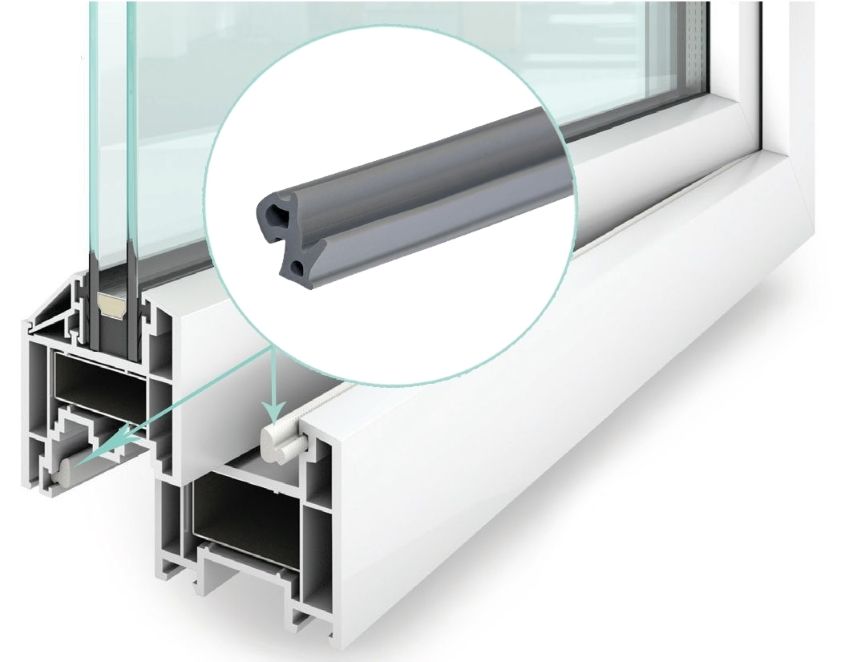

Many people are familiar with the problem of insufficient heat and sound insulation of metal-plastic window designs. Most often it occurs due to wear of the cushioning material. Sealant for plastic windows can be made of different materials and have a different look, but in any case, it must be replaced regularly. Only in this way your windows will retain high performance for a long time.

Why do we need seals for windows

Gaskets for windows are made of rubber, rubber and other materials and perform the following functions:

- protection from external noise – buy window seals for plastic windows is especially recommended for those who live in a noisy area. If the windows of your house overlook a busy highway, a kindergarten yard, or other places where noise disturbs you, installing rubber, silicone or rubber seals will easily solve this problem;

- protection from dust – most of the particles enter the house from the street through the cracks in the windows. Installing sealing gaskets significantly increase the level of cleanliness in your home and eliminate the need for frequent washing of window sills and the space near the window;

- maintaining the temperature in the house – with poor insulation of windows, the house leaves the heat very quickly, and in the summer even air conditioning does not save from the heat. This leads to high energy costs. Sealing gaskets in the windows will make living in the house much more comfortable, will keep you warm in winter and cool in summer, and also help you save on utilities;

- protection against moisture – often moisture from rain or snow seeps into the house through the windows. As a result, even small gaps can lead to constant high humidity. Rubber, rubber or silicone do not let water through, so your home will always be dry and comfortable;

- more comfortable operation of double-glazed windows – sash with gaskets made of elastic materials open and close better, do not slam or creak;

- extending the service life of windows – no matter which windows are installed in your house, wooden or plastic, the use of gaskets will allow them to last much longer, protecting them from the harmful effects of moisture, temperature drops and mechanical deformations. Thus, installing a gasket, you provide your windows with a long life.

Helpful advice! Even if you purchased a window with already built-in rubber gaskets in the profile, they still need to be replaced some time after the start of operation. With high quality windows, it is held about once every 5 years.

There may be several signs that the seal must be replaced. Among them are the following:

- obvious signs of depressurization – constant drafts appeared, the heat does not stay in the room for a long time;

- condensation – the appearance of water droplets on the glass panes and in the corners of the double-glazed windows;

The sealer needs to be replaced if it starts to crack.

