In this article, we will examine the specificity of such a procedure as laying paving slabs on a concrete base: let us point out the advantages and disadvantages of this technology, consider a detailed scheme for its implementation and get acquainted with the basic recommendations for laying paving slabs using such types of material as “Brick” tile , “Old Town” and “Rhomb”.

Laying paving slabs on a concrete base: the expediency of the procedure

Not only owners of country houses and cottages are interested in the procedure for laying paving slabs with their own hands, seeking to equip and improve their personal plots. Tiled flooring is also popular in urban settings.

As an indisputable proof of such popularity, not only eloquent photo examples of paving slabs, which can be seen on the web, but also real solutions found on the streets of any city are.

Most often paving slabs are used to organize the coating:

- around stores, pharmacies, office and office buildings;

- on the paths leading through the lawn;

- in park areas;

- on car parking areas;

- in places for storing large equipment;

- on the squares of the city and other areas where there is increased traffic and load on the sidewalks (areas near theaters, train stations, markets, cinemas, large companies and shopping centers, stadiums, educational institutions, libraries, sports complexes).

Note! For parking spaces for passenger cars, the thickness of paving slabs is selected taking into account the weight loads. You can not use the material purchased for footpaths, for arranging parking. This coating will quickly become worthless.

Most people are accustomed to thinking that the installation of tiled pavement is carried out exclusively on a sandy surface; therefore, the expediency of laying paving slabs on a concrete base is questioned by many of them.

In fact, the concrete surface is considered the most reliable basis for the formation of tracks and platforms from paving stones. This is because the concrete prevents the tile from moving across the surface, called “walking,” and is highly resistant to heavy loads. In some cases, in case of violation of the technology of laying concrete paving slabs, the result may be reversed. Therefore, it is recommended to strictly follow all the requirements and recommendations regarding the construction of such a coating.

Laying paving slabs on the sand: technology and specific work. Pavement technology sidewalks. Recommendations on the choice of bases, materials, tools. Prices for different types of services turnkey.

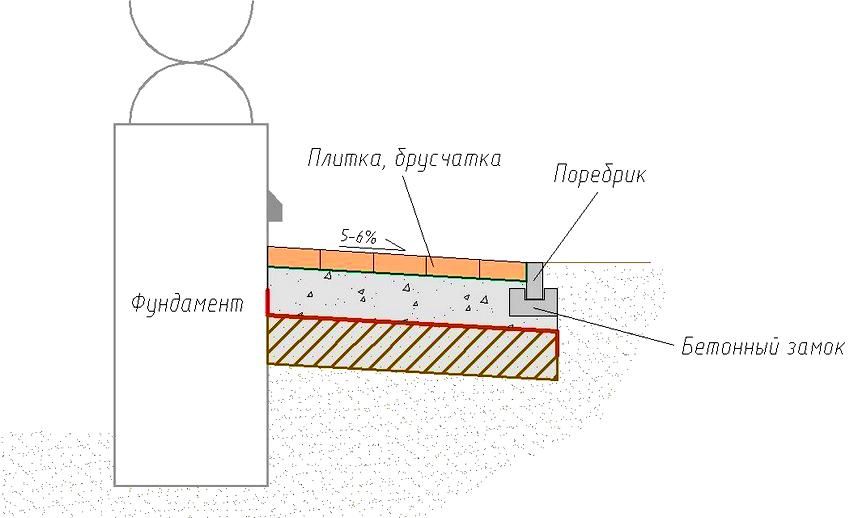

The technology of laying paving slabs on a concrete pavement is equally interesting for both owners of country cottages and city dwellers who have their own store or any other type of business. The blind area itself has many advantages, and in combination with a tiled floor you can get a truly optimal solution in all respects. Due to the slope of the blind area, water will not accumulate on the tile surface.

The blind area is considered an independent structure, which is usually formed around the building in order to protect it. It may be completely devoid of coverage. It is recommended to do the laying of tiled elements on top of it, but this is not a mandatory procedure.

Helpful advice! To make the exterior of your backyard spectacular and harmonious, use the same type of tiled flooring for arranging the paths and the blind area. On the Internet you can find good photos of laying options for paving tiles “Brick” on the blind area around the house and in the yard.

Despite the fact that the finishing of the blind area is not mandatory, it is still worth doing, because the concrete surface looks unattractive and can spoil the appearance of the house and the yard as a whole. For this reason, it is worthwhile to spend money on the purchase of material and call the specialists or perform the procedure yourself.

