The inevitable companion of the garden plot is plant garbage in the form of grass and branches. It is impractical to discard or incinerate such waste, because from it you can get natural fertilizer. It is enough to grind it to a state of chips. The garden shredder will easily cope with this task. However, if there is no financial opportunity to purchase it, then you can make a garden shredder with your own hands. How to do this – this article will tell in detail.

Do-it-yourself garden shredder: basic design elements

A garden shredder, also known as a shredder or chipper, greatly simplifies the process of caring for the dacha. With it, you can easily clean the area from the branches and grass. Recycled raw materials can be laid in the compost pit for natural fertilizer. It is advisable to use the obtained small wood as firewood for heating the house. Chopped chips from fruit trees are ideal for smoking meat.

The design of the garden shredder is quite simple. It consists of the following main parts:

- bunker;

- drive;

- grinding mechanism;

- metal frame with protective cover.

Some models can be equipped with additional elements:

- a hopper for crushed organic garbage;

- pusher;

- strainer for controlling the chips fraction.

The principle of operation of any shredder is the same as that of the meat grinder and is as follows. When the shredder is turned on, the engine starts, which drives the work shaft equipped with a cutting mechanism. At this time, the garden debris gets into the receiving funnel and is crushed to a state of fine chips using a cutting device.

Helpful advice! When carrying out work related to the processing of garden waste, you should use personal protective equipment – glasses, gloves, etc.

Before you start creating a homemade shredder, you must clearly define the type of waste that it will recycle. It directly depends on its design features and performance. Garden shredders are classified according to three main parameters: the type and power of the engine and the type of grinding mechanism.

There are the following options for the grinding mechanism:

- milling, for processing solid wood;

- universal knife;

- roller, for grinding thin branches of trees and shrubs;

- with rotating turbines for grinding thick branches;

- hammer, for the disposal of thin branches;

- trim, based on the use of fishing line, for soft garbage.

When self-assembly of the shredder, preference is given to a knife system or a composing of circular saws. You can perform a two-roll design in which two or three knives are mounted on a massive disc and rotate towards each other.

Schröder can be equipped with an electric or gasoline engine. Each of them has its own important advantages and some disadvantages. Garden shredder, working on gasoline, more mobile. Its operation does not depend on the power source. He is able to recycle thicker large branches. However, such chippers are more bulky and heavy. In addition, they emit harmful substances into the atmosphere during their activities.

Electric motor shredders are lighter and more comfortable to use. However, they are inferior in terms of power and depend on energy resources.

The ability to recycle a certain type of garden waste depends on engine power. For small volumes of waste, where the diameter of the branches does not exceed 20 mm, a 1.5 kW motor is sufficient. If it is necessary to grind branches with a thickness of 20-40 mm, then it is advisable to use an engine with a capacity of at least 3.5-4 kW. To cope with large wood 100-150 mm in diameter can grinders, equipped with a 6 kW engine.

The next design feature of the shredders is the type of drive. This function can be performed by the chain, belt or the motor shaft itself, on which the knife mechanism is fixed.

Creating a shredder with your own hands is a very laborious process that requires a master of technical knowledge and a high level of practical skills. All work consists of two stages. The first, preparatory, is to create a garden shredder drawing with your own hands and to purchase the necessary materials. The second stage is the assembly of the shredder itself.

