both internal and external. At the same time, the amount of material, the amount of work and the organization of the process inside the house itself are more profitable and cheaper. At the same time, there are a number of serious arguments in favor of warming the house outside.

External methods, which include wet facade insulation, suggest the presence of a so-called dew point – this is an area where condensate is released under temperature fluctuations both in the middle of a room and outside. In the case of mounting insulation on the inside of the bearing wall there is a high probability of condensation, which leads to increased humidity in the room. Therefore, this method of thermal insulation is less functional and even hazardous to health, because fungi and mold appear on the walls against dampness.

When external insulation significantly increases the level of heat resistance or thermal inertia of the walls. In other words, the building, insulated outside, retains heat longer with a significant decrease in temperature outside and heats up slowly in the summer heat.

With the external insulation of the house, the wet facade eliminates all kinds of cold bridges, through which, in most cases, the main heat loss occurs in case of arranging the internal thermal insulation.

The external method of facade insulation has its own classification. Distinguish between dry and wet technology. The first option, in turn, includes prefabricated or suspended facades. The main material used in this technology is vinyl or metal siding. The wet facade system is considered to be more practical, highly efficient, economical and attractive.

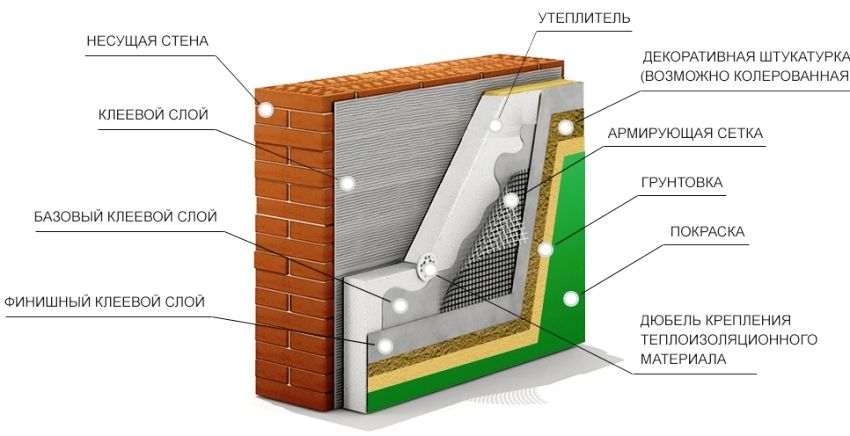

Important! A distinctive feature of a wet facade is layering, where each individual layer plays an important role in the process of insulation and decorating. For the full implementation of the functions, preference should be given only to high-quality materials.

Using the wet technique allows you to get not only good quality insulation, but also beautiful home decor. An important condition is the use of high-quality special solutions. The final stage is the process of applying plaster and painting – these are the key components of the beautiful exterior of the building.

The wet facade technology involves the creation of a multilayer cake outside. The layers are fixed to the wall by applying special adhesive solutions, mastics and plaster, which are dissolved in ordinary water. Hence the name – wet facade. The work involves the observance of a clear order of sequence in the application of layers: primer, adhesive mixture, heat-insulating plates, additional sizing, mesh reinforcement, plastering and painting.

Each phase involving the use of the wet method, be it sizing, plastering or painting, should be performed at temperatures above +5 ° C. Not only the quality of work and the degree of thermal insulation, but also the service life of the decorative insulation depend on the sequence of work, materials and compliance with the conditions. Otherwise, the facade will soon begin to crack and collapse.

Wet wetting technology has a number of undeniable advantages and a certain number of disadvantages. The advantages should include:

- a high degree of decoration and attractiveness of the facade;

- lightness of the heat insulation layer, which allows to apply the technology on buildings with a weak foundation;

- reliable thermal insulation, which retains heat in the house for a long time according to the principle of a thermos and excludes the appearance of “cold bridges”;

- additional protection of the house from the destructive weather effects (moisture, freezing, wind);

- reliable sound and vibration insulation;

- durability (facade made by wet technology, can last up to 40 years);

- eliminates the appearance of condensate and, as a result, dampness in the house, which is due to the “breathing” exterior plaster;

- the cost of a wet facade is acceptable, especially in comparison with other methods of insulation;

- technology does not “steal” useful space in the room.

Speaking about the advantages, it is necessary to mention the disadvantages that this methodology has:

- works should be carried out under optimal temperature conditions outside (if the temperature is below +5 ° C, then it is almost impossible to achieve the desired result);

- each layer requires a certain time for drying, so unexpected precipitations can adversely affect the quality of insulation in the end;

- dust and dirt during operation also adversely affect the result, so the surface should be protected from the wind.

