Linoleum gained popularity among other types of coating a few decades ago, when it was actively laid on the floor of Khrushchev directly on concrete floors. During this time, manufacturers have constantly worked to improve the quality of the material, the introduction of new technologies and the improvement of design. It is laid on a different basis. This article will tell you how to arrange the floor for linoleum on a concrete floor.

Recommendations and stages of laying linoleum on a concrete floor

Apartment owners, both in new buildings and in old houses, in the process of renovation usually ask a typical question: is it possible to lay linoleum on a concrete floor. And the most popular answer both on Internet forums and from experts: linoleum is the main material of flooring in modern buildings.

The process of laying linoleum involves several steps:

- selection of suitable material;

- base preparation and surface leveling;

- surface waterproofing;

- calculation of material consumption for installation;

- marking and cutting linoleum;

- fixing the coating on the floor with adhesives;

- fixing mechanically using plinths.

Each of the stages has its sub-steps, features and importance. The guarantee of successful work lies in the correct choice of linoleum, glue, and in the preparation of the base. The process is much more complicated if it also includes the installation of a heated floor under linoleum on a concrete floor.

Experts recommend not to neglect the stage of leveling the floor under the linoleum before laying, as this is a pledge not only the beauty of the surface, but also the duration of the coating. The smoother the base, the longer linoleum serves.

Regardless of the type of linoleum, before installing it is necessary to prepare the base. This is an important factor affecting the service life of the roll coating. It would seem that even minor cracks, depressions or protrusions can lead to rapid abrasion of linoleum in these problem areas. Therefore, the base should be as flat as possible and clean.

If you have a concrete floor, you need to take care of noise and heat insulation of the surface. Special preparation requires the base when laying a warm floor under linoleum. We will tell about it in a separate section.

Important! It is not necessary to use sheet materials for leveling the surface of an uneven concrete base, since sooner or later they will deform under the contours of the floor and subsequently modify the linoleum.

The usual preparation of a concrete base consists of the following steps:

- Dismantling the old coating. Before leveling the floor under the linoleum, it is desirable to remove the old coating. In rare cases, you can leave the old linoleum. But the coating of linoleum tiles must be removed unequivocally, this also applies to old substrates, insulating layers. There should be a bare concrete base. The surface is thoroughly cleaned from dust and other contaminants.

- The evaluation and diagnosis of a concrete base is determined by the totality of all flaws, including protuberances, slopes, dents, and drops. If they constitute more than 20% of the total area of the room, then it is necessary to perform a concrete screed or pouring the surface with a self-leveling mixture. Such measures will help make the foundation as flat as possible.

- Elimination of minor flaws. If the screed is not necessary, then it is enough to precisely eliminate minor damage. Particular attention should be paid to the defects between the slabs of concrete floors. To do this, use a putty, epoxy resin or cement solution mixed with linseed oil. The cleaned and smooth surface is coated with a primer.

- Laying layers of heat, noise and waterproofing. Before laying linoleum, you need to take care of thermal insulation, since the concrete is cold by itself, and even a coating with a thermal insulation substrate will not save the situation. For insulation, you can lay on the floor under the linoleum fibreboard sheets or plywood.

As a waterproofing, it is recommended to use a plastic film not thinner than 200 microns. It is laid with an overlap of at least 20 cm and approaching the walls by 5-6 cm (the excess is removed after laying linoleum). For soundproofing masking tape is well suited.

A practical approach involves taking into account the structure and durability of linoleum.

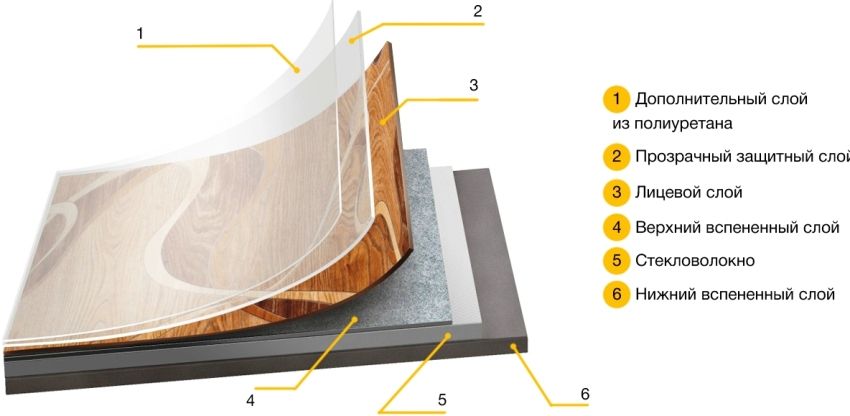

Depending on the structure, linoleum is divided into homogeneous (single layer) and heterogeneous (multilayer). The latter option is usually used in domestic conditions, as it already has the necessary foundation, often insulated or waterproofing.

There are two most common types of linoleum, which are used as a coating on a concrete floor in apartments: a coating of polyvinyl chloride (PVC) and natural linoleum, in its composition includes cork flour, wood resin, lime and linseed oil. Both of these species are harmless to health, resistant to bacteria and repel fat.

