Penoplex flooring today is the most effective way of thermal protection of premises. This material, which in its essence is an improved foam plastic, has an excellent ability to retain heat and at the same time sufficient strength to be used even under a floor screed. Penoplex – This is extruded polystyrene, the types and features of which should be considered in more detail.

Penoplex floor: the main characteristics

Penoplex appeared on the construction market relatively recently, but has become one of the most popular insulants. He gained his popularity because of the advantages that he has:

- absolute safety for health that allows to use material in any premises;

- good density, thanks to which, the material perfectly retains heat;

- vapor permeability that prevents condensation;

- moisture resistance;

- good performance for noise insulation;

- not subject to rotting and mold;

- sufficient strength;

- high elasticity, providing strength and integrity under tension and compression;

- incombustibility resulting from the use of flame retardants;

- long operation, which, according to manufacturers, can reach 50 years;

- high wear resistance class;

- the ability to make a piece of material of any shape using only a knife.

With such an impressive list of advantages, the material has the following drawbacks: the glue is poorly absorbed, which complicates installation and is also loved by rodents.

Penoplex for the floor does not have any special classification. However, there are different types of it, differing in physical and geometrical parameters. The thickness of the material varies from 0.5 to 3 cm, density from 31 to 45 kg / m ?. Standard sizes of plates 120×60 cm.

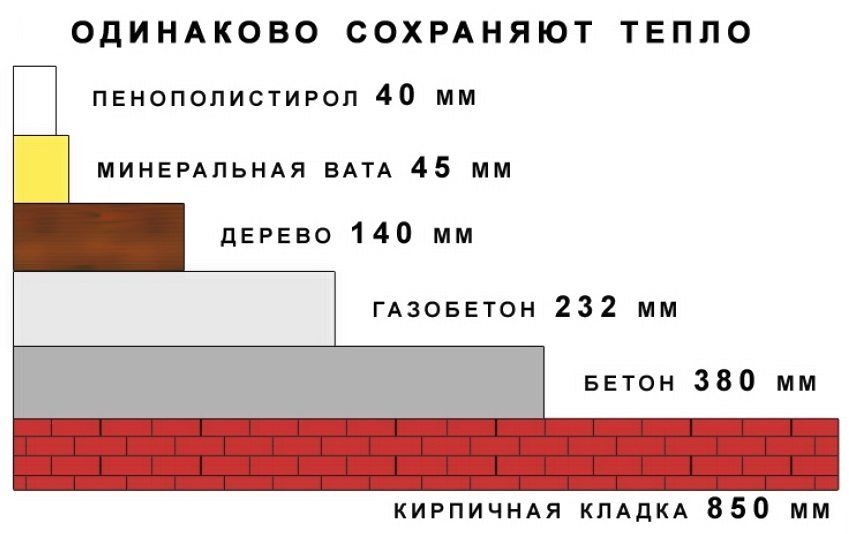

Extruded polystyrene is used for various types of insulation works. They are sheathed inside and outside walls, ceilings and ceilings, loggias and balconies, but especially it is necessary to dwell on the methods of floor insulation with this material.

Helpful advice! When choosing penoplex one should pay attention to its density. Check it is not difficult. The material needs to be compressed with your fingers. After loosening, there should be no noticeable dents. This suggests good quality plates.

The technology of floor insulation using penoplex has some peculiarities for various bases. Most often, this material is used when constructing the floor directly on the ground, on a concrete base, when building various types of “warm floors”, on logs. In addition, the foam is often laid under the floor screed.

Using penoplex for floor screed. Self carrying out insulation works using foam plaster under the classic and self-leveling floor screed.

In order to start work on floor insulation, it is necessary to take care not only of a sufficient amount of materials, but also of the availability of the necessary tools. We list the main ones:

- perforator is required to remove irregularities on the concrete floors;

- a drill having a nozzle for mixing the solution in the case of a screed device;

- building level, with the help of which the alignment of the base pillow or screed;

- ordinary spatulas with sizes of 80-100 mm and 350-450 mm;

- spatula with teeth 1 cm long 20 cm;

- sharp knife for cutting polystyrene foam;

- polyurethane foam for processing of places of passage of engineering networks;

- glue for penoplex. This is a special adhesive composition that does not contain substances that dissolve polystyrene foam.

Laying penoplex floor can be done independently, subject to certain rules and features, given one or another option. In order to understand all the nuances, consider all the options in more detail.

Technical characteristics of extruded polystyrene plates:

| Name of the indicator | Test method | unit of measurement | Value indicator | |

| Type 35 | Type 45 | |||

| Density | GOST 17177-94 | kg / m? | from 33 to 38 | from 38.1 to 45 |

| Compressive strength at 10% linear strain | GOST 17177-94 | MPa | 0.25 | 0.50 |

| Water absorption in 24 hours, not more | GOST 17177-94 | % by volume | 0.2 | 0.2 |

| Fire Resistance Category | GOST 30244 GOST 30402 | G1, B2, D3, RP1 | G4, B3, D3 | |

| Heat conductivity coefficient at (25 ± 5) ° С, not more than | GOST 17177-94 | W / (mX ° C) | 0.028 | 0.030 |