Helpful advice! Wet facade building insulation work should not be carried out during rains. Therefore, it is better to plan the installation for spring or summer, when precipitation falls much less.

Based on the above advantages and disadvantages, the conclusion is that the technology allows to create high-quality thermal insulation, subject to minimal financial investments. The main principle is a clear phasing in the application of all layers. The technology of the work includes three or four stages of the formation of a wet facade. Photos clearly demonstrate this. Each of the layers fulfills its functional purpose.

| Layer of plaster | Main works | Function performed |

| Glue or preparatory | Preparation of the base, installation of fasteners and primer glue | Determines the degree of reliability of fastening future design. |

| Thermal insulation | Fastening heat-insulating plates with glue and dowels | Provides a degree of insulation of the walls of the building |

| Reinforcing | Includes reinforcement mesh installation | It guarantees durability and reliability of the structure and serves as the basis for the final finishing layer. |

| Decorative | Putting decorative plaster in various ways and painting | It protects heat-insulating plates from weathering and ensures the external beauty of the walls. |

All stages perform a number of important functions that ensure the overall reliability, durability and durability of the structure; therefore, each of them requires a responsible approach and detailed study.

Before starting work on insulation should take care to prepare the basic framework. To this end, the walls thoroughly clean and eliminate all defects. It is necessary to cover the cracks with mortar and level the surface. If there is heavy dirt on the surface, it is recommended to use detergents.

Next, the surface is tested for strength. To do this, glue small pieces of insulation on the wall. If they firmly hold and do not break into pieces, then you can proceed to installation. If it is easy to tear off along with the top layer of the wall, you should clean it up again.

After fully preparing the wall, a primer is applied to it. And after drying – a layer of glue. If the surface of the house consists of a material with increased absorption, the ground layer should be more solid. It is better to apply it twice. It is recommended to remove the old plaster from the window and door slopes in advance.

At the preparatory stage, care should be taken to install the profile bar. The plinth profile will help to evenly distribute the load from the insulation boards and protect the bottom row of insulation from moisture.

Helpful advice! A smooth process flow can provide a special set for facade insulation, sold in hardware stores. The adhesive mixture for a wet facade ceresite has proven itself well.

The profile is mounted at a level of approximately 35-40 cm from the ground with a three-millimeter gap between the slats placed horizontally, in case the temperature expands. The profile is attached directly to the dowels or screws. Their number depends on the density and weight of the selected material for thermal insulation. Most often they are placed at a distance of 15-20 cm from each other.

The installation of the heat-insulating layer is one of the main stages, as it is the fixing of insulation plates. The process itself requires adherence to a clear sequence and implementation of a number of rules.

Applying adhesive to the surface of the plate. The adhesive solution is distributed around the perimeter of the material with a wide strip, departing from the edge of approximately 3 cm. In the middle, the glue is distributed pointwise. The main thing is that the adhesive mixture should cover more than 40% of the area of the plate. If lamellar mats serve as an insulating layer, then an adhesive solution should be applied over the entire surface.

Laying plates. Insulation technology wet facade involves the installation of insulation “run” by analogy of brick masonry. In this case, the tiles should be pressed tightly to each other and to the wall. The glue that has stepped out must be removed immediately. The laying process takes place from the bottom up, starting from the base profile. You will need to wait 3-4 days for the glue to dry completely.

Fastening plates with dowels. In the next step, the heat-insulating layer should be additionally fixed with dowels. Their length should be selected based on the thickness of the insulation layer, adhesive solution and the margin for the recess in the wall. If the density of insulation for a wet facade is high, then 5 cm is enough for a deepening margin, for porous materials this figure should reach 8-9 cm. For 1 m? The surface will need from 7 to 15 dowels. Their number depends on the density of insulation boards, the diameter of the mountings and the height of the insulation.

Before installing the dowel, a nest is prepared under it. With proper fastening clamping sleeves will fit close to the heater.

Reinforced base is required to ensure a reliable level of adhesion of decorative plaster over insulation. For this purpose, a special mesh is fixed on the glue base, embedding it in the middle. Installation of the reinforcing layer begins after at least two days after the application of the insulating layer.

Helpful advice! For reinforcement, it is recommended to use an alkali-resistant fiberglass-based mesh with a reliable coating. Otherwise, within a year, the reinforcing layer will begin to break down, and the plaster will simply crumble.

First, the grid is fixed on the angular slopes in the openings of windows and doors, as well as in the joints of vertical slopes and lintels. Then go to the corners of the building from the outside, and in the end – to the rest of the sites.

In conclusion, it should be noted that the use of various options for decorative plaster in the wet facade system, elements of decoration and color design allows for the implementation of various style ideas on the exterior of the building, which cannot be done using other methods of insulation, for example, ventilated facade technology.