Price for laying paving slabs on a concrete base (specialist services):

| Type of work | Price, rub. / M? |

| Top cover removal (asphalt, concrete, etc.) | 150-600 |

| Works with the ready basis from concrete | |

| Dry mix | 150 |

| Laying tiled surface | 300 |

| Concrete site preparation with reinforcement | |

| Sand | 15 |

| Concrete | 315 |

| Reinforcing elements | 180 |

| The cost of the work of specialists | 420 |

| Preparation of a conventional concrete platform | |

| Sand | 15 |

| Concrete (layer thickness 14 cm) | 315 |

| The cost of the work of specialists | 420 |

| Border mounting | |

| Concrete (m. P.) | 70 |

| Sand (m. P.) | 15 |

| The cost of the work of specialists (m. P.) | 75 |

| Installation of drainage systems | |

| Concrete (m. P.) | 55 |

| Sand (m. P.) | 15 |

| The cost of the work of specialists (m. P.) | 70 |

The advantages of working with concrete surfaces:

- A simple installation system – for the formation of asphalt pavements, you will definitely need to hire special equipment, while laying paving slabs on concrete is much easier and faster and you can do it yourself.

- It turns out a strong, reliable and durable base. The modern range of stores is able to offer special types of tiled elements, which ensure the absence of a sliding effect on the floor, even with heavy precipitation.

- The coating is stable even under the influence of sudden temperature changes. It exhibits resistance to various types of damage to mechanical properties. In most cases, the manufacturer provides consumers with a long warranty period for the operation of decorative materials. They depend on the type of tile coating and can be in the range of 10-40 years.

Note! In the winter season, the structure is not exposed to severe icing, since the excess moisture enters the soil through the seams and is absorbed.

Thanks to an extensive range of materials, design possibilities are expanded. The existing layouts for paving slabs “Old Town” are themselves capable of offering several unusual design options.

In addition to this material, there are others that differ:

- by size;

- form;

- quality;

- coloring;

- characteristics and properties.

You can appreciate the photo ways of laying paving slabs, their diversity and decorative effect that they create.

Tiled flooring is easy to repair. To do this, it is not necessary to completely replace the entire sidewalk; it is enough to replace only the damaged elements. If you are working on laying paving slabs “Old Town” or some other coating, experts recommend purchasing material with a margin.

There are many options for laying paving slabs on top of the foundation of concrete. The blind area does not impose special requirements regarding the choice of finishes, therefore the quality and your personal taste are the determining factors. It is even possible to lay paving slabs on an old concrete base.

The process of forming the blind area begins with markup. To perform this phase of construction, you will need a marking cord, as well as a set of wooden pegs. They are placed around the house in accordance with the measurements, after which the cord is pulled through each of them. The quality of the blind area depends on how carefully and accurately the marking is done.

Note! Recreating the paving tile pattern on the blind area from the photo, do not forget about the slope. Most often, this figure ranges from 1-3 ° / m. There are exceptions to the rules when the slope angle is 5 ° / m.

After the marking is done, the upper soil layer is excavated in the area of construction work. Most of the types of paving slabs shown in the photo imply the installation of a 40 cm wide coating. Taking into account this indicator, the depth of excavation of the upper soil layer is determined. Do not forget that the concrete pavement must rise above ground level.

These data are also added to the requirements of the slope, which is formed for the device drainage system.

Even if you are working with one of the simplest options for laying brick paving slabs, the photo as a base does not provide a quality result. It is very important to comply with all the requirements of technology, and not only about paving pavements, but also the formation of a blind area.

The blind construction is quite heavy. At this stage, experts recommend installing borders, which will simplify the work. The fact is that any pattern of laying paving slabs is repelled by a curb that restricts it. At this stage, it will perform another function – the frame.

If you refuse to install the curb, its installation will still have to be done later, and works on the blind area will be complicated by the need to install the formwork structure.

The pit under the curb should go deeper than the laying level. Most often, its bottom is lowered to 30 cm from the lower border of the curb.

Helpful advice! Do not forget to include in these calculations the outflow of water. After all, the curb should not impede the flow of water, which can violate the integrity of the foundation of the building.

After that, at the bottom of the pit, a crushed cushion is formed with a thickness of 15 cm, the material should be carefully tamped. Above, a 2 cm thick concrete mortar is poured and a curb is installed. For full setting and curing will take a day. Making sure that the fill is completely dry, you can take to the implementation of the next array of works.

After installing the curb, the area is leveled and carefully tamped down taking into account the required surface slope. It is recommended to lay several layers of geotextiles on the bottom. This type of material will prevent the growth of plants. Despite the fact that vegetation is not able to penetrate the concrete base, geotextiles will provide additional protection.

In some cases, bituminous material is used as a bottom lining. Laying of this material is carried out in order to increase the waterproofing properties of the coating.

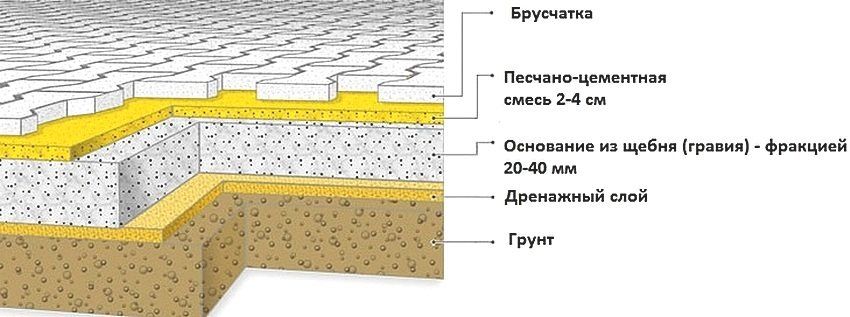

The formation scheme of the concrete base:

- The first in line layer is formed of rubble. If you installed the curbs, this step can be omitted.