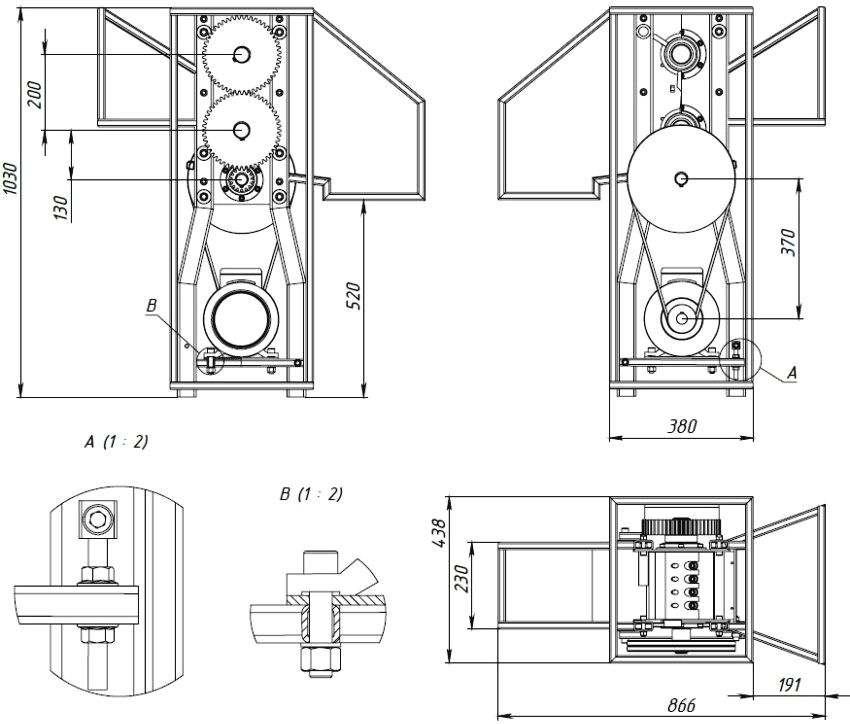

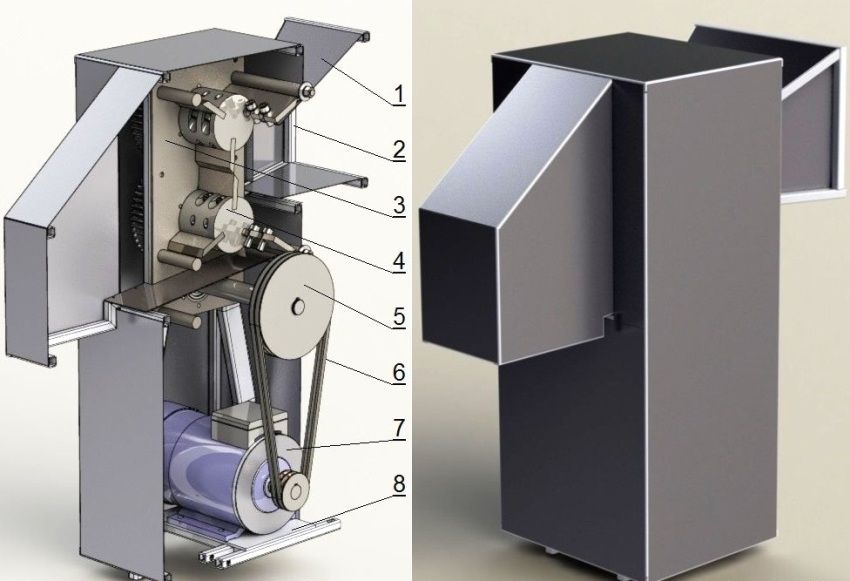

The drawing can be performed by hand or use a special design program on the computer. The basic design of the shredder consists of a hopper, frame, engine, shaft with a knife mechanism and a protective casing.

Examples of drawings of branch shredders with their own hands clearly show that various crushing mechanisms can be used for the cutting system.

In the case of using the stacked pack of circular saws, the chopper drawing will be fairly simple. The shaft is mounted on a metal frame with fixed circular saws in the amount of 15-30 pieces, which is driven by the engine using a belt drive. For this purpose, pulleys are located at the ends of the shaft and engine. As the shredder’s blueprints show with their own hands, the branches for home heating are shredded precisely because of such a cutting system.

Helpful advice! For more efficient operation of the shredder, thin plastic or metal dividers should be installed between the circular saws.

