Pros and cons of the semi-dry floor screed need to know even before the start of its device. This type of organization of the leveling layer under the topcoat has its own distinctive features that allow it to be used in residential premises without the use of large amounts of water. This technology emerged relatively recently from the classic wet method of creating a concrete screed. It is necessary to carefully study the algorithm for laying a semi-dry floor screed. Video of this process will help to understand the nuances of the technology in question.

Features of the creation and proportions of the solution for floor screed

Since the semi-dry method of organizing the screed originated from the wet, then the same ingredients are used. Portland cement M300 or M400 mixed with fine-grained sand. The only difference is that the proportion of floor screed solution is completely different. Water is added to the mixture in a very small amount, just enough to activate the process of crystallization of cement. This mixture is fluid and has the consistency of thick porridge.

This circumstance determines the features of the technology of its creation. The solidification of the solution occurs very quickly due to the small amount of liquid. If the layer is small, then the coupler simply will not have time to mate with the base. This can lead to detachment, which will cause “whipping” when rising on this site. If the thickness becomes more than 5 or 7 cm, then this screed will become very heavy. A pressure of 120 kg can create only 1 m2 semi dry screed floor. Pros and cons between themselves have a very thin line.

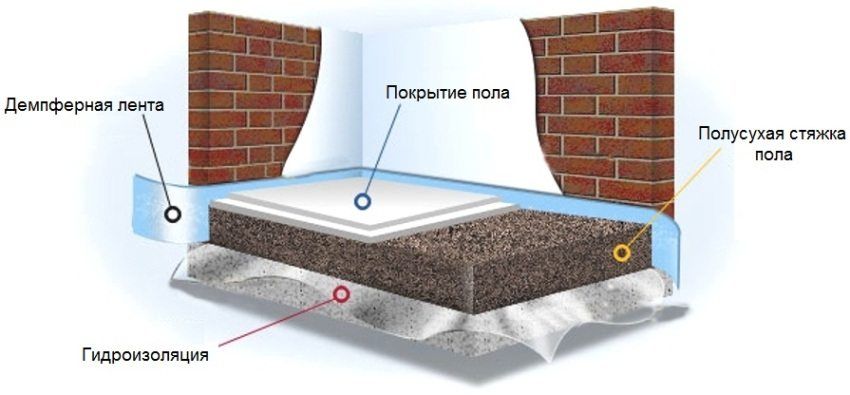

Knowing this, it is necessary to solve the problem of reducing the mass at a constant layer thickness. This can be done only by reducing the density of the whole monolith. The best material for this purpose is the expanded clay from which the pillow is made. Over it fall asleep and level semi-dry mixture. The base on the basis of semi-dry mixture is floating. It is not rigidly bonded with either the floor slabs or the walls. From the floor screed separated by a layer of waterproofing, and from the walls of the damper tape around the perimeter. It also prevents the spread of sound vibrations from the floor to the walls. This measure eliminates cracking of the surface of the screed when the solution dries.

Helpful advice! To reduce the risk of cracking, a reinforcing agent must be added to the semi-dry solution. Most often, they are used as fiber, which with a small mass has sufficient reinforcing properties and strength characteristics.

The pros and cons of a semi-dry floor screed are due to the fact that in it, instead of rebar, I use fiberglass, which is much cheaper and more convenient to install. Dry polypropylene yarns, which are added directly to the solution very strongly bind the monolith screed in all directions. These fibers have a preventive effect on the screed, not allowing the formation of cracks. There is no ban on the use of ordinary mesh as a reinforcement, but it is unwise to do this, since it is necessary to carry out the whole process in three steps. First, the first layer is placed 2–3 cm thick, on which the grid is mounted, tying it with wire. Only after that create a second 2 cm layer of the mixture, which is leveling. This technology is not only more complex, but also more expensive.

Semi-dry screed floor, the pros and cons of which depend on the correctness of its installation, requires careful preparation of the base. Floor slabs carefully inspect and remove all flaking areas from them. Cracks and interfaces with walls are thoroughly cleaned and coated with cement mortar. Remove all traces of paint and grease stains. After that, vacuum the entire surface of the floors, leaving no dust particles.

Mix is prepared from cement of the M400 brand and river or career sand. Since it will be very thick, it is best to mix it in a concrete mixer. In extreme cases, you can use a large plywood sheet with sides. There are certain requirements for all components of the mixture.:

- the sand fraction should be no more than 2.5, with clay inclusions of no more than 3% without particles of peat or other plant fibers. Sand moisture is recommended natural;

- cement must be fresh in intact packages. If the operation of the floor is assumed in difficult conditions, then the brand of cement you need to choose M500;

- water cannot be supplied from reservoirs, as it may contain impurities of biological origin or any pollutants. For that reason, it is better to take ordinary tap water. With all its drawbacks, it is the best option for the preparation of the mixture, from which make a semi-dry floor screed. The pros and cons of this mixture will be considered later.

Helpful advice! In the absence of a concrete mixer, the solution can be prepared on a plywood sheet using the “volcano” method. To do this, the components alternately shovel impose on the sheet, creating a hill similar to a volcano. Then it is all mixed and poured water mixed with fiber in the right amount. The mixture should be wrinkled in the hand, forming a lump, from which it is impossible to squeeze a drop of moisture.

The following algorithm can be described as follows.:

- the creation of a waterproofing layer over the floor with an overlap of 10 – 15 cm on the walls;

- laying around the perimeter of the room damper tape 10 cm wide and from 0.8 to 1 cm thick;

- the creation of elevations from the solution, on which the beacons of the metal profile are stacked by level;

- a solution is poured between shots of beacons and tamped with it. Put the solution so that it reaches the upper edge of the lighthouses. Alignment is done by the rule;

- the screed is immediately sanded until it is hardened, and after a day, the seams are cut through to compensate for the deformation along the walls. Their width is 3 mm, and the depth can reach one third of the thickness of the entire layer.

Helpful advice! The finished screed should be covered with plastic wrap for a week, where it hardens naturally. If it is very hot, then the surface should be watered from a watering can for about 5 days. This will not let her crack.

In general, the pros and cons of a semi-dry floor screed come from the features of its device. However, you can summarize what was said above and name the following advantages:

- little water is used, which contributes to quick drying and prevents water from flowing through the floors to the neighbors;

- the surface is almost perfect;

- there is no shrinkage and cracking during drying;

- due to the reinforcing fibers can achieve a small thickness with sufficient strength.

Among the shortcomings should be highlighted: poor fluidity, the difficulty of preparing the mixture and laying it manually, the fear of moisture due to the possibility of provoking the resumption of the process of crystallization of cement.

Whatever pros and cons of a semi-dry floor screed would not have, its use is fully justified in residential premises, but it is strongly not recommended in bathrooms, bathrooms and kitchens, as water leakage can damage the screed, and with it the finish covering.