- If serious loadings on a covering are supposed, it is necessary to equip a blind area with the reinforcing layer. It can be made of reinforcing bars.

- For a monolithic construction under a pedestrian walkway, a height of 10 cm is sufficient. The basis for the parking lot must be at least 20 cm high.

Helpful advice! For quality results, use concrete marking M200. It is optimal in terms of quality and cost.

Using video laying paving slabs on a concrete base is very simple. Using the recommendations and visual materials, this process can be performed personally.

If compared to the photo samples of laying paving slabs, this technology is largely similar to the technique of working with tiles. A distinctive feature here is a solution having a slightly different composition and consistency.

In the photo of paving slabs, patterns of laying elements of the coating are the most diverse. The specificity of the design does not affect the way of sidewalk installation, as well as the overall technology. There are two methods for laying tiles: sand-cement mix and sand-cement mortar.

In the case of the sand-cement mixture, a thicker consistency of mortar is obtained than that used in the construction of the base. The mixture does not tolerate the presence of small stones, so the sand should be sieved beforehand. This will simplify the work on self-paving paving. The required thickness of the applied layer is 2-3 cm, after that the mixture is leveled using a trowel.

When using the dry method there is a probability of shrinkage of paving slabs. On which solution the specialists place the coating, in this case it does not matter much, since this will require special knowledge. Prices for the purchase of specialized mix are quite high, so it is better not to risk it and give preference to the cement-sand mixture.

In the second case, a cement-sand mortar can be used in a ratio of 3: 1, respectively. After the solution is prepared, it must be laid out on a base, level and tamp.

Helpful advice! Use a wooden or rubber mallet to pave the pavement. She is unable to damage the tile.

Use to get acquainted with the technology of laying paving slabs on mortar, video posted below.

After all elements of the coating are laid out, the surface is wetted with plenty of water. For a certain period, the tile dries out, then the seams between the elements of the pavement are filled. To clean up residual cement and dirt, the coating will need to be rinsed again with water.

Judging by the numerous photos of laying paving slabs “Old Town”, this type of coating compared to other most common. Such popularity is due to the large list of advantages that this material has in itself.

Tile “Old Town” allows you to create interesting patterns and combinations of elements of the coating. In one package of this material can be parts in four different sizes. Sometimes there is a choice of three dimensional combinations in a pack (without the smallest option).

Full package includes:

- large tile;

- square tile;

- an element that is 1/2 the size of a large tile;

- an element that is 1/3 of a large tile or 1/2 of a square.

Due to this size diversity, laying options for paving slabs “Old Town” is enough. Schemes can be complicated by adding a few colors.

On the other hand, the presence of such a large scale in size can cause chaos and disorder. If you do not adhere to a certain pattern in your work, you can get not too beautiful coverage.

Helpful advice! To some extent, a little randomness may even be welcome. The main thing – avoid the formation of stains consisting of clusters of tile elements in the same size or the same color.

If you want to simplify your work as much as possible, it is enough to restrict yourself to a pattern of laying paving slabs of two colors, which is attractive in its own way.

At first it may seem that drawing up schemes from paving slabs is a rather difficult task. In fact, after watching a video, laying paving slabs no longer seems difficult. Using the recommendations regarding the selection of schemes, you can easily navigate the choice.

For example, if you chose the Brick form for your sidewalk, you should pay attention to the following schemes:

- laying of the linear type, which can be complicated by a shift or even do without it;

- modular styling;

- spiral paving.

Thanks to the rounded edges, such tiles perfectly show their decorativeness in all the above-mentioned patterns.

In the photo of paving slabs “Rhomb”, the laying options for the coating look almost like a 3D image. As a result of this paving, a stunning optical illusion arises, giving the impression of a volume effect on the surface of the pavement.

This effect is explained on the photo of paving slabs “Rhombus” by laying based on the use of elements with different external characteristics:

- form;

- surface texture;

- coloring.

In total, the modern range includes more than 40 varieties of tile products with similar geometric data.

Polymer sand tiles are especially popular. The material is able to offer excellent technical characteristics and is suitable for those consumers who want to speed up installation. Products are made on the basis of sand, polymers and dyes and can include elements of completely different configurations.

The installation of polymer-sand paving slabs shown in the video clearly reflects how much the paving process is simplified and accelerated in this case.

Most modern tile coatings perfectly endure the influence of the sun and low temperatures, are distinguished by durability and increased strength, as well as other equally beneficial performance characteristics. Consumers only have to choose the design and color in which the coating will be made.