Very often, when performing finishing work, it is necessary to carry out diagonal cutting of a material with high precision. For these purposes, you should use a special tool. It is a miter saw with a broach capable of accurately and quickly cut the product at any angle and angle. About the features of the choice of tool and its main advantages are described in detail in this article.

What is a miter saw on wood. Purpose of the tool

Tortsovochnaya, pendulum saw for wood and metal, or angle cutter is a stationary detachable highly specialized tool that is used to cut materials at a certain angle. This possibility is provided by the turntable and movable working part with a disk above the bed. The miter saw can handle narrow wooden products in the form of slats, bars and planks. It can also be used to cut hardboard, laminate and OSB. The tool copes well with cutting plastic, aluminum and molded polyurethane decor.

Due to its high speed, accuracy and ease of operation, the end-saw has a wide range of applications. It is used for joinery, installation and finishing works associated with the use of wooden products. The tool is indispensable in workshops for the manufacture of furniture, where it is necessary to perform accurate and high-quality cutting of products.

There are universal tools that perform trimming for metal. Thanks to a special disk, a tool is used to cut metal products from steel, iron and cast profiles. Such face saws for metal are widely used in enterprises that manufacture window frames from metal-plastic profiles.

Important! Do not install a diamond or abrasive wheel on the tool instead of a saw blade.

In the technical documentation of each specific model, the limiting parameters of the product with which the tool can handle are indicated. Tortsovochny saws of the small sizes carry out cut of products up to 60 mm thick. The tool of average dimensions will cope with preparations 70-80 mm thick. Large saws are used for processing products with a thickness of 100 mm or more.

Important! Face saws can not be used for processing products made of stone, ceramics and ferrous metals.

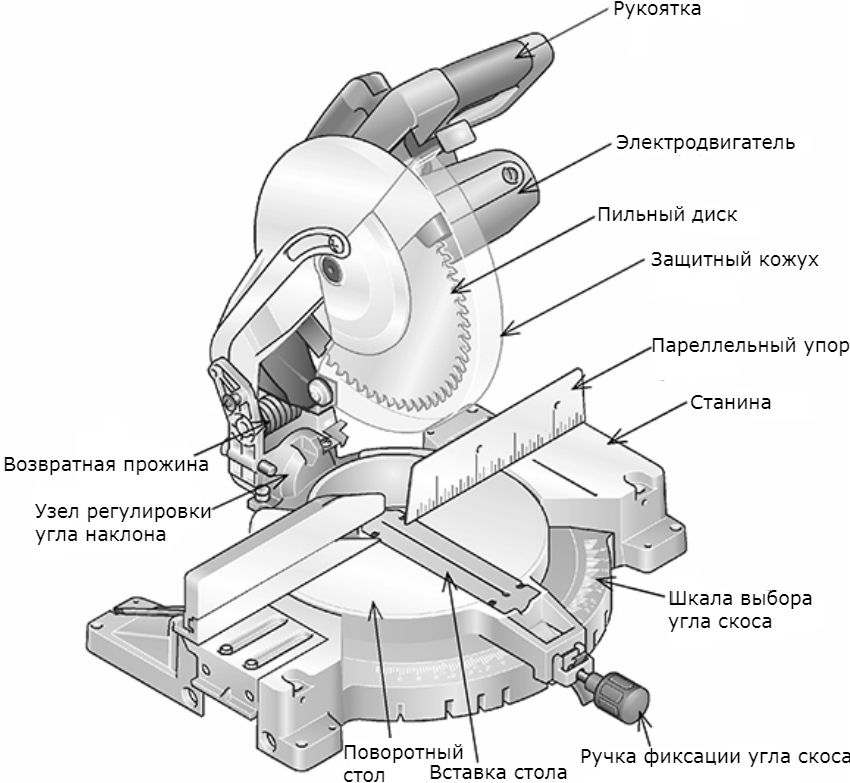

The face saw for a tree has a fairly simple design, which includes a saw blade, a motor with a gearbox, a base and a handle with a start button. The saw motor can be collector or asynchronous. The first option provides a greater number of revolutions, does not need regular maintenance, and only requires a periodic change of brushes. And the second is much quieter and more durable. In the classic version of the device, the engine is located on the right relative to the disk. However, there are improved models where it is placed at the back, which increases the viewing angle during cutting, thus being more convenient to use.

Rotation of the saw blade is performed due to the operation of the engine, which transmits the gear or belt drive through a gearbox. During operation in first gear, the possibility of product slipping even at high engine loads is eliminated. Second gear provides less noise and reduces disk vibration. And this has a positive effect on the quality of work and on the service life of the tool. However, in such devices, the belt quickly wears out, which can also come off during a sudden change of revolutions. There are more reliable and durable models that differ in direct transmission. However, their torque is much lower than analogs.

To extend the capabilities of a conventional end-saw, a broaching mechanism can be built into it. In this case the usual saw turns into the tortsovochny machine on a tree. In such models, the functional module is mounted on two rails that are parallel to each other. This design allows the saw blade to move freely during cutting, which allows for the cutting of wider products.

The functional module is fixed on the frame. This base is a movable round part that can move when setting the angle and stop. The bed for the miter saw is usually made of magnesium or aluminum alloys. The design of the saw includes a protective casing, which is put on the circle when the device is idle in order to avoid injuries.