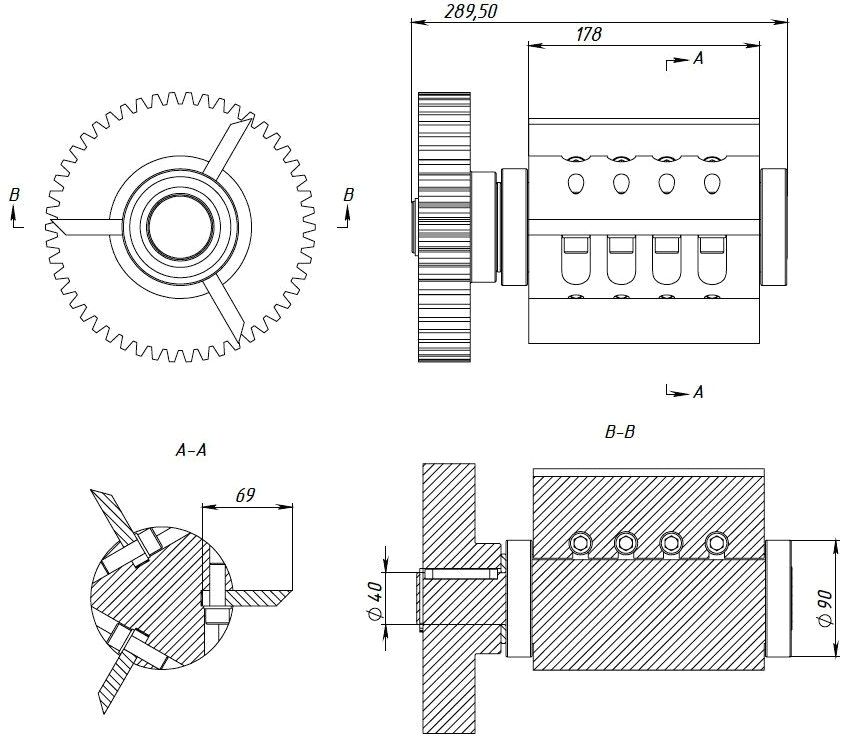

To create a shredder with a knife disk grinding system on the drawing indicates the diameter of the cutting disk, the number of knives and their location. The disk itself can be placed vertically or at some angle. The number of knives affects the degree of grinding. They can be from 1 to 3 pieces.

