In order to cut the tile there are special tools – tile cutters. The choice of this device depends on the intensity of its use. For fairly large amounts of work, it is customary to use a water-cooled electric tile cutter. This adaptation allows to process not only ceramics, but also porcelain stoneware. The article will discuss the main models and characteristics of such a product.

Water cooled electric tile cutter: advantages

Devices that belong to this group are distinguished by high efficiency and long operational life. The water supply system includes elements such as: a hose and a fluid reservoir. The pumping mechanism, which carries out the water intake, is activated simultaneously with the cutting element.

Such a cooling circuit can achieve two main goals. First of all, it prevents overheating of the diamond blade. No less important is the fact that when cutting tiles with ordinary mechanical devices quite a lot of dust is emitted. The use of a water tile cutter allows you to cope with this problem, which makes the processing of ceramic material more convenient. Dust captured by particles of water, immediately deposited on the device.

Under the working surface for cutting tiles is a special container, the height of which can be different. It depends on the model of the device with water cooling. As a rule, this indicator is no more than 10 cm. Dust with water flows down the blade, as a result of which it enters this tank. To ensure normal operation, it should be cleaned from time to time.

Mechanical hand-held devices (for example, Sigma tile cutters) require effort when working with tiles, and also do not save from dusting. In turn, electric tools cope with this task. And they can also function offline. In this case, the hose that delivers water, docked with the tank, which is located under the working surface.

The movement of fluid in an electrical unit is carried out in a closed loop. This allows you to use the minimum amount to perform a large amount of work.

The device traditionally has quite large dimensions. It is a stationary device and operates due to its electrical connection. To ensure maximum comfort when cutting tiles, its platform is located at a height of about 1 m. This allows the master to perform all the necessary manipulations while standing, while maintaining a comfortable body position. The distance from the floor to the desktop can be adjusted, depending on individual preferences.

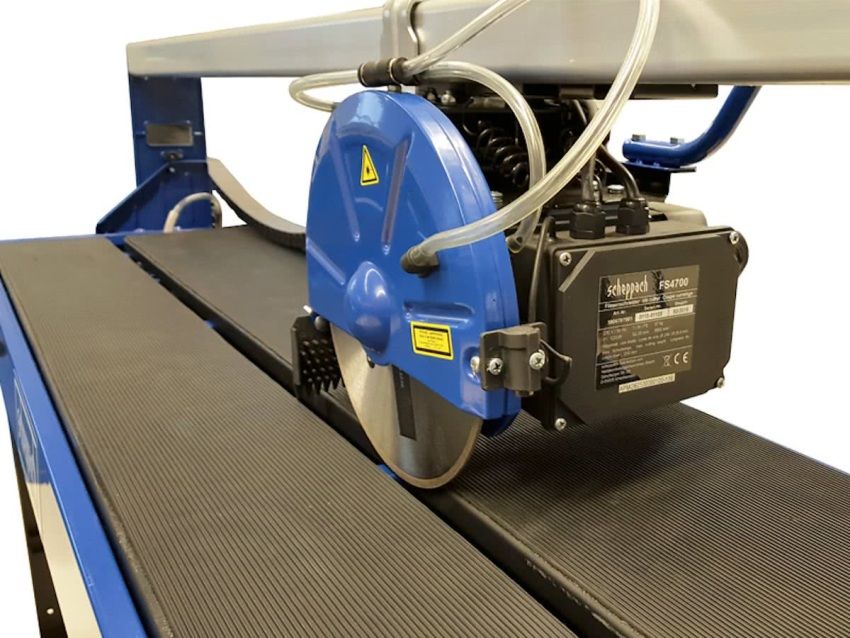

From a constructive point of view, such devices have a certain similarity with circular saws. The device consists of several basic elements, among which are: an electric motor, a cutting wheel, a work surface and a bed. And also this type of tile cutter is equipped with a functional part adjustment system and special locking devices.

Note! As the main cutting element in such devices, as a rule, a diamond disc is used.

The cooling system is fairly simple and provides fluid at the point of contact of the cutting device with a ceramic product. Due to the high quality of diamond blades for tile cutters, devices can be used to process various materials, such as: porcelain stoneware, stone, concrete, glass, etc.

Today there are a huge variety of models of these devices. They are produced by different brands and differ from each other not only in appearance, but also in technical characteristics. All electronic tile cutters are divided into two main types:

- manual;

- professional.

Hand held Such tools have a simple and convenient design. They can function both from an electric network, and from the rechargeable battery (joint stock bank). By the principle of action, they resemble angle grinders, with the only difference that tiles are used as processing products.

The manual electric tile cutter includes a handle, a support element, called a sole, and a fluid reservoir. As well as elements that allow you to adjust the position of the functional part. To work with such a device is desirable only in the horizontal plane. This is due to the fact that, being in a vertical position, the product does not prevent the formation of dust. For more complex jobs, there are manual professional tile cutters.