Helpful advice! For the kitchen and hallway, where the permeability is the highest, it is better to take semi-commercial or even commercial-grade linoleum. In public institutions, the most popular option is commercial homogeneous linoleum.

Another classification depends on the degree of resistance of linoleum to stress. In this case, the roll decorative coating is divided into domestic, semi-commercial and commercial. Judging by the names, residential coverage is intended for residential premises, but this is only at first glance. It is, of course, inexpensive, but has low durability, that is, the price matches the quality. All rooms in the house have different functionality, which should be taken into account when choosing flooring.

The household covering 1,5 mm thick is suitable for offices, drawing rooms and bedrooms. For the corridor, kitchen and children’s room it is better to take linoleum with a thickness of at least 3 mm, which is easier to protect from mechanical damage.

First of all, it should be noted that the colors of the flooring should correspond to the overall design of the room. The choice of quality material depends on the manufacturer. Tarkett has been considered the most popular campaign in the flooring market for many years. Commercial, semi-commercial and household linoleum can be found in various series of this supplier.

Taste preferences are taken into account in different variants of linoleum manufacturers. For example, the Tarkett linoleum Discovery series maximally conveys all the beauty and beauty of natural materials, allowing them to be brought closer to natural ones without harming nature. Tarkett Grand’s linoleum collection is a variety of décor and fancy patterns. It includes both fancy lines and maximum imitation of natural parquet.

In turn, Tarkett linoleum Idyll differs not so much in aesthetics as in practicality and increased strength. It withstands the load from the studs and sharp legs of mobile furniture. The material has good thermal and sound insulation. This series includes various models, including those intended for rooms with high maneuverability. An example is Tarkett Atlanta 1 linoleum from the Idylle Nova collection. The wear resistance of this coating allows it to be used in offices with an average intensity of load and childcare facilities.

Calculating the size of the canvas, you need to take the material with a margin – more by a few centimeters than the floor area. It is quite easy to do in standard square and rectangular rooms. It is enough to measure the dimensions of the room and add 10 cm on each side.

Helpful advice! Accurately calculate the required amount of material will help online calculator. The lengths and widths of the floor (for example, linoleum width 2 m) are entered into the windows. How many meters of linoleum will be required from such a roll will be indicated in a special window.

In rooms with complex outlines, you need to more carefully approach the process of cutting and make more stock. When buying a linoleum with a pattern, you should also take into account the allowances for joining the pattern. It is equally important, when purchasing a coating, to check that the batch number indicated on the labels of linoleum rolls matches.

To avoid seams on the floor, the width of the roll should be equal to the length of one of the walls of the room. The standard width of linoleum is 2 m – 5 m in increments of half a meter. A variety of coating sizes allow you to calculate the most economical option and avoid joints.

The simple secret to avoiding seams is to take a roll size according to the length of one side of the room. For example, in a narrow hallway 1,8×6 meters linoleum with a width of 2 meters will do. How many meters of linoleum will require everything depends on the length of the hallway. In this case, it is 6 meters.

Deciding where to buy linoleum, you can resort to the classic options and visit the hardware store. Modern consumers are increasingly using the order of goods via the Internet, this service – online shopping and delivery – applies to flooring.

How much does it cost to put 1 square. m of linoleum: consumption and cost

It is logical that linoleum – the most important component in the process of laying, it falls on the main costs. In addition, it is necessary to take into account the financial resources needed to purchase other materials. For example, without the substrate and glue installation of linoleum is impossible.

In order to calculate how much it costs to lay linoleum per square meter, as well as the total cost of laying the coating on the concrete floor, you need to add the cost of such materials:

- linoleum;

- cement, putty or self-leveling compound for the base;

- insulating plates, films and elements for their fixation;

- glue or mounting tape for fixing linoleum;

- plinths and materials for their fastening.

Now is not a problem to buy cheap linoleum. Where to get quality is a more difficult task, and in this matter it is better to trust in prestigious shops and professionals.

The price of linoleum per square meter depends on the above qualities of the coating: material, wear resistance, decorative features. Pricing value are class and series of coverage. Price per m? Commercial linoleum, as a rule, does not always exceed the price of semi-commercial. Sometimes it is more expensive domestic coverage of the elite series from a branded manufacturer.

Linoleum is easily laid on the protective layer. The process of its installation is the same as in the case of glueless laying on a flat base of a concrete floor. The coating is fixed with plastic skirting. It is because of the possibility of easy dismantling, for security reasons, linoleum is laid on the infrared floor. Warm floors, provided proper installation, as a result, create additional comfort and convenience, and the floor – a beautiful addition to the overall decor.

Thus, linoleum is ideal as a coating for a concrete floor. It is economical, eco-friendly and easy to install material. Knowing what linoleum is like, having mastered the rules of its installation, you can arrange the flooring yourself. In addition, it is linoleum that is most suitable for installing underfloor heating on a concrete floor.