The presence of a wooden armchair in the house makes it possible to make the rest more comfortable, comfortable and pleasant, and also brings a feeling of lightness and tranquility to the interior. Wooden products make the room cozy, warm. Serve such designs for a very long time. In this publication, we propose to get acquainted with the varieties of this furniture, their shape, advantages, and also tell you how to make wood chairs with your own hands.

Wooden chairs: advantages and disadvantages of structures

It is difficult to imagine an apartment or house in which there are no chairs. Their shape depends on the style of the interior, destination and age of the owner. In addition, anyone who has carpentry skills can make a product on their own using instructions and drawings from the Internet.

Wooden furniture has many advantages in comparison with interior items from other materials:

- Environmental friendliness. Wood furniture is natural, it is harmless, hypoallergenic, and therefore safe.

- Durability, reliability and durability. Wooden furniture is very durable, resistant to mechanical damage, does not lose its functional qualities over a long period of use.

- Sophistication and variety of models. Wooden chairs are characterized by a variety of shapes and sizes. Also, the use of various carvings, special paints and varnishes allows you to create an elegant, attractive piece of furniture that is able to decorate any design.

The disadvantages of furniture made of natural wood, can be attributed to its value, which is quite high. However, there is always the opportunity to try to create a wooden chair with your own hands.

Working with wood is not as difficult as it seems, and if this material is processed correctly, the product will last a very long time. First of all, it is necessary to determine the model of the chair and decide what functions it will perform.

Material selection plays an important role. For the manufacture of reliable, good-quality products do not need to spare money on the highest quality material. Even in this case, the independent production of the chair will cost less than the purchase of an already finished product.

It is important to know that not all wood species are suitable for making furniture. The main factor that influences the choice of a particular type of wood is the load that the structure is able to withstand. Best for the manufacture of chairs from solid wood fit:

- soft breeds – pine, linden, cedar;

- types of medium softness – mountain ash, birch, aspen;

- moderately hard varieties – larch, cherry, beech, pear, walnut, oak;

- solid rocks – maple, ash, hornbeam.

For the manufacture of the simplest chair you will need the following materials:

- bars with a cross-section of 40×40 and 40×60 mm – for the frame;

- slats and lintels, which are made of boards with a thickness of 1-1.5 cm

- a sheet of plywood (if the chair with a back and a soft seat).

Before starting work, you should prepare the following tools:

- table saw;

- jigsaw;

- chisel;

- plane;

- hammer;

- screwdriver;

- drill with drills;

- sandpaper for sanding;

- a mallet;

- clamps;

- stapler;

- pliers;

- screwdrivers;

- roulette and ruler in the form of a triangle;

- wood glue;

- varnish or paint for wood;

- self-tapping screws;

- staples.

Drawings of wooden chairs with their hands with measurements of all the details can be found on the Internet. All the parts of the chair are made according to the indicated values and the necessary holes are drilled.

Helpful advice! Ideal for the production of chairs suitable oak or beech, but this wood is quite expensive. Therefore, for beginners in the joinery, it is better to buy another dense tree that is cheaper, for example, mountain ash.

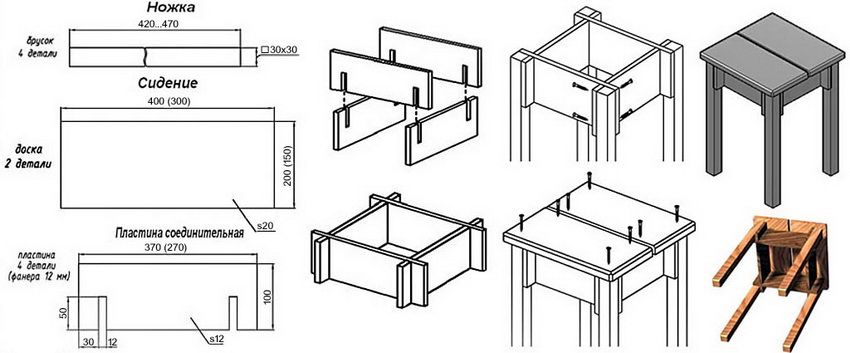

The simplest product to manufacture is a stool, that is, a chair without a back with a hard or soft seat. On the Internet there are many photos with drawings and instructions that will help to understand the process of creating a stool.

For the stool, you will need four beams with a cross section of 40×40 mm and a length of 44 cm. Be sure to make sure that the wood does not have significant roughness. Sandpaper will help to remove them. The stronger the burrs, the harder the sandpaper.

It is also necessary to prepare four barrels – jumpers, which are located at the bottom of the seat and are the support and the main fastening element of the stool. The dimensions of the support are 2x5x28 cm.

The seat is best made from a single wide plank, but often several boards are connected by a “tongue and groove”. Similar thorns need to be executed on the ends of crossing points and on legs. Grooves and spikes should be at least 2 cm.

Before you make a chair, you need to check whether the parts fit well together. Only after that it is necessary to assemble the structure into a single whole and glue it with carpenter’s glue. To enhance the strength of the product, you can fasten parts with screws. They need to be screwed on the front side of the stool cover, having drowned the caps in a tree, and fasteners should be hidden by means of special plastic plugs. The finished product is required to varnish or paint.

Helpful advice! It is necessary to choose the timber of the strictly necessary section. Pre-prepared bars should have a flat and smooth surface. Before starting, it is important to check the material for roughness and cracks.

The most organically among the bright flowering plants in the garden looks like a wooden chair. It is convenient to relax, enjoy the fresh air and the surrounding nature. Wooden interior items are comfortable, reliable and eco-friendly furniture. Folding chairs for giving is also a great idea for small spaces. In addition, such products are conveniently stored when not in use.

