The tile is one of the most widespread finishing materials today. For its proper installation, a whole range of tools is used, one of which is a tile cutter, without which laying tiles is simply impossible. This article will discuss the main characteristics of the manual tile cutter: price, design differences, and the rules for handling the tool.

Which tile cutter to choose: the main characteristics of the tool

Manual tile cutters are used not only for cutting tiles, but also for working with other materials (for example, glass or stone). The choice of one or another kind of such a device depends primarily on the purpose.

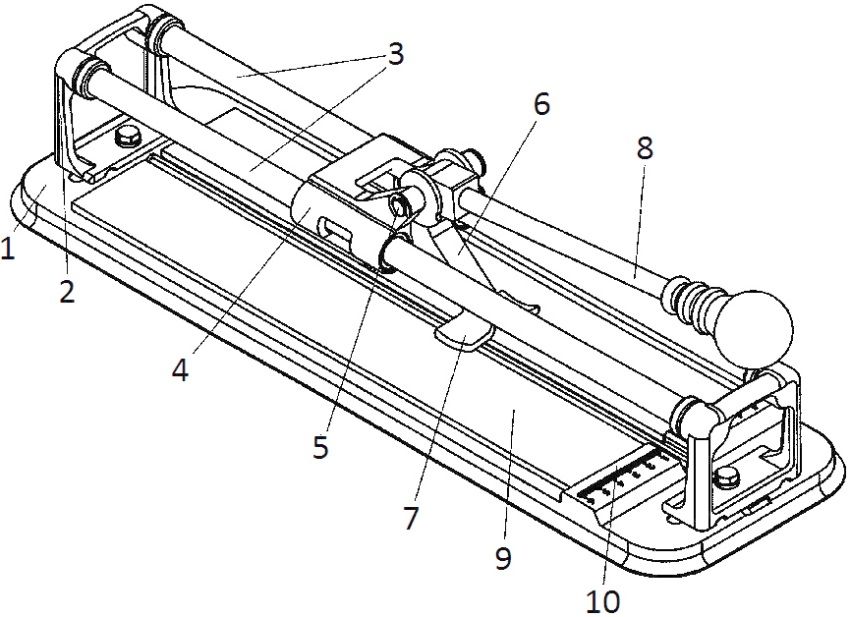

The manual tile cutter functions as follows: first, the tile is fixed in the rail device, after which, along a pre-planned cutting line, a roller is used that has a diamond coating. Thus, the tile is shortened to the required size.

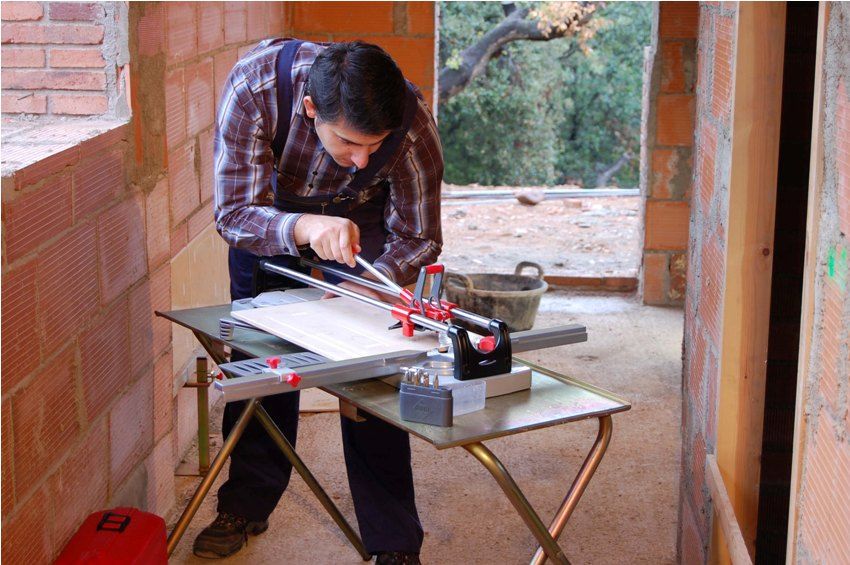

In order to better understand the process of working with this device, it is recommended that you familiarize yourself with the instructions, which describe in detail how to use manual tile cutters. Videos on this topic can also be found on the Internet.

Today, there are many types of handheld cutters, but they are all used to cut the following materials:

- ceramics;

- a rock;

- ceramic granite;

- glass;

- clinker brick.

There are several ways to cut a tile or any other material. The cutting method is determined by the design features of the hand-held device. Consider these methods in more detail:

- conducting risks (lines) with subsequent fracture;

- nibble edges;

- full cut.

Often when laying tile material on a work surface, one encounters various obstacles (for example, protrusions or shoals). To circumvent these obstacles, you must be able to correctly cut the tile. And also often the masters are faced with such a problem as the presence of irregularities in places where the working surfaces come into contact. In such cases, you have to perform bevels on the tiles.

The main functions that manual cutting devices perform:

- trimming facing material;

- straight cuts;

- figured cuts;

- making various holes;

- the organization of recesses;

- cut at an angle of 45 °.

Useful information! In order to simplify the process of laying one or another material, experts advise to purchase multifunctional tile cutters equipped with various additional elements.

When choosing a device for one-time use, you need to pay attention to the characteristics of the tile, and professional models require more careful selection. In any case, when choosing, it is necessary to study the main types and characteristics of devices.