Today in the construction market you can find more voluminous models that run on battery power. The main advantage of such devices is autonomy. They are a kind of transitional link, located between manual and professional devices.

In turn, professional devices are classified according to such a criterion as the location of the motor. It can have two positions:

- above working plane;

- below the work plane.

Devices with motor below. The main characteristics of such models include high quality cut, as well as good protection against dust during operation. The cutting element is represented by the same diamond-coated disk. The design feature of this device is the location of the functional part. The upper half of the cutting wheel is located above the working plane, and the lower one is placed in a tank of water.

This position of the motor allows you to produce compact equipment that is versatile. Such devices are highly popular in the construction market precisely because of their small dimensions. During repairs in the apartment is always difficult to find enough space for a large model.

Lower drive devices allow cutting rather large products from ceramics and other finishing materials. This is due to the fact that there are no limiting structural elements on the work surface.

Useful information! Among the shortcomings of stationary models that have a motor in the lower part, it can be noted that during the cutting it is necessary to move the workpiece with your own hands. Therefore, to work on such a tile cutter, it is desirable to have experience.

Models with a motor on top. They are professional electric tile cutters. Devices of this type have rather large dimensions and are distinguished by a complex structure. To work on a water-cooled top drive electric cooker, it is necessary to have sufficient experience. All instruments with a motor located in the upper part are divided into two types:

- cantilever;

- pavements.

In the first case, the device is equipped with a console, which is fixed with the help of special locking elements. The working platform of such a device is characterized by mobility. Electric bridge cutters include a moving functional part, which is moved with the help of special guide elements.

Electric tile cutter Dewalt D24,000

This type of device is versatile. It can be used for cutting ceramic or paving slabs. And also often the device is used for processing stone. The design of the device includes two supporting elements, which not only increases the accuracy of the cut, but also allows you to perform it at an angle of 45 °. To protect the cutting wheel, it is placed in a special casing.

A machine of this type is quite common in the conditions of small enterprises. He is considered one of the best tile cutters and is able to perform fairly large amounts of work.

The accuracy of the cut in such a device is ensured with the help of special guides. They are made of stainless steel, therefore, are resistant to corrosion. Using such a machine allows you to make cuts up to 61 cm long.

The water cooling system of such an electronic tile cutter includes dual water jet channels. If necessary, their work can be adjusted so that the diamond disc receives the optimal amount of coolant. And also the device of this type is equipped with tanks for trapping water droplets, which are located behind and on the sides.

This device operates from a network with a voltage of 220 V. Its power rating is 1600 watts. Spindle speed – 4200 rpm. The device is rather bulky and weighs 32 kg. The price of this type of electric tile cutter is an average of 64,000 rubles.

Note! The possibilities of DeWalt D24000 are wide enough. In addition to the usual longitudinal cuts, such a device is used to organize holes for sockets.

Electric plaster cutter ZUBR ZEP-800S: characteristics

Such a device has a good performance and includes an electric motor with a power of 800 watts. Like the previous model, this device is equipped with a water cooling system. All important elements of the machine, including the working surface of the table, are made of stainless steel.

Cutting facing materials can be made with this device at different angles (from 0 to 90 °). The maximum length of the cut is 53.5 cm. The device operates from an electrical network with a standard voltage of 220 V. The motor in this electric hob is on top, so it belongs to the professional group.

The rotation speed of the spindle element is 2950 rpm. The weight of such a device is approximately 30 kg. Such a device is quite common and has many positive reviews among consumers. The price of electric tile cutter ZUBR ZEP-800S ranges from 11,000 to 13,000 rubles.

Desktop plitkorez Practice of the Pro 1872

Such a device is a desktop and allows you to quickly and accurately handle tiles. The unit’s engine power rating is 72 watts. Of the features of the device, it can be noted that it allows you to cut the facing materials without applying pre-marking. This is achieved by a parallel stop of the working plane.

The desktop model of this type has a compact size that allows you to move it without any effort. The unit is adapted for cutting products whose length does not exceed 30 cm. It functions from a normal electrical network with a voltage of 220 V. In this case, the rotation speed of the spindle reaches 2800 r / min.

This electric stove is equipped with water cooling and has a special reservoir for the liquid. With it you can cut not only ceramic tiles, but also products made of porcelain stoneware.

Practice of the Pro 1872 differs in small dimensions and has a weight of only 16.5 kg. The cutting depth of the desktop-type device is somewhat less than that of professional machines and is 20 mm in this case. How much does a tile cutter of this type? You can purchase this unit for 7500-8000 rubles.

When diagonal cutting tiles must be very careful to eliminate the likelihood of chipping. Experts do not recommend very much pressure on the cladding product during its processing.

Thus, there are several varieties of electronic tile cutters, each of which is selected depending on the purpose. When choosing this device you should pay attention to its external elements. They must not be damaged. It is also recommended to study the passport of the electric tile cutter. Reviews of different models can be easily found on the Internet in specialized forums.