Specialists who have repeatedly in their practice used metal cutters for a lathe to perform certain jobs, clearly understand what types these tools are. For beginners who come across these elements for the first time, it is difficult to figure out what the distinctive feature of each particular model is and how to choose the right tool to perform certain tasks. To understand the important issue will help this article.

Features of the design of the turning lathe for metal

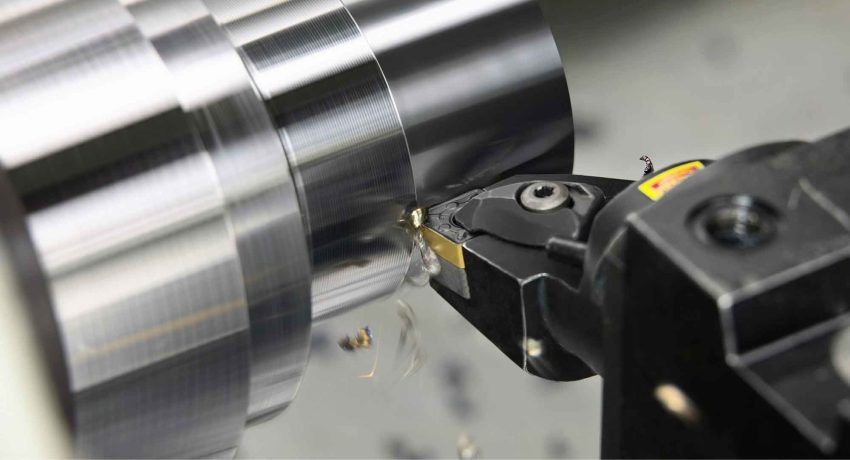

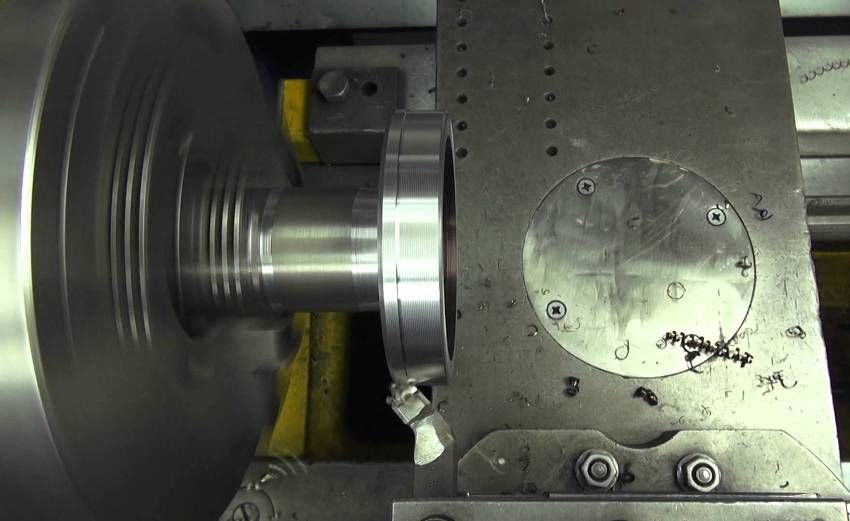

The element design consists of a tool holder, thanks to which the tool is fixed on the machine, and a working head that directly processes the surface of the workpiece. The toolholder may have a square or rectangular cross section. The working part of the tool is formed from several adjacent planes and cutting edges. Their grinding angle depends on the characteristics of the material being processed and the type of processing.

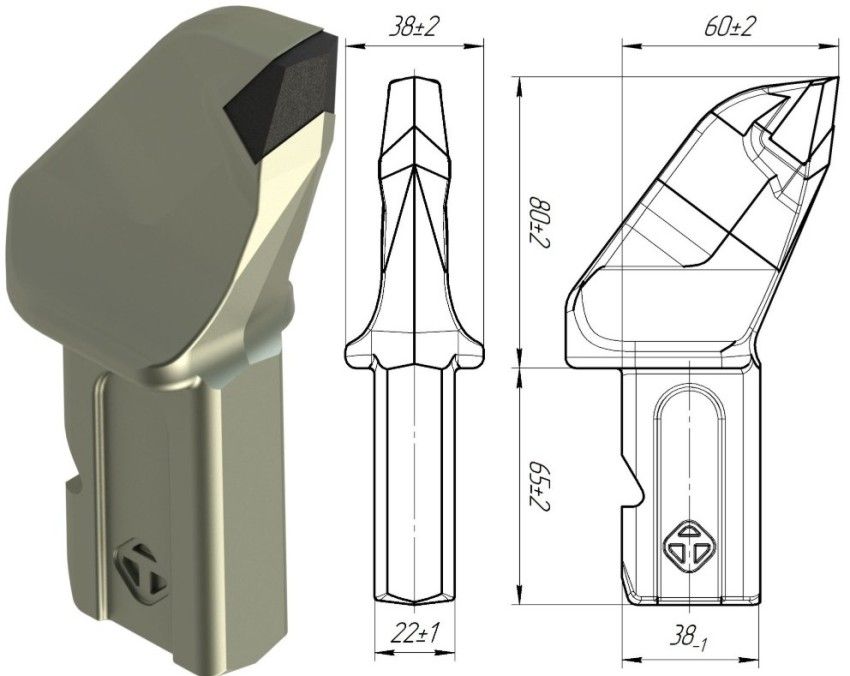

The working head can be solid or with welded or soldered plates. A novelty is metal cutters for a lathe with interchangeable inserts. The first option is represented by a solid element with a holder. Such a tool can be made of special high-carbon tool or high-speed steel. But such incisors are rarely used.

