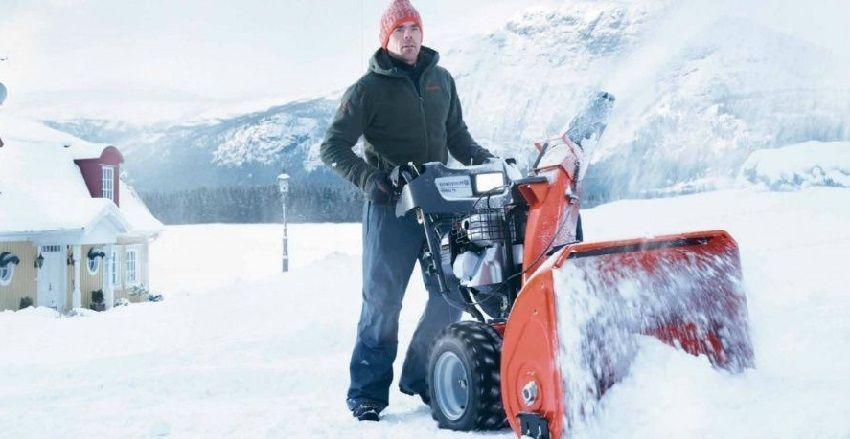

The peculiarities of our climatic zone allow us equally to enjoy both hot summer and cold winter. But in order to clear snow of the last winter, many people decide to purchase a hand snow blower. This simple device will help you get rid of unnecessary physical effort, and also save a lot of time. Consider what options devices are, and by what principle they need to choose.

Manual snow blower: device application area

Manual snow machine is a device that is designed to save you from having to clear a snow-covered house with a shovel. Generally, in order to get rid of the snow, and to ensure easy access to any point, there are only three ways: to scatter the snow with a shovel, use a snow blower or equip a snow melt system.

Of course, the least expensive option is a shovel. But one can not agree that this method takes a lot of time and effort. Moreover, the new snow in the winter falls constantly, and you can get an unpleasant surprise in the form of snowdrifts, in any morning. More convenient, but at the same time and difficult to install method – the system of snow melting. But It is worth noting that many consider this option too expensive and unjustified.

That is why the manual snow blower firmly took its position among the methods of clearing snow, and is widely used in everyday life. Its performance makes it easy to clear the road from the snow to leave or a small yard, whose area does not exceed 400 square meters. m. And now how quickly you can clean a particular area depends on weather conditions, as well as the technical characteristics of a specific device model.

In the process of snow removal, the size of the bucket plays a big role. After all, this parameter determines how high the snowdrift you can remove. Sometimes additionally there is a height adjustment with additional legs. This greatly expands the capabilities of the snowblower.

Manual snow blower is a great solution for those who go to the country in the winter or live in a country house. Unlike a full-fledged snow plow, this option is much more compact. It is easier to store and easier to maintain. Consider how to choose the most suitable model for yourself, what characteristics you should pay attention to and how these devices are arranged.

The principle of operation of the snow plow is very simple: it captures the snow in its path, and throws it aside, thus clearing the path along which it moves. Depending on the features of the mechanism that performs this process, there are one-stage and two-stage units.

Single-stage ones are also called screw screws, and a special pipe is used to throw snow in them. This process is carried out due to mechanical rotation of the screw. In two-stage systems, the mechanism of action is slightly different: the auger collects snow, while the other part, the rotor, is responsible for the ejection.

Depending on the conditions in which the use of a snow plow is planned, the working surface of the auger may be different. His device can be compared with a knife, the edge of which literally cuts off the top of the snow. So, if the snow has only recently fallen, it is more convenient to use a flat edge, while a jagged surface can cope with icy and long-standing snow. In turn, jagged edges differ in the number and size of teeth.

Depending on the material from which they are made, the screws of manual snow blowers are steel, rubber and even plastic. Of course, this or that option has its advantages, however, they all quite easily break down when confronted with such obstacles as stones, stumps and logs. Particularly affected are single-stage devices, where the speed of rotation of the augers for ejecting snow should be maximized.

Acquisition of the manual snow blower implies its use only in life. However, even with home use, there are quite a few requirements for this device. And the material for the manufacture of the impeller – one of the main. Undoubtedly, metal parts have a significant advantage over plastic ones: they last longer and are able to withstand considerable loads. But at the same time, the cost of such devices is much more expensive.

Another important point – the choice of the motor. Obviously, it is the motor that is the main driving force of any such mechanism, and the results of your work, as well as the amount of effort, directly depend on its quality. The two biggest challenges that a snow blower motor has to face are subzero temperature and hard objects that can get inside. And the failure of one component, leads to a malfunction of the entire system.

Helpful advice! It is important to understand that despite the huge selection of hand-held snow blowers of various brands, quite a few companies use the engines of their own production. Quite often, the same motors are purchased, which are simply completed in different ways.

As a preventive measure for the occurrence of malfunctions, use the following scheme of connecting the elements: using a pin or a cut bolt that acts as a fuse, a screw is fixed on the drive shaft. This system allows the bolt or pin to instantly break if a screw locks up. After all, it is much easier to replace such a small constituent element than to engage in complicated and expensive motor repair.

Depending on the type of engines for snow blowers can be divided into two classes: electric and two-stroke internal combustion engines. Using the second option is more profitable and rational, however, electric motors also have a number of advantages: they are cheaper, have low weight, do not pollute the atmosphere, are easier to maintain and have a much lower level of vibration.