One of the main and complex elements of the angle cutter for wood is the saw table. On one side, a stand is attached to it, on the other hand, a disk moves above the fingerboard. I saw with broach neck is much longer. At the end of the device is a clamping handle, which serves to fix the table relative to the base, and a pressure lock, used to quickly adjust the most running angles.

On the table and stand are angular scales, which indicate the angles of rotation and inclination. The table can be rotated in both directions from 0 to 45 degrees. And securely fixed in the chosen direction with a special groove with a latch.

The rack can be immovable or inclined to the left by 45 degrees. A tool with a stand tilt to the right is extremely rare, which is explained by the need to significantly complicate the design of the saw. In addition to the basic graduations, several specials can be provided, which make it possible to choose the optimal angle for cutting skirtings and moldings.

For reliable fixation of blanks of any dimensions, built-in clamps and various stops are used. When working with long products using folding or sliding supports, which are located on both sides of the bed, you can expand the dimensions of the base. Such additional stops are usually included in the miter saw. They are represented by U-shaped steel bars, bent up to the level of the table.

There are more complex base constructions with cast supports, which are fixed relative to the support with wing screws. Many manufacturers complete miter saws, the price of which will not be much higher than classic tools, with individual stands or special tables. They can be placed at some distance from the tool, depending on the length of products.

All devices are equipped with a smooth start, which allows you to block the mechanism during the replacement of the circle, and accordingly stop the engine. All models of miter saws are protected against body breakdown by electricity.

The classic execution of miter saws does not provide for the presence of electronic elements. However, there are models, usually miter saws for metal, which are equipped with electronic speed control function. This feature provides more precise control over the process of performing the work. It is also possible to adjust the equipment for cutting various materials.

Helpful advice! For cutting hard wood, it is advisable to use a saw with electronic adjustment of engine speed.

New models are available in which it is possible to set a certain stable number of revolutions. This is advisable when it is necessary to complete several blanks in a short time. After all, with strong pressure, the speed of the device decreases. At this time, thanks to the electronic controller, a specific speed range is set, which allows for an even and fast cut.

Another useful, but expensive function that increases the cost of the instrument is laser homing. It can be powered from the mains or from the battery. In the first case, a switch is located next to the handle on the tool body. The beam builds a line of cutting, which is especially valuable for an inexperienced craftsman who has not developed intuitive skills of cutting with the help of a miter saw. The trim can also be equipped with a powerful LED backlight, which is placed behind the disc. When it is turned on, the shadow from the disk falls on the workpiece, forming a kind of backlight.

During the work of the tool a large amount of wood dust and sawdust is formed. To prevent their distribution throughout the premises, some models are equipped with a nozzle for connecting a vacuum cleaner, through which the garbage is removed directly from the place of its formation. Modern models provide for the extension of the tabletop by 50 cm or more, which allows you to work with long products, such as laminate.

Before choosing a miter saw, you should study its basic parameters. The main criterion is the purpose of the tool. If the use of the saw is planned in quite rare cases for domestic purposes, then it suffices to buy an end-saw with a standard set of functions. For frequent use of the tool for cutting blanks of various widths, it is advisable to purchase a universal miter saw with a broach, which expands the range of possibilities of the tool. It is the broach function that is used to work with a material of rather large thickness and allows you to increase the width of the cut, the rate of which for ordinary models is not very large, which in turn expands the functional spectrum of the tool.

Helpful advice! In the case of single or rare use of the tool, you can make a mobile and collapsible miter saw with your own hands from the usual grinder and other tools and materials.

The next criterion is the safety of the device. Despite the cost of the tool in its design, there must be a protective cover and the option to block the accidental launch of the device. When choosing a tool, it is necessary to take into account its dimensions and weight. It must be mobile and ergonomic to work with the saw as comfortable and easy as possible under certain conditions. For working at height, it is advisable to use a small and lightweight tool that will not necessarily have less power than a large heavy end saw.

Important! Professional models are more powerful, which is reflected in the weight and dimensions of the device.

The width and depth of the cut determines the purpose of the tool, namely, indicates that it can be processed. For high-quality work, you should choose a saw blade with a diameter of at least 20 cm. The more this indicator is, the easier it is to work with the tool. When choosing a particular model, one should take into account the quality of the material from which the swivel block and the bed are made.

The quality of the cut depends on the characteristics of the end saw and the cutting part. Saw blades are distinguished:

- the shape of the teeth;

- on the outer diameter;

- on the bore.

The bore or internal diameter of the disk is usually 3 cm. The external diameter can be 21, 25 or 30 mm. This indicator is indicated in the characteristic of the instrument and on the front surface of the disc. Choosing the parameters of the cutting product, you should pay attention to the engine for which the specific size of the disk is selected. For powerful engines it is not advisable to use large disks. As a result, you can get poor quality and sloppy cut.

Another budget option is miter saw PIT. The tool has a fairly simple design and is easy to operate. In the implementation of the preliminary settings, the saw will cut the same type of parts at an angle of up to 45 degrees. in minutes. The cost of the tool usually does not exceed 9 thousand rubles.

The choice of miter saw is a very serious and responsible event. To select a quality tool at an affordable price, you first need to decide what tasks it will perform. After that, you should carefully study the characteristics of the selected option and only then make the final decision.