After completion of construction work, proceed to the exterior walls of the building. High-quality lining creates not only the presentable appearance of the structure, but also protects the structure from the negative effects of precipitation, sunlight and mechanical damage. Facade plaster for exterior work is the most popular material, details of which can be found in this article.

Surface preparation with facade putty for exterior work

Before proceeding to the finishing lining of the exterior walls of the building, the foundation should be prepared using facade putty. It is intended for leveling surfaces made of concrete, stone, brick, foam blocks, gas blocks, gypsum boards and other materials. Facade putty for external works should have moisture resistance, frost resistance, parapermeability and elasticity.

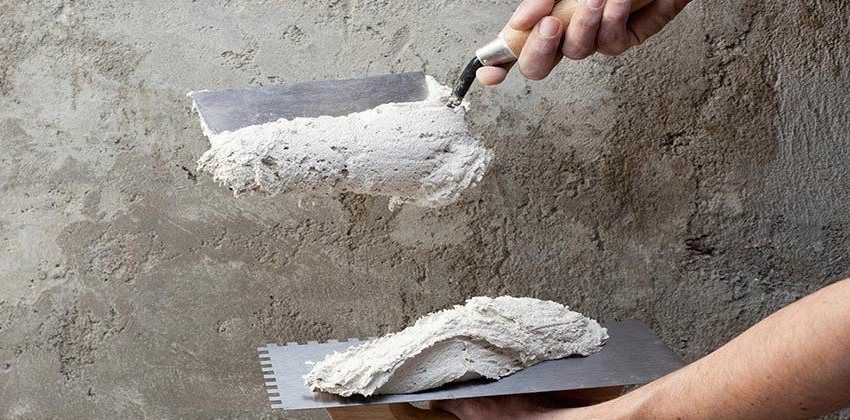

Distinguish starting and finishing facade putty. The starting mixture is applied to the lower trim base. Due to the coarse-grained structure, it is able to smooth out irregularities, drops. Used for embedding chips and cracks. The result is a solid foundation. The working solution should resemble sour cream in consistency. Putty is applied with a layer of not more than 1.5 cm.

The finishing putty, which has a finely dispersed structure, is used for the final leveling of the base and provides a smooth, even surface for the subsequent decorative lining. Working solution prepares more liquid, than starting mix. The thickness of the layer should not be more than 4 mm.

Depending on the composition, the putty may be cement or polymer. Cement compositions are highly resistant to moisture and low temperatures. In the composition of the starting cement mixtures there is quartz sand, and marble dust or quartz ground sand is added to the finishing putty. This is an unpretentious and inexpensive option, however, cracks may appear on the surface during shrinkage of the building. Popular brands of cement putty are Kreisel 662, SCANMIX TT, Knauf Multi-Finish, Plitonite and Facade.

Polymer putties, which include polymeric binders, can be acrylic or latex. Acrylic blends moisture resistant, flexible and plastic thanks to the main component? acrylic. This plaster is applied on a pre-primed concrete or foam concrete surface, a layer of 1-3 mm.

Latex putty made on the basis of latex is produced in the form of an odorless paste and release of harmful substances. This mixture has a high ductility, which eliminates the formation of cracks after it dries. Despite the high cost, creates a durable coating. The most popular brands of polymer putties are SCANMIX LH STANDART, Bolars, Parade Classic.

Now you can proceed directly to the decoration of the walls of the building, using facade plaster for exterior work.

Decorative plaster for exterior work differs from facing materials that are intended for indoor use. The composition of these mixtures contains additives that give the material flexibility, strength, moisture resistance and frost resistance.

Asking a question how to choose facade plaster for exterior work, it is necessary to pay attention to the compliance of the material with such requirements:

- resistance to temperature extremes;

- the presence of water repellency;

- increased degree of vapor impermeability;

- sufficient strength to protect the facade of the building from mechanical damage;

- the coating should create sound and heat insulation;

- increased resistance to harmful radiation;

- the presence of decorative characteristics of the composition.

Any exterior finish creates additional thermal insulation of the building. However, for thin walls, you should choose the so-called warm plaster for exterior work, which will include a special filler. It can be perlite, polystyrene foam, vermiculite, sawdust or foam glass. They increase the insulating properties of the finishing mixture. Thus, a layer of plaster of 3 cm is capable of replacing brickwork with a thickness of 15 cm.