- ice appears on the window sill and on the window itself, which has a very negative effect on the indoor climate;

- the windows cease to protect from noise – all sounds from the street are audible, with the wind a characteristic hum also appears;

- fungus and mold appear on the windows – this indicates a violation of the tightness of the glass unit and moisture accumulation on it;

- the installed seal begins to crack – this means that it has already far exceeded its service life.

If you notice any of the above signs, then this means that you should buy a plastic window seal to replace the failed one and install it. Otherwise, the windows will stop performing their protective functions.

You should also understand that several individual factors affect the tightness of a window:

- quality sealant. It all depends on the material from which it is made. High-quality gasket material must endure repeated compressions and stretches in the process of opening and closing the window, withstand regular temperature drops and other negative factors;

- type of seal connection with the window. The performance characteristics of the latter depend on how the sealing material is attached. This may be sticking, soldering and other options;

- quality replacement. Even the best quality seals for wooden and plastic windows lose most of their properties if they are not installed correctly. It’s relatively easy to install by yourself, but if you do not have the necessary skills and tools for this, it’s best to seek help from experienced specialists.

Helpful advice! If you decide to change the sealing gasket on the window on your own, then you should first familiarize yourself with the numerous instructions and training videos on the Internet.

As already mentioned, the material of which it is made is of great importance when choosing a gasket on the window. There are several options, each of which has its own characteristics of operation, advantages and disadvantages.

EPDM is ethylene-propylene or synthetic rubber. This material is characterized by high quality, reliability, durability and, in turn, is of various types. Types of EPDM are distinguished by what chemical processes occur during its vulcanization. If sulfur is used as a vulcanizing agent, then this rubber is called sulfurous. This type is not recommended to be used in combination with PVC windows of white color, since sulfur can react chemically with the window profile, leaving yellow traces on it.

The second option is pyroxide EPDM, in which organic peroxides act as a vulcanizing agent. It is more expensive than the previous type, but can boast higher levels of durability and reliability. Both types of EPDM seals are characterized by the following advantages:

- large temperature range of use – from -60 to 120 degrees Celsius;

- high resistance to temperature extremes;

- practically insensitive to direct sunlight and ultraviolet radiation;

- have a high level of strength to mechanical deformations;

- long service life – 10-20 years subject to regular maintenance.

The disadvantages of this type of window seal, which can be purchased at any specialized store, also include:

- You can fix it only with glue, you can not weld;

- if you need color seals for plastic windows, the price of 1 meter will be higher than for the same material, but black;

- If you choose a gasket on a sulfur base, then it may have an unpleasant smell.

EPDM seal is a good option, due to its high resistance to various kinds of adverse effects.

TPE or thermoplastic elastomer is most often found in prefabricated glass panes. It is a modified PVC and is characterized by a high rate of springiness. TPE is intended for use in mild climates, as it reacts rather poorly to low temperatures. This property of the gasket is fixed in the new type of thermoplastic polymers – mixed TPE. They are distinguished by the fact that they contain rubber and polyethylene, so they can boast of greater resistance to negative temperatures and, in general, better performance.

The advantages of PVC sealer for windows, which you can buy as easy as EPDM, are the following:

- absolutely safe for human health, as it is made from environmentally friendly materials;

- can be welded and not planted on glue;

- not combustible, i.e. it can be installed in premises with an increased risk of fire;

- much cheaper than EPDM;

- differs in high rates of springiness;

- There are many options for colors.

There are also disadvantages to this type:

- loses its properties at too high or too low temperatures, in the first case it softens, in the second – completely loses elasticity;

- quickly fails with regular mechanical stress, easily deformed;

- does not have a high level of elasticity.

As for the gasket design, it all depends on the color of the windows, as well as your imagination. Usually, the shade of the product is chosen in accordance with the color of the glass unit; however, you can choose the original, install a color model and create an original design in this way. It should be remembered that the color models of seals usually restore the shape after deformation worse than their black counterparts.

Helpful advice! When choosing a compactor for plastic and wooden windows, buy a product with a margin of length, as errors are inevitable during the installation process, at which the gasket length will be constantly cut.

Seals from modern materials for your windows are a reliable protection against cold, heat, dust and noise. You can easily buy them in the store, on the market or via the Internet, and self-installation does not take much time if you have minimal skills in this area.