The length of a manual tile cutter can be different (from 30 to 60 cm), and experts recommend purchasing models of greater length, since they are more versatile. The use of a tool that is 60 cm long makes it possible to make straight and angular cuts of a tile without much difficulty. Consider the main advantages of handheld devices used for cutting:

- The main advantage of the handheld device is autonomy. For such a tile cutter does not need electrical energy;

- a small mass, which affects the mobility of the device and allows its use in conditions of limited space;

- the presence of auxiliary components, which include: a ruler, a square, as well as a “ballerina”. They are needed to simplify the process of cutting tile material.

Note! Devices equipped with a “ballerina”, allow for round holes in the tile under the pipe.

The price of a tile cutter can be different and depends on its design features, component parts, as well as the manufacturer’s company. For example, the cost of foreign devices, as a rule, exceeds domestic counterparts.

Depending on the complexity of execution, all manual cutting devices are classified as amateur or professional.

To amateur devices include nippers and roller cutters. These are very simple from a constructive point of view adaptations, the cost of which is much lower than that of professional models. The use of pliers allows you to perform figured holes in the cladding material, however, they are unsuitable for an even cut.

Roller cutters allow you to make a flat cut, but to use them you need to have special skills. Working with such a cutter implies the most genuine manual work that requires some effort. Their average cost does not exceed 100 rubles, which is financially very profitable.

In turn, professional tools are divided into two main types:

- mechanical;

- electric.

There are two types of mechanical hand-held tile tools:

- roller;

- bearing

The device, which is based on the roller mechanism, is the most common and popular in the construction market. This is due to the ease of production of this device, as well as the fact that its operation does not require any special knowledge and skills.

Using a roller version of a manual mechanical tile cutter allows you to get a fairly neat and even cut. Such accuracy is achieved due to the presence of a rigid carriage in its design. Roller models are great for working not only with thin, but thicker solid tiles.

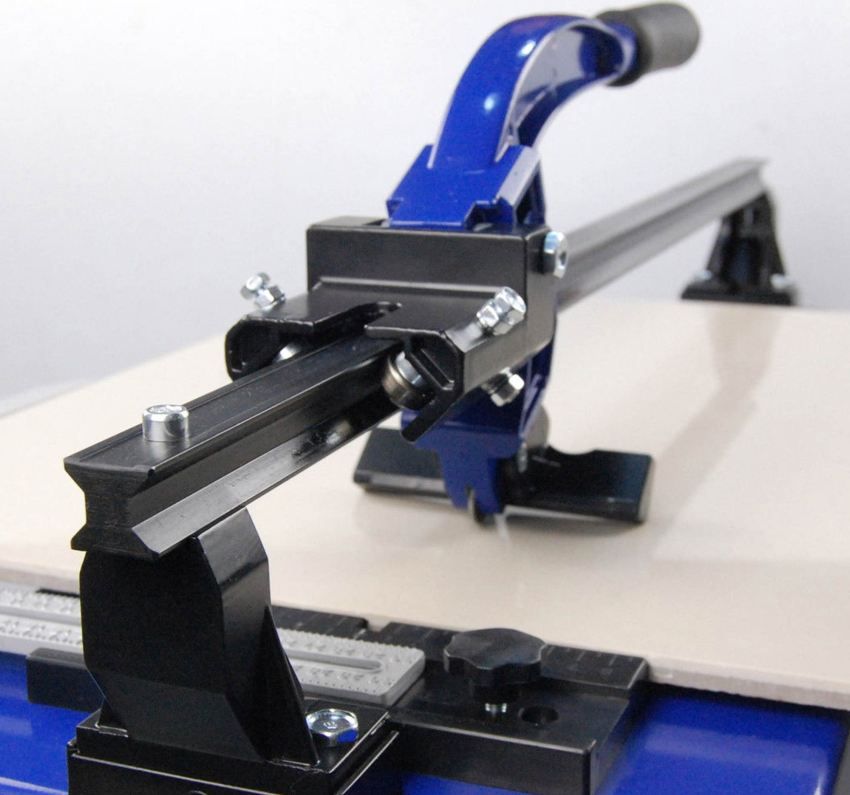

Bearing devices for cutting tiles are equipped with special bushings, which allows for maximum softness of the stroke when making the cut. Their use is recommended when working with non-standard tile material.

Note! As a rule, manual cutting devices are used to process a material whose thickness does not exceed 15 mm. However, it is sometimes necessary to cut the tile with a thickness of 16 mm. In such a situation it is recommended to use the bearing manual model.

Electric manual models are more complex from a constructive point of view and therefore are used much less frequently.

The design of electronic devices for cutting differs from mechanical analogs and has some features. The structure of the manual electric model includes the following structural elements:

- handle (for ease of operation);

- sole, which performs the function of support;

- special adjustment of the depth of immersion and angle of inclination of the cutting element;

- cutting element.

An electronic device for working with tiles and other facing materials has one big plus – the possibility of attaching a dust collector. In the case when a “wet” type of cut is made, a special water tank can be connected to such a device.

It is important to remember that the cuts made by such a device are not of high quality. The main function of the manual electric tile cutter is to replace the angle grinder.

With the help of an electronic model, you can cut quite complex materials that mechanical tile cutters cannot completely handle. The main material of this kind is porcelain. The complexity of working with him lies in his high strength characteristics, which largely determines his purpose – laying on the floor.

Knowing how to cut a tile with a manual tile cutter and performing all the above actions in the right sequence, cutting the material will occur without difficulty. Similarly, trimming up to 1 cm wide can be performed.

The tile cutter is a functional construction tool that is able to significantly simplify the work on laying ceramic tiles. For more effective work with the device, it is recommended to familiarize yourself with various instructions on how to work with manual tile cutters. Videos on this topic can also be easily found on the Internet.