Preferably, the metalworking on the lathe uses incisors with welded or soldered plates. The tool is made of high-speed steel or hard alloy, which contains metals: titanium, tungsten and tantalum. It is characterized by high durability and pricing. This turning tool can be used for processing products from non-ferrous metals, cast iron, any steel and non-metallic materials.

Important! When working with plates of hard alloy should follow the rules of safety, because the products are very fragile.

Very often, when processing the material, turning tools with interchangeable inserts are used. In contrast to the previous version, the plate is mechanically attached to the head with special clamps or screws. The tool is convenient in further operation if the plate is made of mineral-ceramic, which significantly increases the cost of the cutter with interchangeable plates.

The working part for the lathe tool cutter can be made of hard alloy (tantalum-tungsten-titanium, titanium-tungsten, tungsten), high-speed steel (increased or normal efficiency), high quality carbon steel. The cutters can be used for such types of lathes as planing, turning, slotting, automatic revolverto and special.

According to GOST, there are three types of lathe cutters for metal:

- turning and planing, in which the cutting part is made of high-speed steel;

- carbide planers and lathes;

- turning with mechanical fastening plates of ceramics, hard alloys and other superhard materials.

Manufacturers produce these types of cutters:

- checkpoints;

- cutting off;

- threaded;

- cutting;

- boring;

- universal.

Depending on the direction in which the feeding movements are performed, it is possible to distinguish the following types of cutters for a lathe:

- left side type;

- right sided type.

To identify the tool you need to put a hand on the cutter. The location of the edge relative to the thumb of the right or left hand will indicate the type of tool.

Depending on the nature of the work, there is the following classification of incisors:

- for performance of draft works which else carry the name peeling;

- for semi-finishing works;

- for finishing work;

- for the implementation of thin technological operations.

The cutting plate of all cutters, regardless of the type of tool, is made of a certain brand of hard alloys: TK5K10, VK8, T15K6 and T30K4. The most popular are the incisors VK8.

Depending on the principle of installation, the following types of metal cutters for a lathe are distinguished:

- radial;

- tangential.

In the first embodiment, the turning tool relative to the axis of the workpiece, which is processed, is located at an angle of 90 degrees. This type of products is widely used in industrial enterprises, due to the fact that the cutter is quite easily and quickly installed in the machine. In addition, there is a large selection of geometrical parameters of the cutting edge.

Tangential turning tool is located at any angle other than 90 degrees. relative to the axis of the workpiece. Fastening this tool to a lathe turns out to be more time consuming than in the previous version. However, tangential incisors provide better processing of the metal billet. They can be used for lathes automatic and semi-automatic.

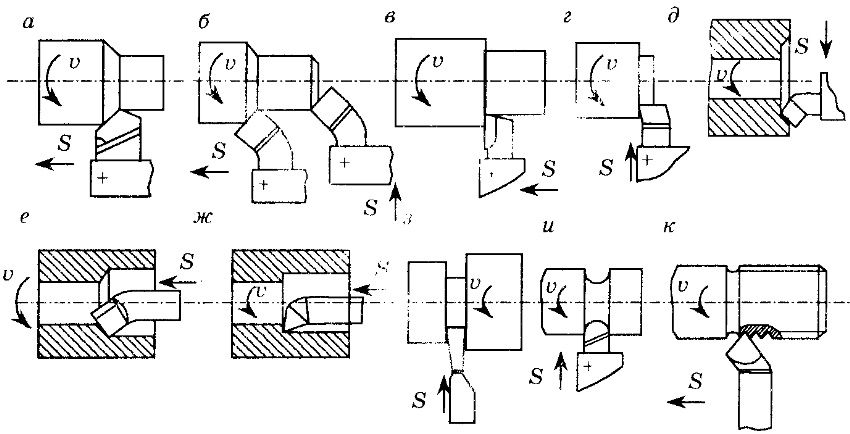

Depending on the location of the main cutting edge relative to the rod, there are such types of turning tools:

- straight lines – all projections of the part have a straight line;

- bent – the upper projection has a curved line, the bottom – a straight line;

- curved – the upper projection is displayed directly with a line, and the side is curved;

- drawn – the tool head, which can be on the axis or shifted to the left or right, has a smaller width than the shaft.