An additional soundproofing layer is provided by the exterior plaster of the house. To do this, it must contain pumice stone, magnesite, or cement with slag or pumice stone. These porous components are able to partially absorb noise.

Helpful advice! If the building is exposed to a high noise level, the exterior plaster, as a reliable sound insulator, is ineffective. Mineral wool or foam plates should be used additionally. Also, you can make warm plaster for the facade.

Among the proposed range of compositions for exterior work can be identified 4 main types of facade plasters, which differ in properties, composition and application technology. There is also a fifth type? gypsum plaster for exterior work. However, it has a high degree of susceptibility to environmental influences, which makes it impractical for external cladding. It can be used for leveling the base or for preparing the surface for subsequent decorative lining.

All facade plasters can form a smooth or embossed surface such as “bark beetle”, “fur coat” or “mosaic”.

The composition of the mineral plaster includes hydrated lime, Portland cement, stone powder, colored clay, additional elements that enhance the performance characteristics of the finished surface and the components responsible for the texture of the finished facade. To increase the resistance to fungus and mold, additional fillers may be present in the mixture.

The mixture is produced in ready-made packages in the form of a powder, which must be diluted with a certain amount of water to obtain a ready solution. It is applied to any type of surface. Before facing the walls, it is necessary to mount the mesh under the facade plaster, which will allow to level the surface, create additional adhesion of the plaster to the base and reduce the risk of cracking.

Cement plaster for exterior work creates a durable, “breathable” decorative coating that does not smolder, does not burn, and does not emit toxic substances when heated. The suitability of the composition for operation is no more than 90 minutes. After complete drying, a strong non-flammable coating with sound and thermal insulation properties is formed on the surface of the wall. Decorative materials for the finishing material provide color additives and granules.

Helpful advice! Due to the low resistance to vibration, mineral plaster should not be used for buildings located near the railways and in areas with high seismic activity.

Mineral plaster can withstand temperature fluctuations from -30 to +45? С. without losing its operational properties. The service life of such a coating is at least 15 years.

The color scale of cement plaster is very limited, which reduces the degree of its decorative effect. The finished surface of cement plaster can be painted in any color, thereby creating a more aesthetic appearance of the building.

Today, Knauf from the Diamond range, which possess enhanced water-repellent properties and resistance to aggressive weathering, are very popular mineral plasters. Using a mixture of Diamond-240, you can get a textured surface “bark beetle”, and Diamond-260 forms a rough lining, which is called “fur coat”. The price of a pack of 25 kg is about 900 rubles.

Another equally popular option is the Bolars mineral facade plaster, which can be purchased at a price of 700 rubles. Having a self-leveling structure, thanks to the modifying additives included in its composition, it creates a perfectly flat and smooth surface.

Acrylic resins are used in the composition of acrylic plaster instead of cement as a binder. In addition, modifiers are used here that increase the plasticity and strength of the coating, dyes, and one of the fillers, such as stone chips, sand, or colored granules, creating a decorative surface structure.

Acrylic plaster is produced in the form of a ready-made solution, which is immediately suitable for application. The layer sets in 20 minutes, and the surface is completely dry after 48 hours. During this time, you should protect the coating from direct sunlight, which promotes cracking of the facing layer.

Helpful advice! Because of the quick setting on the surface, the joints of the layers may be noticeable, so it is better to entrust the work to a professional.

The mixture based on acrylic has a high resistance to temperature extremes. It creates a good moisture resistant surface with additional protection from strong gusts of wind. Due to the high elasticity of the coating, the likelihood of surface cracking is reduced. The facade of the building, made of acrylic plaster, will have increased resistance to abrasion and impact, which increases the life of the surface, which reaches 20-25 years.

However, it is able to quickly attract dirt to itself. To clean the surface, it is enough to water the lining with water from a hose. Another disadvantage of the external composition based on acrylic is the instability of the pigment to UV radiation, which after some time dims. This plaster is not recommended to be applied on the base of the mineral wool and the walls of cellular concrete.

The creation of a decorative layer is applying a facade plaster on the prepared surface. The cost of work on plaster walls depends on the method of application (manual or machine) and texture, and an average of 400 rubles / sq. ?. Additional staining of the facing surface will cost from 170 rubles / sq. ?.

The main purpose of facade plaster is the final, finishing exterior design of the walls of the building. This decorative coating is affordable, durable and has a number of distinctive features that make it one of the most popular facing materials.