A fountain or waterfall is a real decoration of any landscape. Such a construction completely changes the microclimate of the adjacent territory, revives and decorates the exterior. To be able to admire and enjoy the flowing water, you need a pump for fountains. This unit is able to create the required pressure, due to which water rises to the surface and smoothly drops down.

Pump for fountains: purpose and principle of operation of the device

The pump is a special device that cyclically distils water along the established circuit. Often this equipment is used to design decorative hydraulic structures on country estates and suburban areas.

The principle of operation of the fountain with the pump is based on creating a positive pressure that pushes water with a certain force. The power of the unit determines the height of the ejection jet. The composition of the pumping equipment for the fountain may include a different list of constituent elements, depending on the type of device and its manufacturer. But any kit consists of a rotating engine and impeller, affecting the flow force.

The garden pump for the fountain has something like this:

- motor;

- motor housing;

- nozzle;

- retractable tube;

- fluid flow regulator;

- tap for connecting a waterfall or fountain;

- impeller of the pump;

- fountain head;

- spray;

- grid.

The pump for giving differs in mobility and a compact design. The unit is used seasonally. He does not need additional communications and copes with the movement of water without the need to connect plumbing.

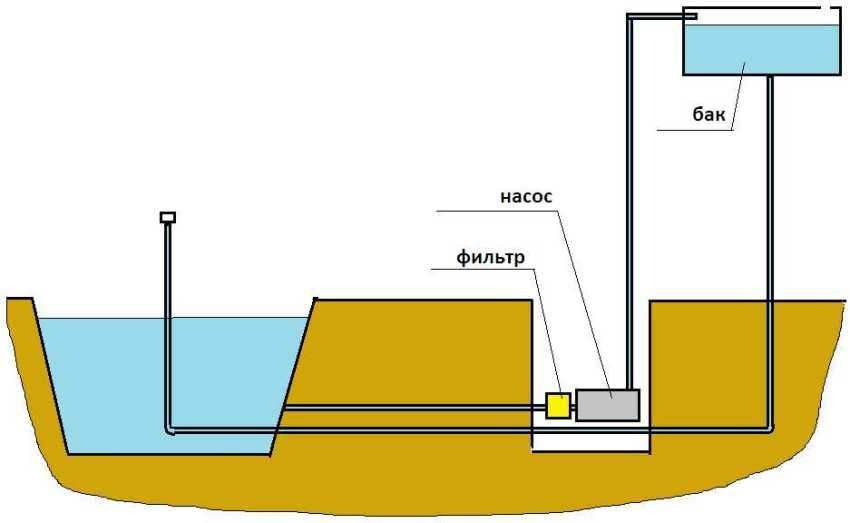

For a country house or a dacha circulating devices are installed that operate in a closed mode. Their receiver for water is located below the bowl with a fountain. With the help of a pump, water is pumped into a pipe through various nozzles, moves up and is sprayed at a certain height. For the waterfall to work, the liquid rises from the tank, falls into the indents and returns to the tank. Such a closed water system cannot be provided without an electric pump.

The submersible device is a wet type of centrifugal pumping equipment. The body is made of durable plastic or stainless steel, which is determined by the conditions of its work. Motor power may be in the range of 6-100 watts.

This type of pump is used for small fountains with a depth of no more than 2 m, floating and submersible tanks, stationary and wall structures. The pump is installed on the bottom of the tank by means of special suction cups that prevent the unit from moving during its operation. If the device is used for ponds, it is placed on a small concrete or brick pedestal in order to avoid falling into the sludge system. In addition, this installation is preferable for fountains, as the wear of cleaning elements decreases.

The pump housing is completely immersed in water. The top element, made in the form of a special nozzle, plays the role of a sprinkler, towering above the water surface at some distance. The suction takes place through the barred lower part of the unit where the filter is installed. Submersible pumps are characterized by low weight and compact dimensions. The pressure in the system largely depends on the cross-section of pipes and supply hoses. The smaller they are, the more intense the jet will be and the greater the density of water flow.

Helpful advice! Periodically, it is recommended that the filter be removed from the housing and cleaned. If it fails, it is necessary to immediately replace it with a new one, since the condition of the filter is directly related to the period of operation of the pump.

The submersible device produces water intake from the lower layers of the reservoir or an external source with its subsequent release through the nozzles. In the first version, the pump should be equipped with a filtration system to avoid clogging of the system. A jet of water splashes over the unit. If the system is manned with a hose of a certain length, the flow can be brought to a certain place, which is set by the idea of landscape design. Joining and lengthening of pipes occurs on the telescopic principle with the help of rubber or plastic compounds.

Submersible pumps operate almost silently with low power consumption (it is required 30% less than for a surface unit). This is due to the fact that the nozzle is located close to the motor, and this contributes to minimal power loss.

The pump operates from the mains, so when installing the system, it must be grounded without fail. For normal operation of the pump, a voltage of 24 V is sufficient. Such devices belong to low-voltage units, for which the power source can be a simple transformer.

The greater the length of the tube and the number of additional structural elements, the more electricity will be consumed. To do this, you need a high-power device. It will be connected to the mains using a cable that must be covered with a waterproof material.