Turning cutters can be:

- straight;

- bent;

- persistent bent off.

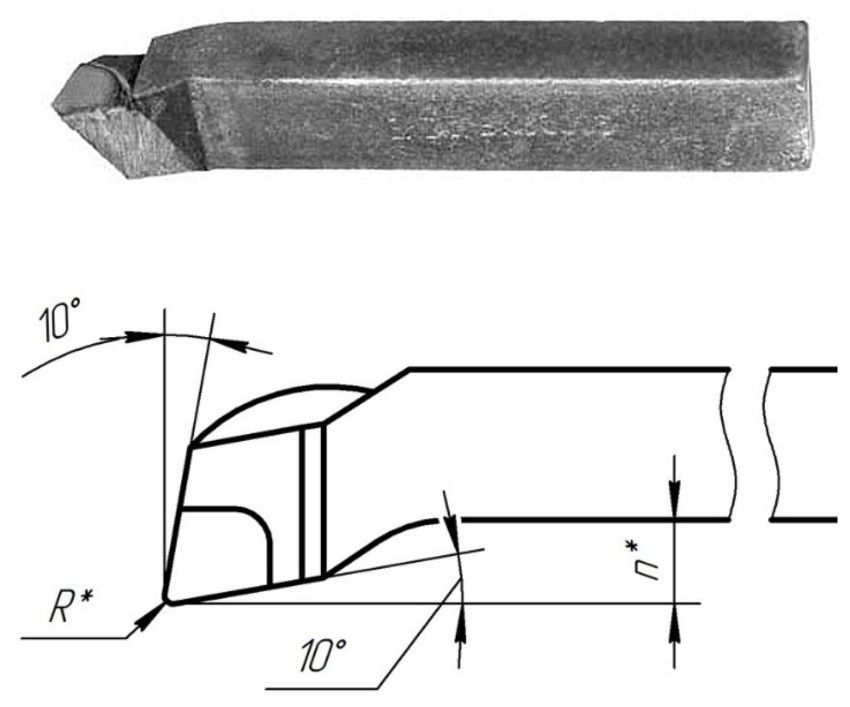

Straight straight cutters are used to process the outer surface of a cylindrical billet. Buy direct cutter GOST 18877-73 can be for 280 rubles. Holders for such a tool can be made in two sizes:

- traditional rectangular shape – 25×16 mm;

- square shape, which is used for the production of special works – 25×25 mm.

In bent cutters, the working part can be bent to the left or right side, which makes it possible to bend around the workpiece from different sides during the work. In addition to machining the end part of the workpiece on a lathe, the tool is used for chamfering. According to GOST 18877-73, the holder for this type of tool can have the following dimensions:

- 16×10 mm – for educational machines;

- 20х12 mm – non-standard product;

- 25×16 mm – universal size;

- 32×20 mm;

- 40×25 mm – made to order for use on the dimensional machine.

The most popular is the resistant unbent cutting tool for a lathe. It is used for processing cylindrical billets. The special bend of the element allows removing excess metal from a round part in one pass. When processing the workpiece cutter moves along the rotation of the part. Bent-through cutters can be left-sided and right-sided. The last option in practice is used much more often. It is possible to buy a through cutter for 320 rub. Bent

The most common is a cutting cutter. It is designed to cut the workpiece of the required size from a metal pipe, pig, rod, which has a length greater than the required value. This type of incisors is difficult to confuse with another tool. The design of the product consists of a thin leg with a plate of hard alloy soldered on the end. The narrower the foot, the smaller the cut, which consequently contributes to reducing the amount of waste. The cut of the workpiece from the total metal body is carried out at a right angle.

Helpful advice! Cutting tools can be cut into a metal product thin grooves of different depths.

Depending on a design of execution there are left-side and right-hand detachable cutters. To determine this, turn the product with the cutting side down and look at which side the tool foot will be located. It is possible to buy a lathe cutter for 190 rubles.

Manufacturers produce cutting tools with the following holder sizes:

- 16×10 mm – for educational machines;

- 20×12 mm;

- 20×16;

- 40×25 – made to order for large-sized machines.

Cutting bent cutter looks very similar to the resistant tool through passage. The working part is also represented by a plate of hard alloys, but has a triangular shape with one rounded side. With this type of cutting tool, you can machine a workpiece across the axis of its rotation, exposing the tool perpendicularly.

Manufacturers also produce cutting thrust cutters, which have a much lower demand in the construction market, due to the limited scope of use of the tool.

Holders for the cutting tool GOST 18877-73 are of such sizes: 16×10 mm, 25×16 mm, 32×20 mm. The cost of the bent tool on average will be 250 rubles.

Among the wide range of turning cutters for metal, you can choose the most suitable option that will cope with the task. To do this, determine which metal will be treated, what operations should be performed, whether it is important to comply with the geometrical parameters of the final product, or it is necessary to ensure high-quality surface treatment. Only then should proceed to the selection tool.