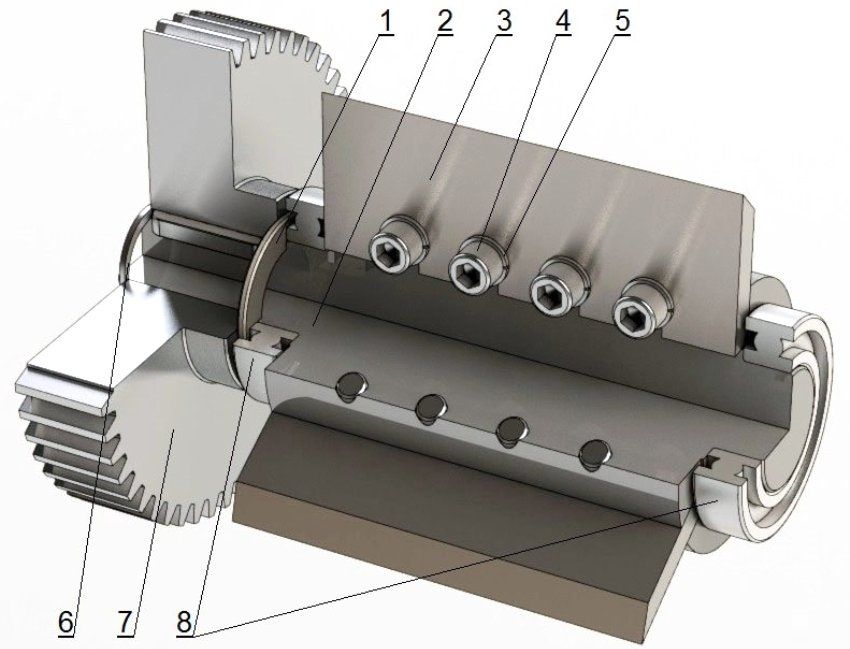

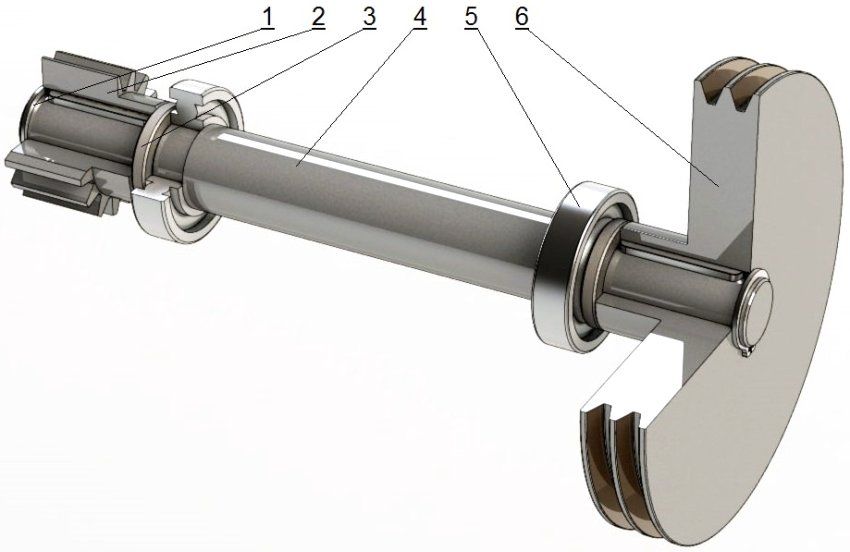

There is the option of creating a chip with two shafts. You can get acquainted with such a grinding system in the video. Drawings of the shredder branches with their own hands with a two-roll cutting system are distinguished by the presence of two shafts with knives, which are located between the metal plates. Each shaft is equipped with 3-4 knives. The knives themselves are fixed with bolts and offset in the direction relative to the center of the shaft.

Four bearings are fixed in the holes of the metal plates, which are responsible for the free rotation of the shafts. And the two gears, driven by the engine, ensure their synchronous rotation. Torque from the engine to the drive is transmitted using a chain or belt drive. The distance between the shafts is selected based on the width of the knives and the thickness of the branches.

Helpful advice! For grinding small branches and grass, electric motors with a large number of revolutions are required. And for grinding larger branches, strength is important. Here it is necessary to reduce the number of revolutions for powerful engines.

To make a garden chipper, where the grinding system is a set of circular saws, you need to purchase the following components:

- Circular saws in the amount of 15-20 pcs. 18 cm in diameter;

- engine;

- 2 pulleys;

- 2 bearings with mounting;

- metal washers in the amount of 17-22 pieces with a thickness of up to 5 mm for the separation of circular saws;

- profile pipes to create a frame;

- Sheet metal thickness of about 2 mm for the hopper and casing.

For a shredder with a knife disk you will need:

- engine;

- sheet metal 2 mm thick;

- sheet metal and knives for the disk.

To create a two-shaft chopper, you need to purchase the following materials:

- petrol or electric engine;

- two plates of metal 10 mm thick:

- a pair of gears to ensure synchronous movement of the shafts;

- gear or pulley to transfer torque from the engine to the shafts;

- pulley for the motor shaft;

- 5 bearings with fasteners;

- chopping knives;

- profile pipes to create a frame;

- sheet metal with a thickness of at least 2 mm to create a hopper and protective casing.

If you are not confident in your own abilities, now you can buy a homemade chopper from the options that will meet all the requirements, and will satisfy your wishes at an affordable price.