Submersible pumps are designed for pumping almost pure water that does not contain pollution. The presence of impurities in water at a concentration of 50 g / m3, whose size does not exceed 0.2 mm. To avoid breakdowns, all pumps are equipped with filters in the form of a stainless mesh with small cells located in the suction element of the pump. They trap mechanical impurities, protecting the internal parts of the pump from premature abrasion and wear.

The advantages of submersible pumps for fountains include the following criteria:

- small cost which is available to any summer resident;

- ease and simplicity in installation, allowing to carry out installation independently;

- high efficiency;

- minimum power consumption;

- noiseless operation that allows you to enjoy the sound of pouring water;

- the invisibility that is associated with the installation of the device on the bottom of the tank, eliminating the need to find a suitable place and the subsequent masking of the unit;

- compact models, which is suitable even for small fountains.

Among the disadvantages of submersible pumps for the fountain can be identified:

- the complexity of the repair and maintenance, it requires draining the tank;

- requires strict observance of electrical safety;

- the need to dismantle the equipment in the winter time.

Surface type pumping units are dry type equipment. They are mainly used for complex multi-level high structures. This device is selected when it is necessary to connect several objects to one pump. In this case, you should focus on the pressure for different elements and correctly adjust the power level of the flow. When connecting two circuits, you must install a tee.

The surface pump has large dimensions and high cost. It should be located in a dry place in the immediate vicinity of the reservoir, from which the capacity of the unit will depend. When connecting long hoses and a large number of various nozzles, the efficiency of the device is reduced. The maximum allowable distance for normal operation of the unit should not exceed 2 m, as indicated in the instructions.

After installation, the unit should be masked so that it does not spoil the appearance of the landscape. Such devices are convenient in operation and maintenance, do not need dismantling in the winter period of time.

Surface aggregates are less sensitive to pollution and organic matter in the water. They can pump water from any source. To do this, it lowers the hose of the device, which is connected to the inlet of the pump. Power cables do not need additional protection, which ensures safe operation of the pump.

Since the structure is located in the open air, it should be provided with adequate protection from moisture and direct sunlight. To do this, the pump is covered with a protective casing, to some extent reducing the noise that the unit emits. Also under the device can be equipped with a separate box or pavilion that protects it from precipitation.

Helpful advice! If water contains coarse suspensions, it is recommended to install a foot valve with a fine filtering mesh on the suction hose.

From the disadvantages of the device can highlight the noise of the pump, which requires the installation of sound insulation. For this, a pavilion or protective housing for the pump is sheathed from the inside with noise absorbing material.

When building a fountain for the pond should always use a filter. It can be simple, external, placed in a pond, ultraviolet. The first option is presented in the form of a small block made of porous material. The product is installed near the grid of the submersible pumping unit. It provides mechanical and biological water purification with continuous operation of the device.

The external filter is a multilayer block that is connected to the pump via an inlet pipe-inlet. Water seeps through a mesh or porous filter, where mechanical water purification takes place. The next layer of the filter is made of porous material. At the bottom of the block is a perforated base. With continuous operation of the pump provides biological water purification in all layers of the filter.

The filter that is located at the bottom of the reservoir is a block filled with fine fraction gravel and porous material for mechanical cleaning.

For polluted natural ponds, the most rational solution is to install an ultraviolet cleaner that works on electricity. This is a block with a special camera with lamps, getting into which water is exposed to ultraviolet radiation. The purified liquid enters the pump suction piping. The main disadvantage of this filter is its high cost.

Choosing pumping equipment for the fountain, you should focus on the performance, operating voltage, power and height of water rise, which are indicated in the passport of the device. The pump must operate at medium speed, while reaching the required power level. If the unit is constantly being laid out to the full, its working life will be exhausted very quickly, which will require replacing the device with a more productive one.

When choosing a pump, you should compare the power of the unit and the size of the artificial reservoir. The height of the jet device should not exceed the third part of the width of the reservoir. In order to get a height of 1.3 m, it is necessary to purchase a pump with a flow rate of at least 800 l / h. To create a jet with a height of 2 m, the unit must be designed for a capacity of 3000 l / h.

Electrical power and voltage determine the power source. Powerful units operate on a 220 V electrical network. They are powered by a cable via a RCD and a circuit breaker. Low-voltage units can operate on 12 and 24 V mains; they use power supplies.

Helpful advice! For spray fountains, it is recommended to give preference to units with high pressure and low productivity, and for waterfalls – to low-voltage pumps with high productivity.

An important criterion is the location of the tank. For fountains located in the room, it is enough to use low-voltage units of 5-8 watts. These are small silent devices that do not create vibration waves. They are mostly not equipped with a filter, because they are dealing with clean water. Such units have a thin and short power cord without grounding. Pumps for fountains and ponds that are outdoors should be equipped with filters. The power cable must be thick and grounded.

Through the bowl the container is filled with water. The tightness of the installation is checked. An ordinary syringe removes air bubbles from the pump. The engine is connected to the power supply. To do this, the red wire of the fan is connected to the plus of the unit, and the black – to the minus. Signal white wire is insulated. The pump is turned on and its performance is checked. During the test, attention should be paid to the absence of beats and leaks. The light turns on, and the backlight is checked.

For the room fountain, of course, you can make a pump with your own hands. And for a pond or waterfall it is better to use ready-made units from well-known manufacturers. The instruction of pumping equipment prescribes all the technical characteristics of the device, according to which it is necessary to select the unit to perform a specific task.