| Operating temperature range | TU | WITH | from -50 to 75 | from -50 to 75 |

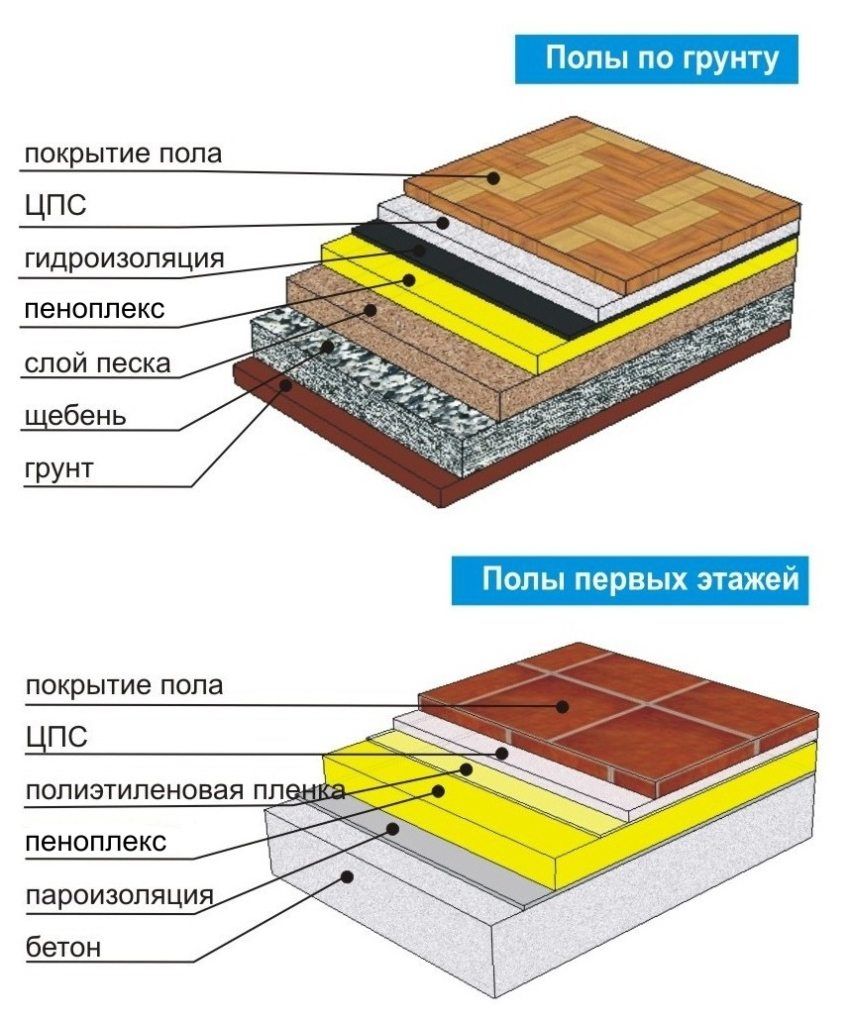

Very often the floor of the first floor of a private house is made right on the ground. In this case, it is necessary to insulate it very thoroughly and make waterproofing. For the purposes of insulation penoplex fits perfectly. According to it, parquet, laminate, tile, linoleum and even self-leveling self-leveling floors are used as a topcoat. Works are performed in the following sequence:

- leveling and tamping the soil under the future floor. The zero level should be 50 cm below the surface of the intended floor, which will allow the whole “pie” to fit into this volume;

- construction of the underlying “pillow” of a mixture of rubble, gravel and sand. Its height is from 30 to 40 cm. The base is very carefully tamped and sprinkled with a 10 cm layer of granite screening or coarse sand. This layer is also well rammed and leveled horizontally;

- in case the floor loads are not significant, the material plates are laid directly on the resulting pillow. The joints between the plates of the foam for the floor are glued with special glue and glued with tape. At the warmed base the penoplex can be no more than 5 cm in thickness. Otherwise, you need to take thicker plates, with a thickness of 5 to 10 cm. Waterproofing is arranged on top of the plates of the film;

- if it is assumed that the floor must withstand considerable loads, before laying the foam panels on the pillow, it is necessary to make a waterproofing and screed of concrete from 5 to 10 cm thick;

- A rough floor can be made from plywood or other similar sheet material over the foam panels. Then stack the topcoat.

Helpful advice! Laying waterproofing on top of extruded polystyrene plates should be made without the use of adhesive compositions based on various organic solvents in order to avoid destruction and dissolution of the plates. It is better to use self-adhesive membranes.

When installing insulation on a concrete base, first of all, you need to ensure its quality. If there are irregularities and deep potholes, then they need to be eliminated by arranging a concrete screed. If the base is sufficiently uniform and even, then penoplex for the floor can be put directly on the plates. This can be done in a “dry” way or with a special glue. Glue is applied with a spatula with teeth. If the insulation is made on the first floor, then it is necessary to make a waterproofing before laying the material. This can be avoided if the adhesive composition is waterproof.

After laying the plates of penoplex they need to be glued together. Further actions depend on the load, which will take the room. If it is large, then you need to make a screed of concrete. If not, then you can arrange a rough floor, on which to do the final coating.

“Warm floors” are constructed using various heating devices. It can be heating pipes, cables and mats with electric heating elements, as well as film systems of “warm floor”. All this is placed on top of the foam slab plates and filled with a tie. Only after that mount the finish coating.

The use of penoplex for lagging is usually done in wooden houses. In the case of a close location of the soil, the method is no different from the one described above, except that the plates are laid between the logs, and the subfloor and the finish covering the logs. If under the house there is a basement or underground, it is necessary to hem boards from the bottom to the logs. Penoplex is laid on them and glue joints. A vapor barrier membrane is laid on top of the resulting surface. Only after that do they stuff the boards of the subfloor, the plywood on top of them and the topcoat.

Helpful advice! In order to make the insulation more effective, you need to lay a layer of waterproofing on the boards lined with lags. It will not allow moisture to penetrate into the plates of penoplex from the basement, as well as to some extent protect against rodents.

All the methods discussed above may, at a certain stage, include the laying of a penoplex under a floor screed.

Penoplex is very warm and easy to install material. It is not by chance that recently it has been used in almost any work on the insulation of buildings and structures. This allows you to significantly reduce energy loss and save a lot of money on heating.