Installation of plastic windows is a serious event that is best trusted by experienced craftsmen. If the installation does not take into account all the nuances, then during the operation of windows, problems may arise, including: poor tightness, heat leakage, as well as fogging of the glass unit. This article will discuss the design features of polymer windows, as well as the algorithm for their installation in high-rise buildings and private houses made of wood.

Design features of plastic windows

Plastic windows are made in most cases from a special polymer material – polyvinyl chloride (PVC). They differ in a variety of shapes and colors, but all have certain constructive similarities. Plastic window includes several main elements, among which are:

- frame;

- sash;

- accessories;

- double glazing.

Note! When installing PVC plastic windows in a window opening, it is necessary to take into account the size and characteristics of the material from which the building is made.

The window frame is the main element of the system. On it are fixed such products as sash and accessories. Sash – movable window elements that can open in several directions. For their work requires the installation of appropriate hardware.

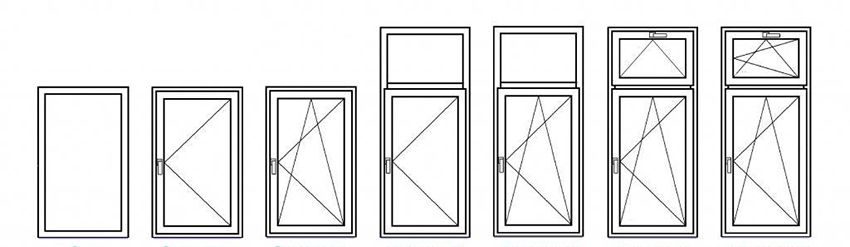

There are three main options for fixing the valves:

- turning;

- folding;

- combined.

In the first case, the movement of the sash occurs inward, and the control of the angle of inclination is carried out through special mechanisms. The second fixation option involves opening the transom relative to the loops installed in the horizontal plane. In turn, the design, fixed by the combined method, combines both of the above methods.

The double-glazed window is a hermetic construction that includes a certain number of glasses joined together with the help of separators. There are several main types of glass packs.

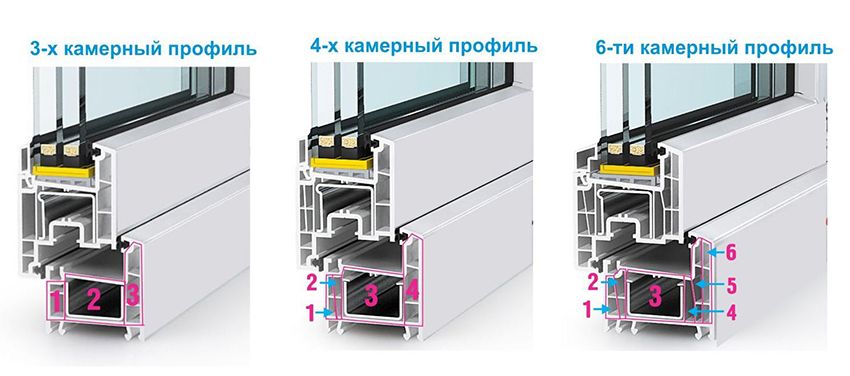

At first glance, the frame is a fairly simple design, but it is not. It is performed from a special window profile, which has a rather complicated device. It has a cellular structure and includes a certain number of chambers, which are separated from each other by partitions.

For a more visual study of the structure of the profile, you can use the search on the Internet. Pictures of plastic windows in the section are freely available and anyone can see them.

One of the main characteristics by which all window profiles are classified is the installation depth corresponding to the thickness of the frame. Today, this indicator varies depending on various factors, but there are certain standards. Manufacturers of plastic window products most often produce frames with an assembly depth of 58, 60 or 70 mm. If necessary, you can purchase thicker structures (with a width of up to 130 mm).

The second equally important characteristic of profiles is the number of cameras. These cavities are filled with air and stretched along the entire length of the window frame. Depending on this, the following types of profiles are distinguished:

- two-chamber;

- three-chamber;

- four-chamber.

There may be more cameras, but the most popular products to date have a three-chamber structure. The frame device assumes the presence of not only empty cavities in the profile, but also reinforced ones. The latter are necessary to give the design the necessary indicators of strength and rigidity. Reinforced cavity in a plastic window contains a polymer layer, and in the metal-plastic – metal (usually aluminum).

Useful information! The operating characteristics of the structure directly depend on the number of cameras in the window profile. Here we can note this pattern: the more chambers, the higher the insulating quality.

All profiles are also subdivided in their form into O- and U-shaped.

O-shaped. Closed circuit, which differs not the best thermal insulation characteristics. The design features of a profile of this type affect its rapid cooling.

U-shaped. Possess higher thermal insulation characteristics and are used in the manufacture of plastic windows much more often.