These recommendations will help to create comfortable and beautiful garden furniture:

- The main requirement for a garden chair to give is transportability. This design should not be bulky so that the product can be easily transferred from place to place in case of bad weather.

- When choosing wood for this model, it is better to give preference to oak, beech or walnut, and you can also use pine, aspen, cedar or larch. These types of raw materials are the most durable and resistant to mechanical stress.

- Since the furniture will be on the street, it must be protected from exposure to sunlight and precipitation.

- The relief of the structure of the material depends on the number of knots on the tree. To make the future chair look even better, it is necessary to treat its surface with a colorless varnish.

- During the assembly of the chair to give your own hands, it is important that all fasteners be drowned in wood as much as possible. This will improve the appearance of the product.

Before starting work, boards should be folded into a shed. Such drying under the influence of wind will give the material strength. Next, you need to perform wood polishing, impregnation with antiseptic substances and drying oil. After that, you need to dry the boards again.

To create a garden chair, you need to prepare the following materials:

- 20 pieces of dowels from solid wood – 2.4×6 cm;

- brass screws – 20 pieces of size 0.45 x 0.5 cm and 20 pieces of size 0.45 x 0.32 cm;

- sandpaper for sanding;

- polyurethane adhesive;

- drying oil and varnish for furniture;

- masking tape

You will need to make the following parts:

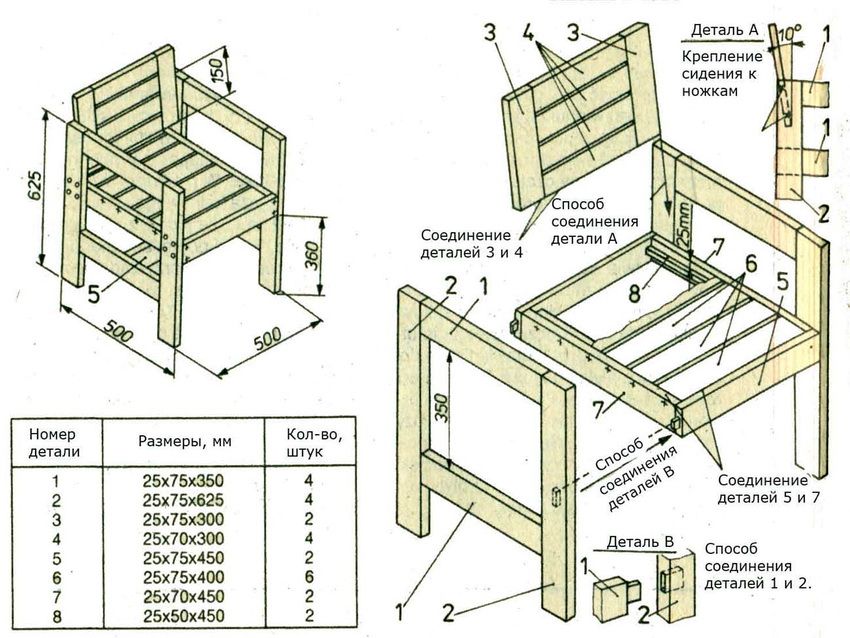

- two rear legs 2.1×25.5×78.8 cm;

- two front legs – 2.1 x7, 6h53, 4 cm;

- supporting armrest with parameters 2.1 x 12.8 x 40.7 cm;

- the back of the chair in the form of a back – 2.1 x 28.0 x91.5 cm;

- lintels – 2.1 x5.2 x59 cm;

- rear support armrest – 2.1 x7, 8h61, 1 cm;

- two strips for insertion – 1.3×2.1×25.5 cm.

For the manufacture of legs, back, armrests and seats need thick boards. To obtain such material, it is necessary to choose boards of similar texture and color and glue them.

To create the rear legs will need a stencil that you need to prepare in advance. Attach it to the board and draw the outline with a pencil. Two blanks are connected using adhesive tape – so you can make two parts at once. Experts advise making the workpiece a couple of millimeters more than indicated in the drawing of the chair, and then using a plane or router to reduce the part to the required parameters.

For the construction of the back will need to cut the blank of glued boards. The lower part of the back should be cut by 12.5 ° so that it is proportionally attached to the rear legs. The upper back is rounded 9 mm. Next, the construction is mounted, parts are adjusted to the millimeter.

The legs are fixed to the back of the chair with screws and wood glue. Corner joints are used to fasten the side parts and legs together. To close the cracks formed apply strips. They are fastened with screws. The better the connections are made, the higher the reliability of the chair.

The seat of the chair is fixed to the back with a groove. Mounting should be done at an angle, this will provide excellent joint density. Cutting the front legs, it is necessary to mow the parts in the upper part at an angle of 6 degrees. After that, you need to attach them to the main structure, using screws and glue.

- If the armchair made of wood (photo illustrate it) will be used in humid places, it is better to choose fine wood as the material: oak, larch or central parts of coniferous trees. In extreme cases, you can make beech and horned parts.

- If the product will alternately be in the house, then on the street, it is recommended to cover it with paint for external and internal works.

- If the chair will be affected by moisture, then it must be treated with a special antiseptic primer.

Helpful advice! If the wooden chair will always be placed in the bedroom, living room or children’s room, then primer treatment is not needed.

The armchair in the interior is the simplest in design furniture, which is very easy to select and purchase. You can get a stylish, exclusive and comfortable thing in the country or in the house, making a wooden chair with his own hands. Often such a venture is much cheaper than buying a finished product. In addition, you can make not only a chair, but also other pieces of furniture, such as a bed, a chest of drawers, a children’s chair or a computer chair with your own hands, of wood. Such products will not only decorate any room, but also give it a special charm and naturalness.