Often, the owners of country houses are seriously wondering whether it is possible to assemble a manual snow blower on their own, using the materials at hand. And the answer to this question is definitely positive. Of course, you will need certain skills and materials, but if you use the drawings and instructions that are offered on the Internet, you can significantly save on the purchase of a snowplow.

First of all, you need to decide what kind of snowthrower you want to do. You can independently assemble both mechanical and electric manual snow blower. Consider the algorithm for creating one of the representatives of each type in stages.

To create the simplest of representatives of manual snow blowers, you can use almost any parts and materials at hand. Spare parts from old electrical appliances, as well as other metal components will do. As a guideline, you can use the relevant drawings or step-by-step instructions.

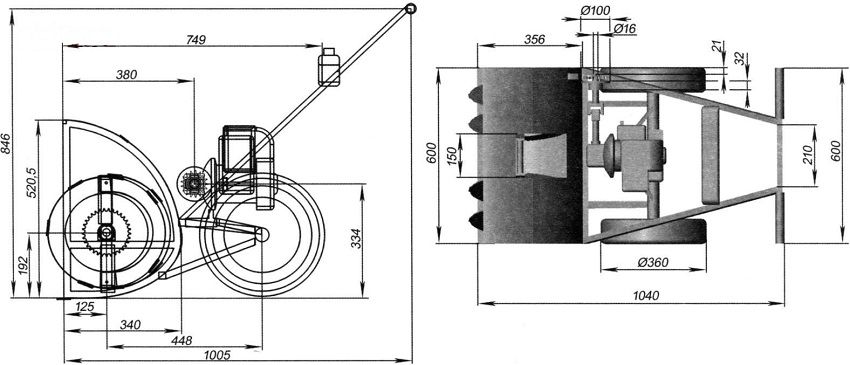

The basis of the design is a metal frame made of pipes or corners. Having established it on runners or wheels, all other mechanism will fasten to it. The easiest way to manufacture runners is to use wooden bars of a suitable shape, at the bottom of which a cut irrigation hose or strips of tin, plastic, etc. is fixed.

Helpful advice! If it is perfectly acceptable to use scrap materials as runners, then wheels of a suitable size will most likely have to be bought separately.

On the frame it is necessary to fix the engine, the speed of which does not exceed 1.5 thousand per minute, and the power is 5-6 kW. For the implementation of the drive mechanism through the gearbox, the easiest way to use the chain transmission and sprockets from the bike. As for the screw, it is mounted on a metal pipe, which, in turn, is attached to the side walls of the snow pick-up bucket in such a way as to be able to rotate.

In order to independently make a screw, you need 4 blades, which can be cut out of metal or conveyor belt. To the center of the pipe, which will serve as the base, an additional plate is attached, which will play the role of a blade, and will be able to throw snow into the pipe. The blades, in turn, are attached on one side to the shoulder, and on the other to the shaft (in some cases, you can find recommendations for the use of an additional plate that strengthens the structure). In order for the mechanism to work properly, the blades must be located in different directions, creating cross-helixes.

Helpful advice! It is important to correctly calculate the required diameter of the metal rings so that they do not touch the back wall of the bucket during the rotation, but they are not located too far.

As for throwing snow, the device of this system is also not too difficult to install. It is enough to make a hole in the upper part of the duct where the pipe will be inserted (usually the diameter is from 15 to 18 cm).

The finishing touch is the control knobs that can be made from metal corners or pipes. After that, it remains only to clean and paint the finished snowthrower, and you can get to work.

The algorithm for creating an electric snow blower looks a bit different. In the process of creation, such a device is certainly a bit more complicated, however, further work with it will be much easier in comparison with mechanical models. Consider step by step instructions for the assembly of such a structure:

- making auger. The process of making a screw for an electric snow blower is not much different from a mechanical one. Similarly, the need to manufacture the shaft and rings. And to the center of the main pipe is additionally attached plate, feeding the snow to the exhaust chute;

- Bucket manufacture. For the bucket it is best to use roofing iron, as it is quite durable, and at the same time it has all the necessary qualities. Its design is extremely simple: it must close the auger on three sides;

Helpful advice! The side walls of the bucket do not have to be metal. They can be made of plywood, with a thickness of at least 10 mm.

- with self-aligning bearings, a shaft with a screw is attached to the side walls. In this case, the distance from the edges of the spiral to the inner wall of the bucket should be at least 2 cm. A piece of sewer pipe, 15 cm or more in diameter, is perfect for arranging the discharge chute. The main rule in this case – the diameter of the exhaust pipe must be greater than the width of the plate, which is responsible for the emission of snow;

- for reliable and convenient installation of an electric motor, additionally manufactured U-shaped frame, consisting of metal corners. For additional fixation of the motor using metal straps;

- in order to ensure comfortable and uniform movement of the device, also use wheels or skis. It is important here that the distance from them to the frame is minimal. If you decide to opt for the wheels, then pay attention that they are resistant to frost and provide maximum adhesion of the snow blower to the surface;

- if you want to make a rotor structure, then you need to additionally make a structure, which is an axis with four rectangular plates. For the best snow fence, they should have special rims on the edges. It is important to respect the proportions so that the rotor does not come into contact with the bucket during operation;

Regardless of which one you decide to buy a snowthrower: a mechanical, electric, or just use an improvised manual model, this issue needs attention. After all, if you responsibly approach the choice, as well as the creation of storage conditions, then the newly fallen snow will bring you only joy.