The last criterion by which profiles for plastic windows are classified is their class (economy, standard or premium). Experts recommend for installation in private purposes to use structures that have a standard class. Economy products freeze too fast, and premiums are distinguished by high cost and the presence of, in fact, unnecessary functions.

As a rule, profiles have a standard white color. Windows in wooden houses are available in the color of various types of wood. If you wish, you can order a profile of any color (red, blue), however, it is necessary to take into account that color designs have a higher cost in comparison with standard white ones. Before choosing colors it is recommended to study photos of plastic windows on the Internet.

Double-glazed window is a very important element of the window. It is limited to the limits of the frame and is fixed in its opening. A glass unit may consist of two or three glasses, which are located at a certain distance from each other. The width of the air chamber between the panes can vary, depending on the window model (from 1 cm and more).

The design of the glass unit is completely sealed, so disassembly is not possible. Docking glasses between them is performed around the perimeter, and between them are special liners. The air in the air chamber has moisture-absorbing properties and is often represented by inert argon gas. Dry air is the main factor determining the insulating properties of glass packs.

If the tightness of the glass unit is broken, then moisture will penetrate into the structure, which will subsequently affect the formation of condensate. There is a standard distance between the panes – 1.6 cm. A similar indicator allows to achieve the highest rate of thermal insulation. If the distance between the glasses will be higher, then the thermal conductivity of the glass will increase.

Depending on the number of cameras, there are the following types of glass packs:

- with one camera (2 glasses);

- with two cameras (3 glasses).

Useful information! As a rule, for the installation of glass in residential buildings used single-chamber construction.

Glasses in standard single-chamber systems are 4 mm wide, and the distance between them is 1.6 cm. The installation depth in this case is 2.4 cm. This design allows not only to provide good thermal insulation and protect the room from frost in winter, but and reduce the noise coming from the street.

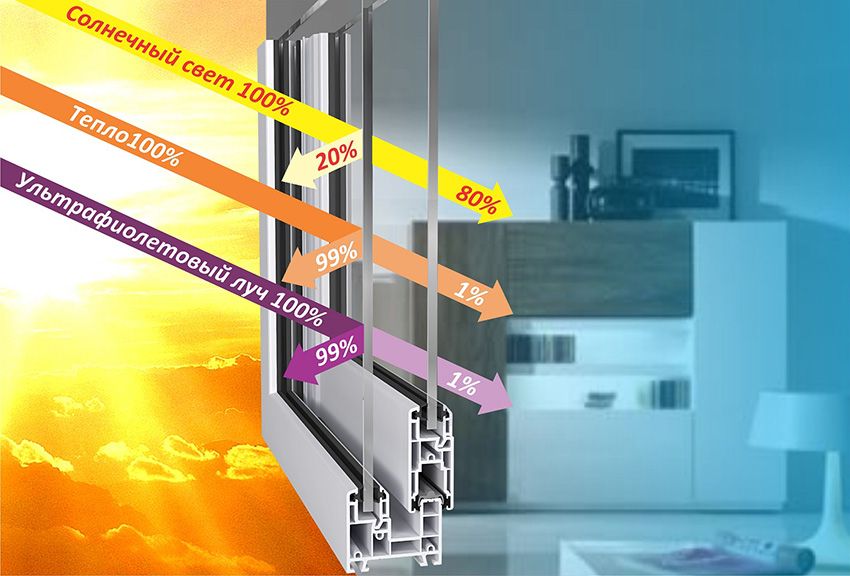

Two-chamber designs are more reliable and have better thermal insulation. From the minuses of such glass packs, it can be noted that they practically do not transmit ultraviolet rays.

Today, you can also find other types of glass.

Soundproofing. The structure of such structures include special glass, which are equipped with a protective film. This reduces the noise level several times. Such windows may vary depending on the thickness of the glass.

Energy saving. They include a special I-glass, which is manufactured according to modern technology and equipped with a metal sputtering. Thanks to this element, the thermal conductivity of the glass unit is reduced several times. I-glass is a reliable screen and does not allow the penetration of thermal radiation into the room.

Protective. Glasses in such models are equipped with protective films that prevent the dispersion of fragments in the event of structural damage. Most often, safety windows are installed in shops and banks.

Tinted. From the name it is clear that such double-glazed windows differ in opaque properties. Experts advise to install them in the event that the windows overlook the sunny side.

Thus, it was considered how to properly install a plastic window in a wooden house. Of course, all the work can be done personally. However, it is better to contact the specialists who will conduct a quick and high-quality installation of the structure.

How much is a plastic window with installation in a wooden house? The price for the installation of this type of construction will cost about 2000 rubles. for 1 m. Taking into account the cost of the window itself, the total amount of money will be approximately 9,500-1,1500 rubles, depending on which plastic window installation company you have chosen.